Method for making nano-groove on quartz glass

A technology of quartz glass and a manufacturing method, which is applied in the direction of chemical instruments and methods, laboratory containers, and manufacturing microstructure devices, etc., can solve the problems of expensive processing costs, achieve rich sources, simple processing processes, and good micro-processing effect of nature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

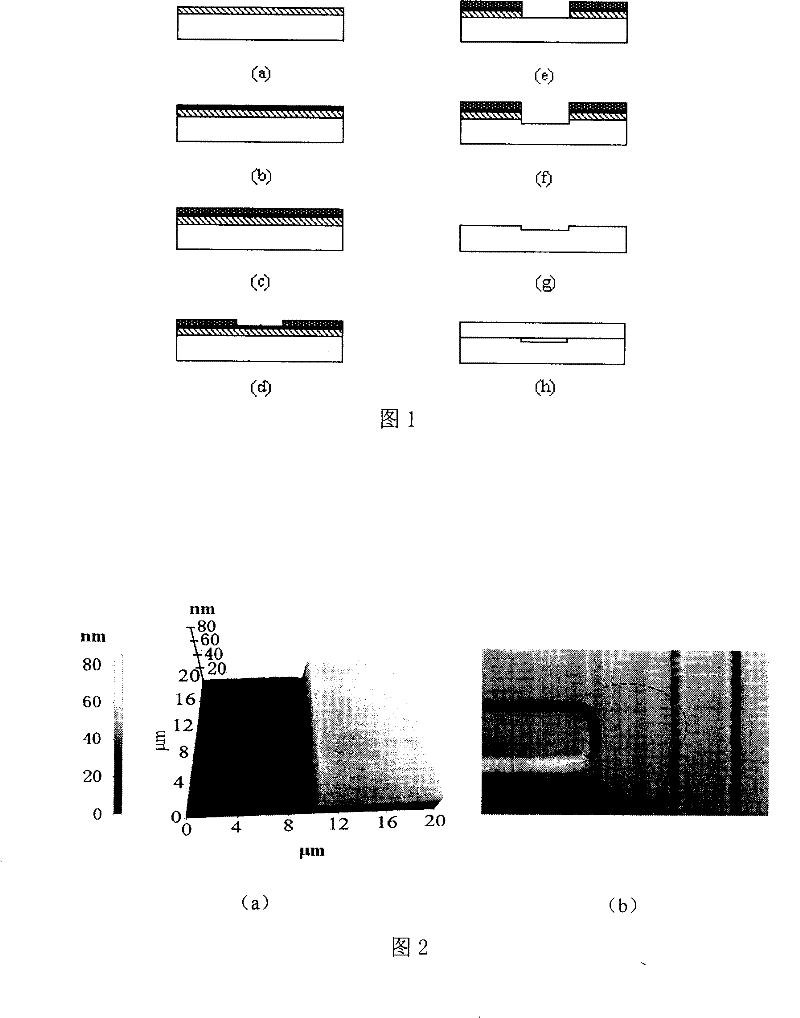

Method used

Image

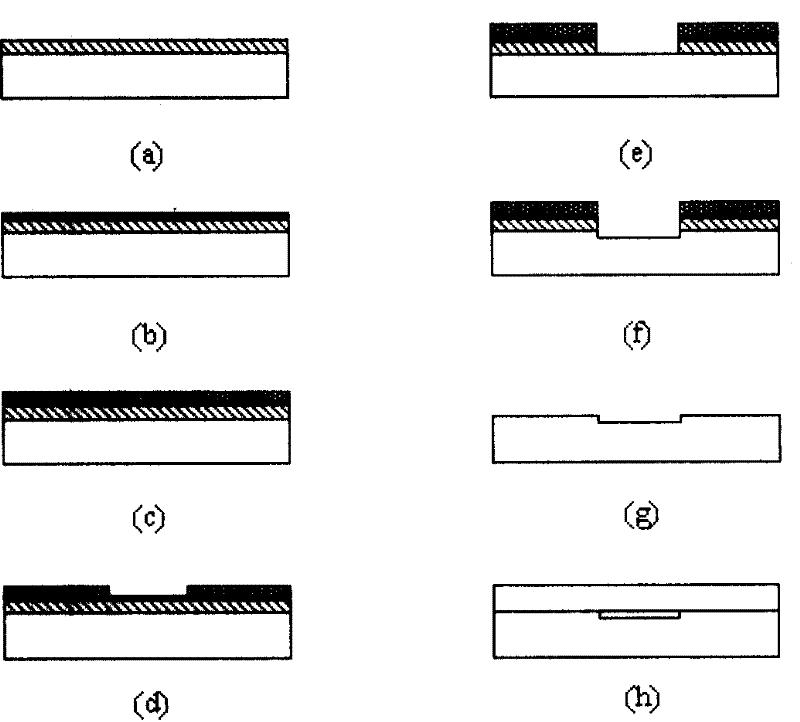

Examples

Embodiment 1

[0028] Fabricate 50nm nanochannels between microtubes.

[0029] 1) First photolithography

[0030] 1. Cleaning: Use acetone, ethanol and deionized water to ultrasonically clean the substrate for 5 minutes; blow dry with nitrogen; dry (120°C) for 20 minutes

[0031] 2. Evaporate organosilicon oxide (HMDS); apply 6809 photoresist, and shake the glue at 4000rpm for 30s

[0032] 3. Pre-baking: 100℃, 6min

[0033] 4. Photolithography: the use intensity is 12mW / cm 2 Lithography machine, Lithography 12s

[0034] 5. Development: 18s

[0035] 6. Base film 10S

[0036] 7. Harden the film in an oven at 120°C for 30 minutes

[0037] 2) Main pipeline corrosion

[0038] 1. Chromium removal: Use chromium corrosion solution (cerium ammonium nitrate 400g + perchloric acid 110mL, deionized water to 1.76L) to remove the chromium layer of the graphic part

[0039] 2. Wash with deionized water 10 times

[0040] 3. Glass corrosion: put in 40-50℃ constant temperature quartz glass corrosion ...

Embodiment 2

[0063] Fabricate a "m"-shaped 100nm nanochannel chip.

[0064] 1) Photolithography (nanostructure)

[0065] 1. Cleaning: Use acetone, ethanol, and deionized water to ultrasonically clean the substrate for 5 minutes; blow dry with nitrogen; dry (120°C) for 20 minutes

[0066] 2. Spin glue, photoresist 6809 4000rpm, 30s thickness: 0.9μm

[0067] 3. Pre-baking: 100°C, 6min (hot plate)

[0068] 4. Alignment photolithography: use an intensity of 12mW / cm 2 Lithography machine Lithography 12s

[0069] 5. Development: 18s

[0070] 6. Base film 10S

[0071] 7. Harden the film in an oven at 120°C for 30 minutes

[0072] 2) Fabrication of nanopipes

[0073] 1. Chromium removal: Use chromium corrosion solution (cerium ammonium nitrate 400g + perchloric acid 110mL, deionized water to 1.76L) to remove the chromium layer of the graphic part

[0074] 2. Nano-corrosion: put in 40-50℃ constant temperature quartz glass corrosion solution (HF:H 2 o 2 :HAC=2:5:5, volume ratio) stirring, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com