Radiation design method in PCB design

A design method and heat loss technology, applied in computing, cooling/ventilation/heating transformation, special data processing applications, etc., can solve problems such as hardware circuit instability, volume structure limitation, damage, etc., to maintain stable and good work. Heat dissipation, improved design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The method of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

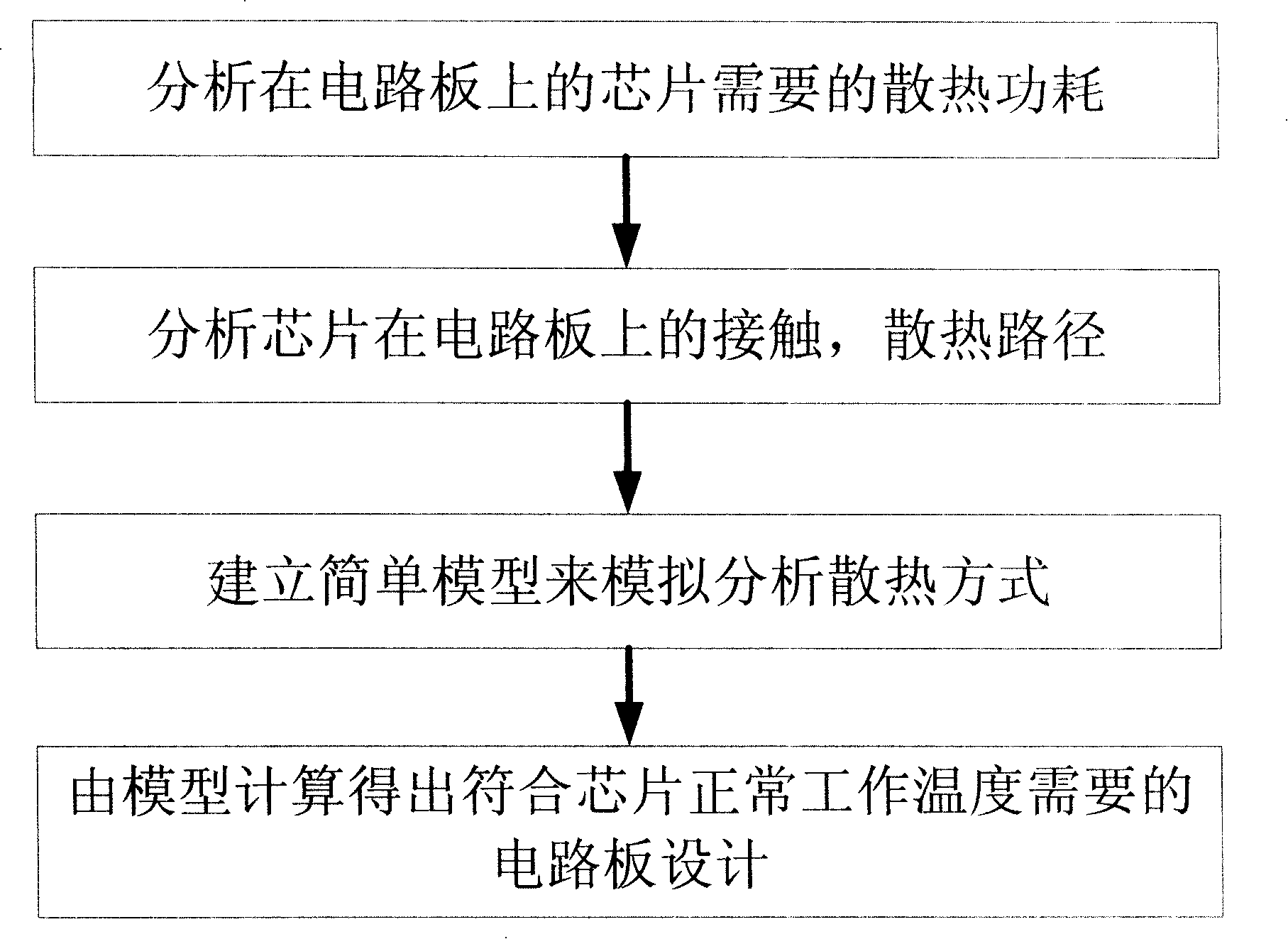

[0012] Such as figure 1 Shown, the inventive method mainly is made up of following aspects:

[0013] A. Analyze a PCB design that will generate a lot of heat loss components; determine the difference between the normal operating temperature of the chip on the PCB and the maximum limit temperature of the chip, and the power consumption of the heat loss required by the chip on the PCB;

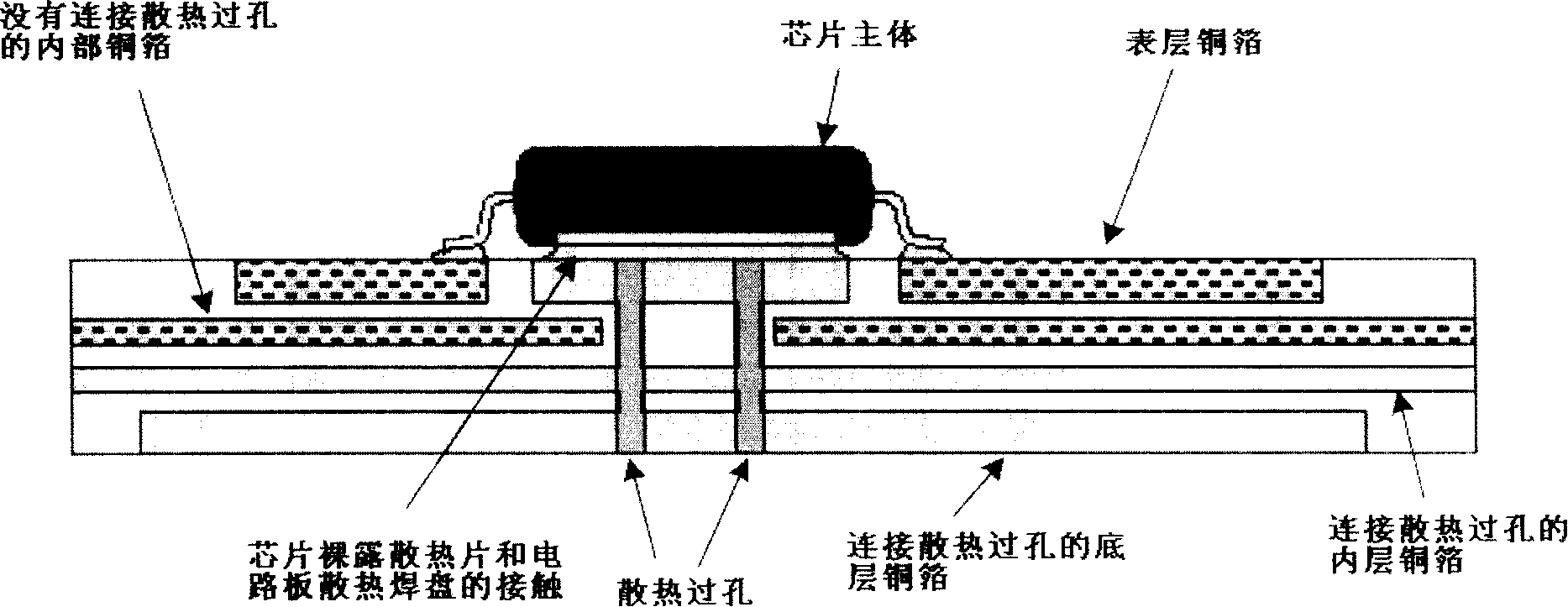

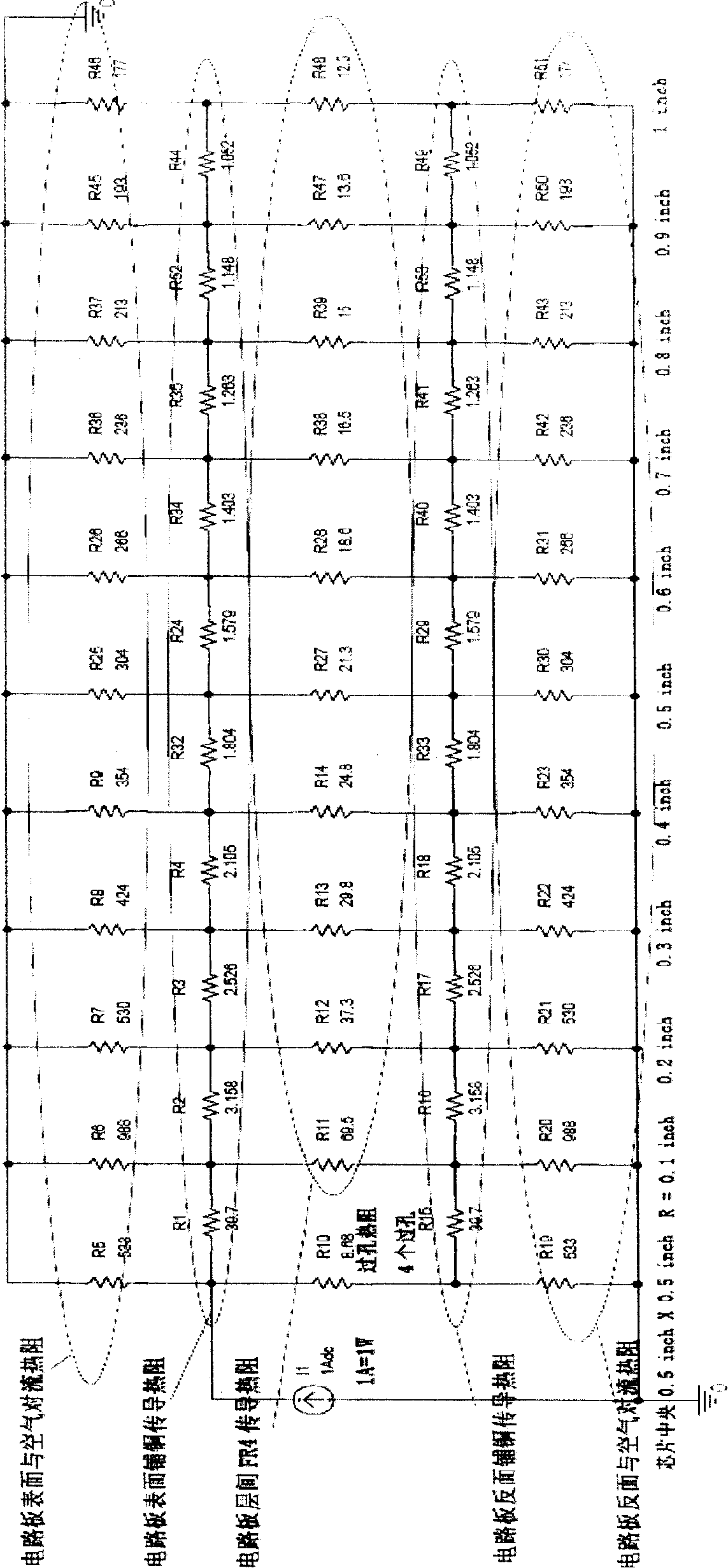

[0014] B. Analyze the soldering contact mode between these components and the PCB, as well as the laminated structure and manufacturing materials of the PCB, and the various thermal conduction methods caused by these factors, and establish a simple model based on the above to simulate the heat dissipation of the PCB;

[0015] C. Design the best heat conduction method on the PCB according to the heat dissipation model, so that the chip can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com