Natural amphoteric polyelectrolyte electric field sensitive aqueous gel and preparation method thereof

A polyelectrolyte and hydrogel technology, applied in the field of natural amphoteric polyelectrolyte electric field sensitive hydrogel and its preparation, can solve the problem of limiting the application range of electric field sensitive hydrogel, limiting hydrogel application, biocompatibility and problems such as poor biodegradability, to achieve good biocompatibility and biodegradability, high environmental friendliness and biosafety, and low prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1: Add 2% carboxymethylcellulose solution dropwise to 2% chitosan solution under low-speed stirring at 40°C, then add a small amount of hydrochloric acid to dissolve a small amount of white precipitate generated, and finally obtain a transparent and uniform Blending solution, wherein the mass ratio of chitosan to carboxymethyl cellulose is 3:2. Stirring was continued at 40°C for 60 min, and then the blend was cast into a box made of polyester film, and dried at room temperature to form a film. The prepared membrane was treated in 1% sodium hydroxide solution for 6 h, then rinsed with deionized water until neutral, and dried at room temperature.

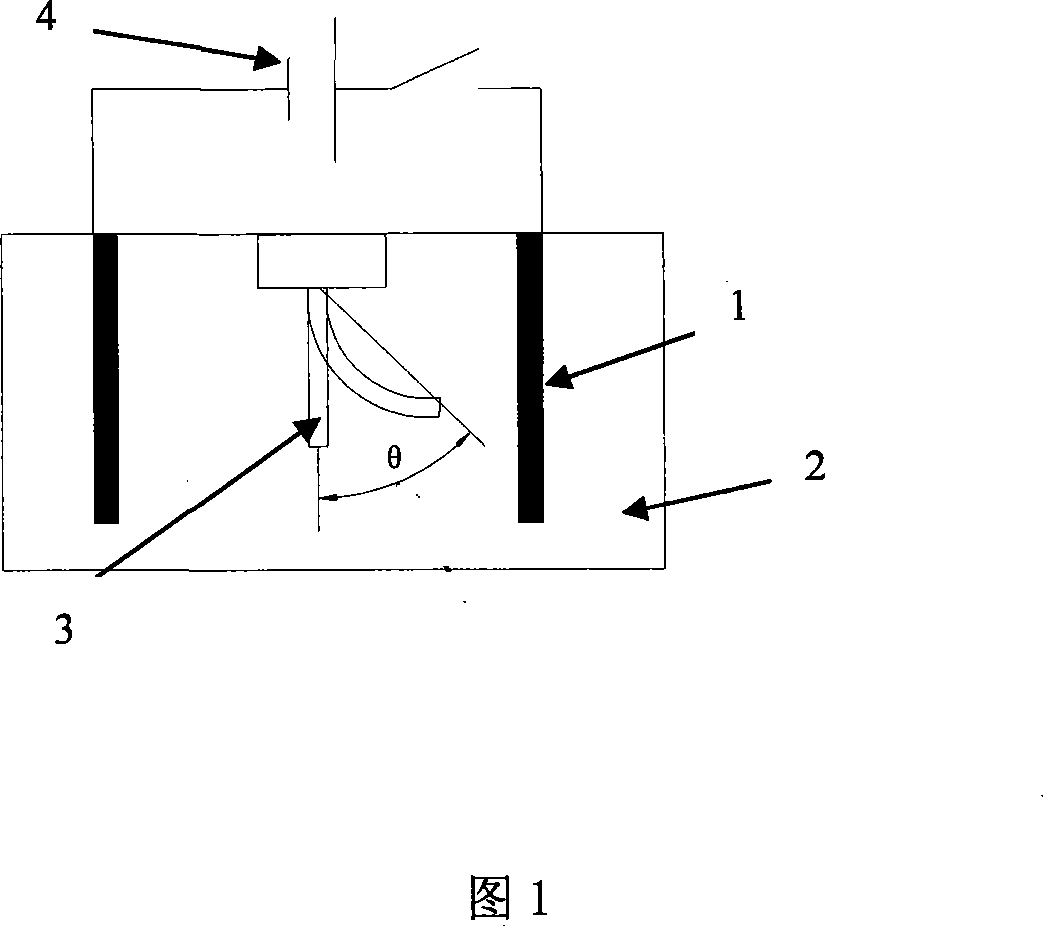

[0018] Soak the dried membrane in a buffer solution with an ionic strength of 0.1 and a pH value of 5.0 for 4 hours to reach swelling equilibrium. Then cut the hydrogel membrane into 10×2×0.2mm 3 The gel strip is vertically placed between two parallel electrodes with a distance of 5cm in the above buffer solution, and...

Embodiment 2

[0020] Example 2: Add 4% carboxymethyl cellulose solution dropwise to 4% chitosan solution under low-speed stirring at 60°C, then add a small amount of hydrochloric acid to dissolve a small amount of white precipitate generated, and finally obtain a transparent and uniform Blending solution, wherein the mass ratio of chitosan to carboxymethyl cellulose is 3:2. Epichlorohydrin whose mass is 0.02 times that of carboxymethyl cellulose was added as a crosslinking agent, and after stirring at 60°C for 120 min, the blend was cast into a box made of polyester film, and dried at room temperature to form a film. The prepared membrane was treated in 2% sodium hydroxide solution for 2 h, then rinsed with deionized water until neutral, and dried at room temperature.

[0021] Soak the dried membrane in a buffer solution with an ionic strength of 0.1 and a pH value of 6.0 for 4 hours to reach swelling equilibrium. Then cut the hydrogel membrane into 10×2×0.2mm 3 The gel strip is verticall...

Embodiment 3

[0022] Example 3: Add 1% carboxymethyl cellulose solution dropwise to 1% chitosan solution under low-speed stirring at 80°C, then add a small amount of hydrochloric acid to dissolve a small amount of white precipitate generated, and finally obtain a transparent and uniform Blending solution, wherein the mass ratio of chitosan and carboxymethyl cellulose is 7:3. After continuing to stir at 80°C for 30 min, the blend was cast into a box made of polyester film, and dried at room temperature to form a film. The prepared membrane was treated in 0.5% sodium hydroxide solution for 12 h, then rinsed with deionized water until neutral, and dried at room temperature.

[0023] Soak the dried membrane in a buffer solution with an ionic strength of 0.1 and a pH value of 7.0 for 4 hours to reach swelling equilibrium. Then cut the hydrogel membrane into 10×2×0.2mm 3 The gel strip is vertically placed between two parallel electrodes with a distance of 5 cm in the above buffer solution, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com