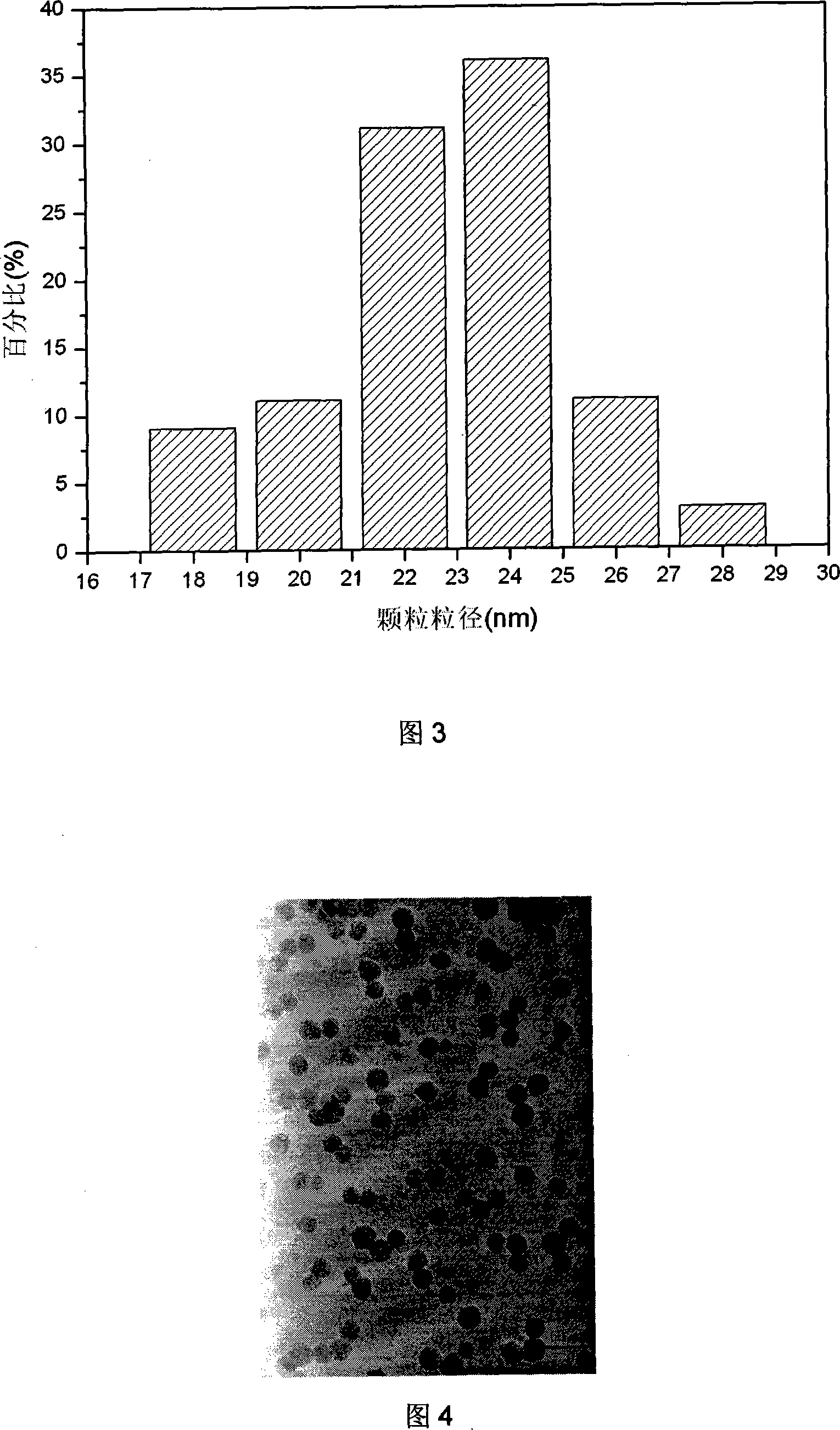

Method for preparing monodisperse magnetic silica dioxide nano particles

A nanoparticle and silica technology, applied in the direction of silica, etc., can solve the problems of magnetic silica nanoparticle size, dispersion and particle surface modification, and achieve good dispersion and uniform particle size , good magnetic response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Weigh 2.16g (0.008mol) FeCl 3 ·6H 2 O and 1.11g (0.004mol) FeSO 4 ·7H 2 O was dissolved in 40ml of deionized water, and under the protection of nitrogen at room temperature, 20ml of ammonia water with a concentration of 1.5mol / l was added point by point to the above solution to obtain a black precipitate. The precipitate was fully washed 5 times with deionized water by means of magnetic separation to obtain a black precipitate for future use. Under stirring conditions, 0.0009g Fe 3 o 4 The precipitate was pipetted into a solution of 0.8ml ethanol and 20ml water, and the solution contained 0.00009g sodium oleate. The pH value of the above reaction system was adjusted to 6 with 0.1 mol / l perchloric acid. Add 0.015g of sodium silicate to the above reaction system, then raise the temperature to 80°C, and maintain the temperature for ultrasonic dispersion for 30min. After the sonication is finished, turn to room temperature and add 30 μl (3-mercaptopropyl)trimethoxysi...

Embodiment 2

[0036] Weigh 2.16g (0.008mol) FeCl 3 ·6H 2 O and 1.11g (0.004mol) FeSO 4 ·7H 2 O was dissolved in 40ml of deionized water, and under the protection of nitrogen at room temperature, 20ml of ammonia water with a concentration of 1.5mol / l was added point by point to the above solution to obtain a black precipitate. The precipitate was fully washed 5 times with deionized water by means of magnetic separation to obtain a black precipitate for future use. Under stirring conditions, 0.0009g Fe 3 o 4 The precipitate was pipetted into a solution of 0.8ml ethanol and 20ml water, and the solution contained 0.00009g sodium oleate. The pH value of the above reaction system was adjusted to 6 with 0.1 mol / l perchloric acid. Add 30 μl of (3-mercaptopropyl)trimethoxysilane (MPS) and 0.015 g of sodium silicate to the above reaction system, then raise the temperature to 80° C., and maintain the temperature for ultrasonic dispersion for 30 minutes. After the sonication is finished, turn to...

Embodiment 3

[0038] Weigh 2.16g (0.008mol) FeCl 3 ·6H 2 O and 1.11g (0.004mol) FeSO 4 ·7H 2 O was dissolved in 40ml of deionized water, and under the protection of nitrogen at room temperature, 20ml of ammonia water with a concentration of 1.5mol / l was added point by point to the above solution to obtain a black precipitate. The precipitate was fully washed 5 times with deionized water by means of magnetic separation to obtain a black precipitate for future use. Under stirring conditions, 0.0009g Fe 3 o 4 The precipitate was pipetted into a solution of 0.8ml ethanol and 20ml water, and the solution contained 0.00009g sodium oleate. The pH value of the above reaction system was adjusted to 5.6 with 0.1 mol / l perchloric acid. Add 0.015g of sodium silicate to the above reaction system, then raise the temperature to 70°C, and maintain the temperature for ultrasonic dispersion for 30min. After the sonication is finished, turn to room temperature and add 40 μl of (3-mercaptopropyl)trimeth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com