Method for synthetically reutilizing ammonia and hydrogen in tail gas discharged from indigo production

A technology of tail gas and indigo, applied in separation methods, chemical instruments and methods, vapor condensation, etc., can solve problems such as air or water pollution, environmental pollution, resource waste, etc., to reduce pollution, achieve obvious economic benefits, and reduce waste liquids. The effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

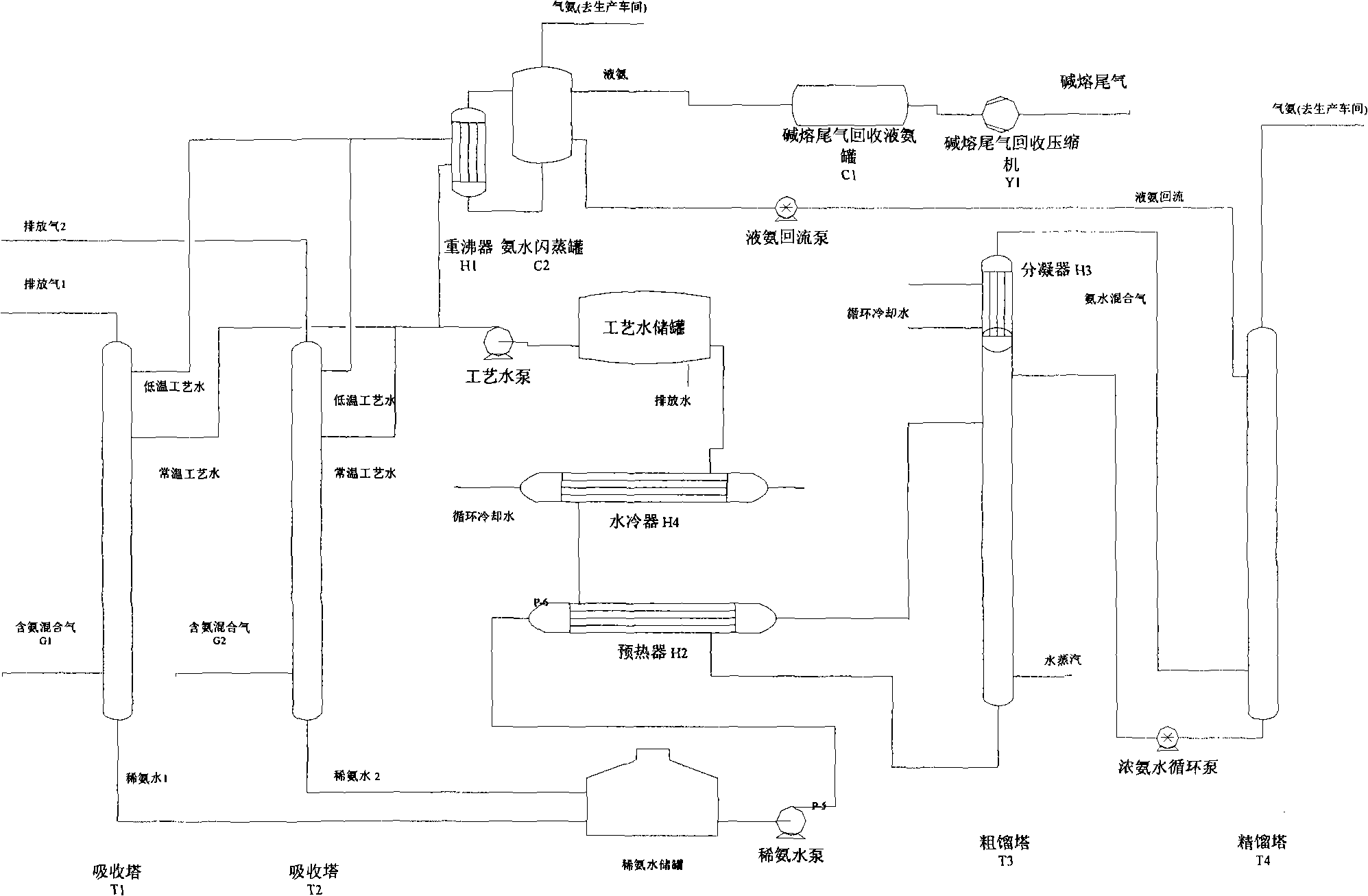

[0023] The process of recovering indigo production tail gas is as follows: figure 1 shown, including the following steps:

[0024] 1) The relatively stable composition and flow rate of the ammonia-containing tail gas discharged from the alkali melting section is recovered by ammonia compression method, that is, after the tail gas is buffered and bagged for dust removal, it is cooled and enters the compressor Y1, and then condensed to form liquid ammonia and stored in the storage tank C1;

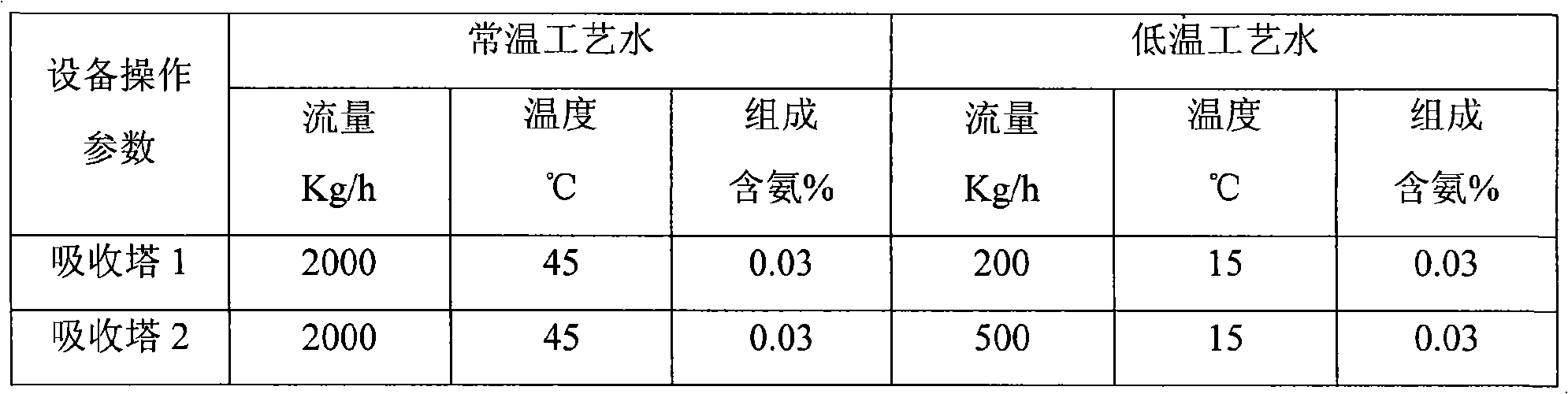

[0025] 2) The tail gas G1 containing ammonia, air and water vapor discharged from the potassium and sodium salt synthesis section is sent to the absorption tower (T1) through the fan. The tail gas G1 is mainly composed of ammonia and mixed with air (air ≤ 30%)) and saturated water vapor, the operating pressure is normal pressure, through the two-stage absorption of normal temperature process water and low temperature process water in the absorption tower, dilute ammonia water and exhaust ga...

Embodiment 2

[0035] The process flow is the same as in Example 1, and the parameters are the same, except that the low-temperature process water in the absorption tower 2 is changed to normal temperature process water (30° C.). The result shows: the ammonia content becomes 0.008 (8 times than the concentration of discharge in embodiment one) in the absorption tower 2 discharge gas, contains ammonia 560ppm. recovery rate reduces in the gained hydrogen.

[0036] From the above results, it can be seen that the cooling capacity of ammonia evaporation is cleverly used in the process, which reduces the ammonia content in the purified tail gas and improves the recovery rate of ammonia. At the same time, the reboiler set in the process also has the function of adjusting the amount of ammonia gas. When the production of the workshop fluctuates to a certain extent, the amount of ammonia gas used can be adjusted to meet the production needs and solve the problem of continuous ammonia gas consumption. ...

Embodiment 3

[0038] Process flow is as embodiment 1, and main process parameter is also identical. In this embodiment, liquid ammonia is directly used as reflux without using a rectifying column, and an ammonia compressor is installed at the top of the column and a condenser is installed.

[0039] Comparing the operating results of Examples 1 and 3, both processes can reach the quality index of ammonia recovery, meeting the needs of indigo production. But embodiment three increases investment (a compressor and a condenser) and energy consumption (increase 19kw) than embodiment one

[0040] It can be seen from the above results that direct reflux of liquid ammonia is cleverly used in the process flow of the present invention, which meets the operation needs of the rectification tower, and achieves the purpose of saving investment and reducing consumption. Moreover, the reflux of liquid ammonia directly does not need to wait for the hysteresis of heat transfer and mass transfer, the adjustm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com