Variable temperature martensite local strengthening austenite low manganese steel hammer head material and preparation process thereof

A local strengthening and austenitic technology, which is applied in the field of austenitic low-manganese steel hammer head materials, can solve the problems of affecting the strengthening effect, Ti burning loss, and increasing Ti burning loss, so as to save heat treatment costs, increase service life, The effect of saving ferromanganese alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In the following, the specific content of the present invention will be further described by taking the local strengthening of the hammer head of a hammer crusher as an example.

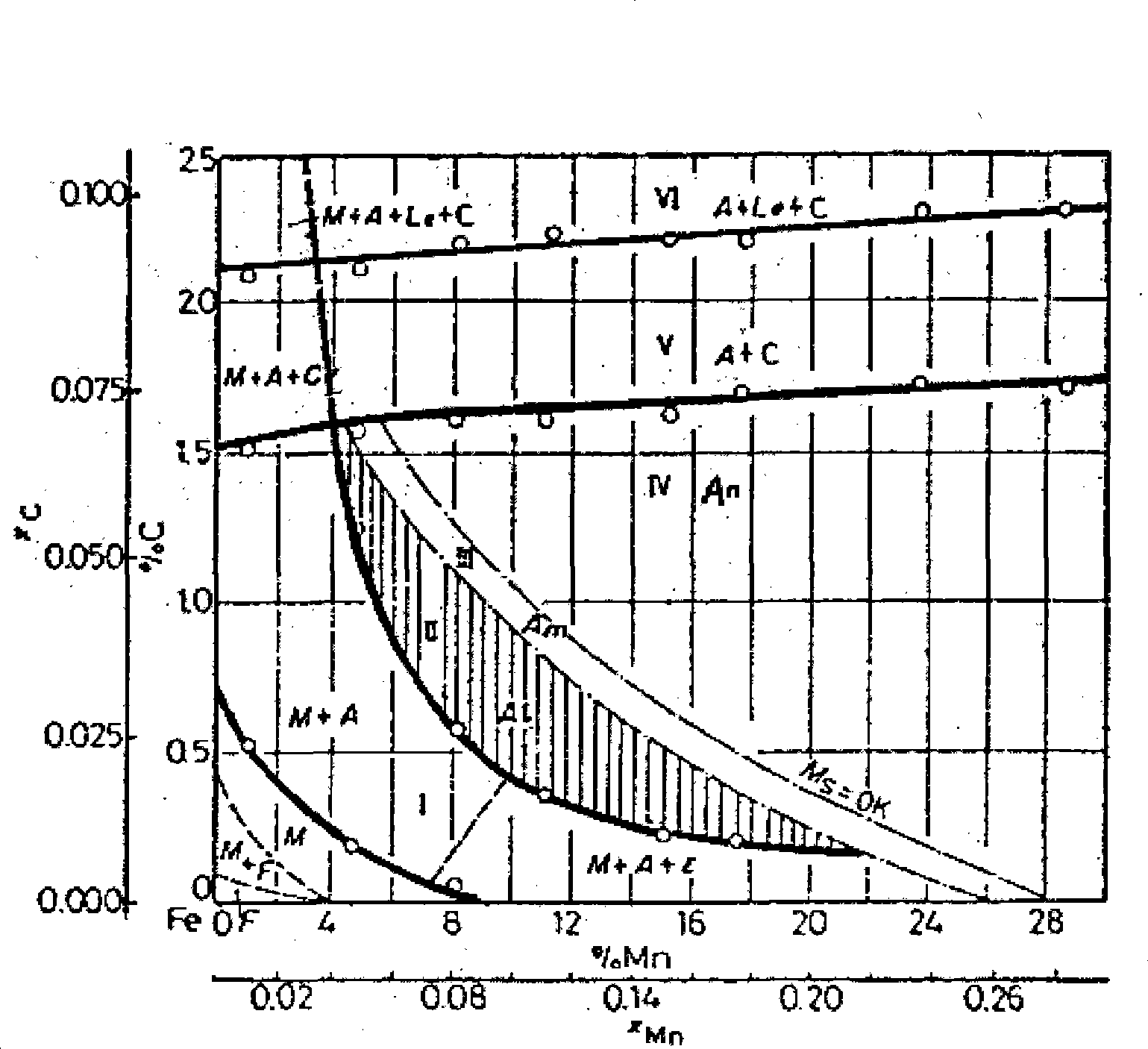

[0029] The specific process principle of the invention is as follows: first, the alloy composition design of the metastable austenitic manganese steel is carried out, and the Mn content is reduced from 13% to below 7.5%. Control and adjust the C content so that the matrix alloy composition falls within A 亚 In the (metastable austenite) region, a metastable austenite matrix structure is obtained, and its martensite transformation temperature M s Control it between -80°C and -30°C; after pouring, when the temperature of the casting drops to the austenite region, quickly immerse it in a water pool whose temperature is lower than 30°C, and perform direct water toughening treatment to obtain metastable austenite Tensile matrix structure, and then, with the help of short-term local liquid nitrogen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com