Method for preparing nano-micro level sun-screening agent with emulsification function

An emulsifying function, nano-micron technology, used in cosmetic preparations, skin care preparations, cosmetics, etc., can solve the problems of low disassociation rate, rapid aging of wrinkles, and increased strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

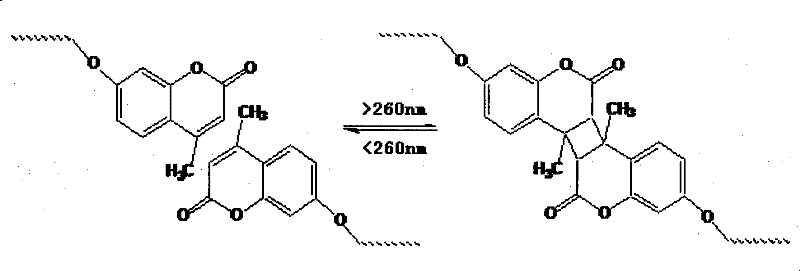

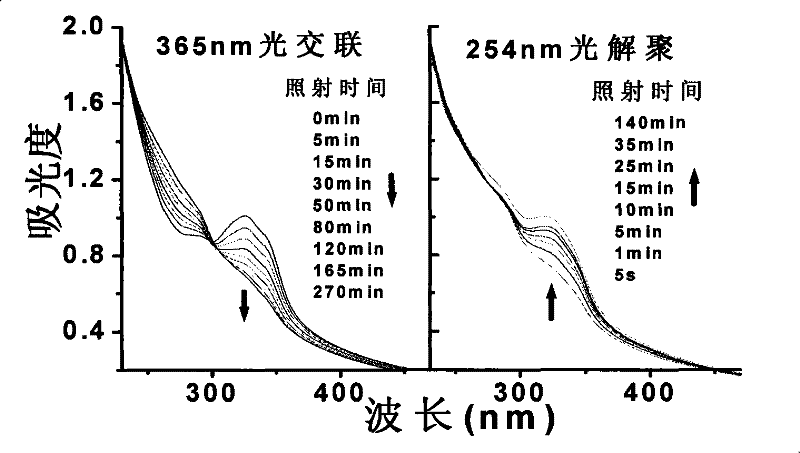

[0026] Example 1: One-time feeding of dimethylaminoethyl methacrylate, 4-methyl-7-p-vinylbenzylideneoxycoumarin, and methyl methacrylate in a molar ratio of 15:15:70 , adding azobisisobutyronitrile accounting for 2% of the total molar amount of reactants to initiate, react at 60° C. for 24 hours, purify, add lactic acid for neutralization, and obtain a photosensitive amphiphilic copolymer. Dissolve the copolymer in dioxane to make a 5wt% solution, add ultrapure water dropwise to it until a blue phase appears, continue stirring at a constant speed for 2-12 hours, remove the dioxane to obtain a pure photosensitive amphiphilic copolymer Micellar aqueous solution, micellar form such as Figure 4 shown. The aqueous solution of micelles is irradiated under ultraviolet light with a wavelength of 365nm for 15-300min, the double bond in coumarin absorbs ultraviolet light and opens, and photocrosslinking occurs, and the dissociation occurs again under the ultraviolet light of 254nm for...

Embodiment 2

[0027] Example 2: N-vinylpyrrolidone and 4-methyl-7-p-vinylbenzylideneoxycoumarin were charged at one time according to the molar ratio of 50:50, and added 2% of the total molar amount of the reactants. Initiated by azobisisobutyronitrile, reacted at 80°C for 12 hours, purified, neutralized by adding lactic acid, and vacuum dried to constant weight to obtain a photosensitive amphiphilic copolymer. Dissolve the copolymer in dioxane to make a 5wt% solution, add ultrapure water dropwise to it until a blue phase appears, continue stirring at a constant speed for 2-12 hours, remove the dioxane to obtain a pure photosensitive amphiphilic copolymer Micellar aqueous solution. The aqueous solution of micelles is irradiated under ultraviolet light with a wavelength of 365nm for 15-300min, the double bond in coumarin absorbs ultraviolet light and opens, and photocrosslinking occurs, and the dissociation occurs again under the ultraviolet light of 254nm for 0.5-120min. link. Add the pol...

Embodiment 3

[0028] Example 3: Methacryloyloxyethyl trimethylammonium chloride, methacryloyloxyethyl cinnamate and methyl methacrylate were prepared in a molar ratio of 15:15:70 or 30:30:40 One feeding, adding 1% azobisisobutyronitrile to the total molar amount of reactants to initiate, react at 70° C. for 20 hours, purify, add lactic acid for neutralization, and vacuum dry to constant weight to obtain a photosensitive amphiphilic copolymer. Dissolve the copolymer in dioxane to make a 5wt% solution, add ultrapure water dropwise to it until a blue phase appears, continue stirring at a constant speed for 2-12 hours, remove the dioxane to obtain a pure photosensitive amphiphilic copolymer Micellar aqueous solution. The micellar aqueous solution is placed under a UV lamp with a wavelength of 365nm and irradiated for 15-300min. The double bond in the cinnamoyl group absorbs UV light to open, photo-crosslinking occurs, and then cyclizes to form a three-dimensional network structure. 120min will...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com