Process for preparaing reversing chip of pure-golden Au alloy bonding LED

A flip-chip, alloy bonding technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of device light extraction efficiency, high device junction temperature, and reliability, etc., to improve stability and yield, Improve stability and yield, optimize heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] In order to prepare the above-mentioned pure gold Au alloy bonded LED flip chip, the preparation method of the present invention comprises the following steps:

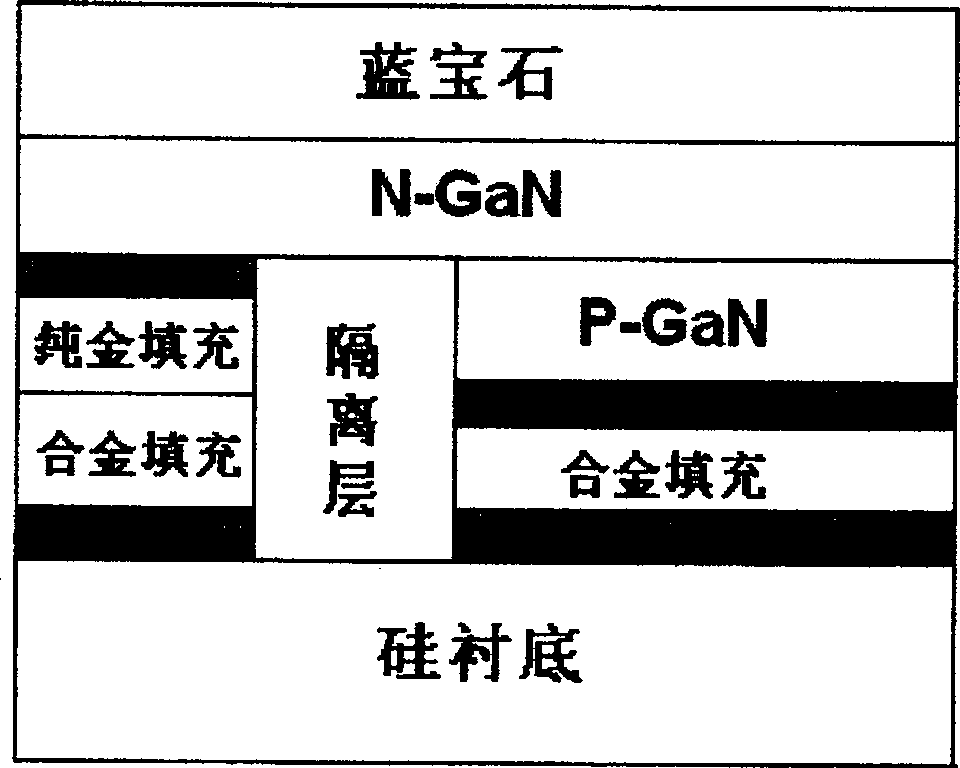

[0035] First, use MOCVD (metal organic chemical vapor deposition) equipment to epitaxially grow GaN-based high-power LED structure epitaxial wafers, and the substrate is sapphire (Al 2 o 3 ). Then etch the steps of the N surface and the scribe line of the chip size to expose the N-GaN mesa, so as to be used as the N electrode and the welding pad. The N-type mesa is etched by reactive ion etching equipment RIE, and the reactive gas is Cl:Ar=10:3.

[0036] Using ICP (Coupled Plasma Etching) or RIE (Reactive Ion Etching) equipment to dry-etch the P-GaN layer and the light-emitting layer with chlorine ions and argon ions, and make the P-GaN layer and the light-emitting layer The underlying N-GaN layer forms the electrical contact and is etched with photoresist or SiO 2 Make a mask.

[0037] Afterwards, a layer...

Embodiment 1

[0042] Embodiment 1, adjust the welding temperature and time.

[0043] The process parameters for welding the LED chip and the silicon substrate together are as follows:

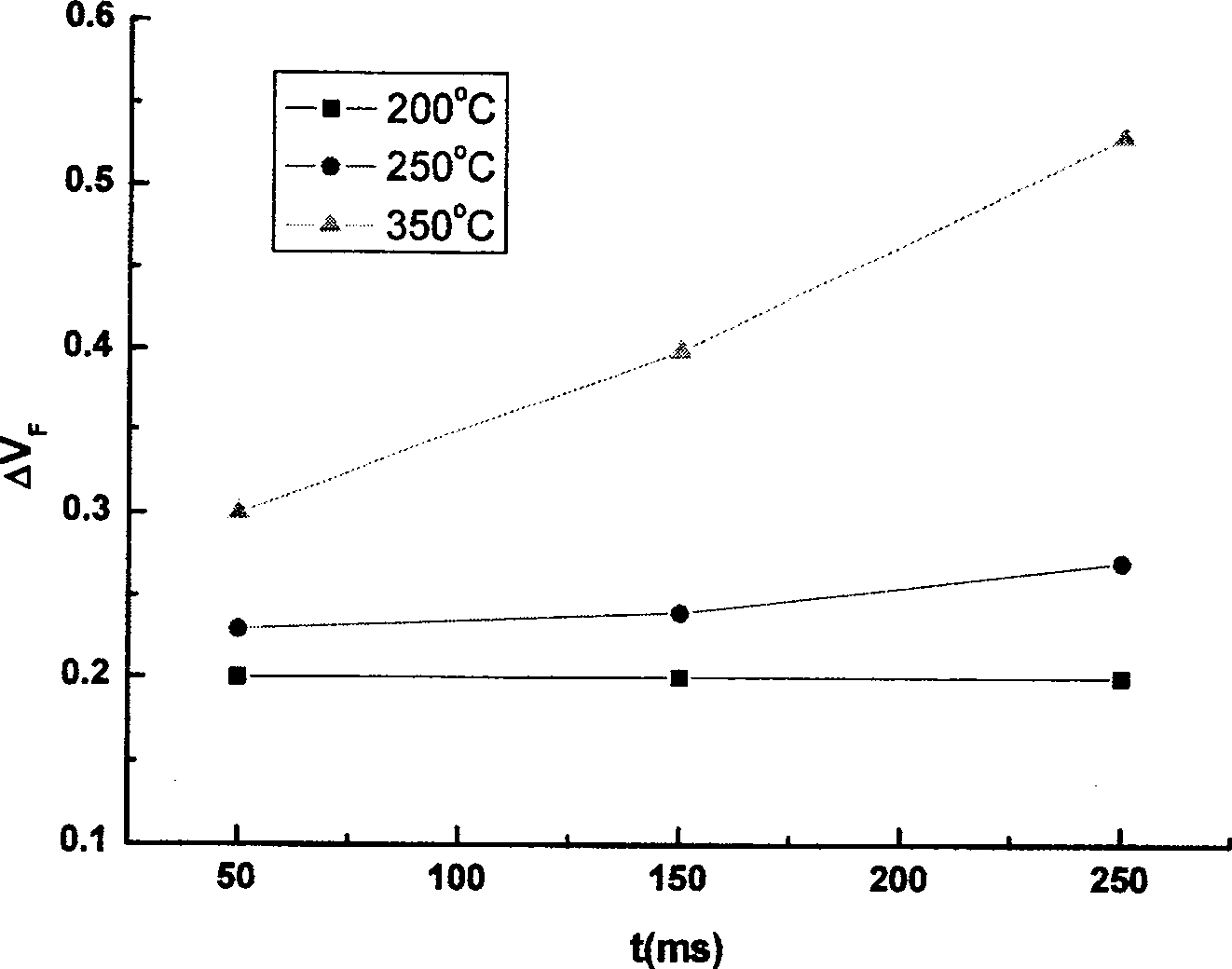

[0044] The heating and bonding temperature is controlled at 200°C to 350°C, and the welding time is adjusted within a range of 50ms to 250ms. Depend on figure 2 It can be seen that under the premise that the welding temperature parameters remain unchanged, the grain V measured by adjusting the welding time F (Forward voltage) difference between each other △V F . Among them, when the welding temperature is 200℃, the difference △V F Only 0.2V. When the welding temperature increases, the difference △V F increase, and when the welding temperature is higher, 350°C, the difference △V F It increases significantly with the increase of welding time.

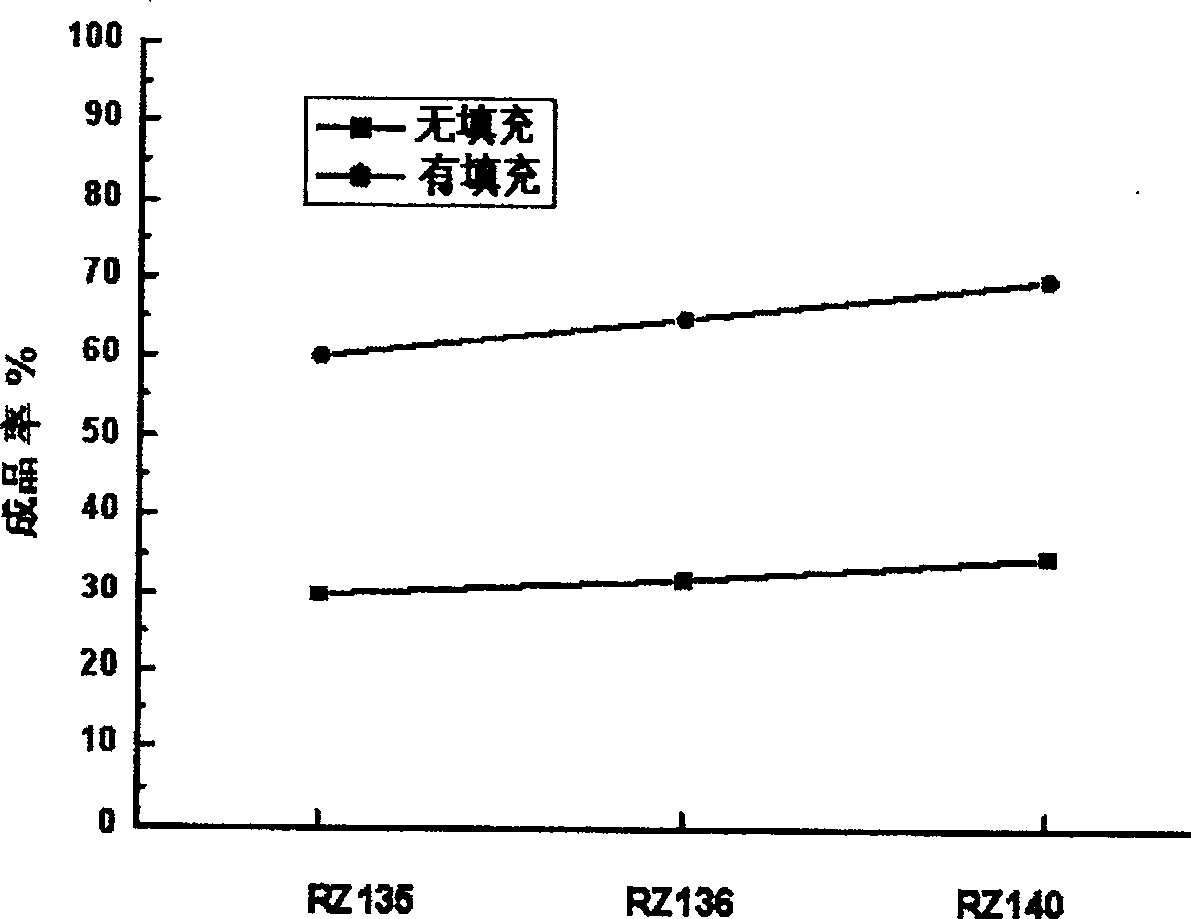

[0045] image 3 It is a comparison of the yield of the invented technology flip chip (with filling) and the prior art flip chip (without filling). It can be ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com