Silk-screen printing electrode and method for synthesizing chloramphenicol molecular imprinting film

A technology of screen printing electrodes and molecularly imprinted membranes, which is applied in the field of polymers, can solve the problems of not being able to replace solid phase enrichment, separation devices, extraction cartridges, high cost, and long preparation time, and achieve favorable detection results and processing The method is simple and the holes are evenly distributed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

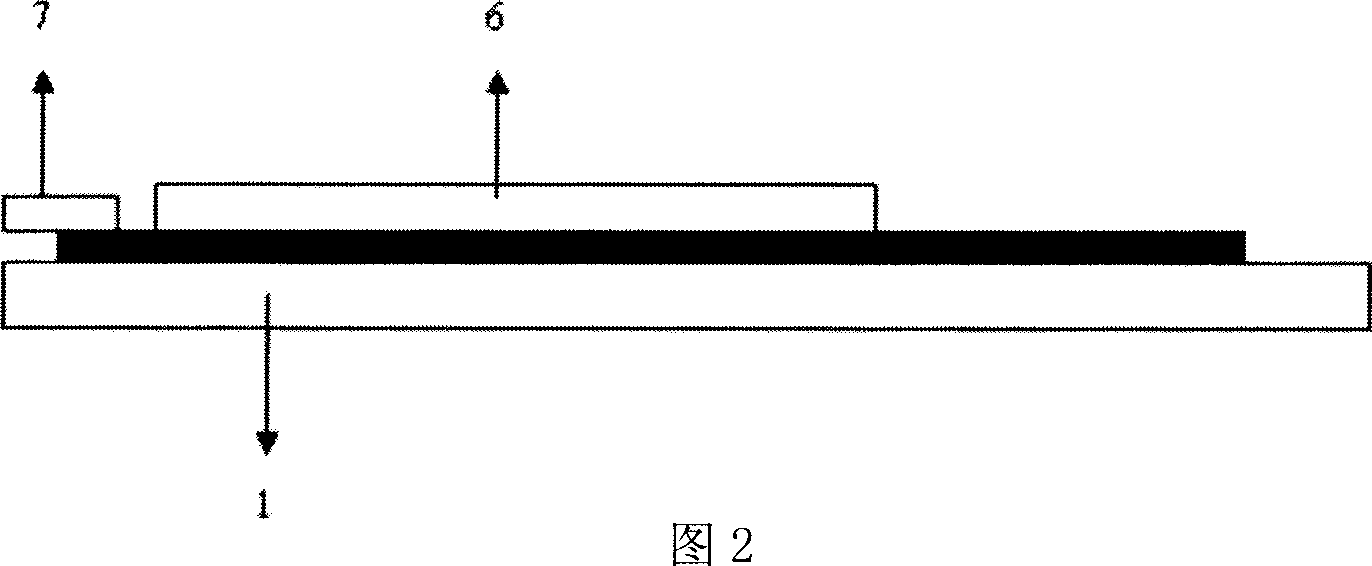

[0047] Use screen printing technology to print conductive silver paste on the electrode substrate 1 to print two electrode connecting wires 3 and the substrate of the connecting terminal 2, the surface of the electrode connecting wire 3 is coated with a layer of PVC insulator, and the working electrode 4 and the counter electrode 5 at the lower end A layer of conductive graphite is coated by sputtering graphite method. Soak in 50% nitric acid, and then rinse with distilled water for 3 times. Let dry and store at 4°C for later use.

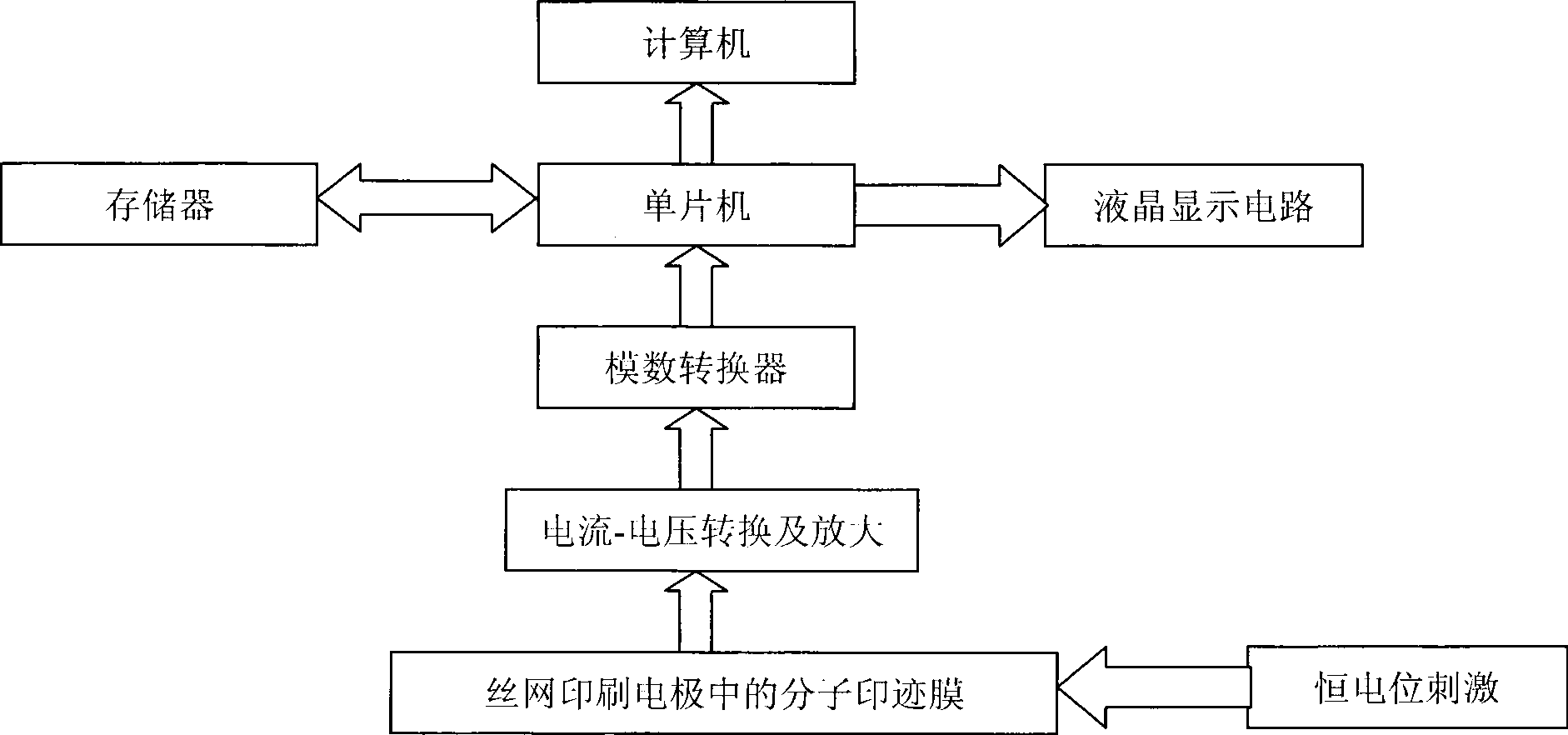

[0048] Weigh 0.05g of chloramphenicol and 70μl of methacrylic acid functional monomer and dissolve in 380μl of tetrahydrofuran solvent, mix ultrasonically for 10 minutes, add ethylene glycol dimethacrylic acid crosslinking agent, mix ultrasonically for 10 minutes, and then add to the reaction system 70 μl of water-based polyurethane adhesive, after ultrasonic mixing for 10 minutes, add 0.02 g of initiator azoisobutyrocyanide, after ultrasonic mixi...

Embodiment 2

[0056] During the preparation of chloramphenicol molecularly imprinted membranes, the ultraviolet polymerization time was continuous irradiation for 30 minutes, and other conditions remained unchanged. During the detection process, the preparation of the standard curve was the same as in Example 1, and pork was used as the detection sample.

[0057] Sample processing: Take 5 pork samples confirmed by high performance liquid chromatography-mass spectrometry to not contain chloramphenicol residues, take 1 gram of meat samples, put them into the sample cup of the tissue homogenizer, add 10 ml of 0.1M pH to 7.2 Phosphate buffer solution, crushed and homogenized, transferred to a 15ml centrifuge tube, added 1ml of chloramphenicol standard solution containing 40μg / L, then extracted with 6ml of ethyl acetate, shaken and mixed for 15min, Collect the organic phase containing chloramphenicol, evaporate and remove the organic solvent at 40°C and 240mbar, and finally add acetonitrile-2M p...

Embodiment 3

[0059] In the preparation process of the chloramphenicol molecularly imprinted membrane, the screen-printed electrode terminals, electrode connections, working electrodes and counter electrodes were all printed with conductive silver paste, and the others were the same as in Example 1. During the detection process, the preparation of the standard curve was the same as in Example 1, and chicken eggs were used as the detection sample.

[0060] Sample treatment: Take 5 egg samples confirmed by high performance liquid chromatography-mass spectrometry that do not contain chloramphenicol residues, take 5ml and put them in a 10ml centrifuge tube, shake and mix for 15min, add 1ml of chloramphenicol containing 20μg / L Standard solution, then extracted with 3ml ethyl acetate, collected the organic phase containing chloramphenicol, evaporated to remove the organic solvent at 40°C and 240mbar, and finally added 5ml acetonitrile-2M perchloric acid aqueous solution, the volume ratio was 3:2, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com