Making method for flexible dye sensitized solar battery nano crystal thin film

A dye-sensitized, solar cell technology, applied in the field of nanocrystalline photoanode film manufacturing, achieves the effect of low industrialization characteristics and improved cell efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

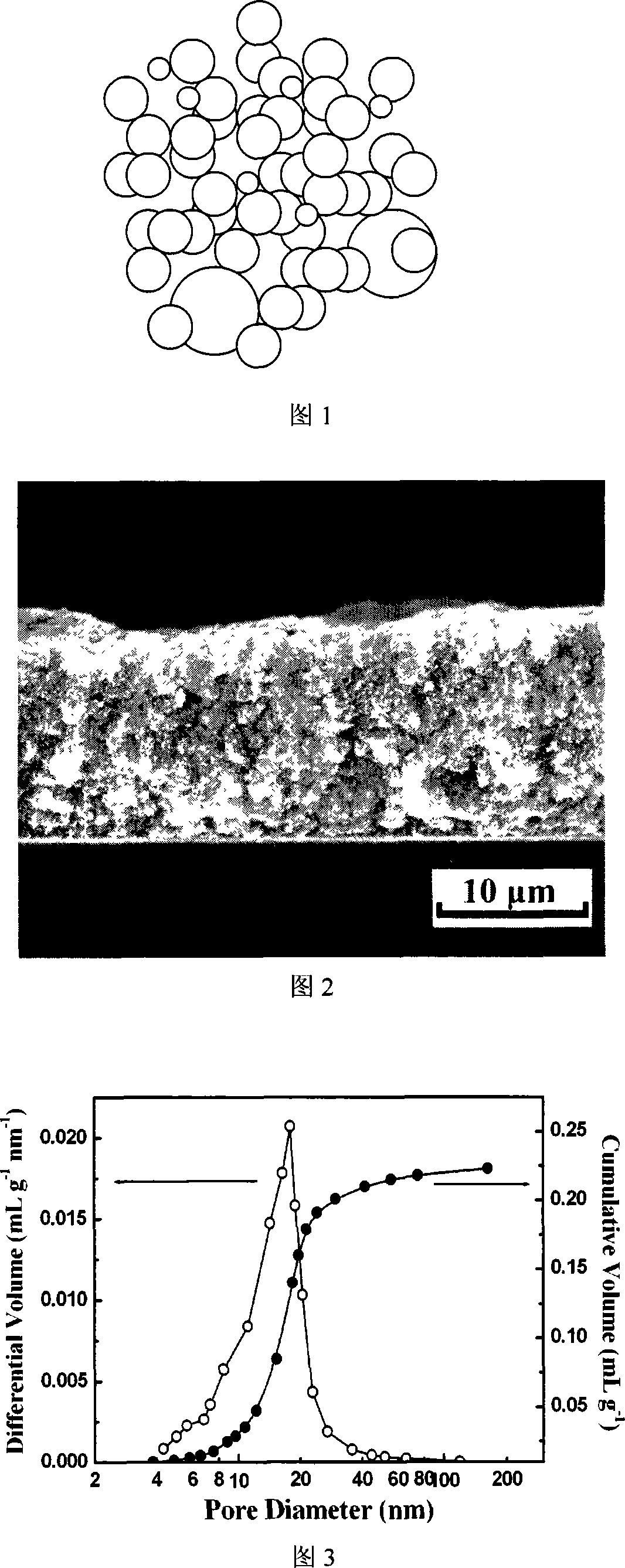

[0036] Commercially available P25 nanometer TiO powder 36g, commercially available 200nm anatase TiO produced by Germany XX company 2 Powder 4g, added to 0.05mol / L, 70°C TiCl 4 Ultrasonic vibration was carried out in 1000ml aqueous solution for 10min, then heated to 500°C for 30min, TiCl 4 TiO formed after hydrolysis 2 In the initial TiO 2 The primary particles can be better connected between the particles, so that the TiO 2 The connections between the primary particles are strengthened. The obtained sintered blank is crushed to obtain micron / submicron porous nanostructure powder. With this porous nanostructured TiO 2 The powder is used as a raw material to prepare a porous nanostructure film by spraying on the surface of a flexible conductive substrate (such as ITO-PET, conductive polyester plastic) by vacuum cold spraying method. The cross-sectional structure of the film is shown in Figure 2, and the film is evenly distributed on the surface of the substrate. The nano...

Embodiment 2

[0038] Use 50g of 15nm anatase-type TiO2 nano-powder and 100ml of sol obtained by hydrolyzing 5g of butyl titanate, ultrasonically disperse for 5 minutes, heat to 400°C for 20 minutes, and the Ti-containing substances in the sol are on the surface of the initial TiO2 particles and between them Crystallization to new TiO 2 , the primary particles can be better connected together, and the obtained sintered blank is crushed to obtain micron / submicron porous nanostructure powder, and the porous nanostructure TiO 2 The powder is used as a raw material to prepare a porous nanostructure film by spraying on the surface of a flexible conductive substrate by a vacuum cold spraying method. The film was subjected to UV treatment for 3 hours with a 125W medium-pressure mercury lamp at a distance of 4 cm from the surface of the film to make the connection between the nanoparticles inside the film better.

Embodiment 3

[0040] Furthermore, using the self-sintering connection of nano-TiO2 particles, the nano-TiO2 2 The powder was heat-treated at 520°C for 4h, and the porous nanostructured TiO 2 The powder is used as a raw material to prepare a porous nanostructure film by spraying on the surface of a flexible conductive substrate by a vacuum cold spraying method. If the film is hydrothermally treated at 100°C for 10h, and then treated with 28GHz microwave for 5 minutes, the purpose of strengthening the connection between particles can be achieved. Then dry the broken and sieved porous nanostructure powder, and spray the powder on the surface of the flexible conductive substrate by vacuum cold spraying method to prepare a porous nanostructure film.

[0041] The method of the invention can not only prepare the dye-sensitized solar cell nanocrystal film on the flexible substrate, but also prepare the porous nanostructure film on the hard conductive glass surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com