Conical guide smokeless vertical steam boiler

A steam boiler and diversion cone technology, which is applied in steam boilers, steam generation, solid fuel combustion, etc., can solve the problems of no advanced combustion technology, affecting heat transfer effect, low thermal efficiency, etc., and achieve economic and social benefits Significant, save coal resources, improve the effect of thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

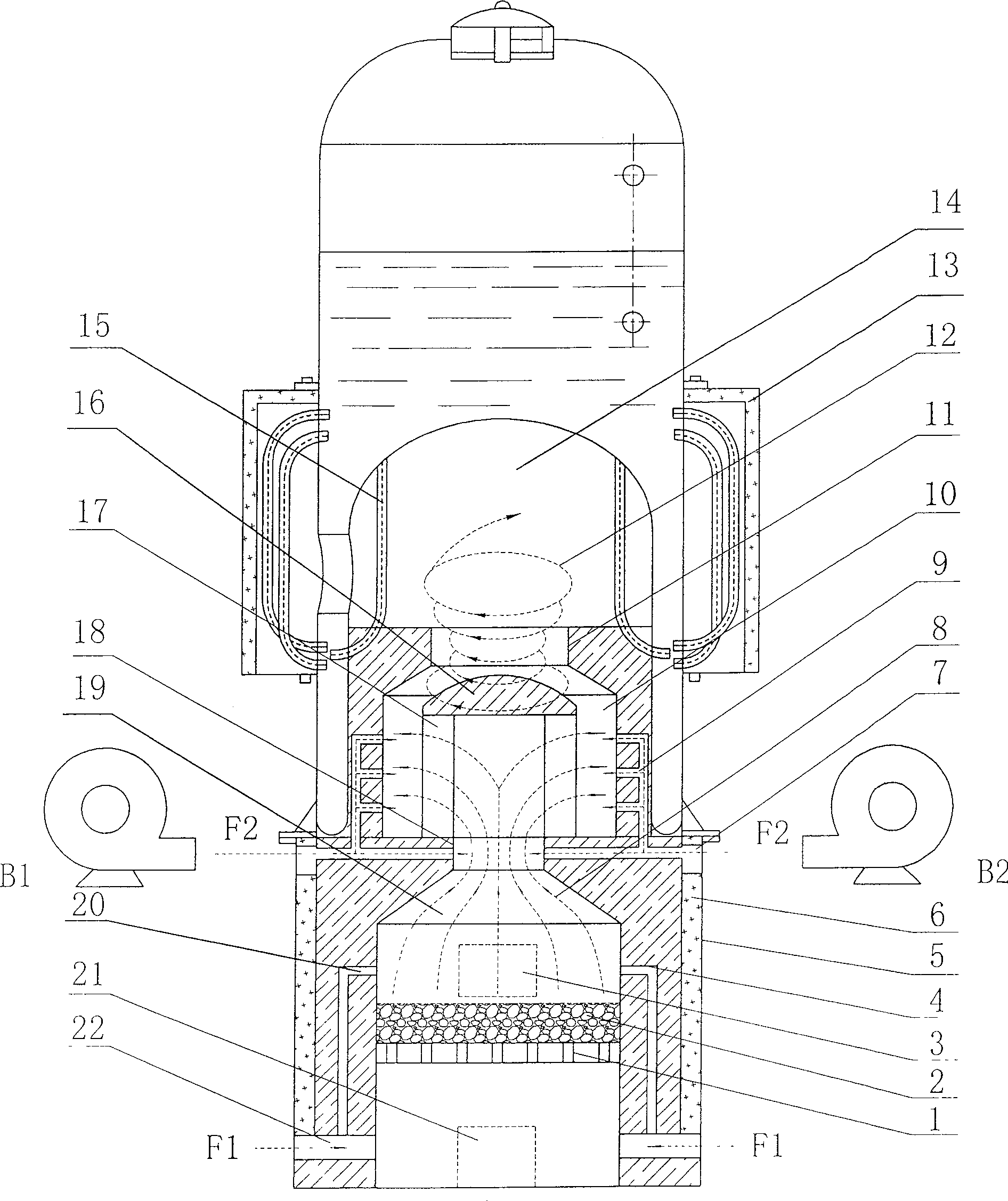

[0030] The present invention will be further described in conjunction with the accompanying drawings of the above-mentioned embodiments.

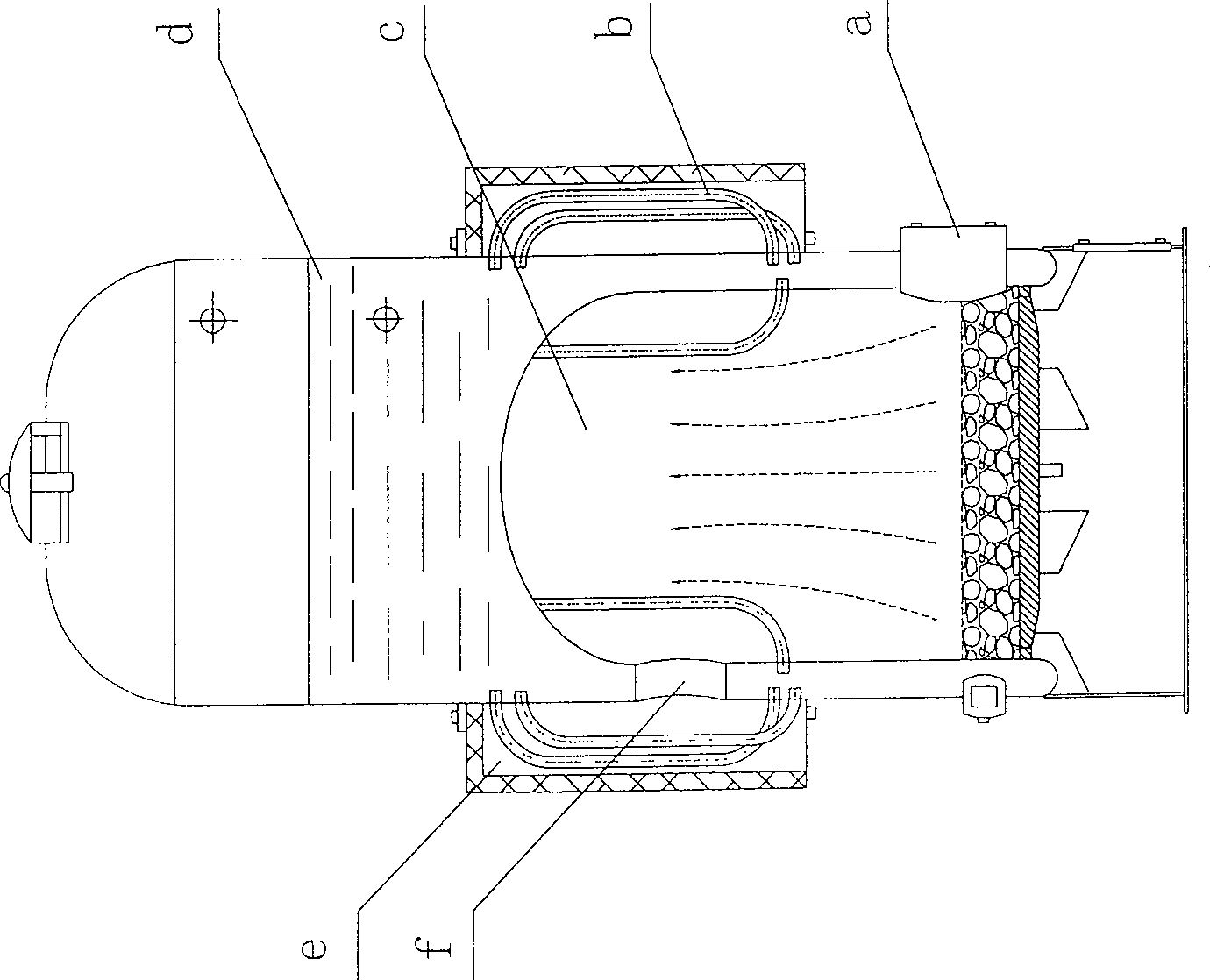

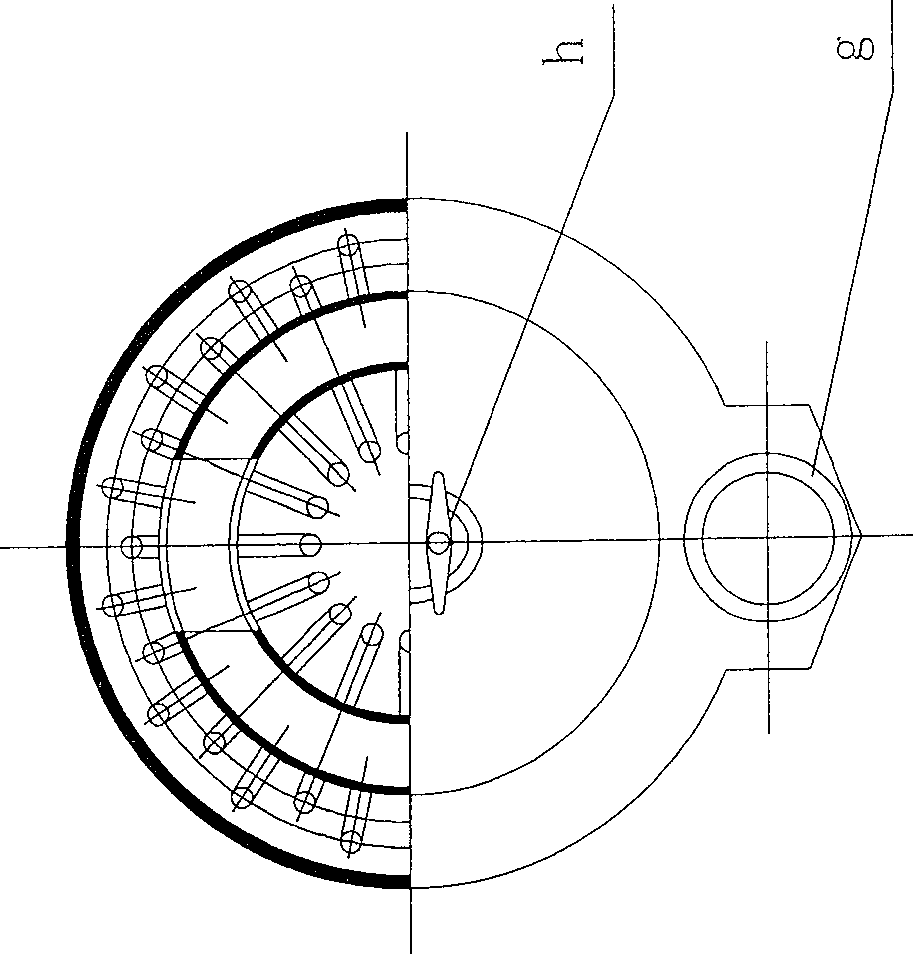

[0031] image 3Shown is the embodiment 1 of the diversion cone type pure smokeless vertical steam boiler according to the present invention, which includes a metal shell 5, curved water pipes and combustion devices, the outer curved water pipe is placed in the smoke box 13, and the inner curved water pipe The hot gas chamber 14 is formed between them, the combustion furnace 19 of the combustion device is below the hot gas chamber 14, the fire grate 1 is below the combustion furnace 19, and the ash chamber is below the fire grate 1, and a coal charging furnace door is provided corresponding to the combustion furnace 19. Corresponding to the ash chamber, an ash door 21 is provided, and the ash chamber is equipped with a primary combustion-supporting tuyere. The primary combustion-supporting air auxiliary tuyere 20 is also distributed around t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com