Degradable chemical bitter earth alloy bracket and method of preparing the same

A chemical oxidation and magnesium alloy technology, applied in medical science, surgical adhesives, metal material coating technology, etc., can solve the problems of high waste liquid treatment cost, containing hexavalent chromium ions, affecting alloy composition, etc., and achieve low cost , excellent mechanical and pharmacological properties, and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

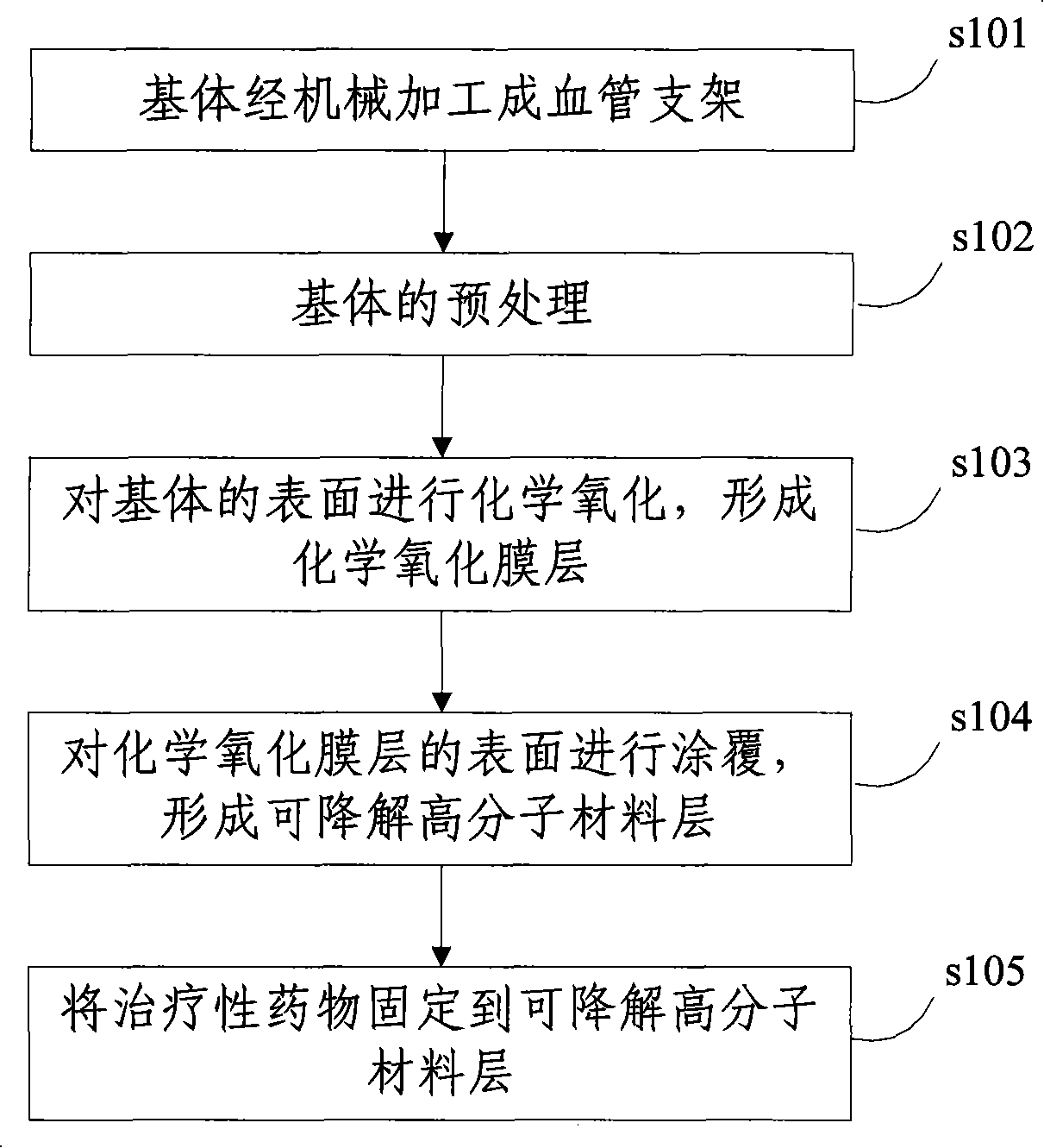

[0025] The flow chart of a method for preparing a degradable vascular stent with a composite coating in an embodiment of the present invention is as follows: figure 1 shown, including the following steps:

[0026] In step s101, the matrix is machined into a stent, and the matrix is made of pure magnesium or a magnesium alloy material. The matrix can also be processed into bone sutures, bone nails, bone connectors, vertebral discs, suture anchors, hemostatic forceps, hemostatic screws, hemostatic plates, hemostatic clips, tissue adhesives, sealants, or artificial bones.

[0027] Step s102, pretreatment of the substrate, the pretreatment includes the steps of degreasing, pickling and alkali washing to remove impurities such as grease and oxides on the surface of the magnesium alloy. The pretreatment of described substrate comprises:

[0028] Put the matrix into the degreasing liquid for degreasing, the composition of the degreasing liquid is: NaOH5~10g / L, NaOH 2 CO 3 5~1...

Embodiment 1

[0040] Example 1: After high-purity magnesium is polished, it is carved into a vascular stent with a laser. First sand with progressively finer sandpaper to mechanically remove surface oxides. Then degrease, pickle and alkali wash. The degreasing solution is NaOH 5g / L, Na 2 CO 3 5g / L and Na 2 SiO 3 5g / L. The temperature of the degreasing solution is 303K, and the time is 30 minutes; the pickling solution is a mixed solution of 20ml / L acetic acid and 5g / L sodium nitrate. The temperature of the pickling solution is 303K, and the pickling time is 3 minutes. Rinse with clean water after taking it out, and then soak the high-purity magnesium stent in alkaline washing solution. The alkaline washing solution is a sodium hydroxide solution with a pH value of 12 and 10g / L, the temperature is 303K, and the alkaline washing time is 5 minutes. After taking it out, rinse it with clean water, and then put the high-purity magnesium stent into the chemical oxidation solution.

[00...

Embodiment 2

[0046] Example 2: AZ91D magnesium alloy is polished and then laser engraved into a vascular stent. First sand with progressively finer sandpaper to remove surface oxides. Then degrease, pickle and alkali wash. The degreasing solution is NaOH 5g / L, Na 2 CO 3 5g / L and Na 2 SiO 3 5g / L. The temperature of the degreasing solution is 303K, and the time is 30 minutes; the pickling solution is a mixed solution of 20ml / L acetic acid and 5g / L sodium nitrate. The temperature of the pickling solution is 303K, and the pickling time is 3 minutes. Rinse with clean water after taking it out, and then soak the magnesium alloy stent in alkaline washing solution. The alkaline washing solution is a sodium hydroxide solution with a pH value of 12 and 10g / L, the temperature is 303K, and the alkaline washing time is 5 minutes. After taking it out, rinse it with clean water, and then put the magnesium alloy stent into the chemical oxidation solution.

[0047] The composition of magnesium m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com