Microparticle-supported carbon particle, method for production thereof, and fuel cell electrode

A manufacturing method and technology of microparticles, applied in battery electrodes, chemical instruments and methods, circuits, etc., can solve problems such as the reduction of catalytic ability, and achieve the effect of reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058]

[0059] 2.53 g of cerium chloride heptahydrate was dissolved in 100 ml of water, and 3 equivalents of citric acid were added to cerium to prepare an aqueous solution containing cerium-containing citric acid coordination ions. 5 g of Bulkan XC-72 (registered trademark, carbon black manufactured by CABOT, with an average particle size of 30 nm) was added to the aqueous solution and dispersed by ultrasonic waves, followed by stirring for 2 hours to adsorb the coordination ions on the surface of the Bulkan. Thereafter, hydrothermal treatment was performed at 180°C for 5 hours, and drying was performed at 90°C to obtain carbon particles carrying a cerium compound.

[0060] Next, 0.19 g of chloroplatinic acid hexahydrate was dissolved in 30 g of ethanol to prepare an ethanol solution of platinum. The ethanol solution was impregnated into the previously obtained cerium compound-carrying carbon particles (powder), and after drying at 60°C, the carbon particles were heat-treated in ...

Embodiment 2

[0063]

[0064] Dissolve 1.44 g of cerium chloride heptahydrate and 1.33 g of chloroplatinic acid hexahydrate in 100 ml of water, and add equivalent citric acid to the cerium ion and platinum ion to prepare an aqueous solution containing cerium and platinum citric acid coordination ions.

[0065] Next, 5 g of Bulkan XC-72 (registered trademark, carbon black manufactured by CABOT, with an average particle size of 30 nm) was impregnated with an aqueous solution containing the above-mentioned citric acid coordination ions, and the above-mentioned coordination ions were adsorbed on the surface of the above-mentioned Bulkan. After drying at 90°C, heating treatment was performed at 700°C in nitrogen to obtain platinum-substituted cerium oxide (Ce 0.6 Pt 0.4 )O 2 Particles of carbon particles.

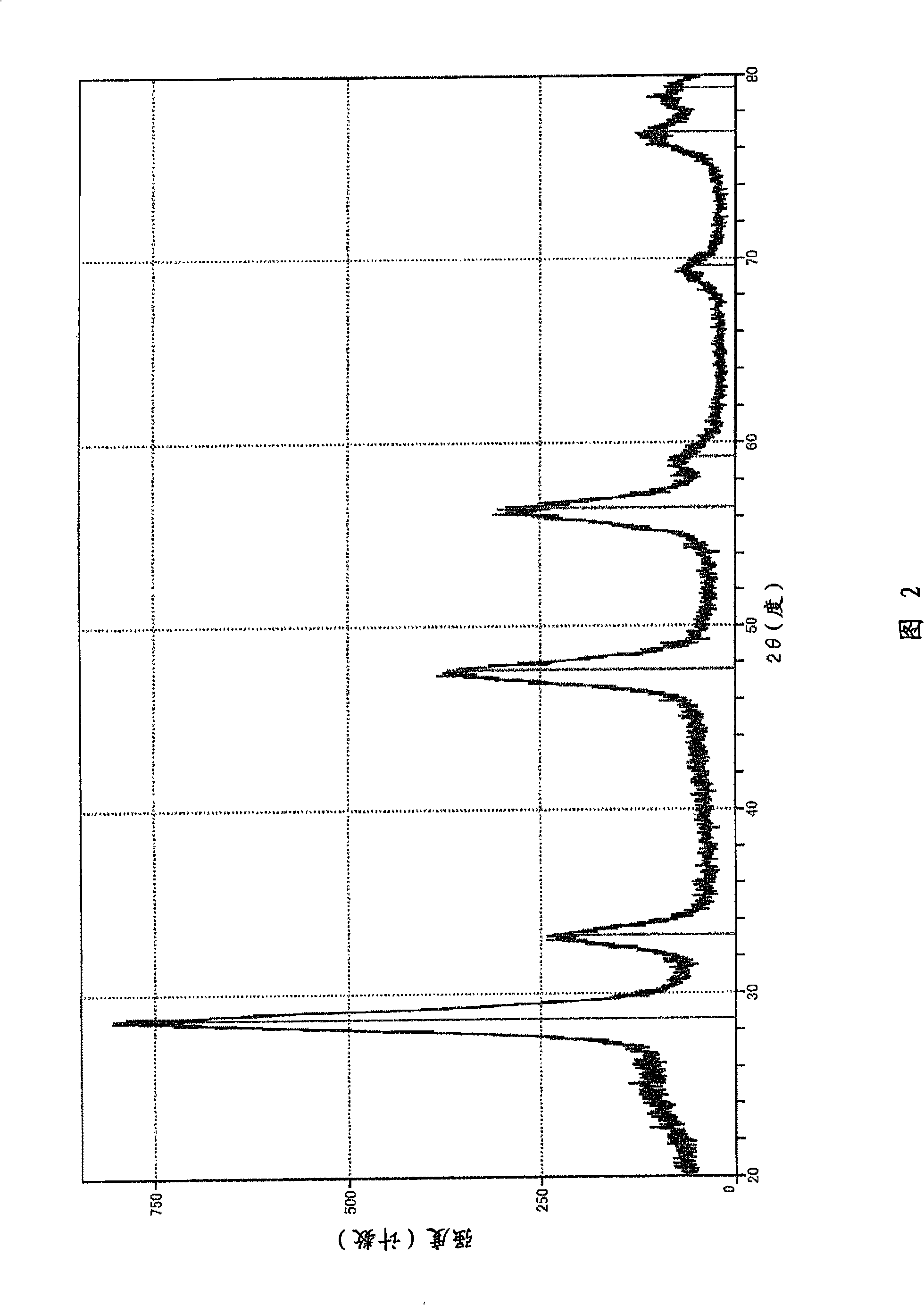

[0066] For the support (Ce 0.6 Pt 0.4 )O 2 Powder X-ray diffraction spectroscopy was performed on the carbon particles of, and the results confirmed that although the peak position shift caused ...

Embodiment 3

[0069]

[0070] In the method for producing fine particle-carrying carbon particles of Example 1, after obtaining cerium compound-carrying carbon particles in the same manner as in Example 1, 0.09 g of ruthenium chloride trihydrate was dissolved in 30 g of water to make the ruthenium aqueous solution The above-mentioned carbon particles supporting the cerium compound were impregnated, except that the same operation as in Example 1 was carried out to obtain ruthenium-substituted cerium oxide particles (Ce 0.95 Ru 0.05 )O 2 Of carbon particles.

[0071] For the support prepared in this way (Ce 0.95 Ru 0.05 )O 2 The result of powder X-ray diffraction spectrum measurement of the carbon particles of, it was confirmed that a clear single-phase peak of the cerium oxide structure appeared as in Example 1. It can be seen that the ruthenium element enters the crystal lattice of the cerium oxide. At this time, the average crystallite size calculated from the half-value width of the diffract...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com