Electronic nose of using sensor of acoustic surface wave and partitioning column of gas chromatography jointly, and detection method

A technology of gas chromatography separation and surface acoustic wave, which is applied in the field of electronic nose, can solve the problems of poor stability and repeatability of sensor measurement signals, lower sensitivity than surface acoustic wave sensor, and limit the practical application of gas sensor, so as to solve the problem of overlapping response, The effect of good repeatability and high Q value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

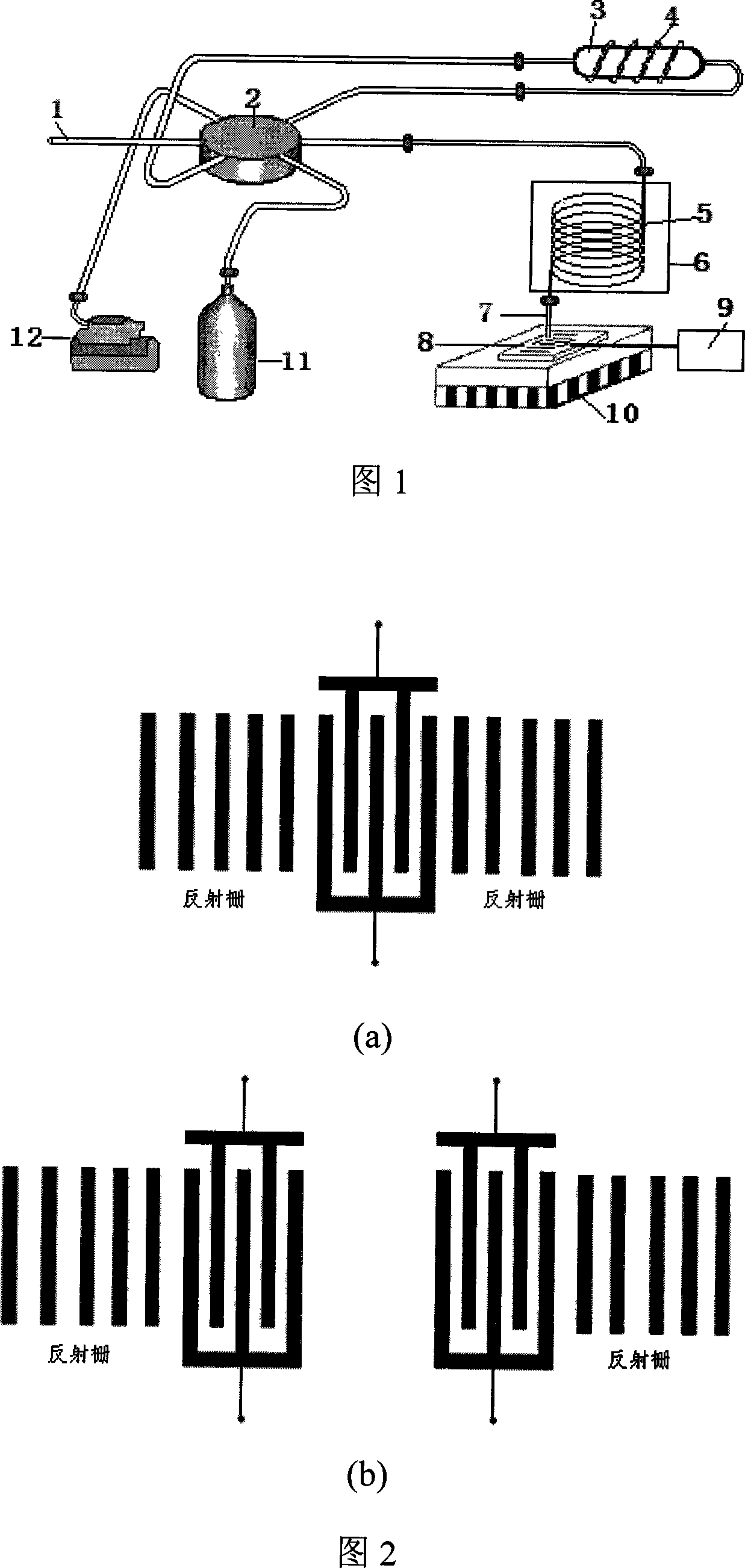

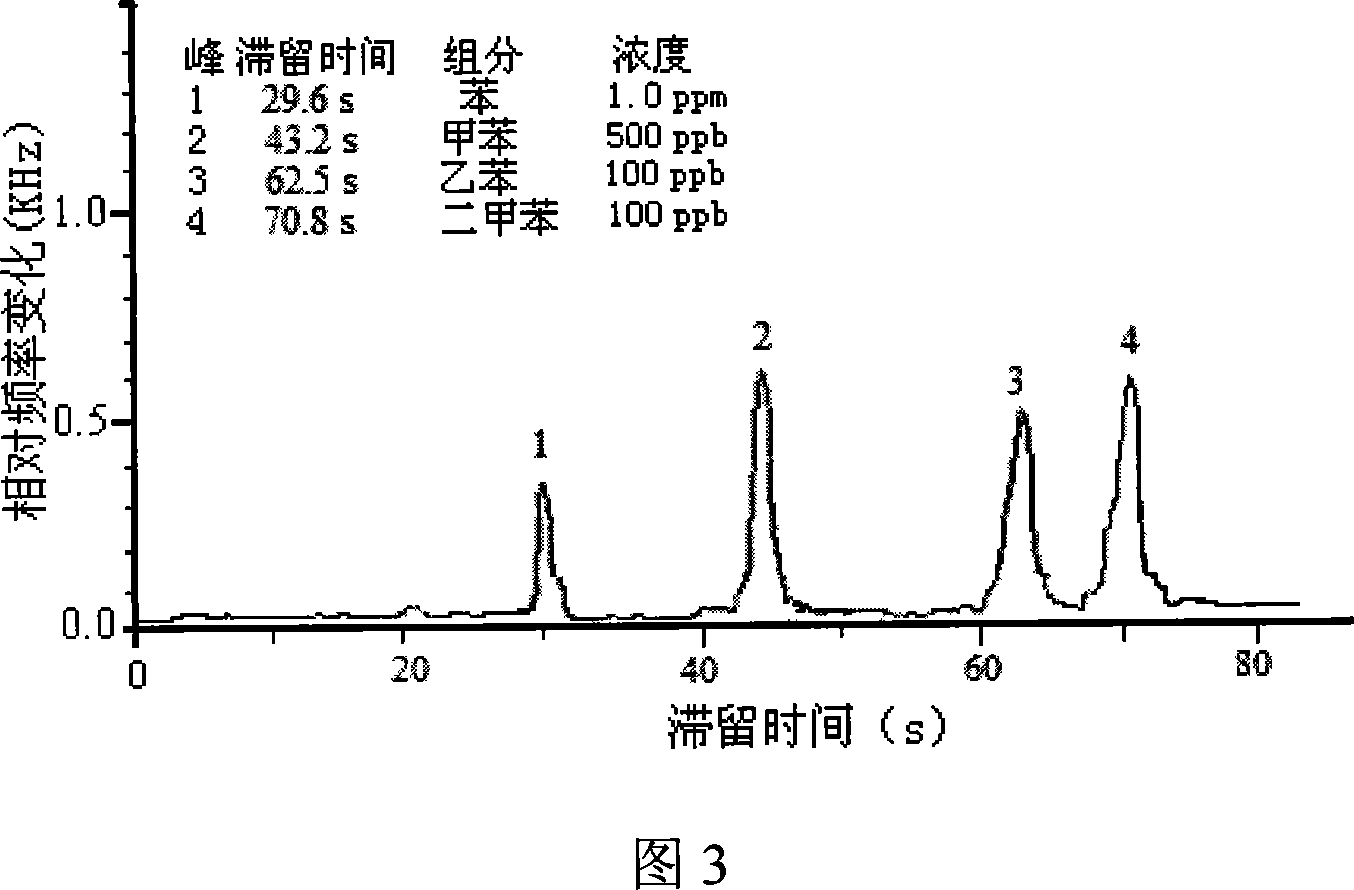

[0021] Select the mixed gas of benzene, toluene, ethylbenzene and xylene as the mixed gas to be tested, first control and adjust the heating device 6 provided on the periphery of the gas chromatographic separation column 5, and keep the gas chromatographic separation column 5 at 40°C for 2 to 3 minutes, Then the gas chromatographic separation column 5 is heated at a heating rate of 10°C / s until it rises to 150°C, and the flow rate of the carrier gas is 1.5ml / min, so that the mixed gas to be measured is separated from the gas chromatographic separation column 5 successively, and in one analysis Before the discharged gas flows through the micronozzle 7, a positive voltage is applied to the semiconductor refrigeration chip 10 to cool the base of the surface acoustic wave sensor 8 at a temperature of 10°C, so that the hot gas decomposed from the gas chromatography separation column 5 passes through the micronozzle 7 Spray onto the surface of the surface acoustic wave sensor 8 to ca...

Embodiment 2

[0024]With the mixed gas of acetone, ethanol, methyl alcohol, isoprene, acetic acid, propionic acid as the mixed gas to be measured, at first control and adjust the heating device 6 that the gas chromatographic separation column 5 periphery is provided with, make the gas chromatographic separation column 5 in 35 Keep at ℃ for 2 minutes, then heat the gas chromatographic separation column 5 at a heating rate of 8 ℃ / s until it rises to 140 ℃, and the flow rate of the carrier gas is 0.8ml / min, so that the mixed gas to be measured is desorbed successively from the gas chromatographic separation column 5 , before a decomposed gas flows through the micronozzle 7, a forward voltage is applied to the semiconductor refrigeration chip 10 to cool the substrate of the surface acoustic wave sensor 8 at a temperature of 5°C, so that the heat decomposed from the gas chromatography separation column 5 The gas flow is sprayed onto the surface of the surface acoustic wave sensor 8 through the mi...

Embodiment 3

[0026] The mixed gas of butanone, pentane, chloroform, dimethylamine, butanol, amyl alcohol, and trichloroethylene is used as the mixed gas to be measured. The separation column 5 is kept at 38° C. for 2 to 3 minutes, and then the gas chromatographic separation column 5 is heated at a heating rate of 9° C. / s until it rises to 145° C., and the flow rate of the carrier gas is 1.2 ml / min, so that the mixed gas to be measured is transferred from the gas chromatograph The separation column 5 successively resolves, and before a kind of resolved gas flows through the micronozzle 7, a positive voltage is applied to the semiconductor refrigeration chip 10, and the substrate of the surface acoustic wave sensor 8 is refrigerated, and the temperature is 7° C. The hot gas analyzed by the separation column 5 is sprayed onto the surface of the surface acoustic wave sensor 8 through the micro nozzle 7, and condensation and adsorption occur. The frequency detector 9 is used to detect the drift ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com