Method for preparing bleed air bleed air controllable polycarboxylic acids water reducing agents

A technology of polycarboxylate-based water reducer, which is applied in the field of preparation of air-entraining controllable polycarboxylate-based water-reducer, can solve problems such as instability, and achieve improved compressive strength, high water-reducing rate, and high-quality products. adaptable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Add 138.65g of water into the reactor, and when it is preheated to 75-80°C, add dropwise On the other side, add dropwise a mixed solution consisting of 0.125g sodium bisulfite, 3.875g ammonium persulfate and 138.65g water, drop it in 6~7h, keep it warm for 2~3h after the reaction, cool to room temperature, and use hydrogen Sodium oxide adjusts pH=6.5-7.5 to obtain the air-entraining controllable polycarboxylate water reducer of the present invention. Experiments have proved that the defoaming time of the water reducer is 80s, and the air content of the prepared concrete is 4.5%.

Embodiment 2

[0024] Add 138.65g of water into the reactor, and when it is preheated to 75-80°C, add dropwise On the other side, add dropwise a mixed solution consisting of 0.125g sodium bisulfite, 3.875g ammonium persulfate and 138.65g water, drop it in 6~7h, keep it warm for 2~3h after the reaction, cool to room temperature, and use hydrogen Sodium oxide adjusts pH=6.5-7.5 to obtain the air-entraining controllable polycarboxylate water reducer of the present invention. Experiments have proved that the defoaming time of the water reducer is 30s, and the air content of the prepared concrete is 3.0%.

Embodiment 3

[0026] Add 138.65g of water into the reactor, and when it is preheated to 75-80°C, add dropwise On the other side, add dropwise a mixed solution consisting of 0.25g sodium bisulfite, 3.75g ammonium persulfate and 138.65g water, drop it in 6~7h, keep it warm for 2~3h after the reaction, cool to room temperature, and use hydrogen Sodium oxide adjusts pH=6.5-7.5 to obtain the air-entraining controllable polycarboxylate water reducer of the present invention. Experiments have proved that the defoaming time of the water reducer is 22s, and the air content of the prepared concrete is 2.0%.

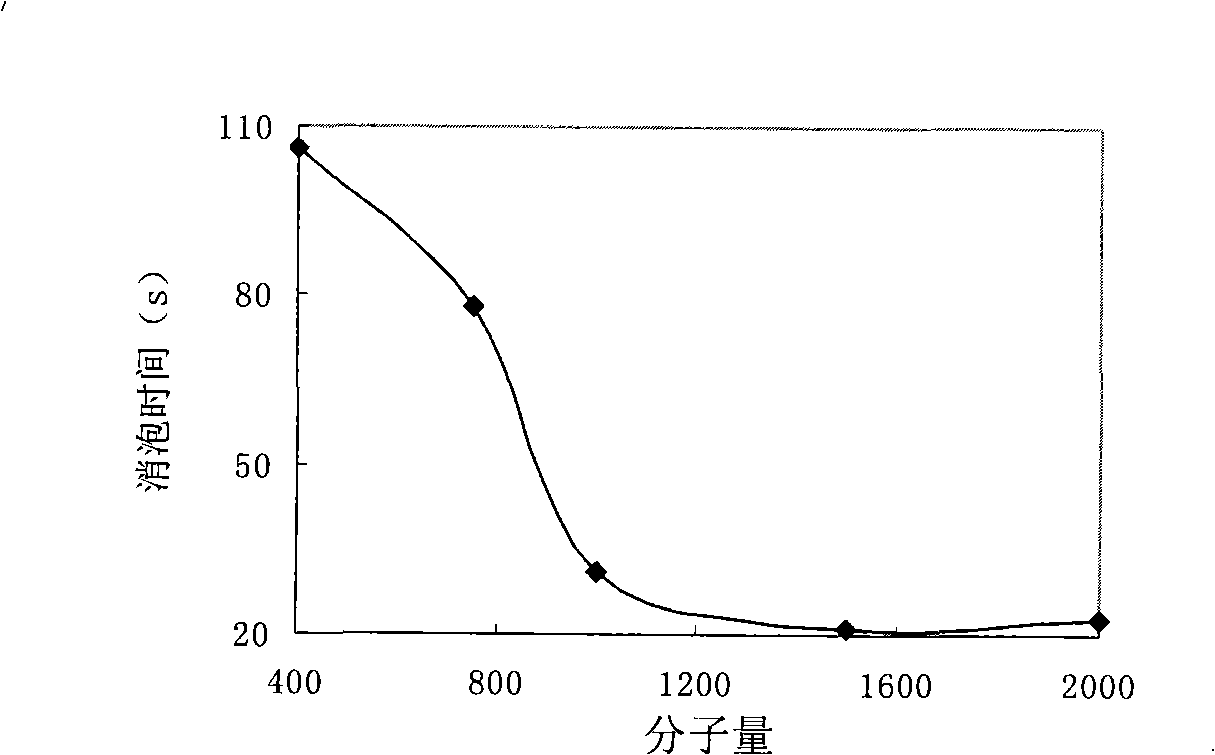

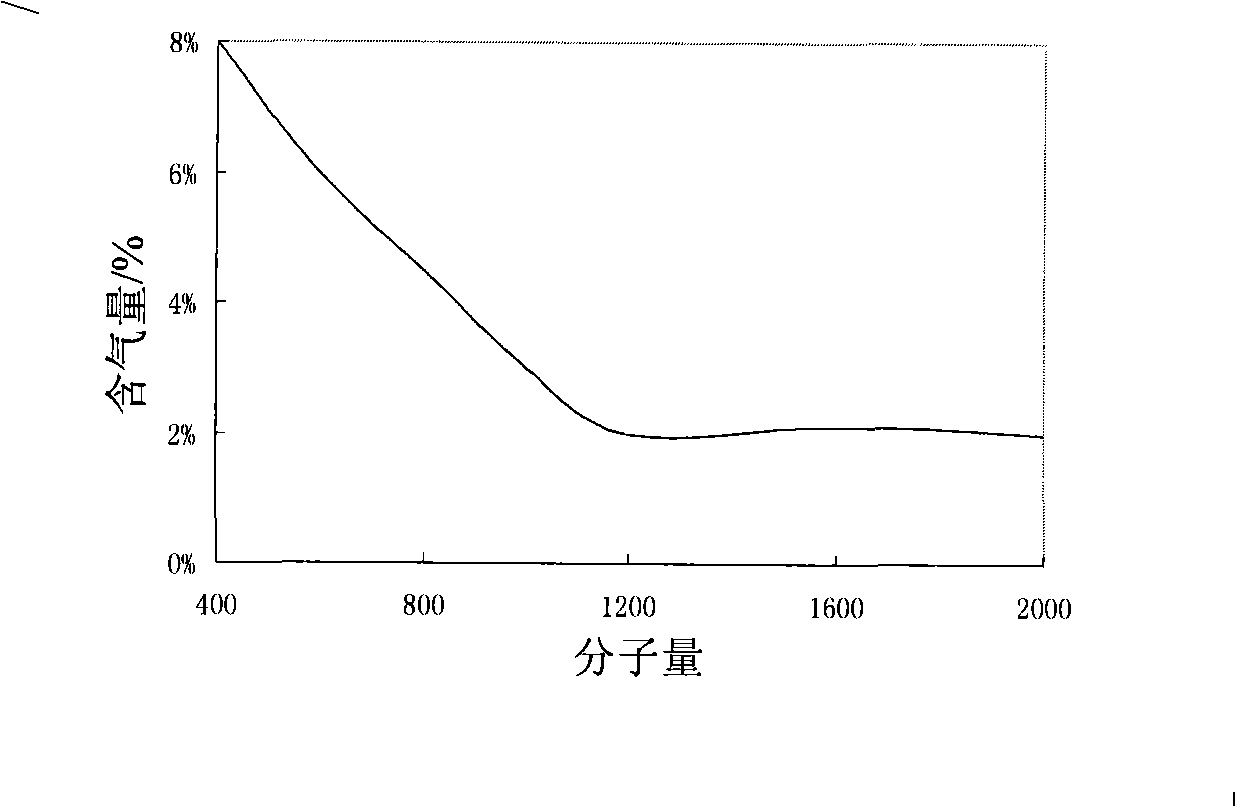

[0027] figure 1 and figure 2 It is a graph showing the experimental results of the relationship between the molecular weight of different polyethylene glycol monomethyl ether methacrylates and the defoaming time and gas content of the water reducer of the present invention. Experimental proof (see figure 1 , figure 2 ), the present invention can realize by adjusting the ratio of the produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com