Gliding quartz boat for growth low-melting point semiconductor material

A semiconductor and low melting point technology, applied in the field of growth boats, can solve the problems that it is difficult to grow high-quality heterogeneous epitaxial single crystal materials and affect the electrical properties of materials, so as to improve electrical properties, distribute components uniformly, and avoid carbon contamination. dirty effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

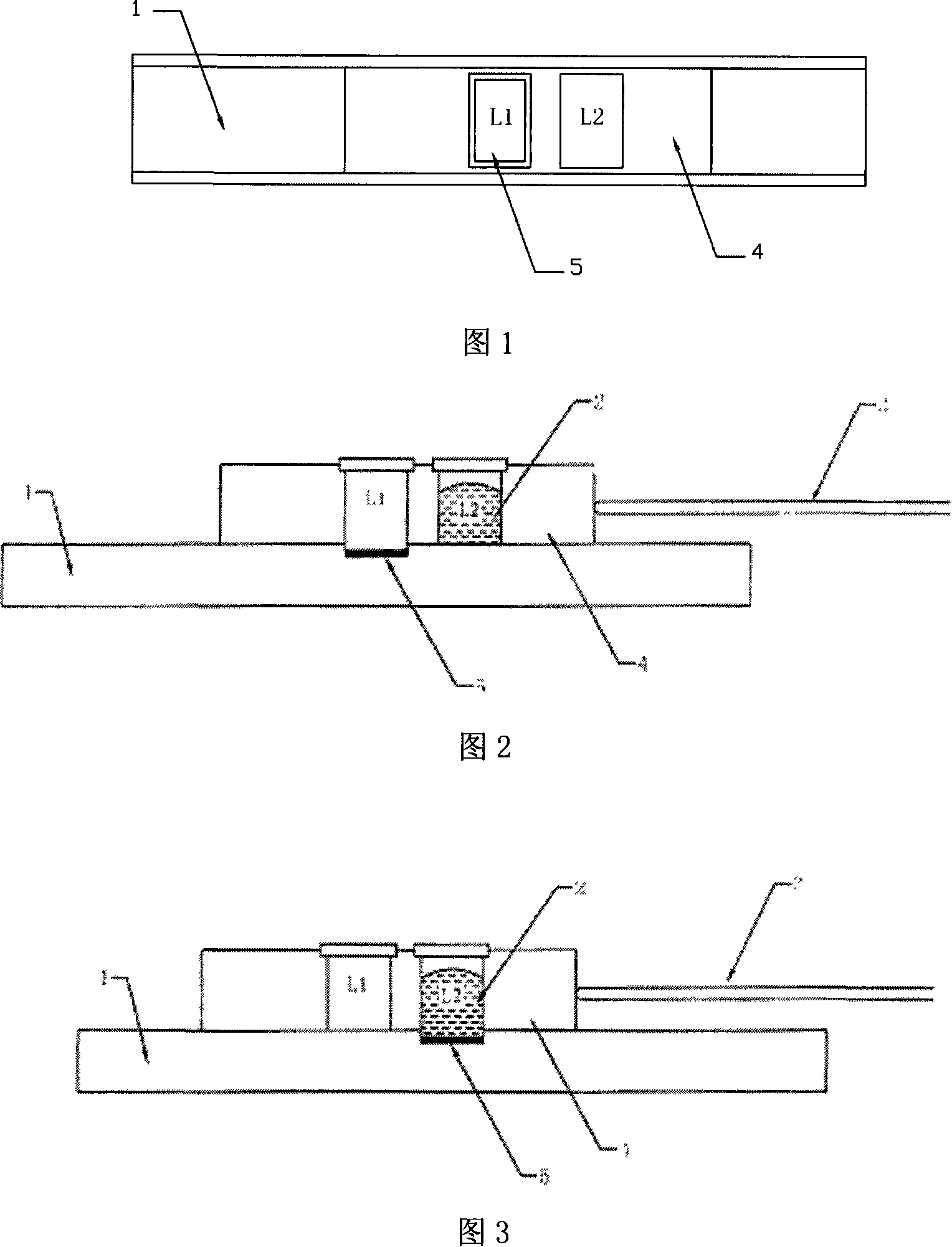

[0020] Please refer to Figures 1-4. The sliding quartz boat of the present invention is made of high-purity quartz raw materials. The upper half of boat is briquetting block 4. The middle part of the compact 4 is provided with two wells (L1, L2) vertically penetrating the compact 4, and the bottom of the compact 4 is flat except for the two wells, and is polished to a mirror-level smoothness, so that the growth The surface of the epitaxial layer is smooth. The bottom half of the boat is the base plate 1, and a groove is opened on the base plate 1, and the substrate 5 is placed in the groove. The briquetting block 4 with a well is installed on the bottom plate 1 and matched with the bottom plate 1, and the briquetting block 4 is pushed to move on the bottom plate 1 by the quartz push rod 3 to complete material growth.

[0021] working principle

[0022] The growth material of the present invention utilizes a conventional liquid phase epitaxy system, but has a special growth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com