Resource recycling method of high-impurity-content copper smelting slag

A technology of copper smelting slag and recovery method, which is applied in the direction of improving process efficiency, can solve the problems of not exerting economic value, not having economic benefits of copper smelting enterprises, and increasing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0106] The hot-melt smelting slag discharged from the flash smelting furnace is treated as the processing object, and the temperature is within the range of 1280°C. The molten copper smelting slag contains the following components in weight percentage: 1.2% copper, 0.72% lead, 5.88% Zinc, 1.2% arsenic, 0.39% antimony, 0.51% bismuth, 0.02% tin. Include the following steps:

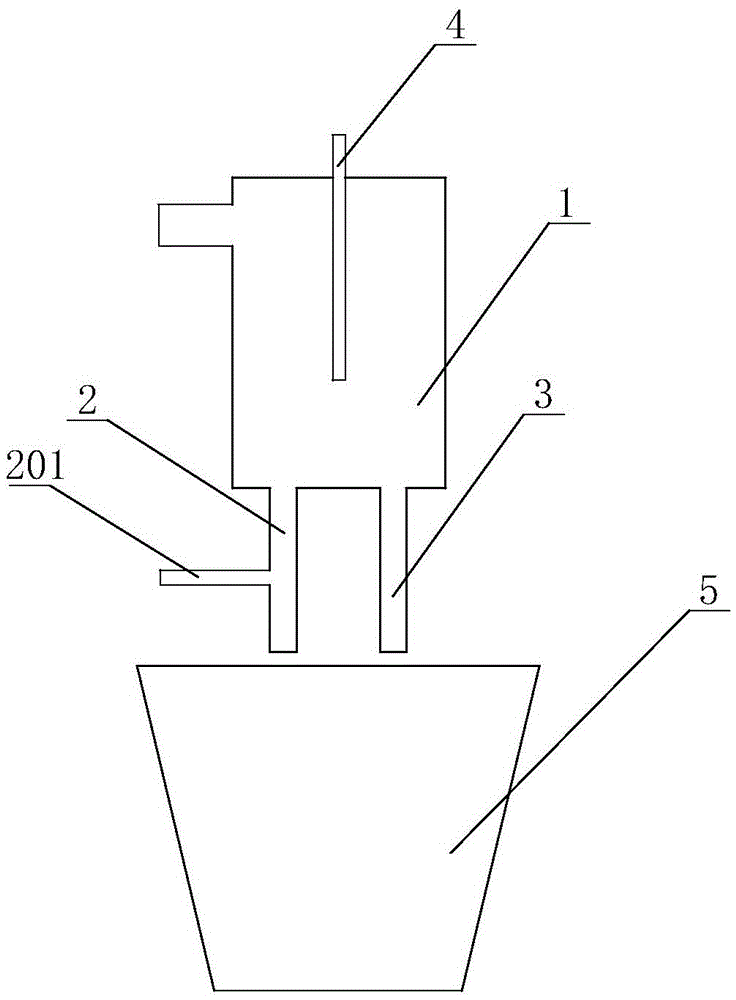

[0107]1) Add the molten copper smelting slag melt into the slag holding container 5; then immerse the liquid inlet pipe 2 and the liquid outlet pipe 3 into the slag holding container 5 to a certain depth below the upper liquid level of the copper smelting slag melt, and then Turn on the vacuum pump to evacuate the cavity in the refining furnace 1 into a vacuum state. At this time, the copper smelting slag melt in the slag container 5 rises and flows into the cavity of the refining furnace 1 along the cavity channels in the liquid inlet pipe 2 and the liquid outlet pipe 3. cavity;

[0108] 2) Inject the dr...

Embodiment 2

[0115] The hot-melt smelting slag discharged from the flash smelting furnace is treated as the processing object, and the temperature is within the range of 1250°C. The molten copper smelting slag contains the following components in weight percentage: 1.4% copper, 0.52% lead, 4.50% Zinc, 1.0% arsenic, 0.23% antimony, 0.25% bismuth, 0.02% tin. Include the following steps:

[0116] 1) Add the molten copper smelting slag melt into the slag holding container 5; then immerse the liquid inlet pipe 2 and the liquid outlet pipe 3 into the slag holding container 5 to a certain depth below the upper liquid level of the copper smelting slag melt, and then Turn on the vacuum pump to evacuate the cavity in the refining furnace 1 into a vacuum state. At this time, the copper smelting slag melt in the slag container 5 rises and flows into the cavity of the refining furnace 1 along the cavity channels in the liquid inlet pipe 2 and the liquid outlet pipe 3. cavity;

[0117] 2) Inject the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com