Preparation method of nano magnetite/diatomite composition for removing Cr6+ in water

A nano-magnet and diatomite technology, applied in water/sewage treatment, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problems of inability to reduce hexavalent chromium to trivalent chromium, coarse particles, low treatment efficiency, etc. problems, to achieve the effect of reducing cost, reducing agglomeration, increasing effective surface area and utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] 1) Weigh 170g FeCl 3 ·6H 2 O with 122gFeCl 2 4H 2 O, join in the reactor that is filled with 5L distilled water in advance, then add 200g diatomaceous earth, fully stir to form uniform suspension.

[0018] 2) Heat the suspension to 60°C and keep it warm, then slowly add the ammonium hydroxide solution with a concentration of 10% (mass percentage) into the suspension under continuous stirring until the pH of the suspension reaches 9 When the dropwise addition was stopped, the insulation was continued and stirred for 1 hour.

[0019] 3) Carry out solid-liquid separation of the suspension by centrifugation, wash with distilled water-centrifuge for several times, stop washing until the pH value of the supernatant is neutral.

[0020] 4) Vacuum-dry the obtained precipitate at 40° C. for 24 hours, and then grind and pulverize to obtain the nano-magnetite / diatomite composite of the present invention.

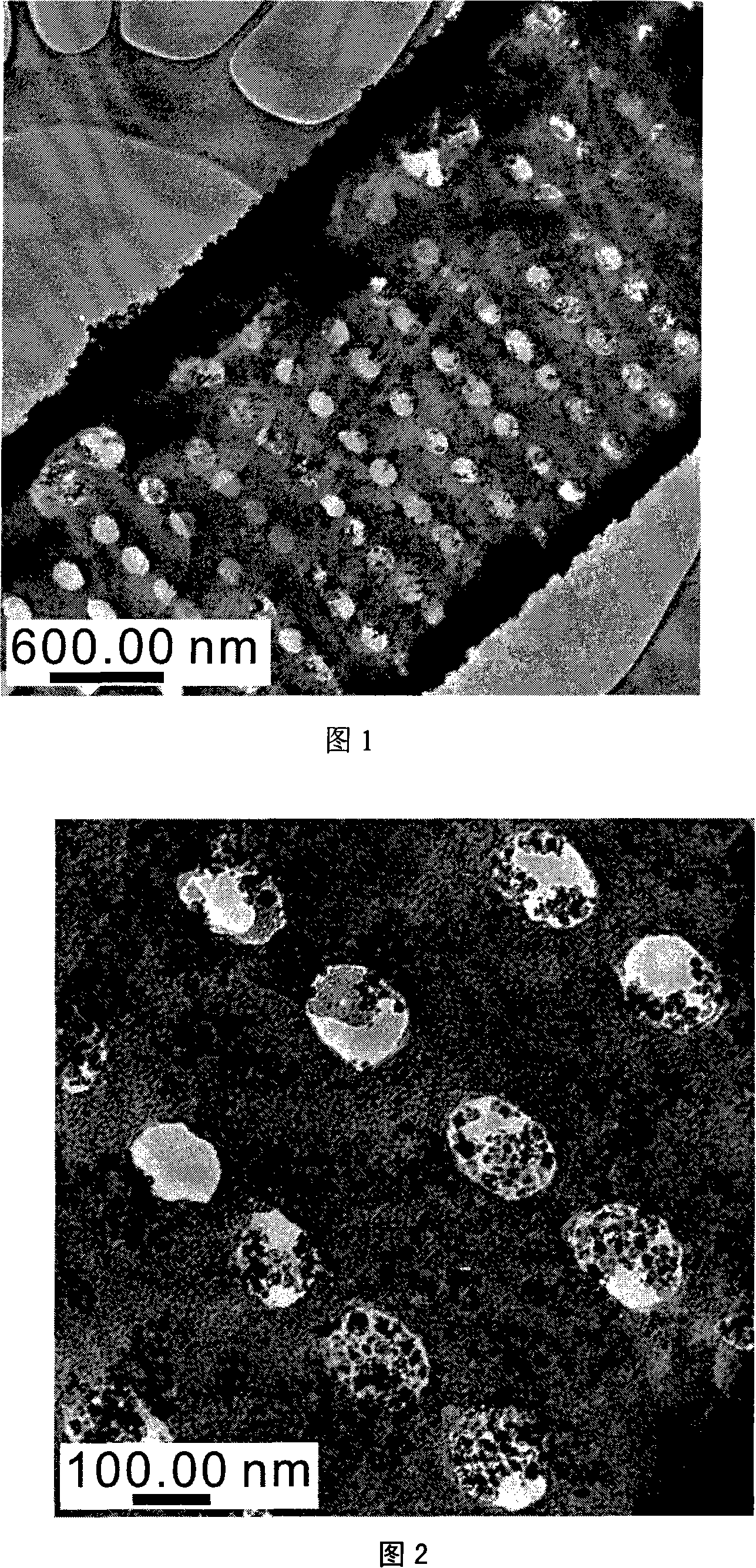

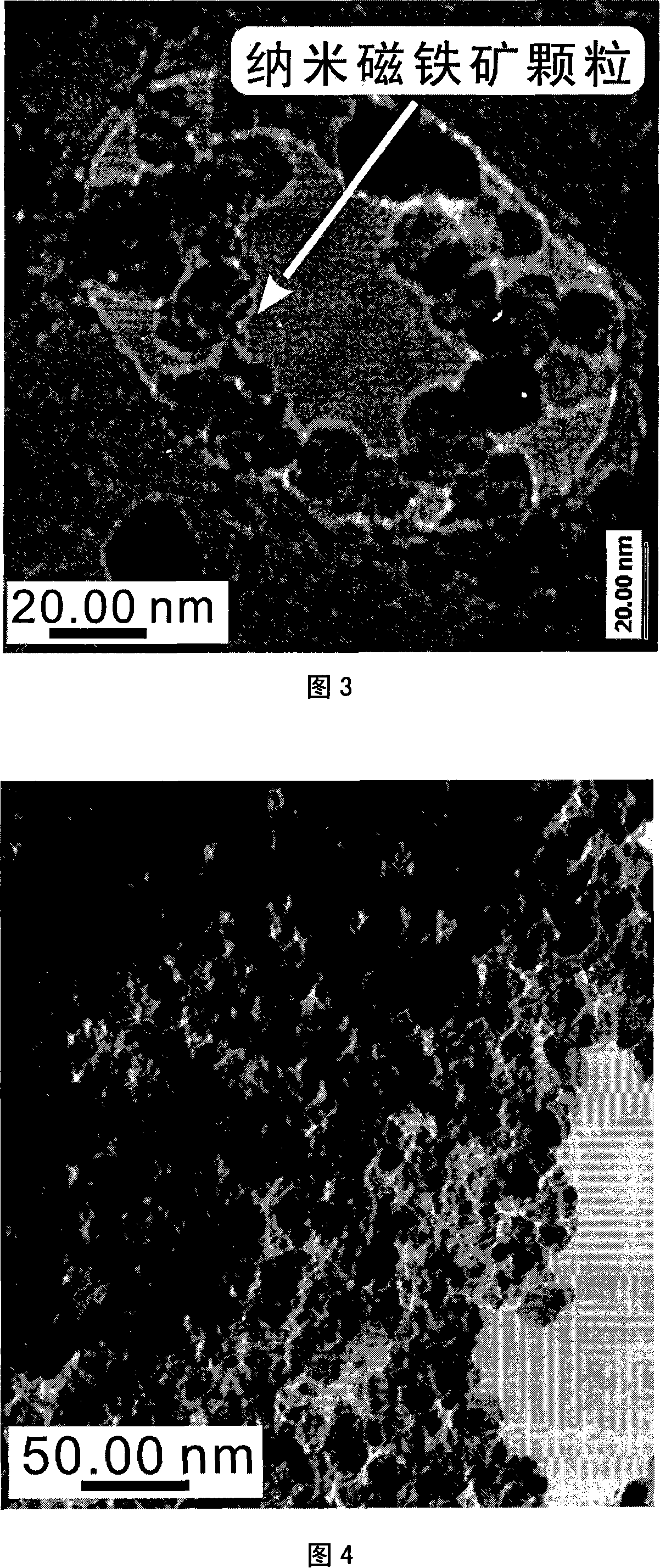

[0021] Using X-ray diffraction analysis, chemical analysis, infrared s...

Embodiment 2

[0023] 1) Weigh 8.5gFeCl 3 ·6H 2 O with 6.1gFeCl 2 4H 2 O, join in the beaker that is filled with 250ml distilled water in advance, then add 5g diatomaceous earth, fully stir to form uniform suspension.

[0024] 2) Heat the suspension to 60°C and keep it warm, then slowly add the ammonium hydroxide solution with a concentration of 10% (mass percentage) into the suspension under continuous stirring until the pH of the suspension reaches 9 When the dropwise addition was stopped, the insulation was continued and stirred for 2 hours.

[0025] 3) Centrifuge the suspension to separate the precipitate, wash with distilled water-centrifuge the precipitate for several times, stop washing when the pH value of the supernatant is neutral.

[0026] 4) Vacuum-dry the obtained precipitate at 40° C. for 24 hours, and then grind and pulverize to obtain the nano-magnetite / diatomite composite of the present invention.

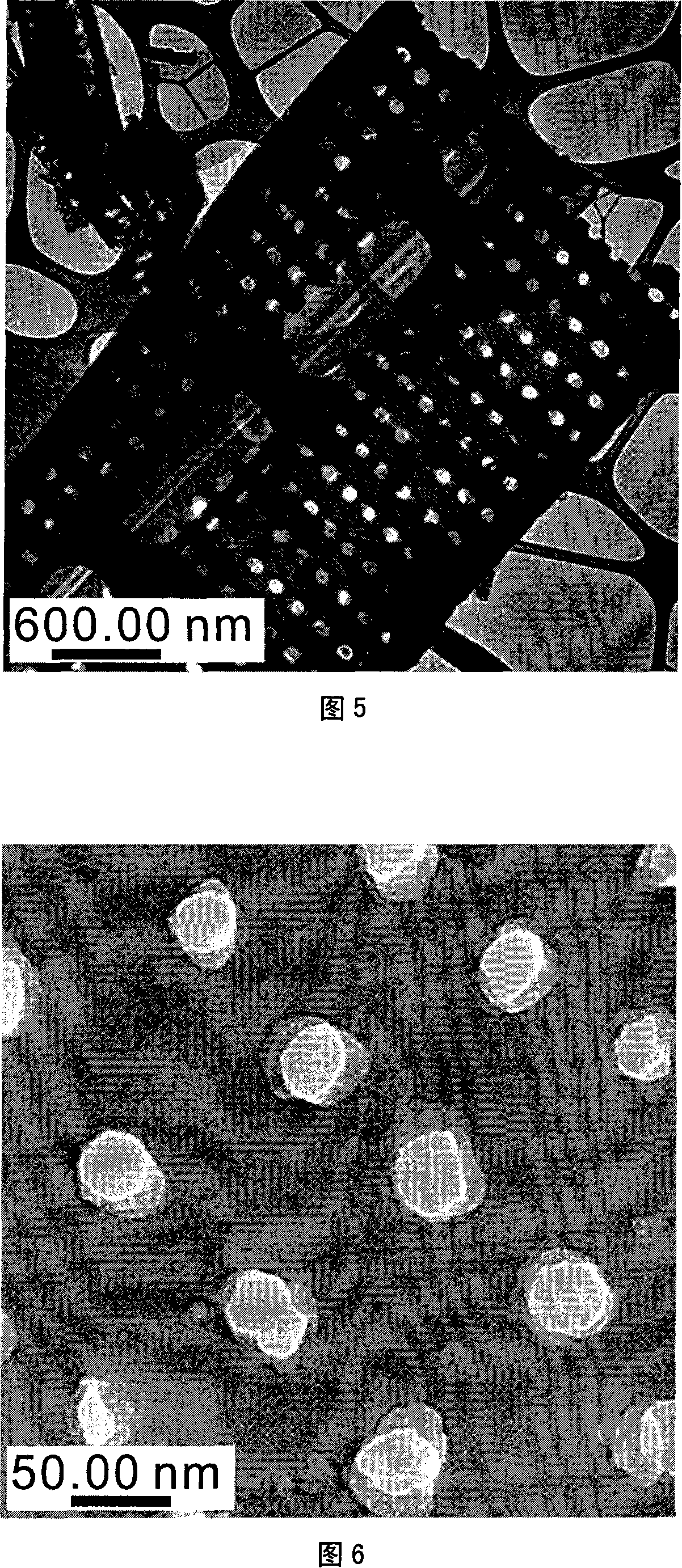

[0027] Through X-ray diffraction analysis, chemical analysis, infrared ...

Embodiment 3

[0029] Potassium dichromate (K 2 Cr 2 o 7 ) for Cr 6+ source, formulated Cr 6+300ml of wastewater with a concentration of 200mg / L and a pH value of 3.0. Take by weighing the nano-magnetite / diatomaceous earth composite 38.5g that makes in the embodiment 1, add to the formulated Cr-containing 6+ In wastewater, stir for 5 minutes and let stand for 15 minutes. Then a common circular magnet with a diameter of 16 cm is used to realize the solid-liquid separation of the precipitate and the liquid. After testing, the pH of the treated water is neutral, where Cr 6+ The concentration is lower than 0.01mg / L, which meets the discharge standard.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com