Method for reducing thermal strain of surface acoustic wave device chip packaging

A surface acoustic wave device and chip packaging technology, applied in the direction of electrical components, impedance networks, etc., can solve the problems of surface acoustic wave device electrical parameter degradation, device consistency, compliance and adverse effects on reliability, etc., to achieve processing technology compatibility , Simple and compact structure, improve the effect of deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

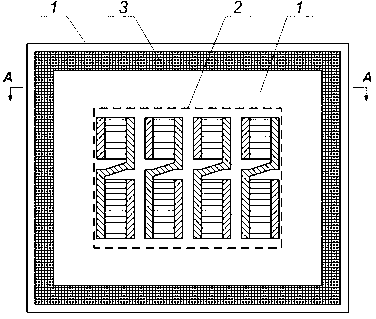

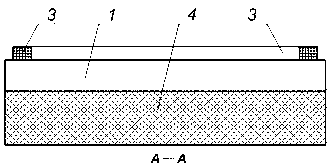

[0020] Such as figure 2 As shown, an annular metal strip 3 is fabricated by physical deposition and photolithography in the edge region of the surface of the piezoelectric single crystal substrate 1, and the annular metal strip 3, the piezoelectric single crystal substrate 1 and the packaging base 4 form a The composite structure with complementary thermal-mechanical properties reduces the distributed thermal strain generated on the surface of the piezoelectric single-crystal substrate 1 due to the thermal-mechanical mismatch between the piezoelectric single-crystal substrate material and the packaging material. The technical realization steps of the endless metal belt structure involved in this embodiment are:

[0021] (1) adopting the magnetron sputtering method to make an aluminum-copper alloy film with a copper doping ratio of 0.5% on the surface of the piezoelectric single crystal substrate 1;

[0022] (2) Manufacturing an aluminum-copper alloy annular metal belt 3 at t...

Embodiment 2

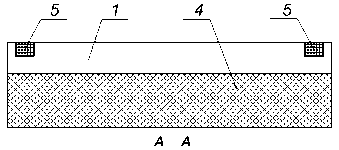

[0025] Such as image 3 As shown, an annular metal strip 5 embedded in the surface layer of the piezoelectric single crystal substrate 1 is fabricated by physical etching, physical deposition and photolithography in the edge region of the piezoelectric single crystal substrate 1, and the annular metal strip 5 is embedded in the surface layer of the piezoelectric single crystal substrate 1. Article 5. The piezoelectric single crystal substrate 1 and the packaging base 4 form a composite structure with complementary thermal-mechanical properties, which reduces the thermal-mechanical characteristics mismatch between the piezoelectric single crystal substrate material and the packaging material. Distributed thermal strain generated on the surface of the crystal substrate. The process implementation steps of the embedded annular metal strip 5 involved in this embodiment are:

[0026] (1) At the edge of the surface of the piezoelectric single crystal substrate 1, an annular groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com