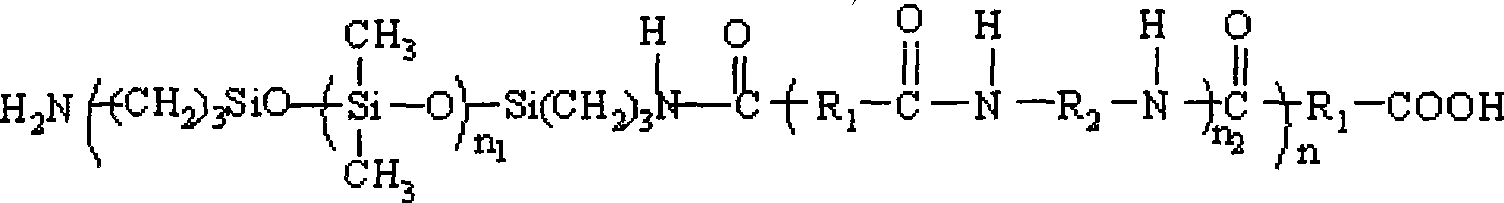

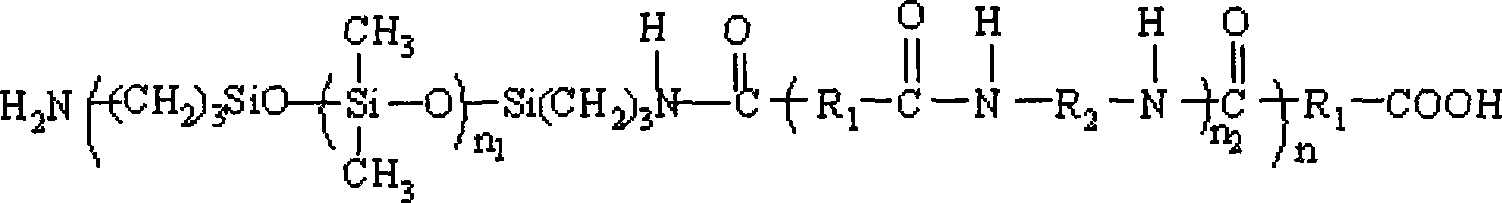

Dimethyl silicone polymer-polyamide multi-block elastomer and production method thereof

The technology of polydimethylsiloxane and dimethylsiloxane is applied in the field of polydimethylsiloxane-polyamide multi-block elastomer and its preparation method, and can solve the problem of high cost and complicated preparation process , low performance and other problems, to achieve the effect of good high temperature resistance, simple preparation method and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

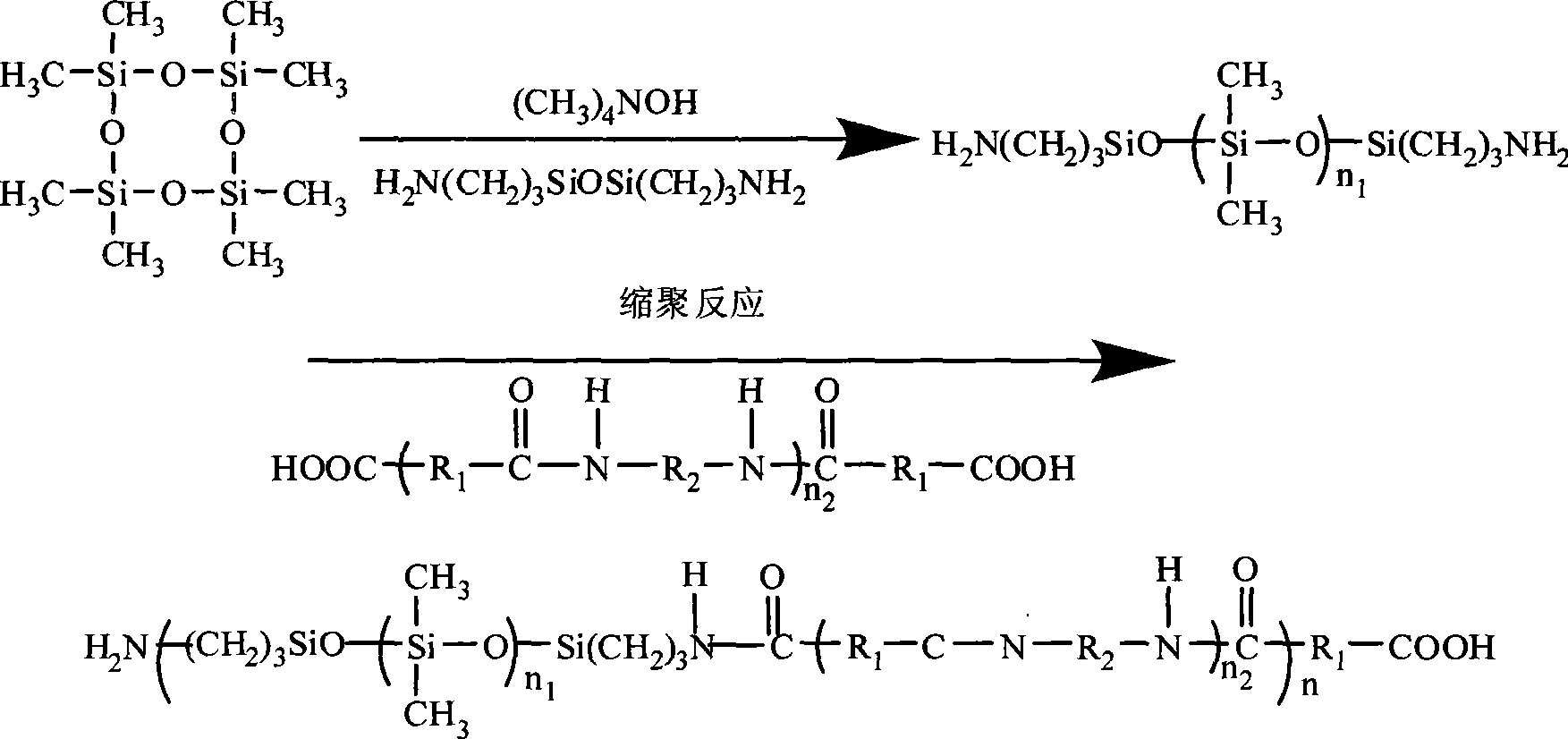

Method used

Image

Examples

Embodiment 1

[0026] In a reactor equipped with a stirrer, a reflux condenser and a nitrogen pipe, add 525 g of octamethylcyclotetrasiloxane, and remove the air and moisture in the system with a small amount of nitrogen flow. Then, add 0.105g of tetramethylammonium hydroxide and 62g of bisaminopropyltetramethyldisiloxane, pass in nitrogen protection, stir and react at 90°C for 20h, pass in a small amount of nitrogen, and heat up to 150°C to decompose and break the ring Catalyst 0.5h. Then remove low boilers at 140° C. and 0.07 KPa to obtain amino-terminated silicone oil with a molecular weight of 2000 g / mol. 500g amino-terminated silicone oil, 224.6g hexamethylenediamine and 258g succinic acid are added to water and ethanol (V 水 :V 乙醇 = 1: 1) in the mixed solvent, the concentration of the solution is 50%, the water bath is heated to 60 ℃ and stirred, the reaction is two hours and the pH value of the salt solution is adjusted to 7.0, the salt solution is added in the polymerization kettle,...

Embodiment 2

[0028] In a reactor equipped with a stirrer, a reflux condenser and a nitrogen pipe, add 525 g of octamethylcyclotetrasiloxane, and remove the air and moisture in the system with a small amount of nitrogen flow. Then, add 0.105g of tetramethylammonium hydroxide and 35g of bisaminopropyltetramethyldisiloxane, pass in nitrogen protection, stir and react at 90°C for 20h, pass in a small amount of nitrogen, and heat up to 150°C to decompose and break the ring Catalyst 0.5h. Then remove the low boilers at 140° C. and 0.07 KPa to obtain amino-terminated silicone oil with a molecular weight of 5000 g / mol. 500g amino-terminated silicone oil, 242g hexamethylenediamine and 258g succinic acid are added to water and ethanol (V 水 :V 乙醇 = 1: 1) in the mixed solvent, the concentration of the solution is 50%, the water bath is heated to 60 ℃ and stirred, the reaction is two hours and the pH value of the salt solution is adjusted to 7.0, the salt solution is added in the polymerization kettl...

Embodiment 3

[0030] In a reactor equipped with a stirrer, a reflux condenser and a nitrogen pipe, add 525 g of octamethylcyclotetrasiloxane, and remove the air and moisture in the system with a small amount of nitrogen flow. Then, add 0.105g of tetramethylammonium hydroxide and 62g of bisaminopropyltetramethyldisiloxane, pass in nitrogen protection, stir and react at 95°C for 20h, pass in a small amount of nitrogen, and heat up to 150°C to decompose and break the ring Catalyst 0.5h. Then remove low boilers at 140° C. and 0.07 KPa to obtain amino-terminated silicone oil with a molecular weight of 2000 g / mol. 500g amino-terminated silicone oil, 144.6g hexamethylenediamine and 303g sebacic acid are added to water and ethanol (V 水 :V 乙醇 =1:1) in the mixed solvent, the concentration of the solution is 50%, heated to 60°C in a water bath and stirred, reacted for two hours and adjusted the pH value of the salt solution to 7.1, added the salt solution into the polymerization kettle, slowly Rais...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com