Photoinduced hydrogen production catalytic system taking graphene as electron mediator and containing iron-sulfur cluster compound and preparation method and application of catalytic system

A catalytic system and cluster technology, applied in the field of photo-induced hydrogen production catalytic system, can solve the problems of violating the green concept of photo-induced hydrogen production, violating the green concept of photo-induced hydrogen production, low hydrogen production effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] Embodiment 1 Synthesis of iron-sulfur cluster compound A, the chemical formula of the iron-sulfur cluster compound A is [Fe 2 (μ-SC 3 h 6 S)(CO) 5 ][Fc(PPh 2 ) CHO], the preparation process is as follows:

[0081]

[0082] Concrete preparation steps are as follows:

[0083] 1) Under the protection of nitrogen, add 193mg (0.5mmol) Fe to a 100mL round-bottomed flask equipped with a magnetic stirrer to remove water and oxygen. 2 (μ-SC 3 h 6 S)(CO) 6 , 199mg (0.5mmol) Fc (PPh 2 ) CHO, 55.6mg (0.5mmol) Me 3 NO·2H 2 O and 20 mL of acetonitrile to obtain a mixed solution, and stirred at room temperature for 5 hours to obtain a reddish-brown solution.

[0084] 2) The solvent was dried by rotary evaporation, thin-layer separation was carried out with tetrahydrofuran and n-hexane at a volume ratio of 1:3, the second reddish-brown band was collected, and the solvent was dried to obtain a reddish-brown solid A (229.8 mg, yield 60.8%) .

[0085] The structural data o...

Embodiment 2

[0086] Example 2 Synthesis of the model substance B capable of intramolecular electron transfer, the chemical formula of the model substance B is 5-{[Fe 2 (μ-SC 3 h 6 S)(CO) 5 ] (PPh 2 Fc)}-10,15,20-triphenylporphyrin, the preparation process is as follows:

[0087]

[0088] Concrete preparation steps are as follows:

[0089] 1) Under nitrogen protection, add 540mg (0.7mmol) of compound A and 200mL of dichloromethane into a 250mL round-bottomed flask equipped with a stirring magnet to remove water and oxygen, and stir to dissolve to obtain a mixed solution.

[0090] 2) Add 0.21 mL (2.1 mmol) of benzaldehyde and 0.19 mL (2.8 mmol) of pyrrole to the above mixture, and stir at room temperature for 15 minutes to obtain a reaction solution.

[0091] 3) Add BF to the above reaction solution in the dark 3 ·Et 2 O0.036mL (0.28mmol), react at room temperature for 16 hours.

[0092] 4) Next, 688.5 mg (2.8 mmol) of chloranil was added to the above reaction solution, and heated...

Embodiment 3

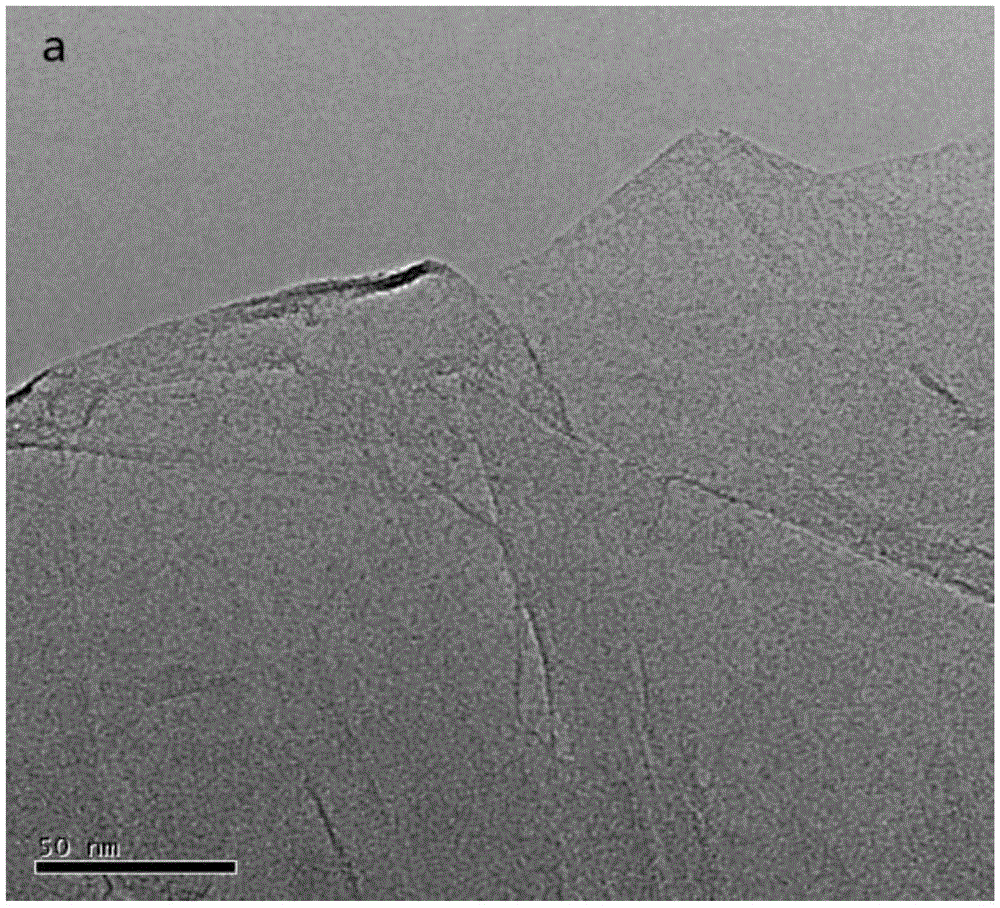

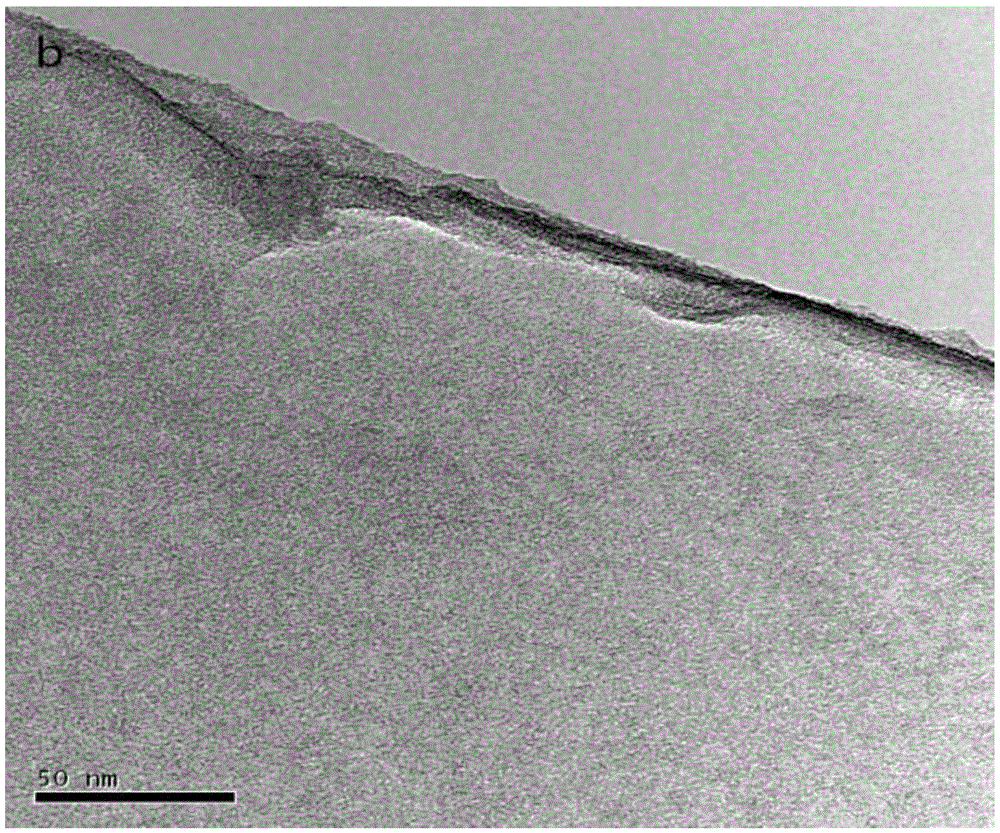

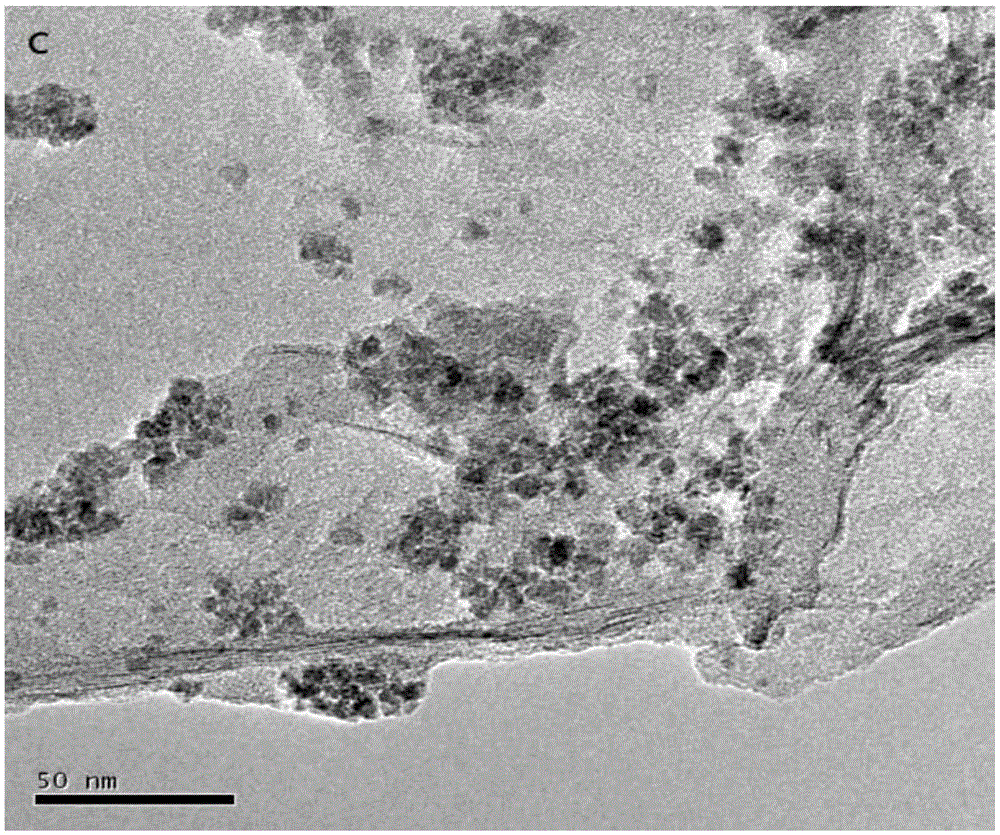

[0095] Embodiment 3 synthesis takes graphene as the intermediary nano material C, and the preparation process is as follows:

[0096]

[0097] Concrete preparation steps are as follows:

[0098] 1) Put 160mg of TPP-NHCO-GO into 300mL of dimethylformamide solution and sonicate for 1h to obtain a mixed solution.

[0099] 2) Pour the above mixture into a 500mL three-necked flask, install a condenser tube, add 33.3mg of compound A (0.044mmol), 35.6mg of CH 3 NHCH 2 COOH (0.4 mmol), heated and stirred at 120°C for 24 hours to obtain a reaction solution.

[0100] 3) Add 33.3mgA and 35.6mgCH to the above reaction solution 3 NHCH 2 COOH, followed by 48 hours of reaction.

[0101] 4) Continue to add 33.3mg of compound A and 35.6mg of CH to the reaction solution 3 NHCH 2 COOH, reacted for 48 hours.

[0102] 5) Cool to room temperature, wash with tetrahydrofuran and anhydrous methanol three times, and dry in a vacuum oven at 60° C. to obtain nanomaterial C.

[0103] product a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com