Method for preparation of polycrystalline silicon solar cell textile layer

A technology for solar cells and polycrystalline silicon, applied in the field of solar cells, can solve the problems of poor anti-reflection effect, high cost, complicated process, etc., and achieve the effects of being beneficial to industrial application, fast production and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

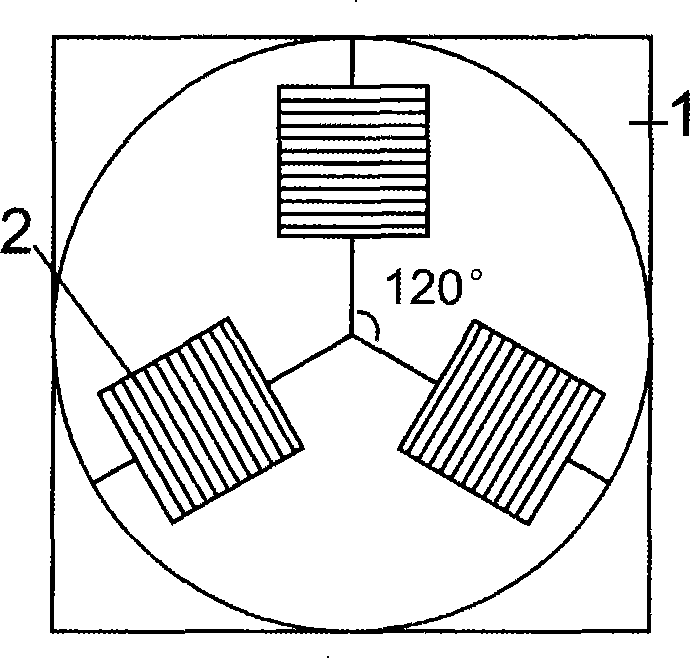

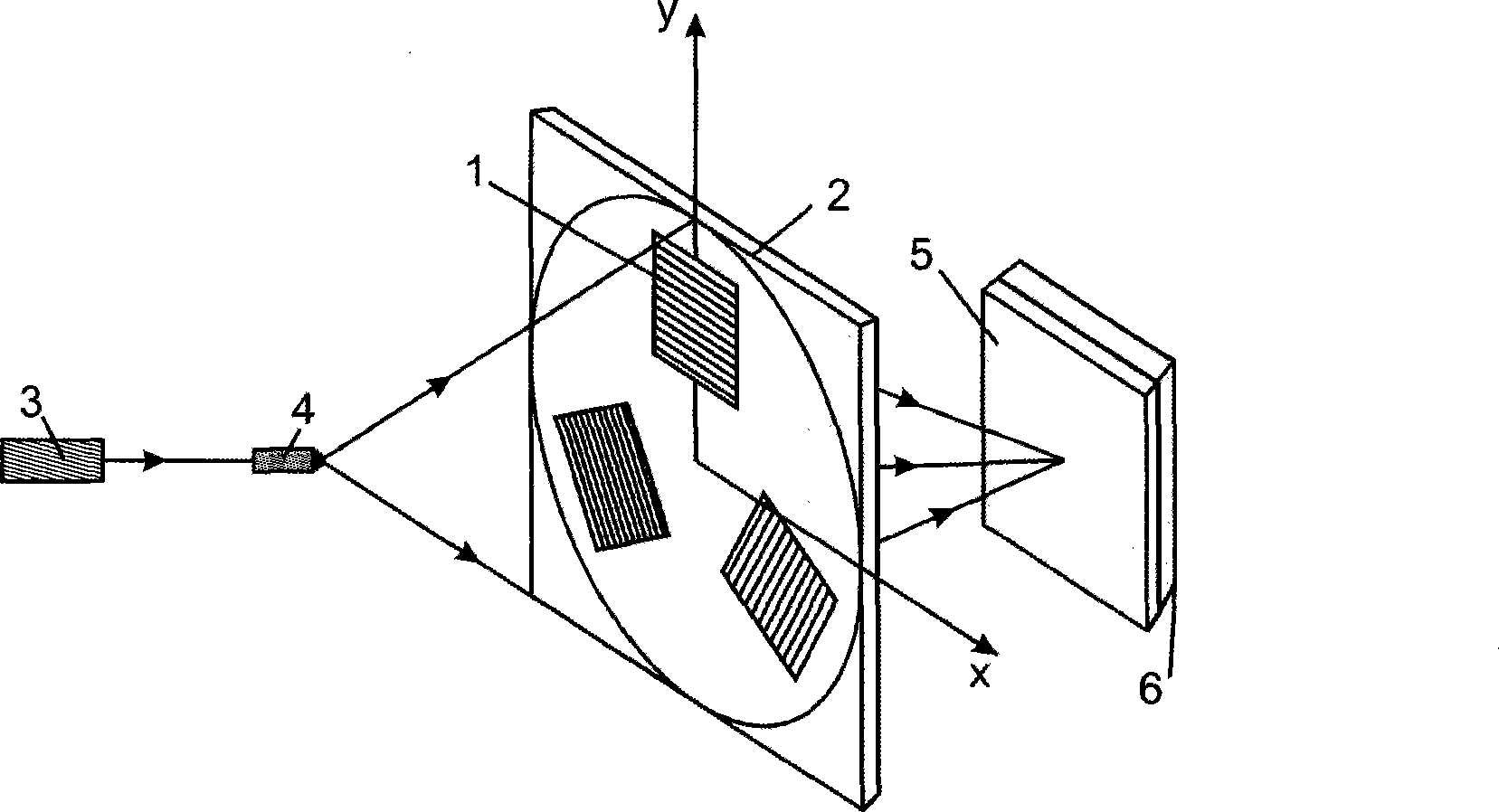

[0027] see figure 1 and 2 , the laser light output by the laser 3 is projected on the holographic optical element 1 after being expanded by the spatial filter 4 . Holographic optical elements 1 such as figure 1 As shown, it is made by holography and consists of three groups of identical holographic gratings 2 with 120° symmetry. When the expanded laser beam is vertically projected onto the holographic optical element 1, due to the action of the three sets of diffraction gratings, the holographic optical element 1 diffracts three sets of diffracted light, which converge on the central optical axis at the same angle, and the interference pattern is similar to Lattice structure in hexagonal crystals. The recording material is placed in the area where the three beams of diffracted light overlap and interfere, and the hexagonal periodic microstructure pattern can be recorded after exposure.

[0028] The laser adopts argon ion laser (wavelength 458nm), which is determined by the...

Embodiment 2

[0035] Similar to Example 1, the difference is that the angle between the three beams of light is adjusted to be 8.78°, and the microscopic photo of polysilicon etched with a period of 2 μm microstructure pattern is obtained. Figure 4 .

Embodiment 3

[0037] Similar to Example 1, the difference is that the angle between the three beams of light is adjusted to be 5.67°, and the microscopic photo of polysilicon etched with a microstructure pattern with a period of 3.09 μm is obtained. Figure 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com