A silver-ZnO electric contact and its making method

A zinc oxide and electric contact technology, applied in contacts, circuits, electric switches, etc., can solve problems such as ZnO particle agglomeration, and achieve the effects of sufficient zinc oxidation, stable contact resistance, and high electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

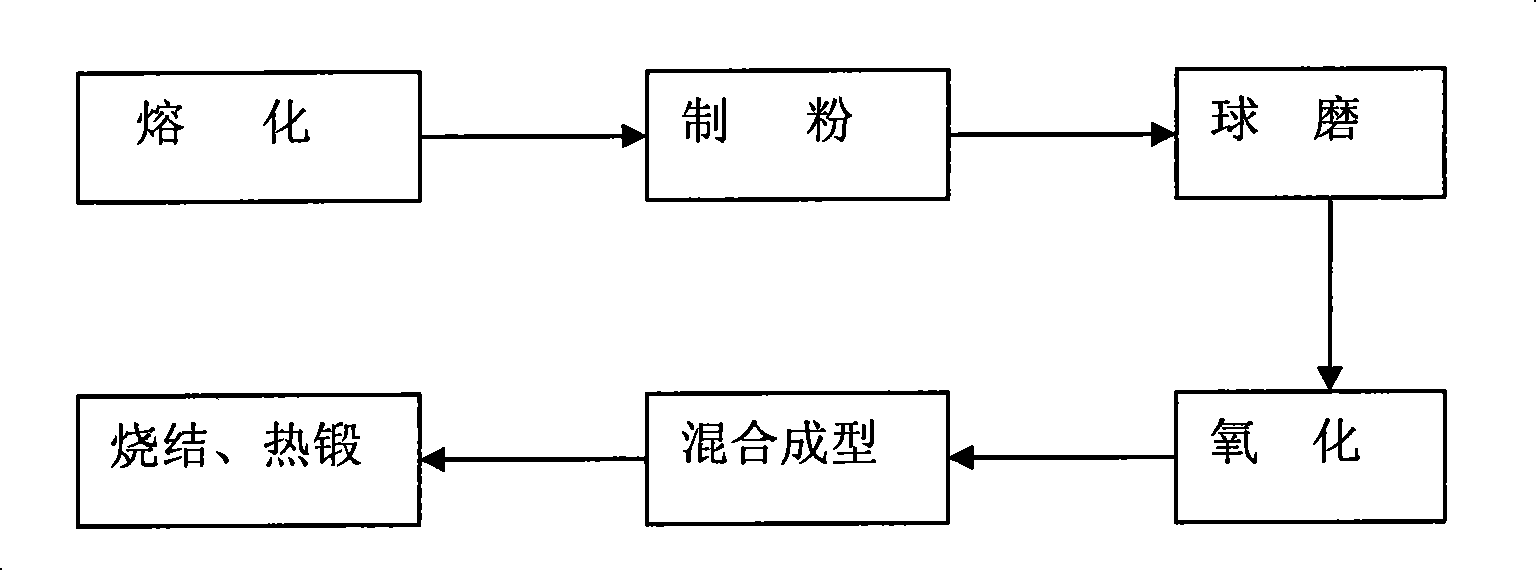

Method used

Image

Examples

Embodiment 1

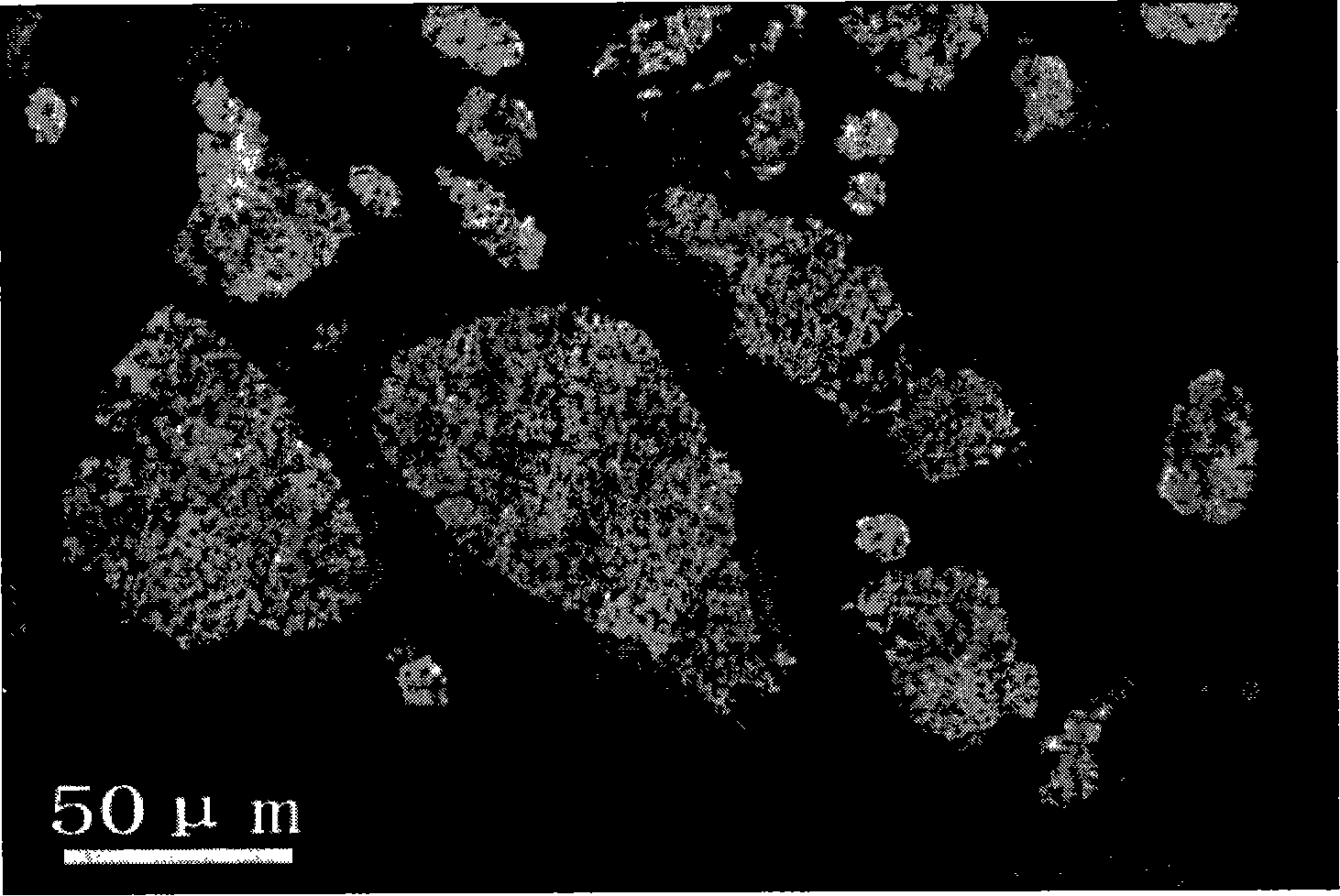

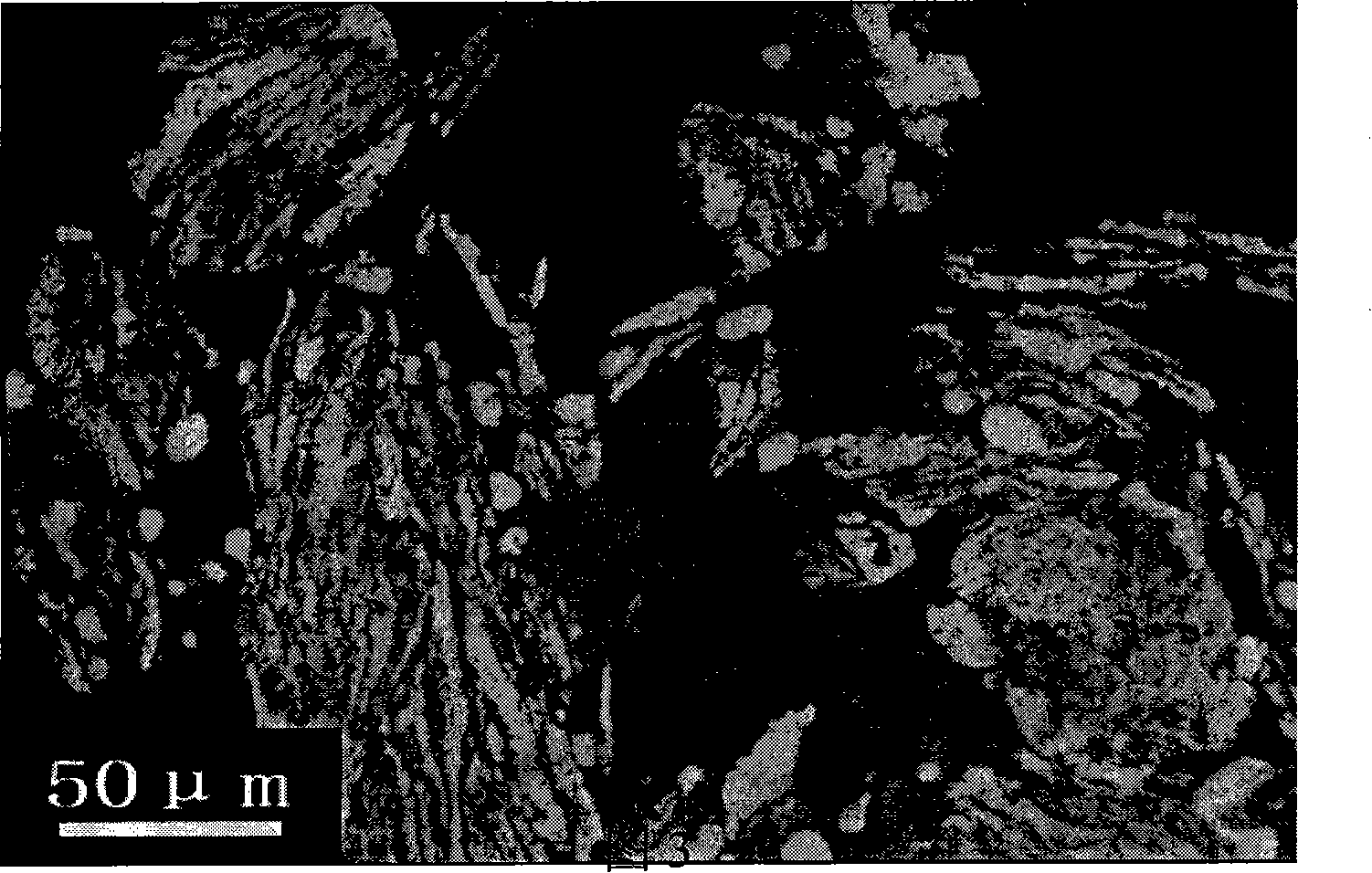

[0040] Embodiment 1: Get 2 kilograms of silver, 252 grams of zinc, put in medium-frequency induction furnace and smelt into liquid state, carry out alloy atomization with high-pressure gas atomization equipment, the solid particle-containing liquid after atomization is dried into alloy powder, After screening, put the powder with a particle size of 100-325 mesh into a ball mill for ball milling, the ball milling time is 25 hours, the ball-to-material ratio is 5:1, and the ball milling medium is alcohol. After ball milling, put the powder into an oxidation furnace for oxidation. The oxidation temperature is controlled at 500°C, and an oxygen pressure of 20 atm is maintained. Take it out after oxidation for 4 hours, and add 125 grams of MoO after the inspection meets the requirements. 3 , La 2 o 3 , and Bi 2 o 3 Mix evenly, put the mixed powder into a ball mill for mechanical alloying, then conventional molding, sintering at 700°C for 5 hours, take out and hot forge to obtain...

Embodiment 2

[0041]Embodiment 2: Get 2 kilograms of silver, 237 grams of zinc, place in the intermediate frequency induction furnace and melt into liquid state, carry out alloy atomization with high-pressure gas atomization equipment, the solid particle-containing liquid after atomization is dried into alloy powder, After screening, put the powder with a particle size of 100-325 mesh into a ball mill for ball milling, the ball milling time is 100 hours, the ball-to-material ratio is 10:1, and the ball milling medium is alcohol. After ball milling, put the powder into an oxidation furnace for oxidation. The oxidation temperature is controlled at 700°C, and the oxygen pressure is maintained at 50 atm. Take it out after oxidation for 1.5 hours, and add 5.9 grams of WO 3 Mix evenly, put the mixed powder into a ball mill for mechanical alloying, and then shape it, sinter it at 860°C for 3 hours, take it out and extrude it into wire, and then draw it to get the finished product.

Embodiment 3

[0042] Embodiment 3: take 2 kilograms of silver, 119 grams of zinc, place in the intermediate frequency induction furnace and melt into liquid state, carry out alloy atomization with high-pressure gas atomization equipment, the solid particle-containing liquid after atomization is dried into alloy powder, After screening, put the powder with a particle size of 100-325 mesh into a ball mill for ball milling, the ball milling time is 50 hours, the ball-to-material ratio is 5:1, and the ball milling medium is alcohol. After ball milling, put the powder into an oxidation furnace for oxidation. The oxidation temperature is controlled at 600°C, and the oxygen pressure of 30atm is maintained. After oxidation, take it out for 2.5 hours, and add 44 grams of ZrO after the inspection meets the requirements. 2 Mix it with TaC evenly, put the mixed powder into a ball mill for mechanical alloying, and then shape it, sinter it at 800°C for 4 hours, take it out and extrude it into wire, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com