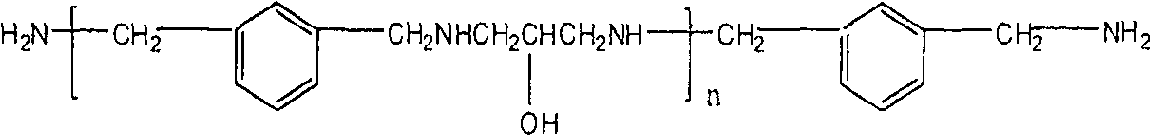

Aqueous dimer acid amide curing agent, preparation method and application thereof

A dimer acid amide and curing agent technology, used in coatings, epoxy resin coatings, etc., can solve problems such as poor hardness, and achieve the effects of mild conditions, low toxicity and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Add 28.5g of dimer acid and 28.4g of N-ethylpiperazine into a reaction kettle equipped with a stirrer, condensation and water separation device, nitrogen protection, thermometer and heating mantle, and gradually heat up to 140°C, stirring continuously during the heating process, so that The two components are fully mixed to obtain a light yellow clear solution; the reaction temperature is controlled at 150°C, and the reaction time is slowly refluxed for 3 hours, so that the dimer acid and N-ethylpiperazine form a salt at a low temperature; when the temperature of the reactor reaches 150-170 ℃, water begins to be separated at room temperature, continue to heat up to 230 ℃, keep warm at this temperature for 2 hours until the water is basically evaporated, continue to reflux for 0.5 hours, stop heating; start vacuum distillation at low temperature, when the temperature Return to 230°C, excess N-ethylpiperazine is distilled off, stir at this temperature for 1 hour, when subs...

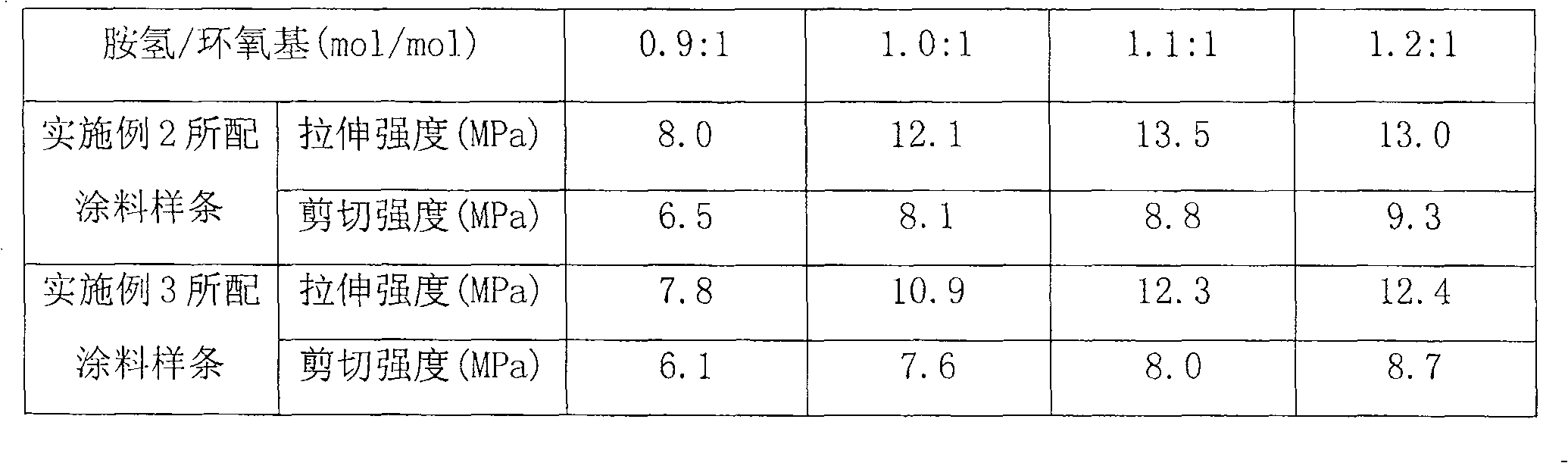

Embodiment 2

[0031] Add 28.5g of dimer acid and 31.0g of N-ethylpiperazine into a reaction kettle equipped with a stirrer, condensation water separator, nitrogen protection, thermometer and heating mantle, and gradually heat up to 140°C, stirring continuously during the heating process, so that The two components are fully mixed to obtain a light yellow clear solution; the reaction temperature is controlled at 150°C, and the reaction time is slowly refluxed for 4 hours, so that the dimer acid and N-ethylpiperazine form a salt at a low temperature; when the temperature of the reactor reaches 150-170 ℃, water begins to be separated at room temperature, continue to heat up to 230 ℃, keep warm at this temperature for 3 hours until the water is basically evaporated, continue to reflux for 0.5 hours, stop heating; start vacuum distillation at low temperature, when the temperature Return to 230°C, excess N-ethylpiperazine is distilled off, stir at this temperature for 1 hour, when substantially no...

Embodiment 3

[0034]Add 28.5g of dimer acid and 32.3g of N-ethylpiperazine into a reaction kettle equipped with a stirrer, condensation water separator, nitrogen protection, thermometer and heating mantle, gradually heat up to 140°C, and keep stirring during the heating process, so that The two components are fully mixed to obtain a light yellow clear solution; the reaction temperature is controlled at 150°C, and the reaction time is slowly refluxed for 3 hours, so that the dimer acid and N-ethylpiperazine form a salt at a low temperature; when the temperature of the reactor reaches 150-170 ℃, water begins to be separated at room temperature, continue to heat up to 230 ℃, keep warm at this temperature for 2 hours until the water is basically evaporated, continue to reflux for 0.5 hours, stop heating; start vacuum distillation at low temperature, when the temperature Return to 230°C, excess N-ethylpiperazine is distilled off, stir at this temperature for 1 hour, when substantially no N-ethylp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| amine value | aaaaa | aaaaa |

| amine value | aaaaa | aaaaa |

| amine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com