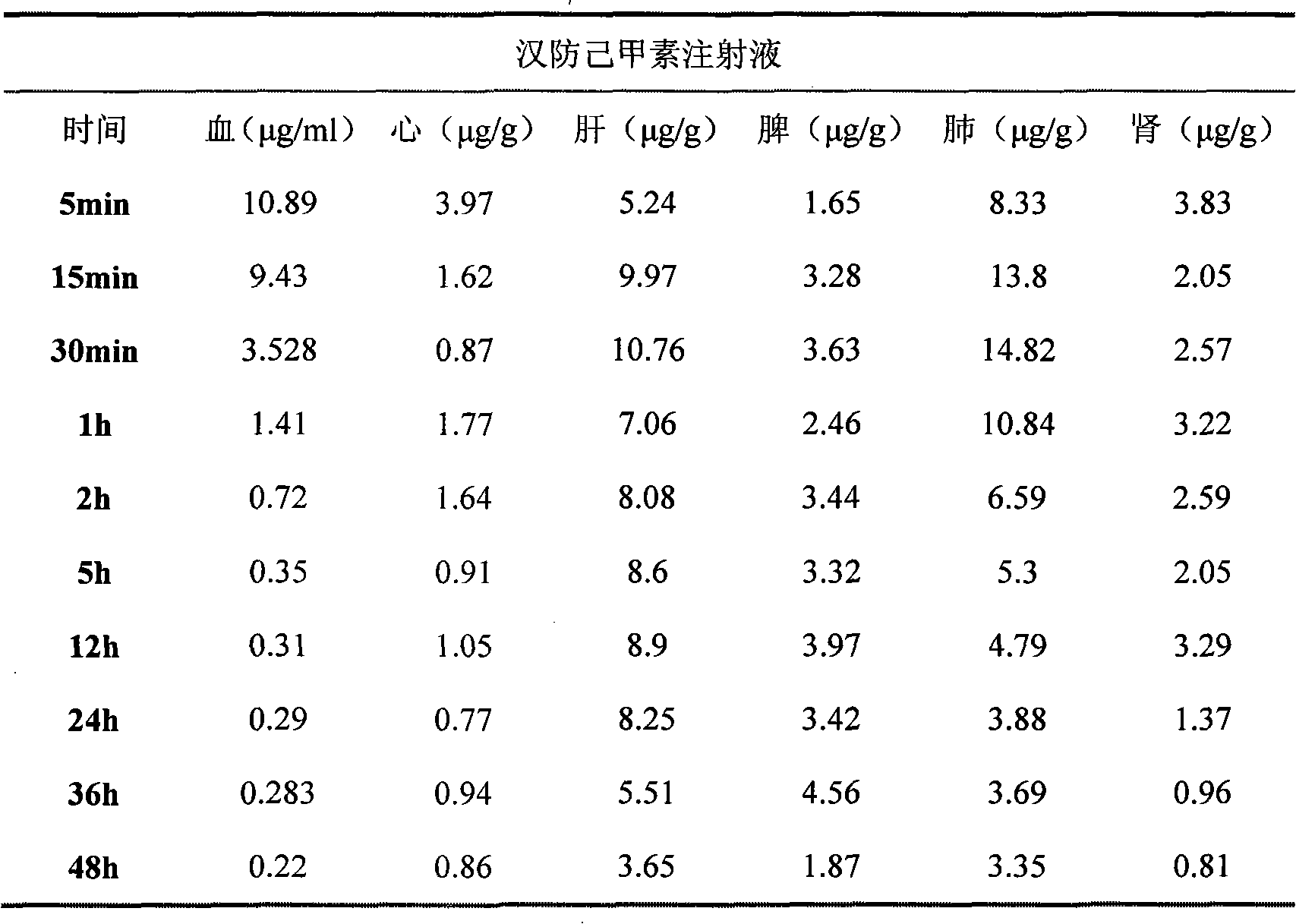

Tetrandrine nanoemulsion injection and method of preparing the same

A technology of tetrandrine and nanoemulsion, which is applied in the direction of pharmaceutical formula, emulsion delivery, medical preparations of non-active ingredients, etc., can solve the problems of affecting the drug release effect and unsatisfactory stability, and achieve the improvement of drug bioavailability Low density, easy industrial production, and increased dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] a. Take tetrandrine 0.6g, Tween-80 15.5g, polyethylene glycol 400 7.8g, ethyl oleate 5g, glycerin 1.5g, oleic acid 0.5g and water for injection 70g, set aside;

[0066] b. Dissolve tetrandrine in a mixture of Tween-80 and polyethylene glycol 400, add ethyl oleate, glycerin and oleic acid, mix well, and set aside;

[0067] c. Stir at normal temperature and pressure, and at the same time slowly add the amount of water for injection dropwise until the system forms a clear liquid, and the tetrandrine nanoemulsion with a transparent appearance is obtained.

[0068] d. Filling and sterilizing the tetrandrine nanoemulsion to prepare the tetrandrine nanoemulsion injection.

[0069] After testing, the average particle diameter of the tetrandrine nanoemulsion is 16.8nm.

Embodiment 2

[0071] a. Take Tetrandrine 1.2g, polyethylene glycol-vitamin E succinate 15.0g, propylene glycol 8.0g, soybean oil for injection 10.0g, glycerin 2.0g, oleic acid 2.0g and water for injection 62g, set aside;

[0072] b. Dissolve tetrandrine in a mixture of polyethylene glycol-vitamin E succinate and propylene glycol, add soybean oil for injection, glycerin and oleic acid, mix well, and set aside;

[0073] c. Stir at normal temperature and pressure, and at the same time slowly add the amount of water for injection dropwise until the system forms a clear liquid to obtain a transparent tetrandrine nanoemulsion with a particle size of 10-100 nm.

[0074] d. Filling and sterilizing the tetrandrine nanoemulsion to prepare the tetrandrine nanoemulsion injection.

[0075] After testing, the average particle diameter of the tetrandrine nanoemulsion is 21.5nm.

Embodiment 3

[0077] a. Take Tetrandrine 1.8g, polyethylene glycol-vitamin E succinate 19.5g, propylene glycol 7.0g, soybean oil 15.0g, glycerin 1.2g, oleic acid 2.5g and water for injection 50.5g, set aside;

[0078] b. Mix polyethylene glycol-vitamin E succinate, propylene glycol, ethyl oleate, glycerin, and oleic acid, stir at normal temperature and pressure, and slowly add water for injection dropwise until the system forms a clear liquid;

[0079] c. Add tetrandrine, stir and dissolve to obtain tetrandrine nanoemulsion with a particle size of 10-100 nm and a transparent appearance.

[0080] d. Filling and sterilizing the tetrandrine nanoemulsion to prepare the tetrandrine nanoemulsion injection.

[0081] After testing, the average particle diameter of the tetrandrine nanoemulsion is 18.3nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com