Pr/Nd based biphase composite permanent magnetic material and block body preparing method thereof

A nano-composite, permanent magnet material technology, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problems of low density, decoupling, low magnetic performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

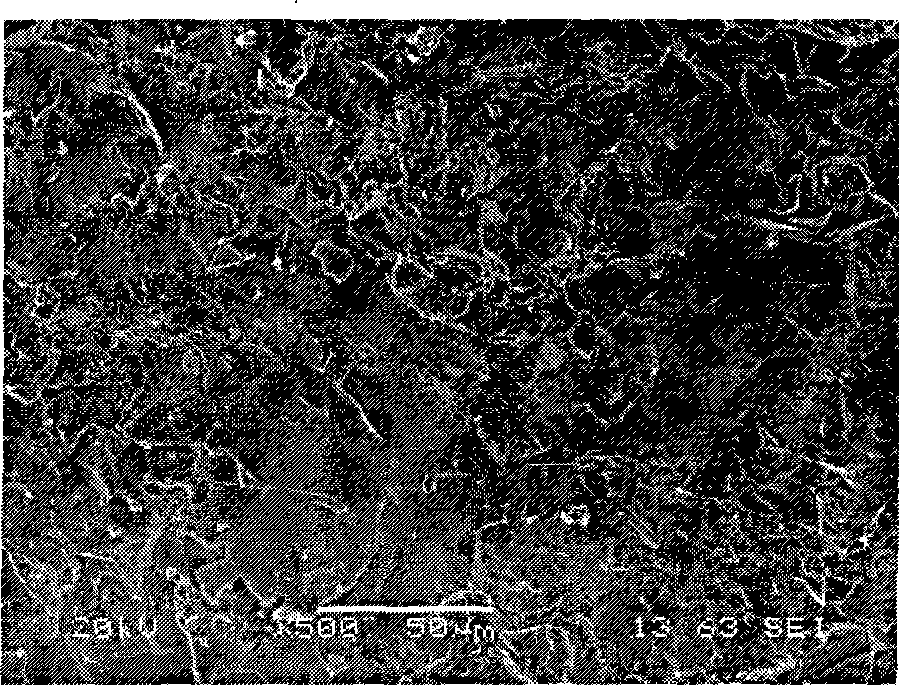

[0025] According to the alloy formula (Pr 70 Nd 30 ) 9 Fe 80.5 Tb 1 Ti 3 V 0.5 B 6 Each alloy raw material was weighed, and the master alloy was repeatedly smelted four times under the protection of Ar, and the melt was rapidly quenched on a water-cooled molybdenum wheel at a cooling rate of 50m / s to prepare a compound with (Pr, Nd) 2 Fe 14 B / α-Fe Nano-Quenching Ribbons. Put the prepared quick-quenched strip into the mold of the graphite box, place it in a six-sided top pressure ultra-high pressure equipment, and sinter it under the Ar gas environment. The fixed pressure is 30GPa, the heating rate is 10°C / min, and the heating temperature reaches Sintering was carried out at 500°C, the holding time was 10min, and the sample was cooled with the furnace. Finally, a fully dense block (Pr, Nd) is obtained 2 Fe 14 B / α-Fe dual-phase nanocomposite permanent magnet material, its internal microstructure is as follows figure 1 shown. The nanocrystalline grain size distributi...

Embodiment 2

[0027] According to the alloy formula (Pr 45 Nd 55 ) 9.5 Fe 79.3 Tb 1.2 Ti 4 V 1 B 5 Each alloy raw material was weighed, and the master alloy was repeatedly smelted four times under the protection of Ar, and the melt was rapidly quenched on a water-cooled molybdenum wheel at a cooling rate of 40m / s to prepare a compound with (Pr, Nd) 2 Fe 14 B / α-Fe Nano-Quenching Ribbons. Put the prepared quick-quenched strip into the mold of the graphite box, place it in a six-sided top pressure ultra-high pressure equipment, and sinter it in an Ar gas environment. The fixed pressure is 1GPa, the heating rate is 15°C / min, and the heating temperature reaches Sintering was carried out at 800°C, the holding time was 10min, and the sample was cooled with the furnace. Finally, a fully dense block (Pr, Nd) is obtained 2 Fe 14 B / α-Fe dual-phase nanocomposite permanent magnet material. It is characterized by transmission electron microscopy that the grain size of nanocrystals is evenly d...

Embodiment 3

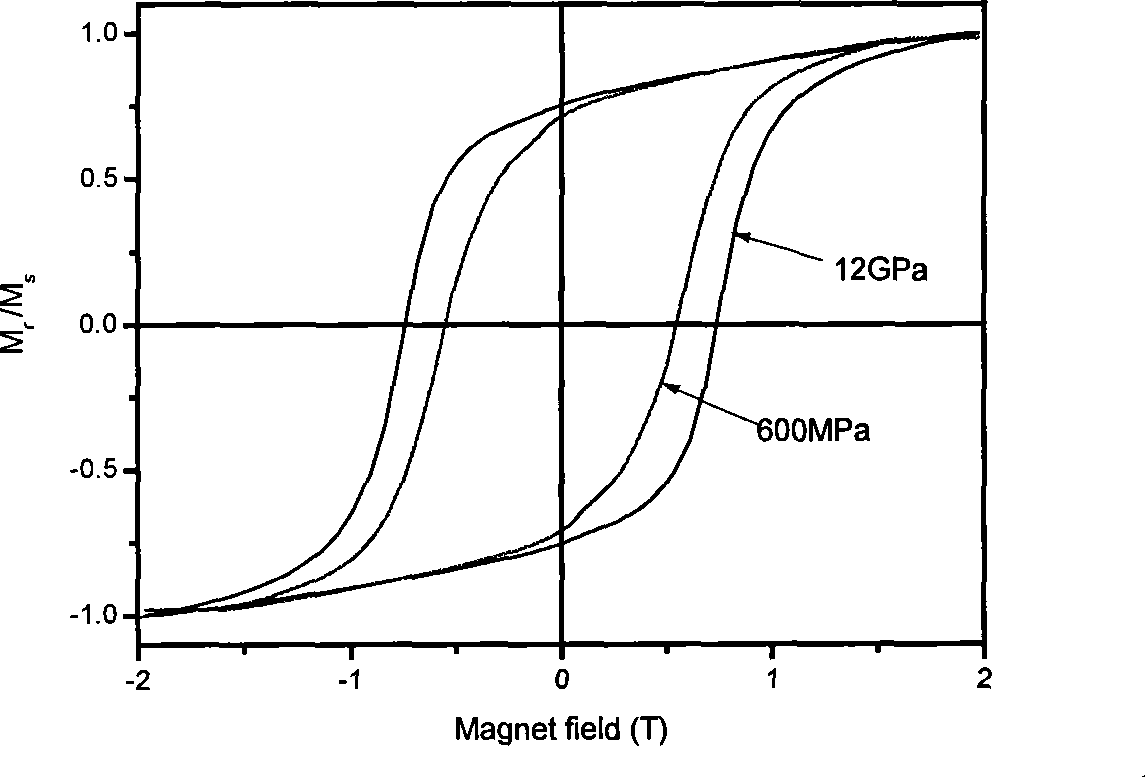

[0029] According to the alloy formula (Pr 50 Nd 50 ) 9.5 Fe 79.3 Tb 1.2 Ti 4 V 1 B 5 Each alloy raw material was weighed, and the master alloy was repeatedly smelted four times under the protection of Ar, and the melt was rapidly quenched on a water-cooled molybdenum wheel at a cooling rate of 10m / s to prepare a compound with (Pr, Nd) 2 Fe 14 B / α-Fe Nano-Quenching Ribbons. Put the prepared quick-quenched strip into the mold of the graphite box, and put it in the ultra-high pressure equipment with six-sided top pressure at N 2 Sintering in an air environment, fixed pressure is 12GPa, heating rate is 40°C / min, heating temperature is 900°C for sintering, holding time is 13min, and the sample is cooled with the furnace. Finally, a fully dense block (Pr, Nd) is obtained 2 Fe 14 B / α-Fe dual-phase nanocomposite permanent magnet material. It is characterized by transmission electron microscopy that the grain size of nanocrystals is evenly distributed, and the average size ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com