Customized polishing pads for CMP and methods of fabrication and use thereof

A chemical mechanical, polishing pad technology, applied in the direction of manufacturing tools, grinding/polishing equipment, wheels with flexible working parts, etc., can solve complex and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0134] The way the polymer is prepared prior to molding or casting can affect the properties of the polishing pad and its consistency. For example, there are two well-known methods of formulating polyureas and polyurethanes, known as one-step and two-step techniques. In a single-step technique, all reaction components (eg, monomers, chain extenders, crosslinkers) react together. This process is difficult to control due to factors such as varying local concentrations of reactants and non-uniform local thermal gradients, which result in widely varying polymer product properties. In the two-step technique, the isocyanate is pre-reacted with a polyamine or polyol chain extender in the first step to form a high molecular weight prepolymer. This functionalized prepolymer is then further reacted with polyamine or polyol curing agents and / or chain extenders to complete the formation of polyurea or polyurethane. This process is more controllable, but requires higher processing temper...

example 1

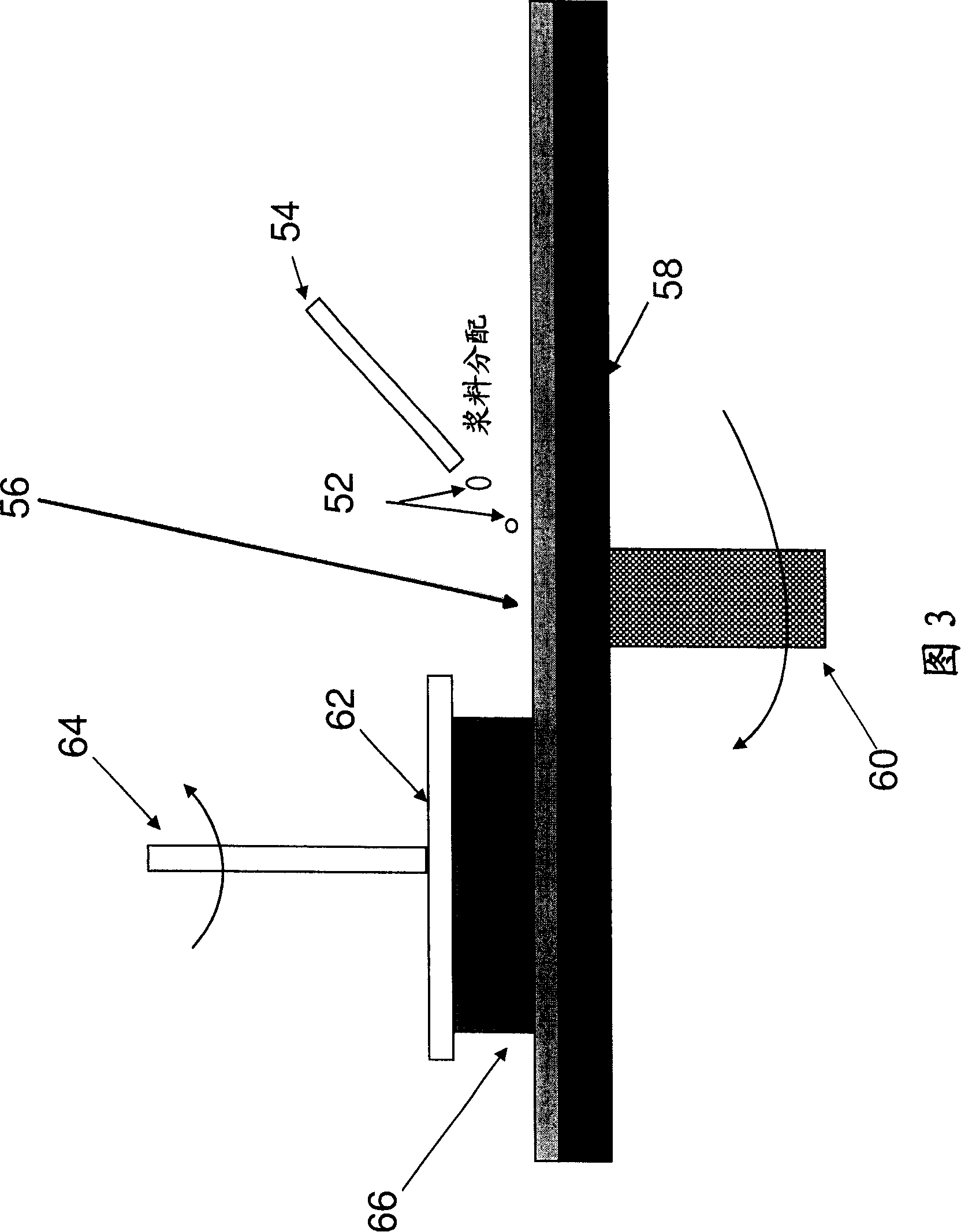

[0260] Example 1: Process for Forming Windowed Pads

[0261] An in situ window forming fabrication process may be used. The manufacturing process was designed such that each of the following product streams: curing agent, diol, prepolymer, and microspheres were added continuously prior to mixing or during mixing, respectively. This is shown schematically in FIG. 21 . Using this manufacturing process, each desired feedstock flow can be easily controlled to deliver the desired amount of curing agent, glycol, prepolymer, and microspheres.

[0262] While this process offers great adjustability and flexibility, one of the other goals that can be achieved using this fabrication process is the in-situ formation of windows. During the manufacturing process, each part of the mold that needs to be filled to make the pad can be traversed at a predetermined speed by the insertion nozzle. To achieve transparency in a localized area, the flow of microspheres can be shut off or reduced when...

example 2

[0264] Example 2: Properties of polishing pads with windows transparent to visible light

[0265] As an example, this recipe is specified for the manufacture of graded CMP polyurethane pads having windows measuring 0.75 by 2.25 inches for polishing wafers. Polyurethane polishing pads are produced with predetermined hardness, pore size and porosity. The durometer of the pad is from about 65D to 75D, and the pore density is about 25% to 15% of the pad material for a pore size of 35-55 μm, respectively. The durometer value of the pad is typically 45D-75D (Shore durometer scale), and in one instance preferably about 70D for windows. In order to achieve the desired objective of optical endpoint detection using commercially available CMP equipment, the pad window is preferably transparent to visible light, since visible light is used in such detection schemes. Figure 23 shows a fully transparent pad.

[0266] The properties described in Sections II-VIII of custom pads for CMP tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com