CO2 tolerance multi-phase mixed conductor compact oxygen permeable film material and preparation method and use thereof

A technology of multi-phase mixing and oxygen-permeable membrane, applied in semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc., to achieve the effect of improving CO2 resistance, high oxygen flux, and low thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The organic acid complex method preparation and film forming examples of the material of the present invention.

[0025] Preparation of Sm by organic acid complex method 0.85 Ce 0.1 Fe 0.8 Mn 0.2 O 3-δ Take the material as an example, according to the stoichiometric ratio of the material 4.25:1:8:2, the Sm 2 O 3 (Pre-dissolved in nitric acid), Ce(NO 3 ) 3 ·6H 2 O, Fe(NO 3 ) 3 ·9H 2 O and Mn(NO 3 ) 2 Respectively dissolve in water, add appropriate amount of citric acid and ethylenediaminetetraacetic acid. The molar ratio of citric acid, ethylenediaminetetraacetic acid (ethylenediaminetetraacetic acid is first dissolved in ammonia water) and metal ions is 2:1:1, and the pH value is adjusted to 8 with ammonia water. Put the clarified precursor into an oven and heat it at 250°C for 10 hours. After spontaneous combustion occurs, the powder is heated at 2°C / min to 1000°C for 5 hours, and then cooled at 3°C / min to 20°C to obtain the material of the present invention. Powder.

[00...

Embodiment 2

[0028] The solid-phase reaction method preparation and film forming examples of the material of the present invention.

[0029] Preparation of La by solid phase reaction method 0.85 Ce 0.1 Ga 0.3 Fe 0.6 Al 0.1 O 3 -δ material as an example, according to the stoichiometric ratio of the material 4.25:1:1.5:3:0.5, the La 2 O 3 , CeO 2 , Ga 2 O 3 , Fe 2 O 3 And Al 2 O 3 After the powder is mixed, ethanol is added, placed in a ball mill for wet grinding for 24 hours, and then dried in static air. The dried powder is placed in a high-aluminum crucible, and fired in an air atmosphere at 950°C for 10 hours at a temperature rising and falling rate of 2°C / min to obtain the material powder of the present invention.

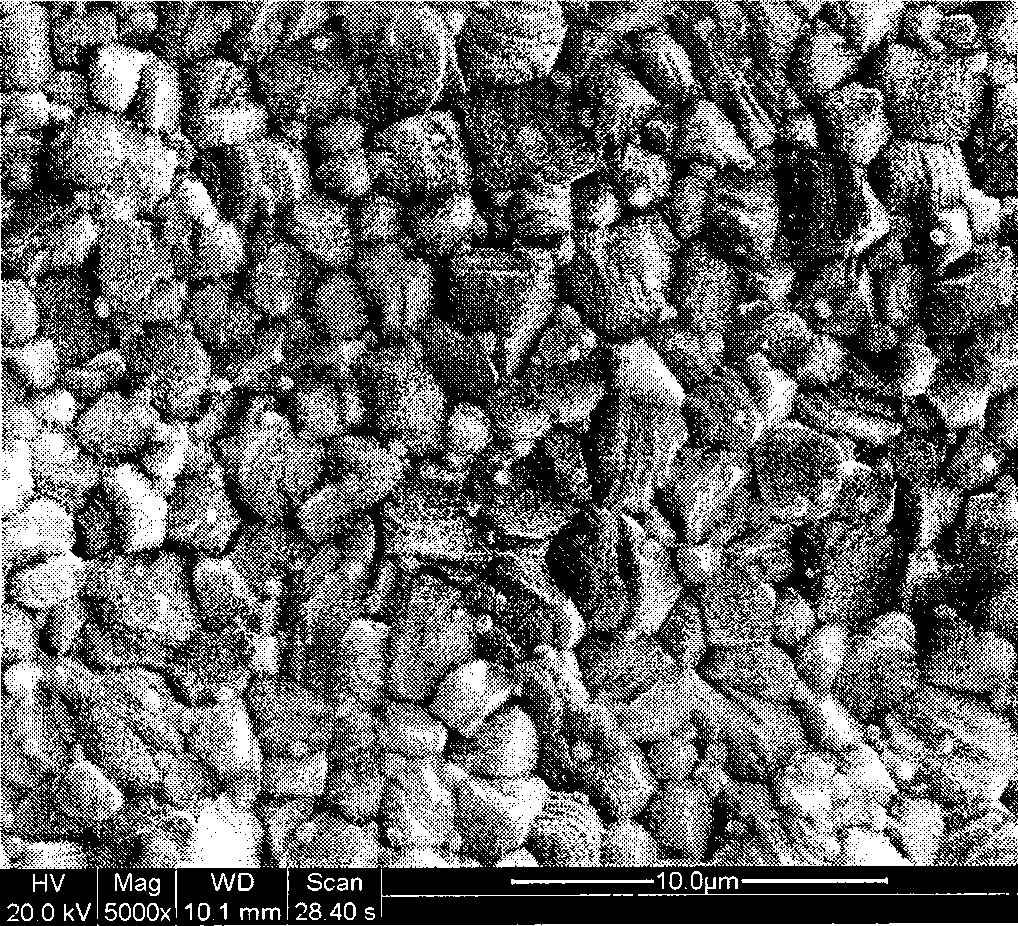

[0030] The powder is produced under a uniaxial pressure of 400 MPa to produce a green film. The green film is sintered in a high-temperature furnace at 1250 ℃ for 20 hours at a temperature rise and fall rate of 1 ℃ / min, and then cooled to room temperature. The surface microstruc...

Embodiment 3

[0032] Prepare the material Sm of the present invention according to the organic acid complexation method of Example 1 0.85 Ce 0.1 Fe 1-x Mn x O 3-δ The following table shows the configuration of various elements

[0033] sample The molar ratio of Sm, Ce, Fe and Mn x=0.1 4.25∶1∶9∶1 x=0.2 4.25∶1∶8∶2 x=0.3 4.25∶1∶7∶3

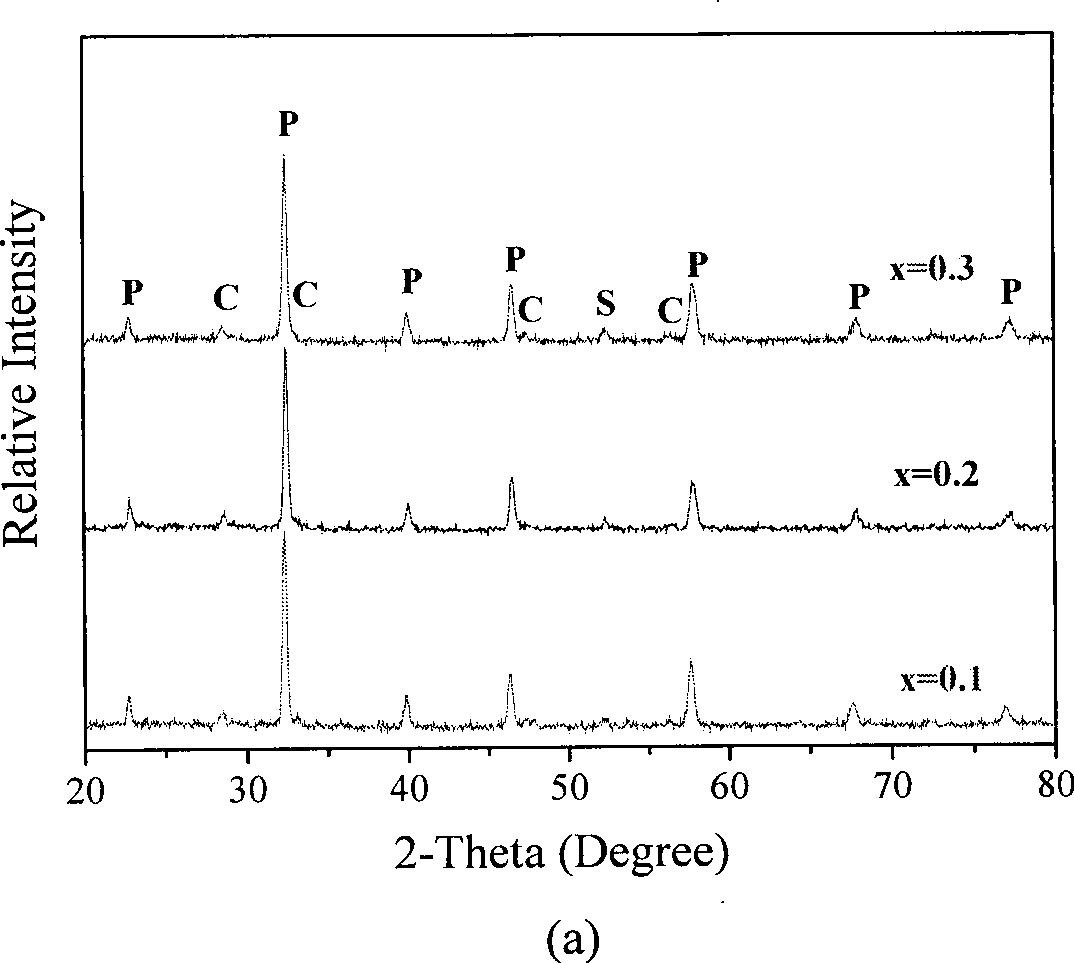

[0034] The above three powder samples were subjected to X-ray diffraction test, and the results are shown in figure 2 (a). From figure 2 (a) It can be seen that the prepared Sm 0.85 Ce 0.1 Fe 1-x Mn x O 3-δ The samples all formed a complete main phase of perovskite, in addition to CeO 2 Relative to Sm 2 O 3 phase. This shows that the prepared material is a multiphase mixed conductor material.

[0035] Prepare the material La of the present invention according to the solid-phase reaction method of Example 2 0.85 Ce 0.1 Ga 0.3 Fe 0.7-y Al y O 3-δ The following table shows the configuration of various elements

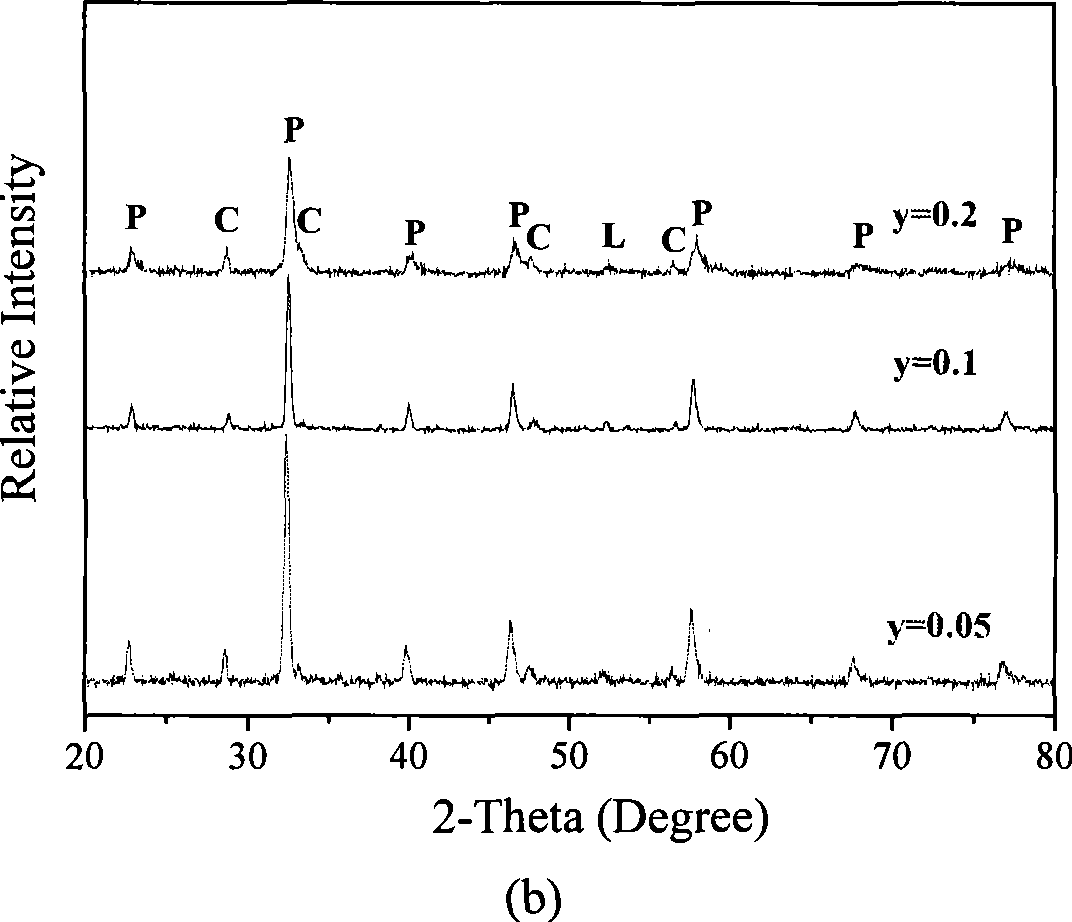

[0036] sample T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com