Polymethyl methacrylate/polyaniline nano fibre composite resistor type film gas sensor and preparation method thereof

A polymethyl methacrylate, nanofiber technology, applied in the direction of material analysis, measurement device, instrument, etc. by electromagnetic means, can solve problems such as restricting the application and further development of electrospinning, increasing contact resistance, and little research. , to shorten the response and recovery time, reduce contact resistance, and achieve good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

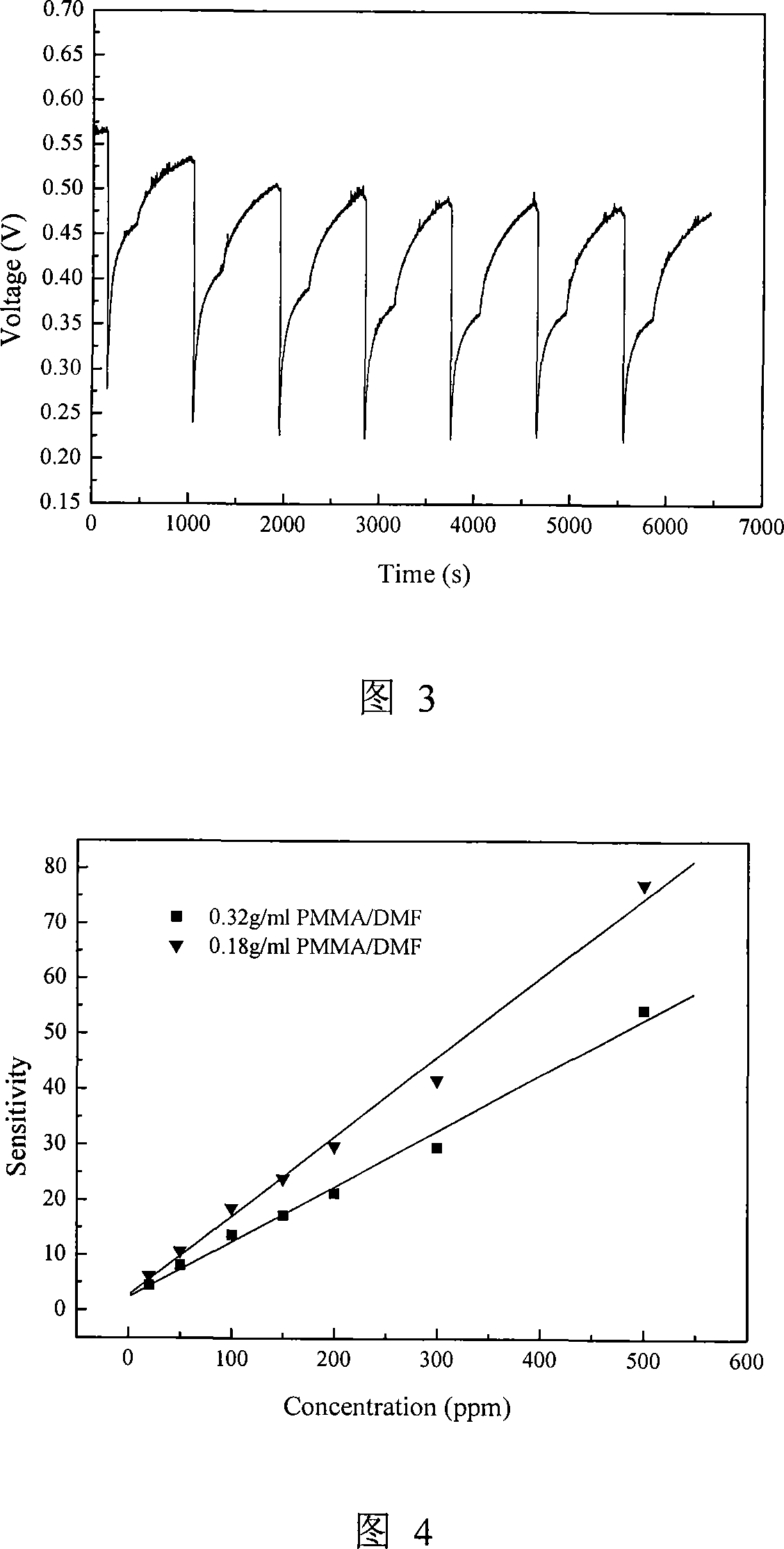

Embodiment 1

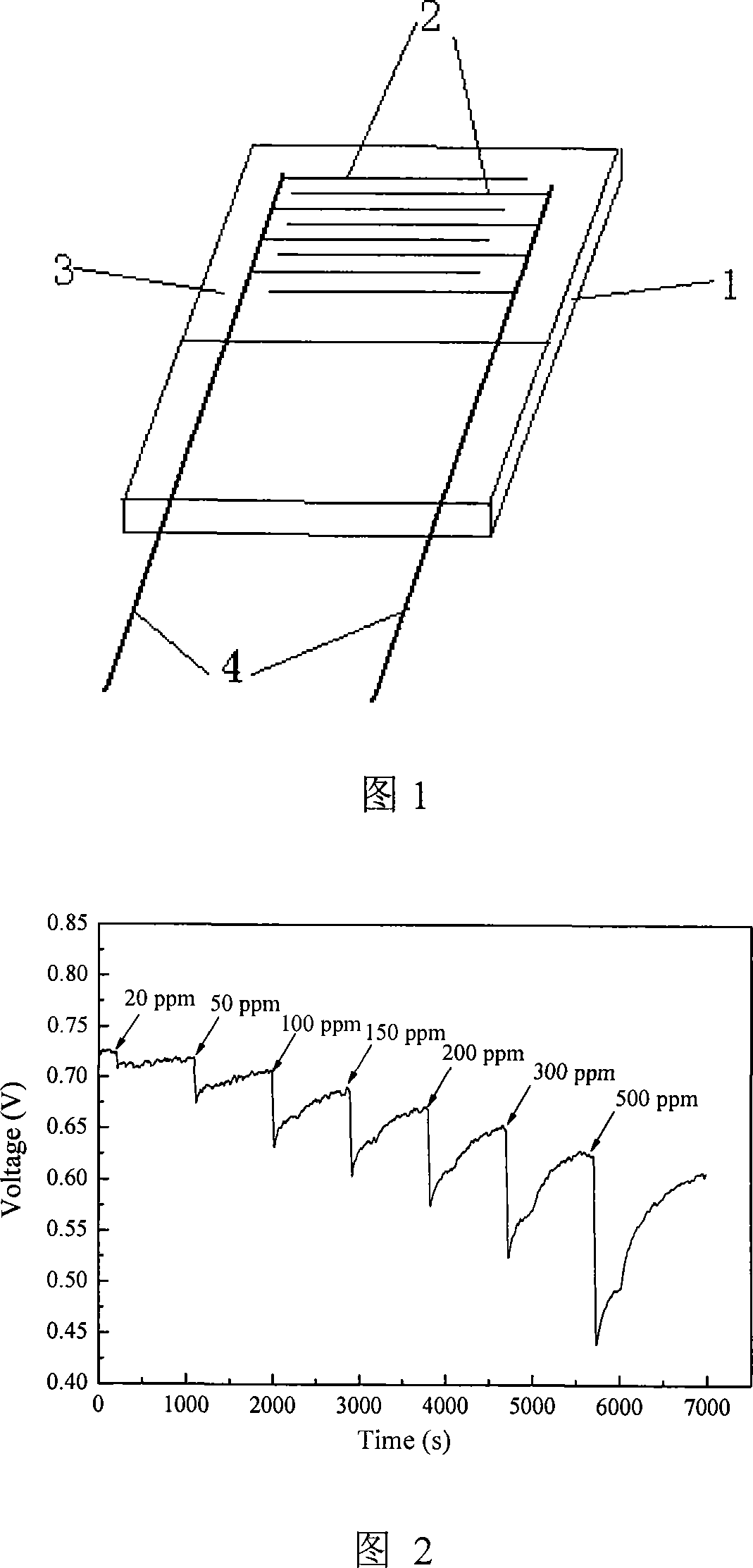

[0029] 1) Soak and clean the surface photolithography and evaporate the ceramic substrate with interdigitated gold electrodes with absolute ethanol and acetone. There are 5 pairs of interdigitated gold electrodes. The interdigitated gold electrodes have a width of 200 μm and a gap of 200 μm. drying spare;

[0030] 2) Preparation of polymethyl methacrylate nanofibers by electrospinning: the N, N-dimethylacetamide solution with a concentration of 0.18 g / ml polymethyl methacrylate was packed in a plastic syringe with a stainless steel needle inside, and fixed on top of the syringe. Connect the anode of the high-voltage power supply to the needle with a copper wire, and the cathode of the high-voltage power supply is connected to the copper plate as the receiving plate, and the copper plate is provided with a cover glass; the distance between the needle and the copper plate is 15cm; between the syringe needle and the copper plate, apply High voltage, the power supply voltage is 2...

Embodiment 2

[0035] 1) Electrode cleaning is the same as in Example 1;

[0036] 2) Prepare polymethyl methacrylate nanofibers by electrospinning, wherein the N,N-dimethylacetamide solution with a concentration of 0.32g / ml polymethyl methacrylate is packed in a plastic with a stainless steel needle Inside the syringe and fixed on top of the syringe. Connect the anode and the needle of the high-voltage power supply with a copper wire, while the cathode is connected to the copper plate as the receiving plate; the distance between the needle and the collecting plate is 15cm; apply high-voltage electricity between the needle of the syringe and the receiving plate, and its power supply voltage is 20KV, use a medical syringe pump to squeeze the solution out of the syringe, and the solution flow rate is 0.2mL / h. The extruded solution forms continuous nanometer-sized fibers under the action of a high-voltage electric field, deposits on the cover glass, forms a film after a certain period of time, ...

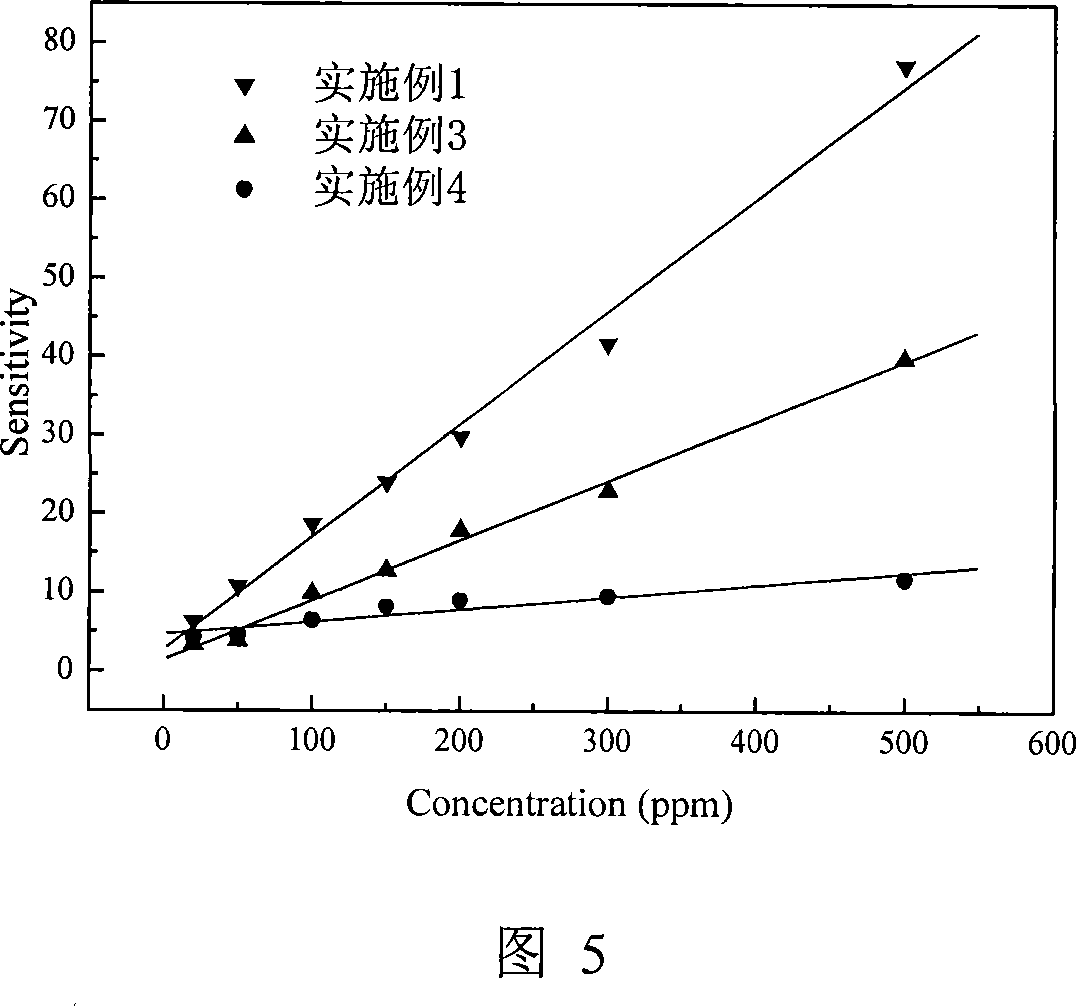

Embodiment 3

[0041] 1) Electrode cleaning is the same as in Example 1;

[0042] 2) The electrospinning process is the same as in Example 1;

[0043]3) At a temperature of 20°C, the solution containing 0.1M APS, 1M aniline and 2M sulfosalicylic acid (SSA) was first stirred for 10 minutes, and then the coverslip with PMMA nanofibers was placed in the above solution middle. After 40 min of polymerization, the coverslip was removed from the beaker and washed with 0.001 M sulfosalicylic acid (SSA) solution to remove residual reagents and adsorbed PANI particles to obtain a polymethylmethacrylate / polyaniline nanofiber film ;

[0044] 4) The ceramic substrate electrode with gold fingers is placed horizontally in the above SSA solution, lifted vertically from below the solution covered with nanofiber composite film, so that the composite film is transferred to the electrode, and dried with nitrogen at room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Interdigital width | aaaaa | aaaaa |

| Interdigital gap | aaaaa | aaaaa |

| Interdigital width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com