Ultra-thin shielding film and circuit board capable of changing circuit impedance, and method for preparing same

A technology of circuit impedance and manufacturing method, applied in the fields of magnetic field/electric field shielding, printed circuit components, printed circuit secondary processing, etc., can solve the problems of easy breakage of metal layers, easy delamination, failure to shield and grounding, etc. , to achieve the effect of excellent bending performance, easy processing and impedance control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A method for manufacturing an extremely thin shielding film capable of changing circuit impedance, comprising the following steps:

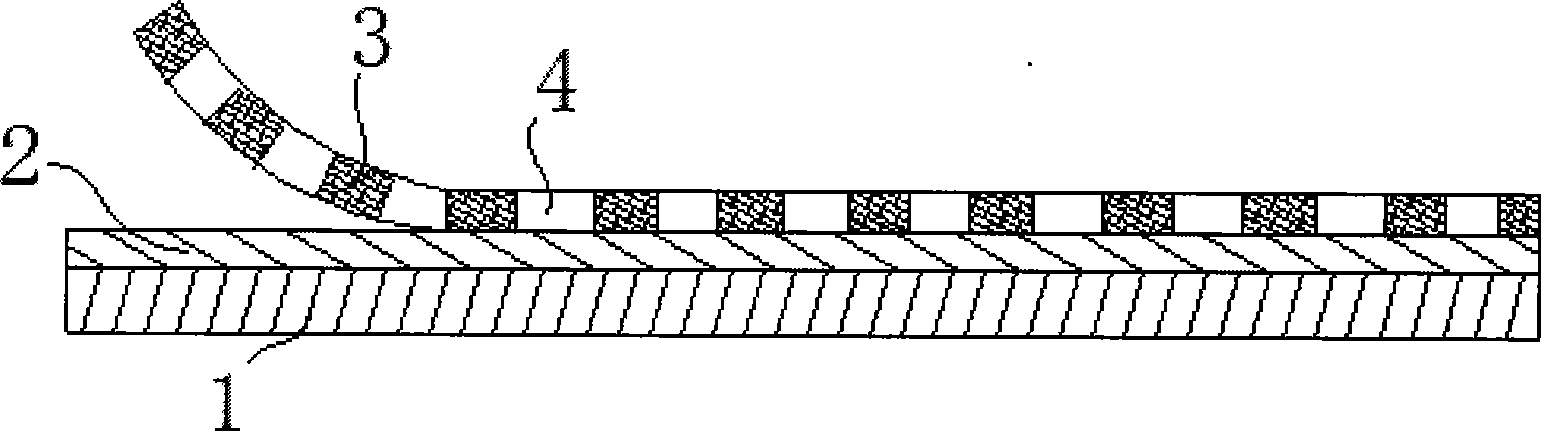

[0049] 1), forming a peelable grid metal foil on the carrier:

[0050] Such as figure 1 As shown, the step of forming the peelable mesh metal foil 3 on the carrier 1 is: pre-vacuum sputtering a layer of sputtered metal on the surface of the carrier 1 that can improve the peeling strength of copper, nickel or other metals from the carrier. Layer 3, then design the size of the carrier grid according to the impedance requirements of the product, and use methods such as drilling, punching, laser cutting or etching to form a grid of the same size on the carrier, and finally pass the roll shape on the sputtered metal layer A thin copper layer, a thin nickel layer, or a nickel-copper alloy layer is electroplated to form the meshed metal foil layer 3 . The meshed metal foil may include copper foil, nickel foil, aluminum foil and the like. The c...

Embodiment 2

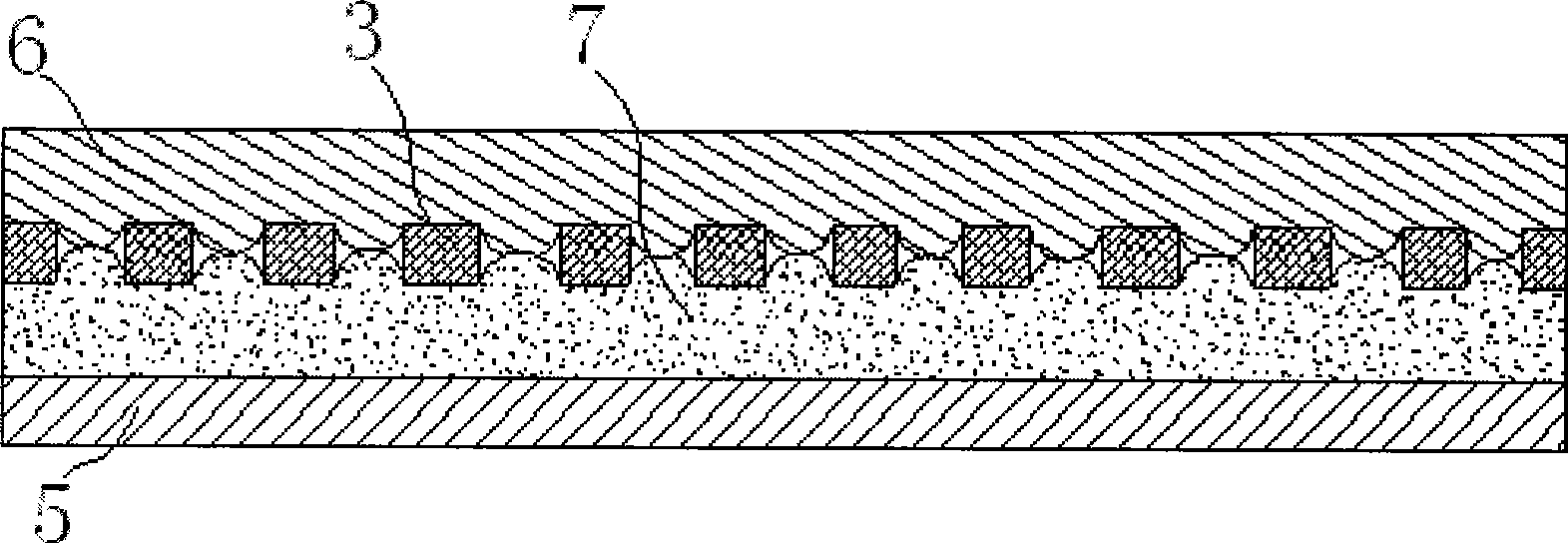

[0055] A method for manufacturing an ultra-thin shielding film capable of changing circuit impedance is based on the specific optimization of transferring the meshed metal foil to the insulating covering layer on the basis of the embodiments, including the following manufacturing steps:

[0056] 1), forming a peelable meshed metal foil on the carrier;

[0057] 2) Lay the outer shielding protective film transfer layer on the grid metal foil surface;

[0058] 3) Transfer the meshed metal foil on the carrier to the transfer layer of the outer shielding protective film, and remove the carrier.

[0059] 4), coating the insulating cover layer on the cover transfer layer, pre-curing; the described coating of the insulating cover layer on the transfer layer of the cover layer is on the transfer layer release film of the cover layer coated with silicone oil as required Coating the insulating covering layer, the insulating protective film has a certain initial tack, and the thickness i...

Embodiment 3

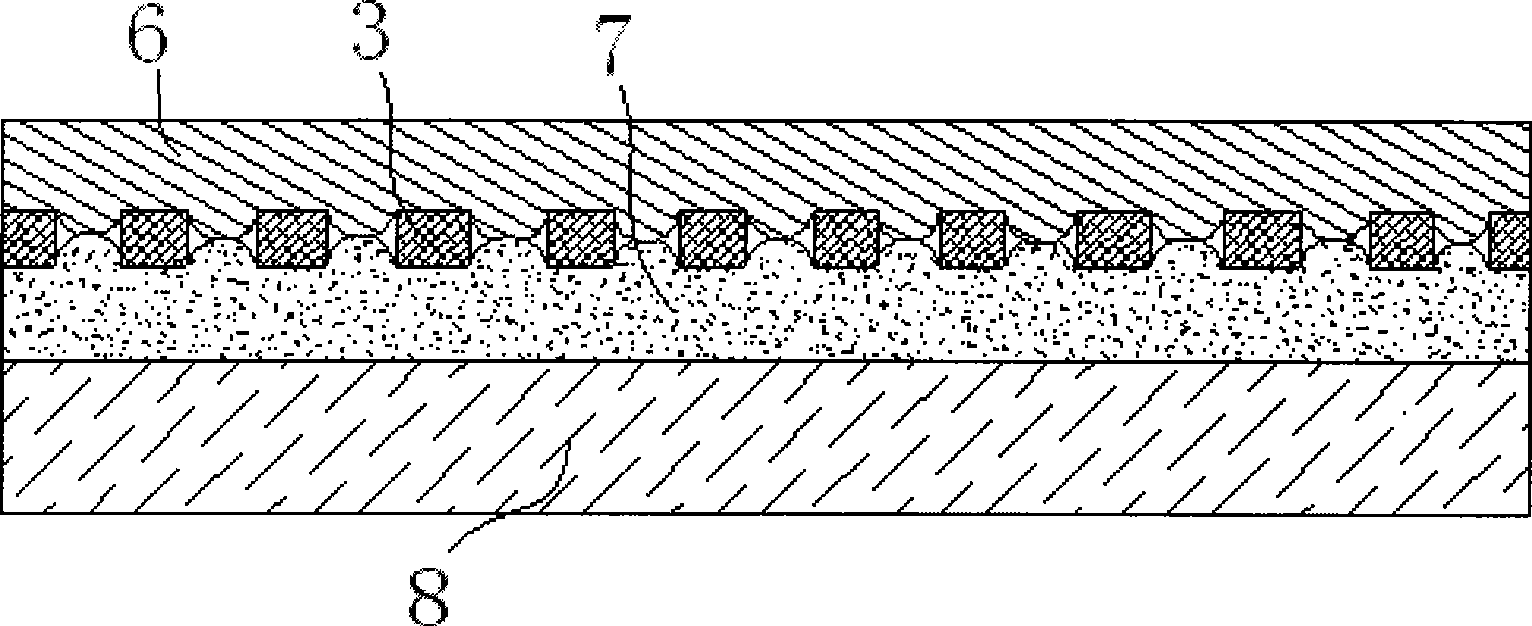

[0064] A method for manufacturing a printed circuit board covered with an extremely thin shielding film capable of changing circuit impedance, comprising the following manufacturing steps:

[0065] 1) cleaning and processing the surface of the single-sided circuit board substrate forming the circuit;

[0066] 2) An extremely thin shielding film that can change the impedance of the circuit is laminated on the front.

[0067] The substrate of the circuit board can be a uniform circuit formed on a single-sided substrate. The specific process can be directly attaching a film on the substrate, exposing, developing, and etching to form a uniform line, and then pressing the cover film.

[0068] In this embodiment, the ultra-thin shielding film that can change the impedance of the circuit is used to realize the impedance control of the single panel, which can replace the two-layer flexible circuit board. Generally, double-sided flexible copper clad laminates are used to realize the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com