Method for preparing high-entropy alloy containing immiscible element

A high-entropy alloy and immiscible technology, applied in the field of preparation of high-entropy alloys containing immiscible elements, can solve the problems of immiscibility, inability of elements to be solid solution, solid solubility limitation, etc. The effect of using the range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

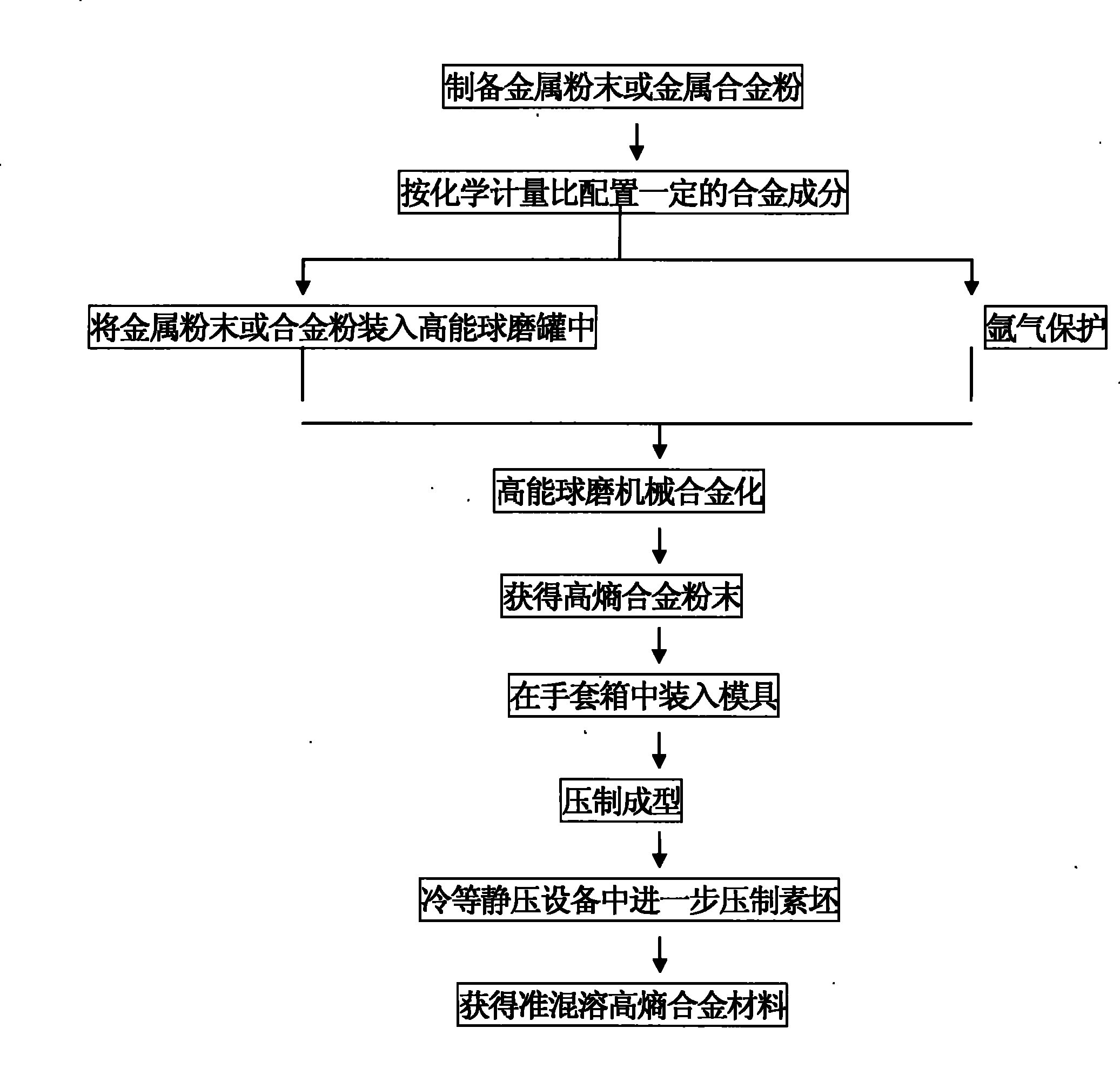

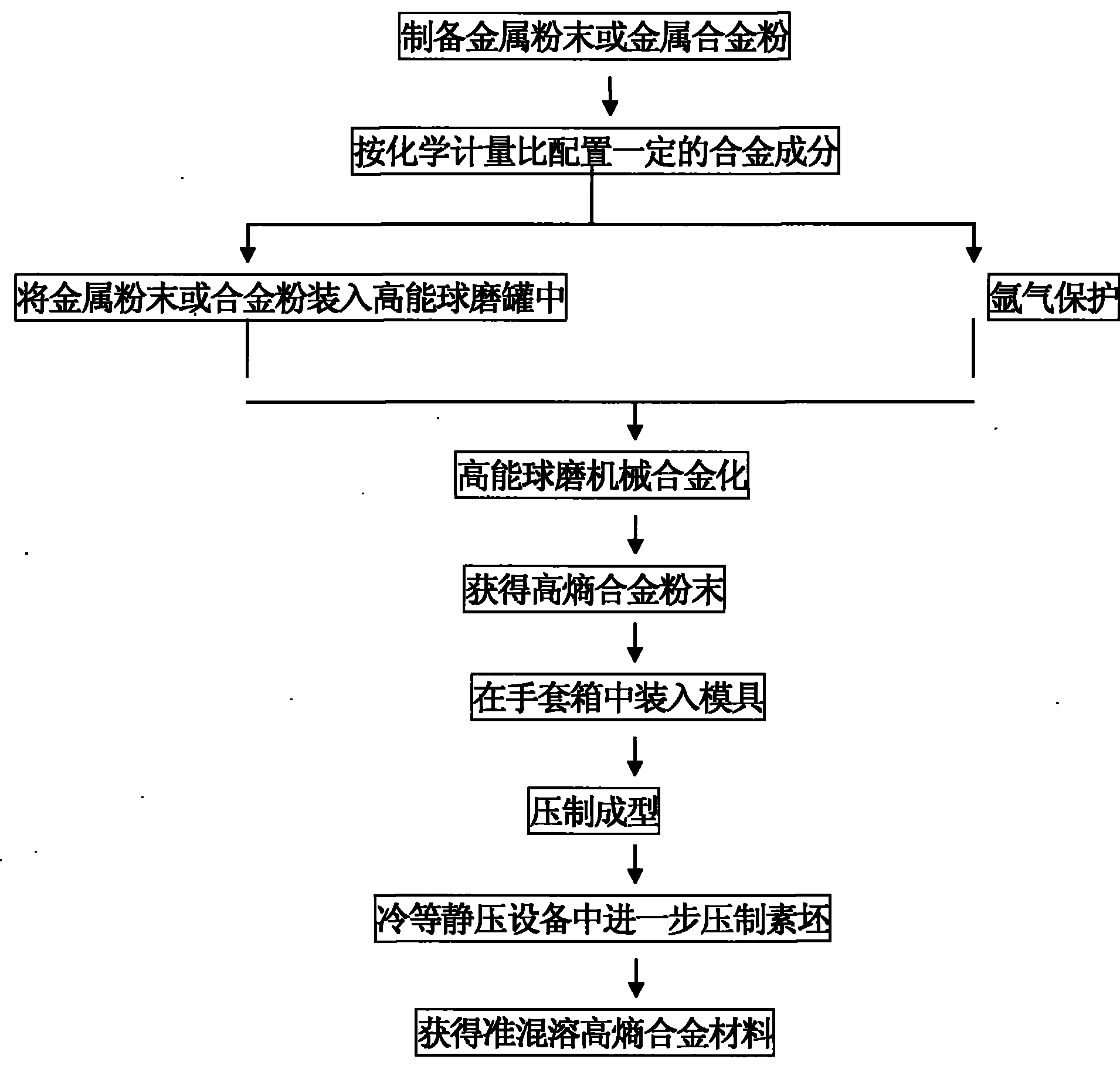

Method used

Image

Examples

Embodiment 1

[0039] al 31 sn 26 Cu 17 Ni 10 Ti 10 Zn 6 High entropy alloy preparation:

[0040] 31% aluminum (Al) powder by weight (the element content percentages mentioned herein refer to weight percentages without special instructions), 26% tin powder (Sn), 17% copper powder (Cu), 10 % of nickel powder (Ni), 10% of titanium powder (Ti), 6% of zinc powder (Zn), the preparation of alloy powder, wherein aluminum and tin elements belong to the solid immiscible system. After 4 hours of hydrogen annealing in a reducing atmosphere furnace, put it into a corundum ball mill jar, vacuumize it, fill it with argon, and carry out mechanical alloying under an argon protective atmosphere. The speed of the planetary high-energy ball mill is 800rad / min, and the ball milling time is 15 hours. The collected ultra-fine high-entropy quasi-miscible alloy powder is taken out of the glove box, put into the pre-prepared mold, and pressed in both directions in the steel mold. The molding pressure is 350MP...

Embodiment 2

[0042] Pb 21 sn 20 Ag 17 Nb 16 Mg 14 mn 6 B 6 High entropy alloy preparation:

[0043] 41% lead (Pb) tin (Sn) quasi-alloy powder by weight percentage, 17% silver powder (Ag), 16% niobium powder (Nb), 14% magnesium powder (Mg), 6% manganese powder ( Mn), 6% boron powder (B), prepare alloy powder, wherein lead, tin and boron elements belong to solid immiscible system with each other. After hydrogen annealing in a reducing atmosphere furnace for 3 hours, put it into a ball mill jar made of corundum material, vacuumize it, fill it with argon gas, and carry out mechanical alloying under an argon protective atmosphere. The rotation speed of the planetary high-energy ball mill is 1000rad / min, and the ball milling time is 25 hours. The collected ultra-fine high-entropy quasi-miscible alloy powder is taken out of the glove box, put into the pre-prepared mold, and pressed in two directions in the steel mold. The molding pressure is 300MPa, and it is further pressed by cold isost...

Embodiment 3

[0045] Zr 21 W 16 Cr 14 Nb 13 Mo 13 Fe 10 f 7 Cu 6 High entropy alloy preparation:

[0046] By weight 21% zirconium (Zr) powder, 16% tungsten powder (W), 14% chromium powder (Cr), 13% niobium powder (Nb), 13% molybdenum powder (Mo), 10% Iron powder (Fe), 7% hafnium powder (Hf), 6% copper powder (Cu), prepare alloy powder, in which copper and chromium elements belong to the solid-state insoluble system. After hydrogen annealing in a reducing atmosphere furnace for 8 hours, put it into a corundum ball mill jar, vacuumize it, fill it with argon, and carry out mechanical alloying under an argon protective atmosphere. The planetary high-energy ball mill rotates at 1200 rad / min, and the ball milling time is 45 hours. The collected ultra-fine high-entropy quasi-miscible alloy powder is taken out of the glove box, placed in a pre-prepared mold, and bidirectionally pressed in the steel mold. The molding pressure is 350MPa, and it is further pressed by cold isostatic pressing e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com