Preparation of a metal-containing film via ALD or CVD processes

A metal thin film, metal amide technology, applied in metal material coating process, thin material processing, semiconductor/solid-state device manufacturing, etc., can solve problems such as deterioration of leakage current characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1. Preparation of zirconium silicate films by PEALD at different temperatures.

[0038] An exemplary zirconium silicate film is deposited in a shower head type ALD reactor, manufactured by Quros Co, South Korea. The temperature of the chip is controlled by a proportional integral derivative (PID) controller. The thin film is deposited on a silicon wafer, which is a boron-doped p-type (100) wafer with a resistivity of 1-50 Ohm.cm, manufactured by LG Siltron, South Korea. The metal amide precursor used for deposition is tetrakis(ethylmethylamino)zirconium (TEMAZ), which is placed in a temperature-controlled bubbler, model BK500UST, manufactured by AirProducts and Chemicals, Inc. of Allentown PA, and uses argon as the carrier Gas delivery. The silicon-containing precursor used for deposition was bis(tert-butylamino)silane (BTBAS), which was placed in a temperature-controlled bubbler, model BK1200USH, manufactured by Air Products and Chemicals, Inc. of Allentown PA, usi...

Embodiment 2

[0040] Example 2. Preparation of zirconium silicate film by PEALD at 250°C.

[0041] The three exemplary films were deposited in the same manner as described in Example 1, except that the heater temperature was 250°C. The sheet temperature is 200°C, 250°C, 300°C and 350°C. The temperature difference between the sheet and the heater varies with the temperature of the heater.

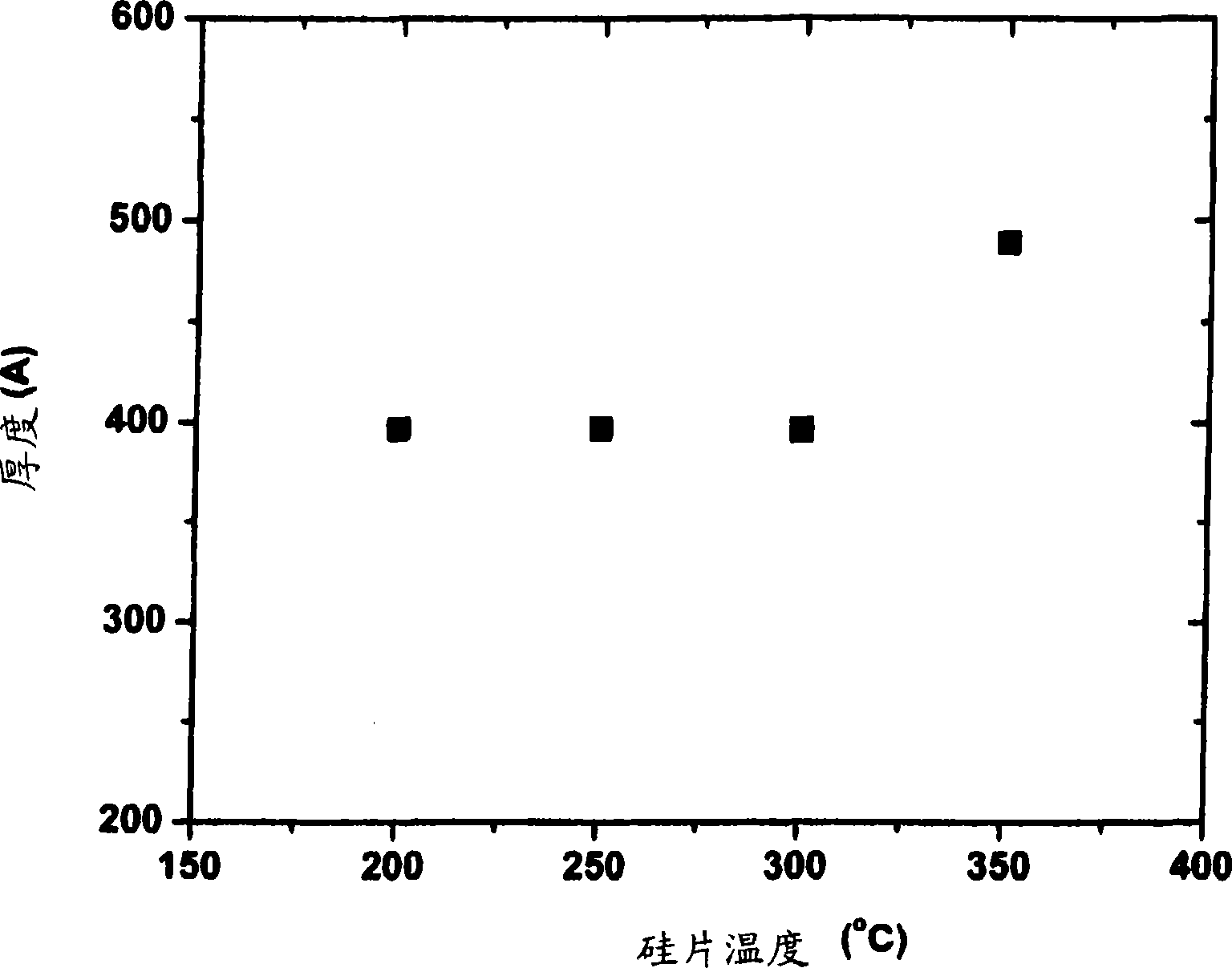

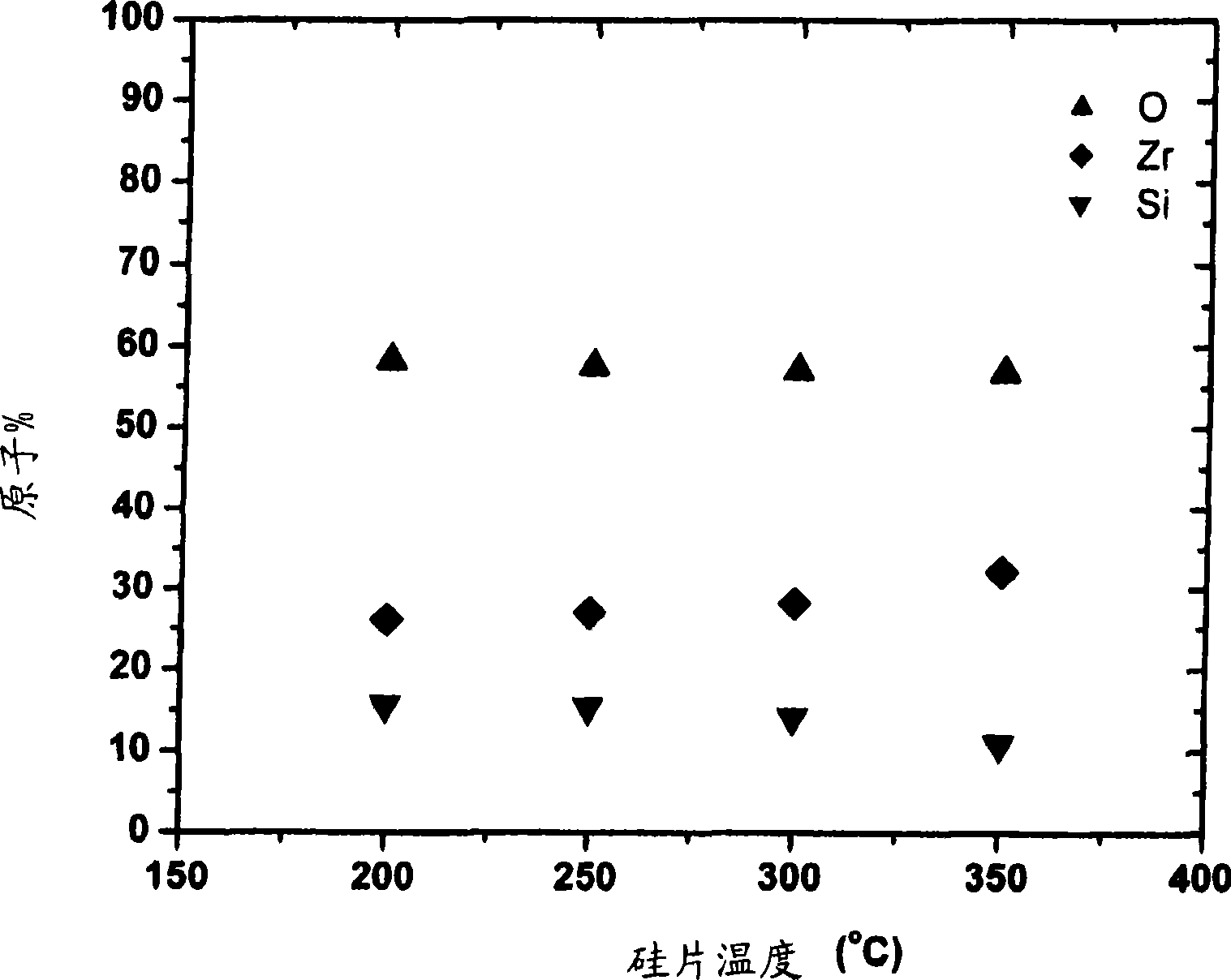

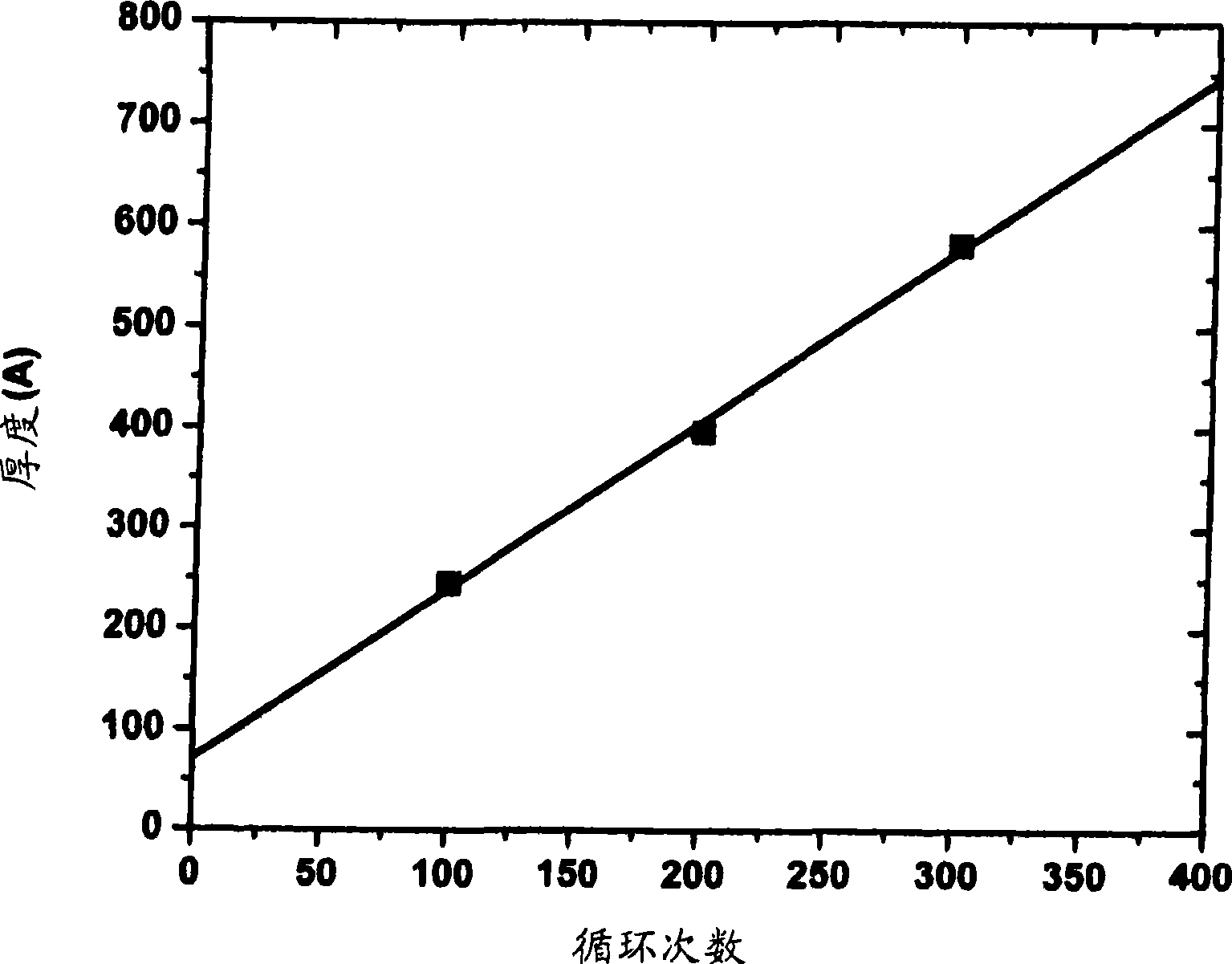

[0042] image 3 Illustrates the results of the above test. The thickness of each exemplary film deposited at different temperatures was measured in Angstroms by ellipsometry, using a model SE800 ellipsometer, manufactured by Sentech Instruments. image 3 Provides a comparison of the thickness and temperature of the three types of ZrSiOx films deposited in the PEALD process.

Embodiment 3

[0043] Example 3. Prophetic example of preparing zirconium oxide and silicon oxide nano-laminated films by PEALD at 250°C

[0044] The nano laminated film containing zirconium oxide and silicon oxide can be prepared in the following method. The reaction chamber pressure is about 1.0 Torr, first 200 cycles of ZrO 2 Deposited in the following cycles: TEMAZ was bubbled into argon carrier gas at a flow rate of 25 sccm for 3 seconds; argon purge gas at a flow rate of 500 sccm for 5 seconds; oxygen plasma gas at a flow rate of 100 sccm for 5 seconds during RF plasma generation; argon at a flow rate of 500 sccm Purge the gas for 5 seconds. Subsequently, 50 cycles of SiO2 Deposited in the following cycles: BTBAS was added by bubbling argon carrier gas at a flow rate of 25 sccm for 0.5 seconds; argon purge gas at a flow rate of 500 sccm for 5 seconds; oxygen plasma at a flow rate of 100 sccm for 5 seconds during RF plasma generation; during RF plasma generation The oxygen plasma lasts for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com