High fluorescent efficiency cadmium telluride quantum point prepared by cathodic tellurium electric pole

A cadmium telluride quantum dot and cathodic technology is applied in the field of nanomaterials, which can solve the problems of wide fluorescence half-peak width of quantum dots, uneven particle size distribution, complicated preparation process, etc., and achieves low pollution, low cost, and repeated reaction. high sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

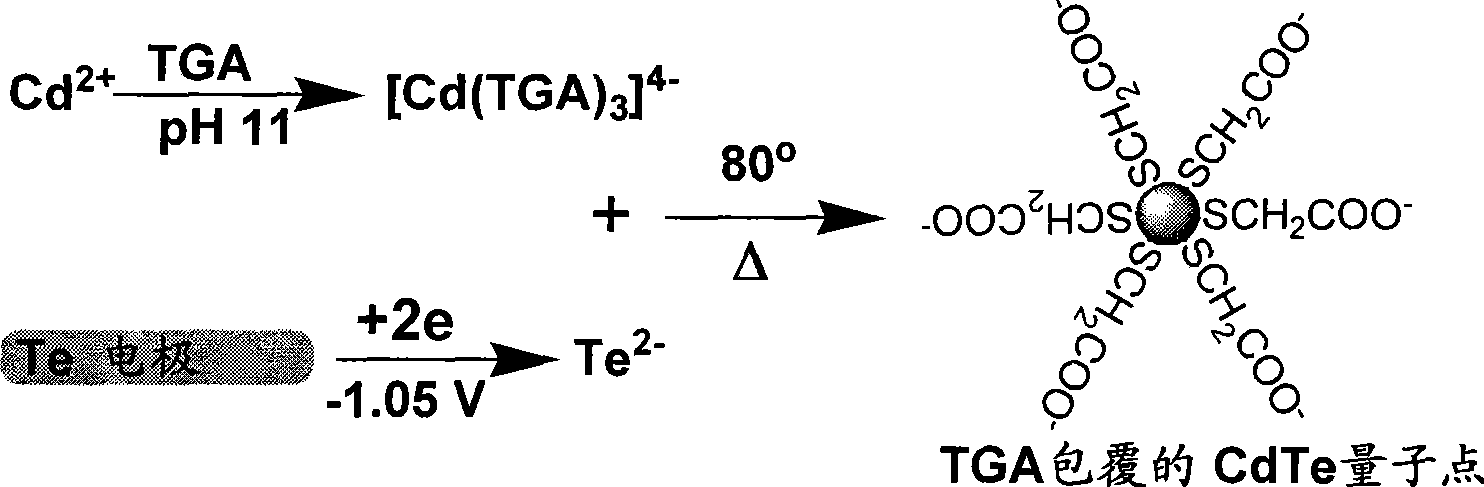

[0021] The preparation of embodiment 1. thioglycolic acid (TGA) coated cadmium telluride quantum dots:

[0022] (1) 20mL5mM CdCl 2 Mix with 17 μL thioglycolic acid, adjust the pH to 11.2 with 0.1M NaOH, and then dilute to 40 mL. The resulting colorless and clear solution is purged with nitrogen for 30 minutes.

[0023] (2) With the solution obtained in (1) as the electrolyte, the Ag / AgCl electrode as the reference electrode, the Pt wire as the counter electrode, and the tellurium electrode as the working electrode, keep it for a certain period of time at the potential of -0.95V, as respectively The molar ratios of cadmium and tellurium in the cadmium telluride precursor solution obtained by controlling the electrolysis time to 15, 30 and 46 minutes were 1:0.20, 1:0.41 and 1:0.64, respectively. The precursor solution was pale yellow.

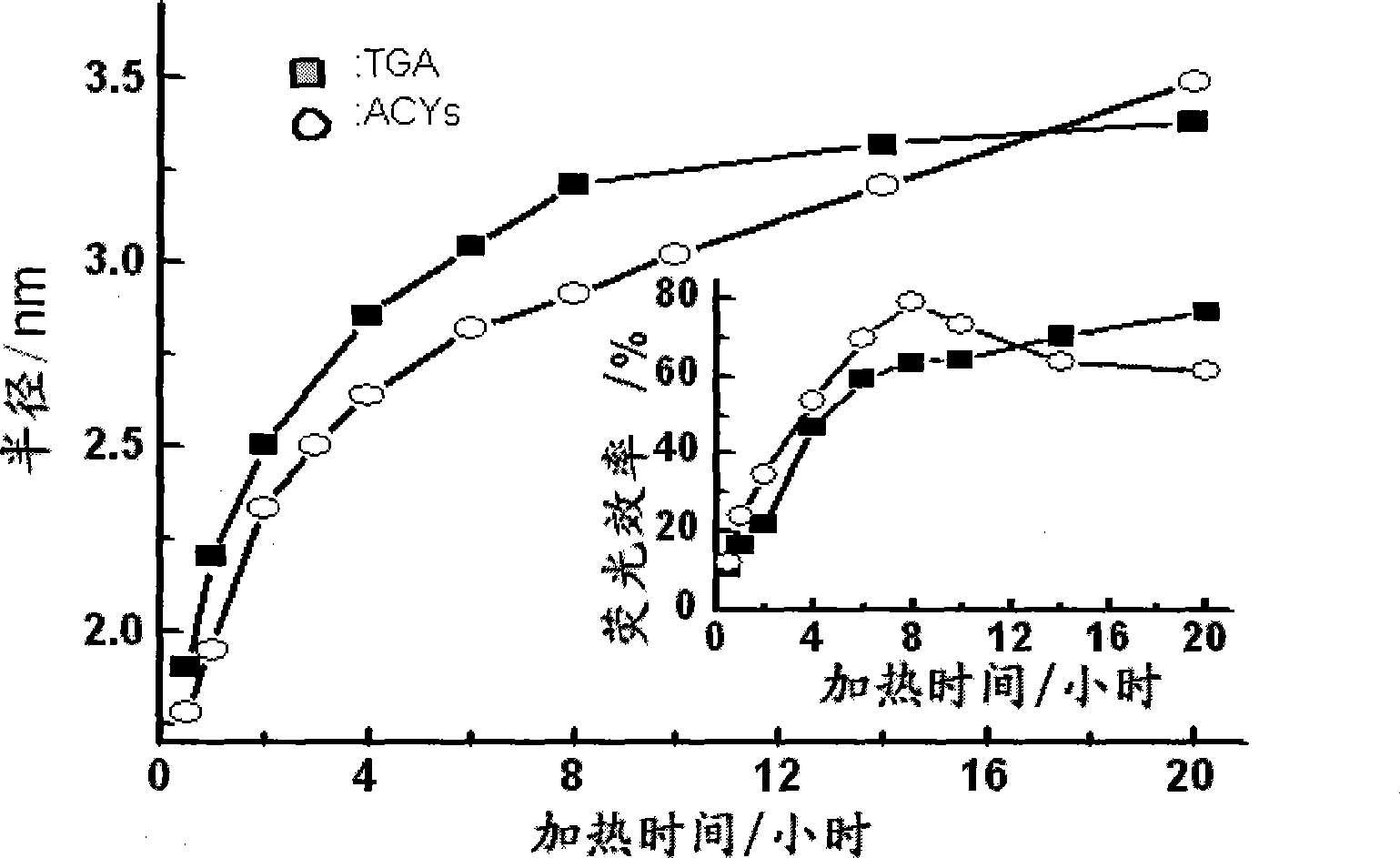

[0024] (3) Place the cadmium telluride precursor solution in a water bath at 80°C and heat it to reflux for different times. The size of the q...

Embodiment 2

[0026] Embodiment 2. Preparation of cadmium telluride quantum dots coated with acetyl cysteine (ACYS):

[0027] (1) 20mL5mM CdCl 2 Mix it with 17mg ACYS, adjust the pH to 11.2 with 0.1M NaOH, and then dilute to 40mL. The resulting colorless clear solution is passed through nitrogen for 30 minutes.

[0028] (2) With the solution obtained in (1) as the electrolyte, the Ag / AgCl electrode as the reference electrode, the Pt wire as the counter electrode, and the tellurium electrode as the working electrode, keep a certain time at the potential of -0.95V to obtain a light Yellow cadmium telluride precursor solution.

[0029] (3) The cadmium telluride precursor solution was placed in a water bath at 80°C and heated to reflux for different times to obtain ACYS-coated cadmium telluride quantum dots of different sizes. figure 2 shown.

[0030] (4) After cooling the solution obtained in (3), place it in a dialysis bag, and dialyze it in secondary water for 24 hours to remove free i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com