A double alloy nanocrystalline rare earth permanent magnet and its preparation method

A technology of rare earth permanent magnets and nanocrystals, applied in the direction of magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., can solve problems such as thermal deformation, nanocomposite magnets cannot be sintered, etc., to improve density, reduce material costs, The effect of low material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

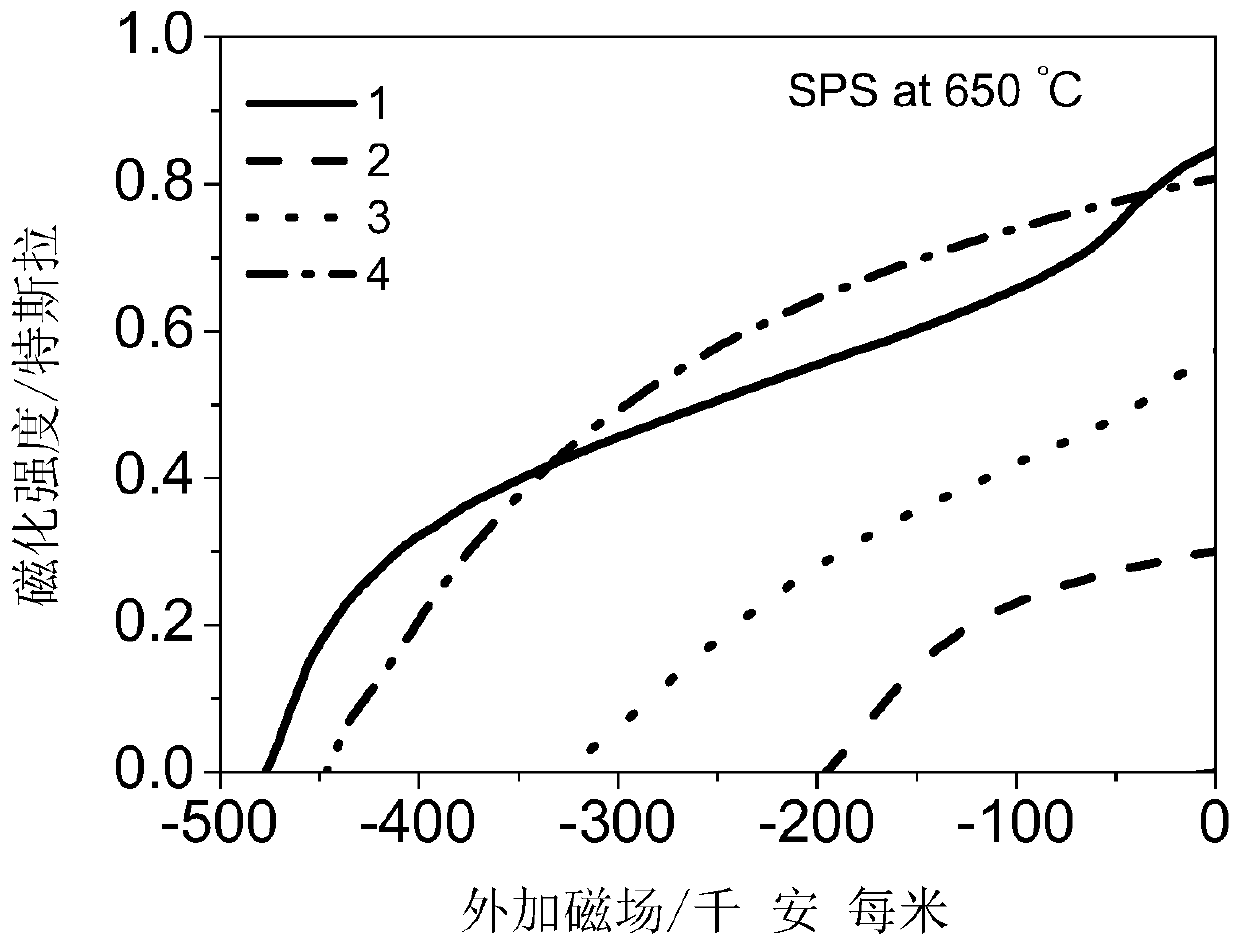

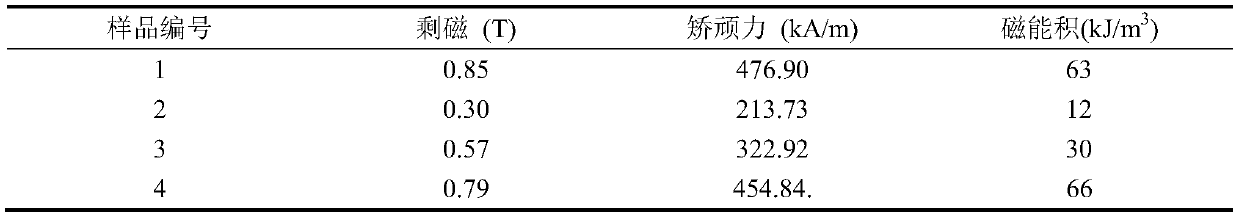

Embodiment 1

[0033] Sieve the commercial nanocomposite Nd-Fe-B (rare earth 10%, Fe 84%, B 6%) magnetic powder, and screen the magnetic powder with a particle size of 105-300 μm. Take 10g of magnetic powder and put it into a graphite mold with a diameter of 20mm, and then sinter it on SPS-825 spark plasma sintering equipment. The sintering pressure is 50MPa. Set the sintering temperature T sps is 650°C, the heating time is 7min, and the sintering holding time is t sps For 7min, the vacuum degree during sintering is less than 6Pa. This sintered sample is designated as No. 1 sample.

Embodiment 2

[0035] According to the alloy composition ratio Ce 17 Fe 78 B 6 (Atomic percentage) Ce, Fe and FeB alloys with a purity greater than 99.95% were weighed, and the weighed alloys were put into an electric arc melting furnace to be melted into button-shaped ingots. The ingot was broken into small pieces of 3-5g. In the belt throwing machine, under the protection of Ar gas and the roll speed of 18m / s, alloy thin strips were obtained by melt quenching technology.

[0036] Ce will be obtained 17 Fe 78 B 6 Put the alloy strip into a glove box, grind it into magnetic powder with a mortar, and then sieve the magnetic powder with a particle size of 105-300 μm. Take Ce with a mass of 10g 17 Fe 78 B 6 The magnetic powder is put into a graphite mold with a diameter of 20mm, and then sintered on the SPS-825 spark plasma sintering equipment. The sintering pressure is 50MPa. Set the sintering temperature T sps is 650°C, the heating time is 7min, and the sintering holding time is t...

Embodiment 3

[0038] MQ magnetic powder (Example 1) with a particle size of 105-300 μm and a mass fraction of 50% and 50% of Ce 17 Fe 78 B 6 A total of 10 g of magnetic powder (Example 2) was put into a graphite mold with a diameter of 20 mm, and sintered on a SPS-825 spark plasma sintering equipment. The sintering pressure is 50MPa. Set the sintering temperature T sps is 650°C, the heating time is 7min, and the sintering holding time is t spsFor 7min, the vacuum degree during sintering is less than 6Pa. This sintered sample is designated as sample No. 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com