Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Suppress pressure changes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

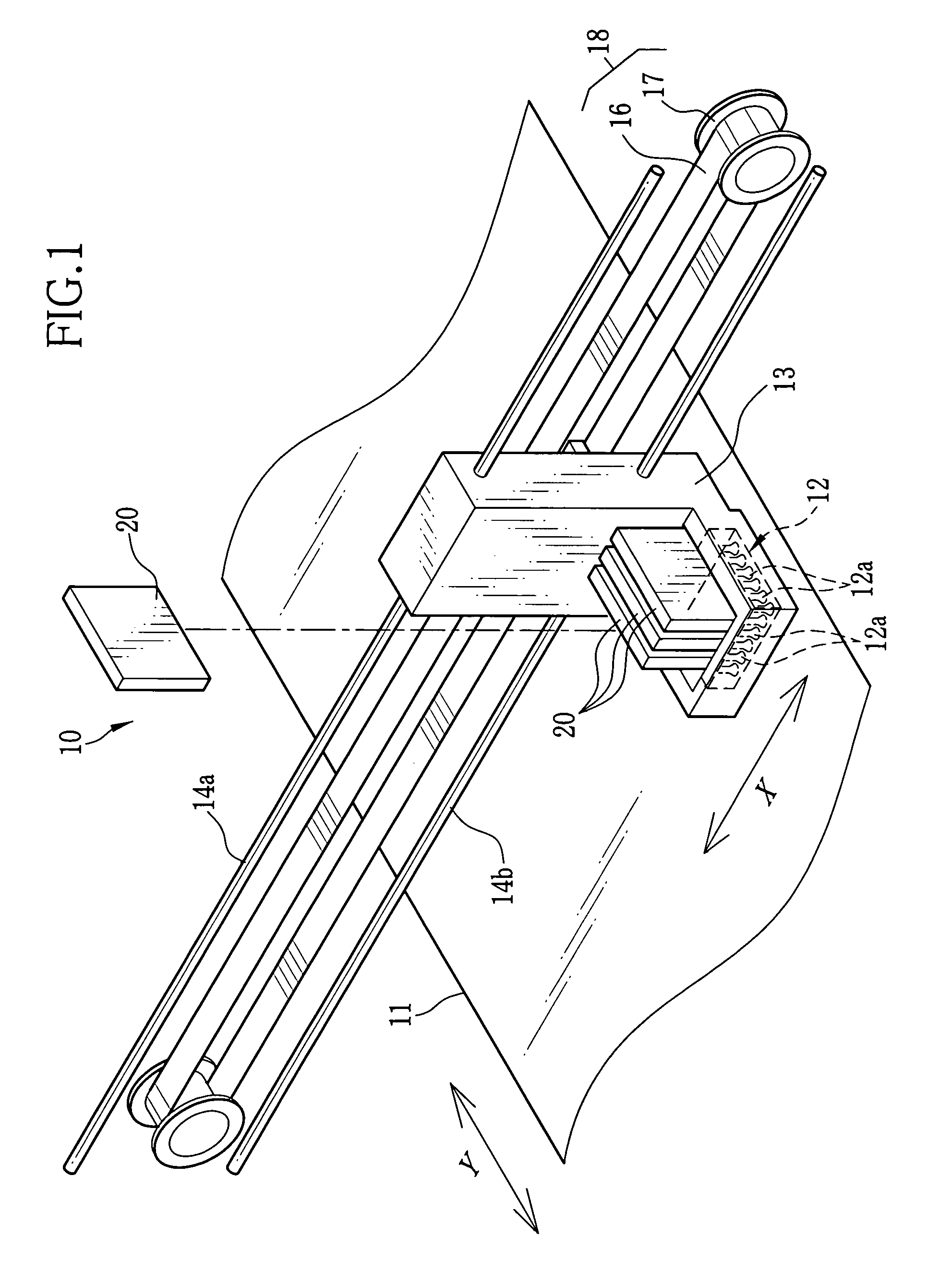

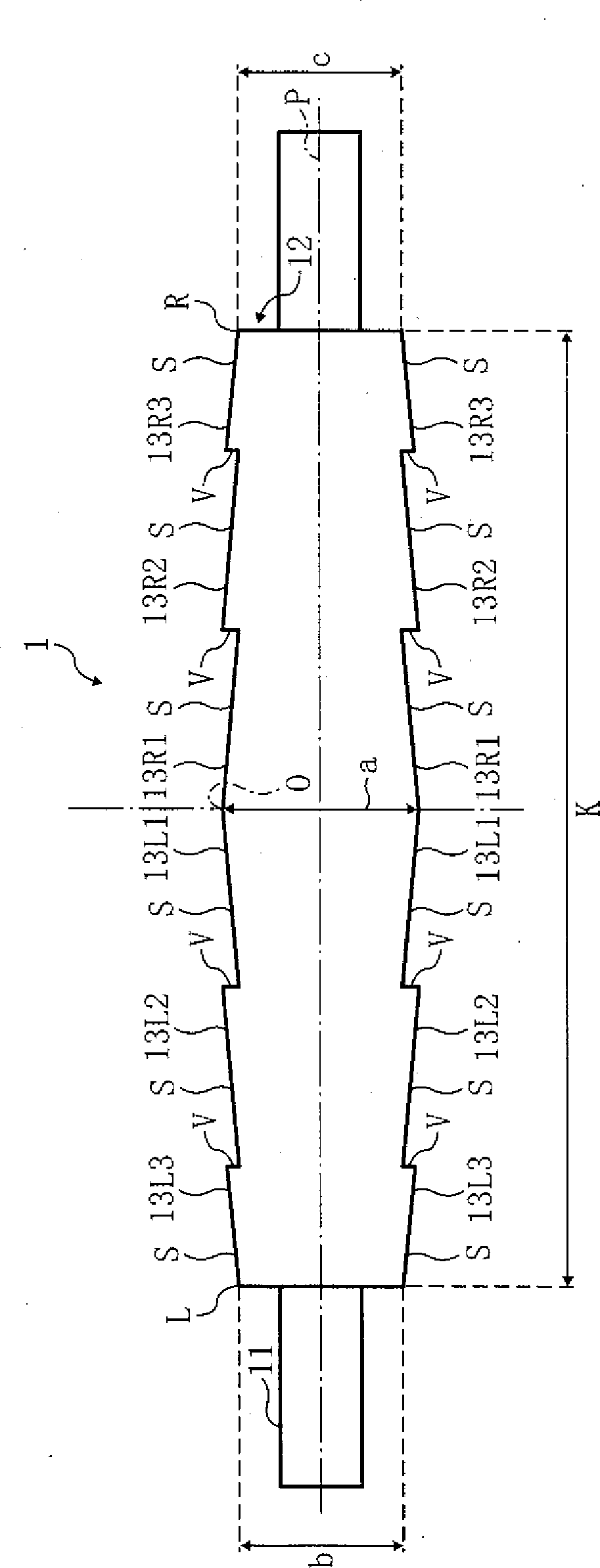

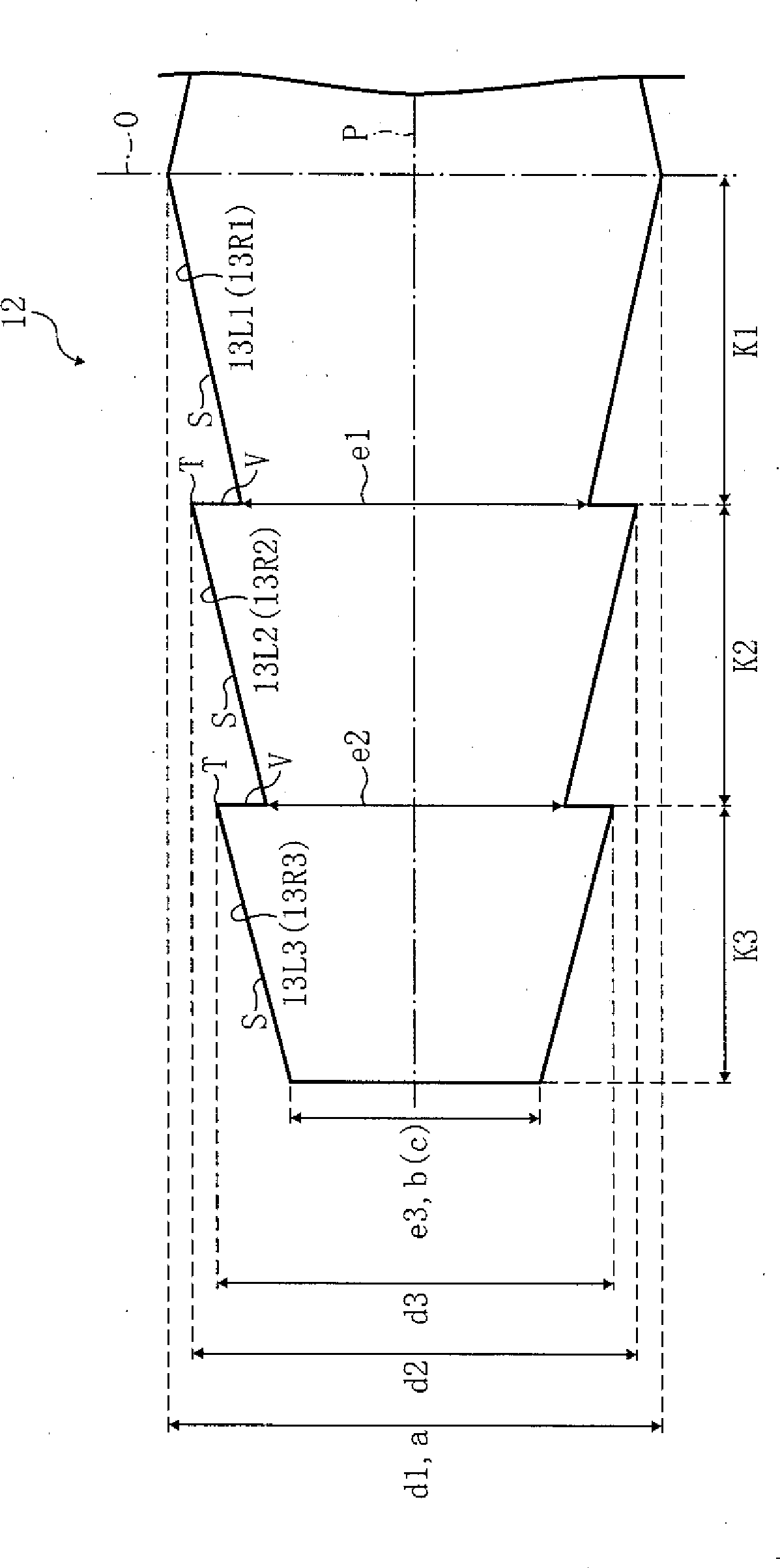

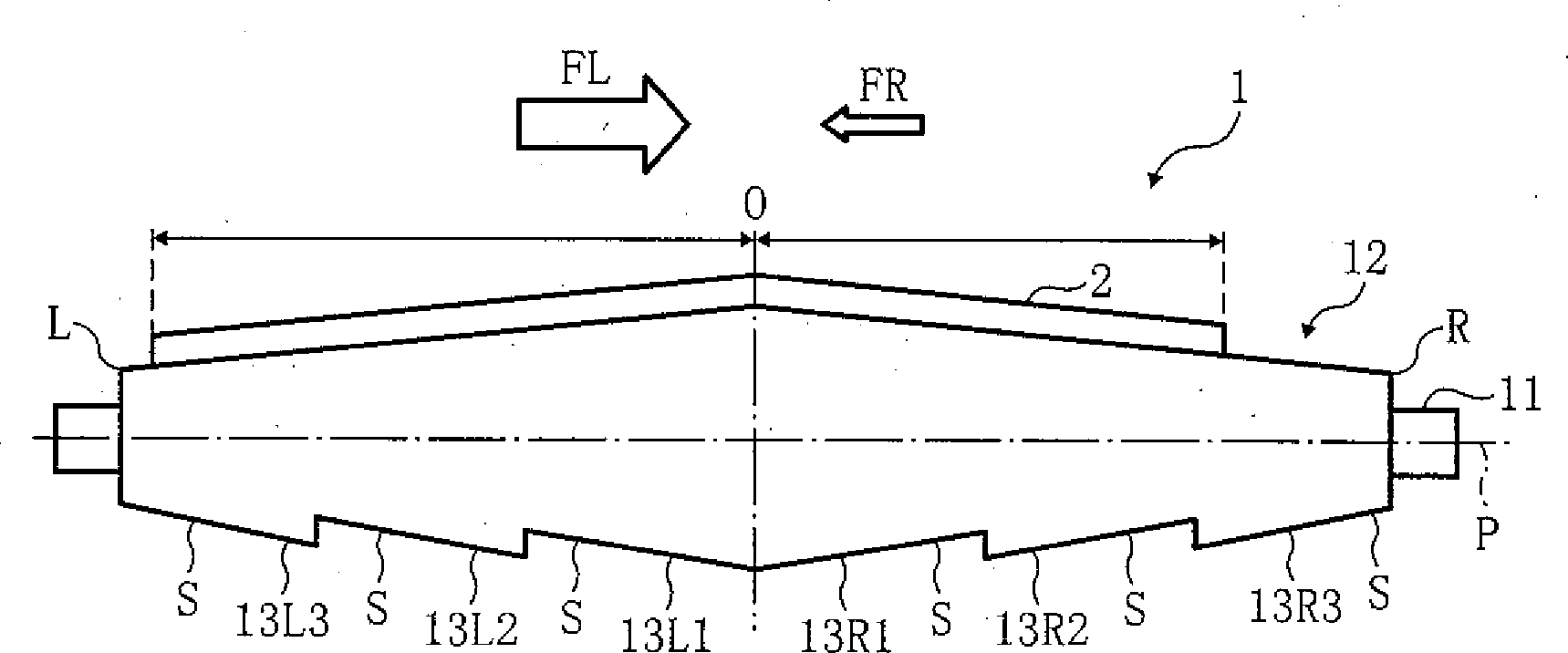

Speaker device

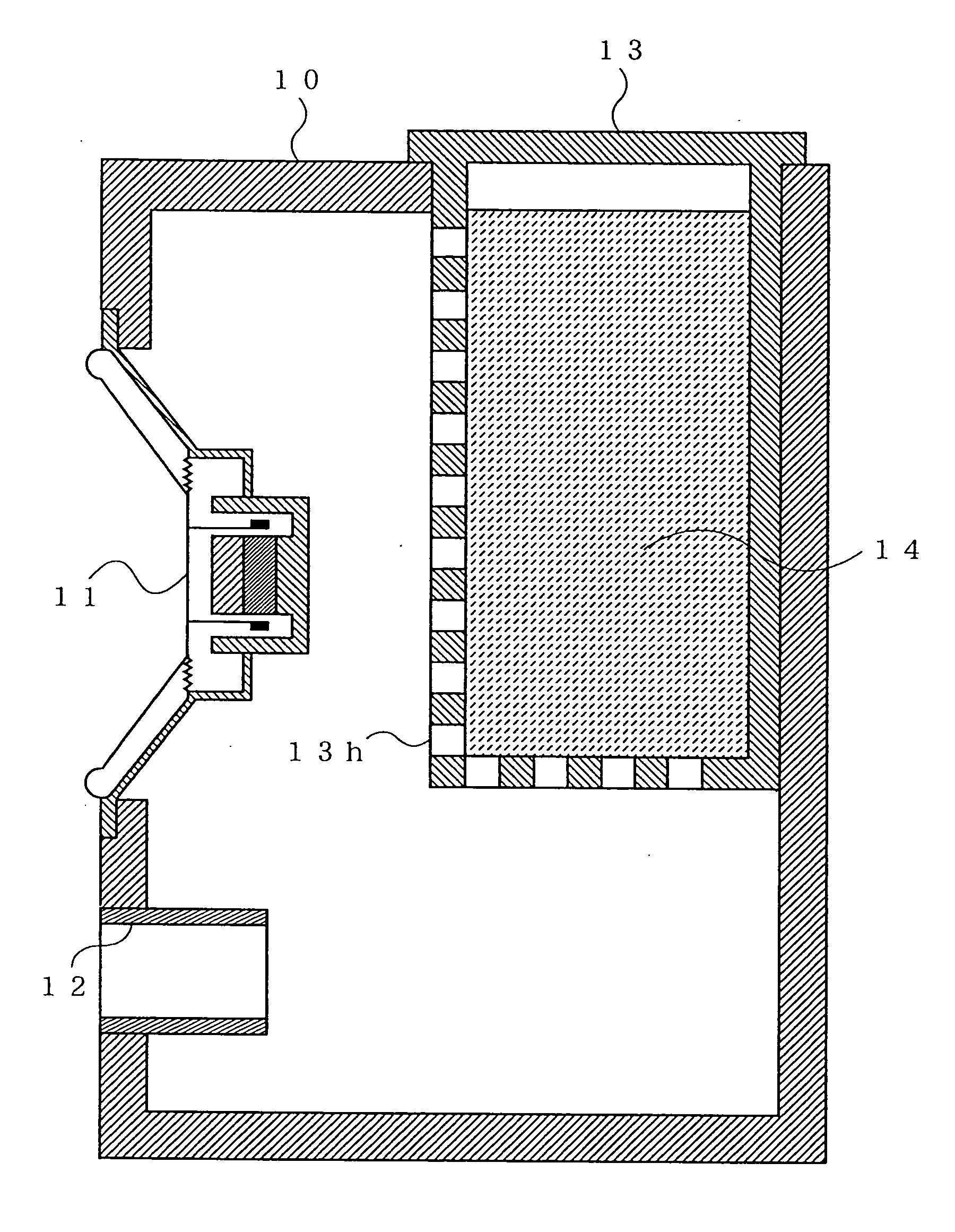

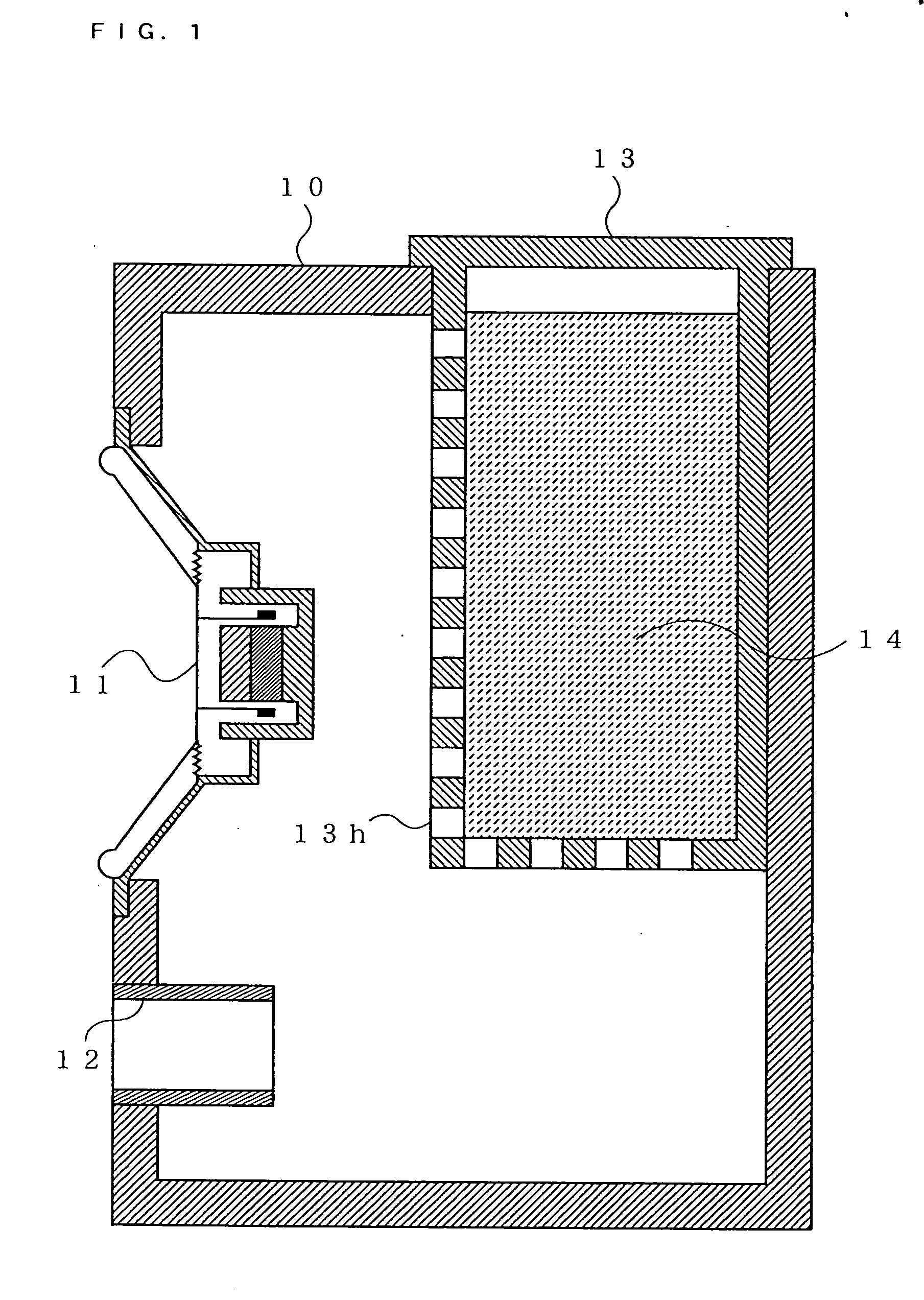

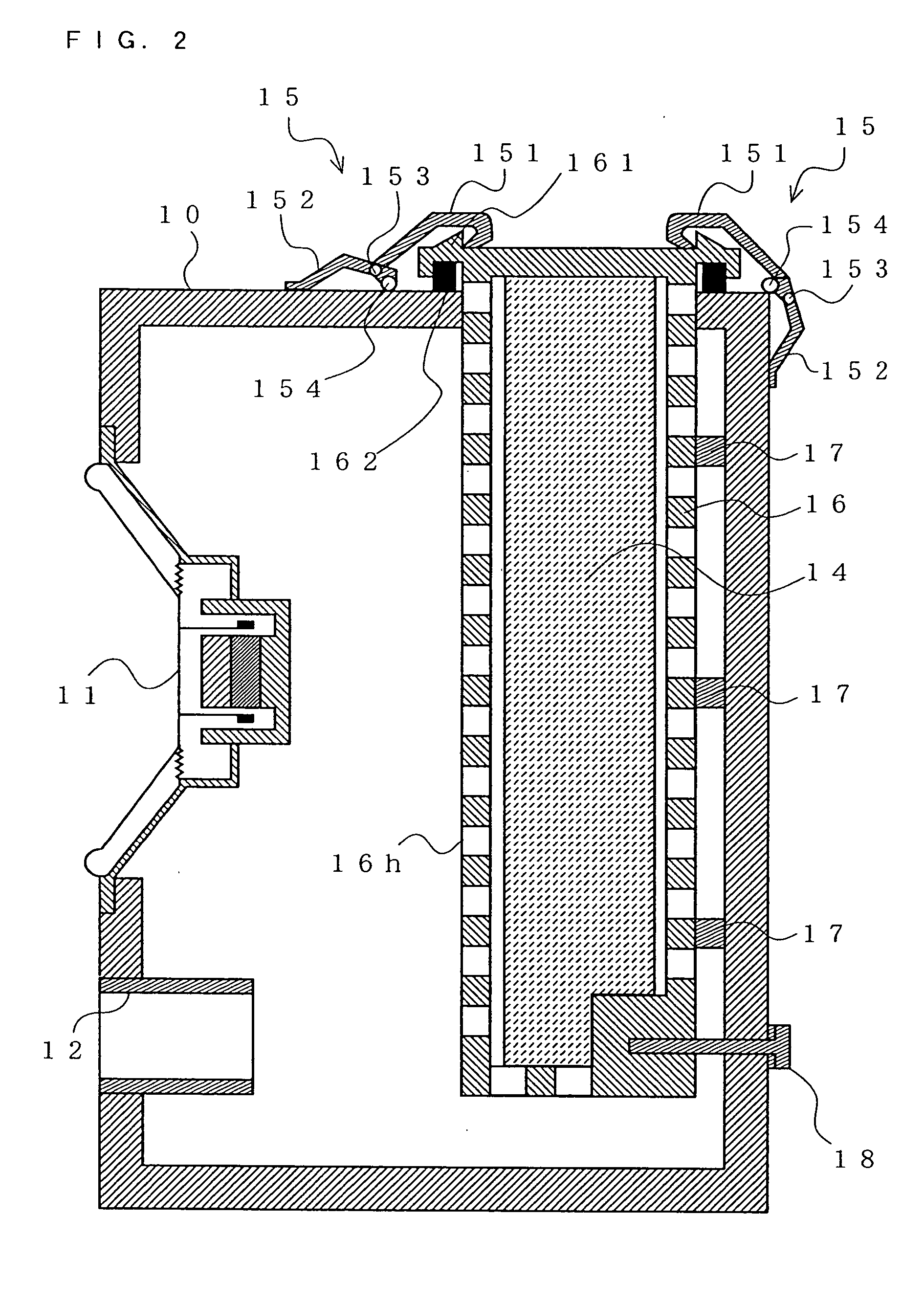

InactiveUS20070165895A1Increase rangeSuppress pressure changesFrequency/directions obtaining arrangementsTransducer casings/cabinets/supportsMagnetic tapeEngineering

A speaker device includes a cabinet (10), a speaker unit (11), a port (12), a cartridge (13), and an adsorbent material (14). The adsorbent material (14) is disposed in the interior of the cartridge (13). The cartridge (13) is a container removable from the cabinet (10). When the adsorbent material (14) is deteriorated, the cartridge (13) is replaced or the adsorbent material (14) is reactivated, thereby making it possible to maintain, over a long period of time, the effect of physical adsorption provided by the adsorbent material (14).

Owner:PANASONIC CORP

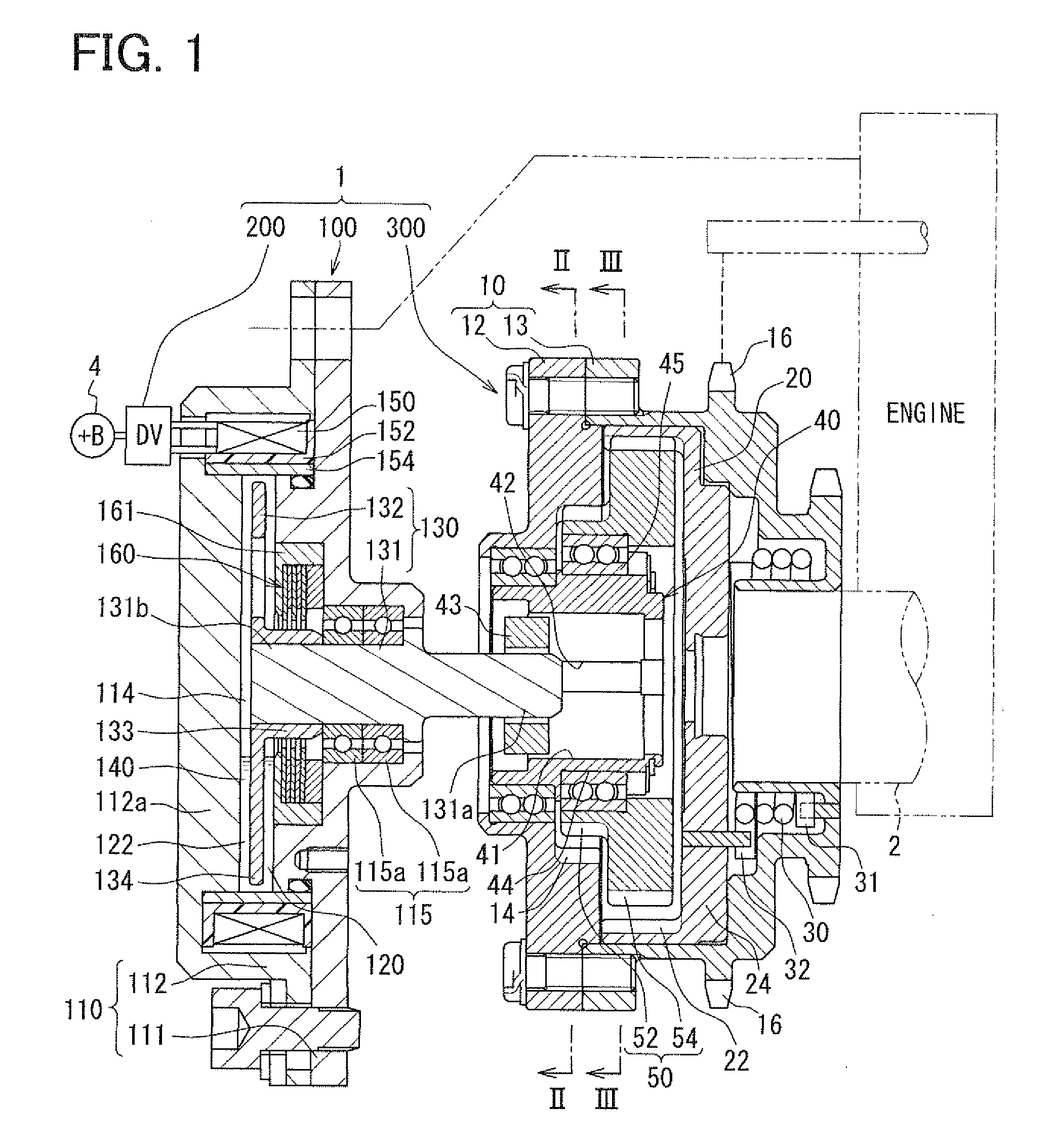

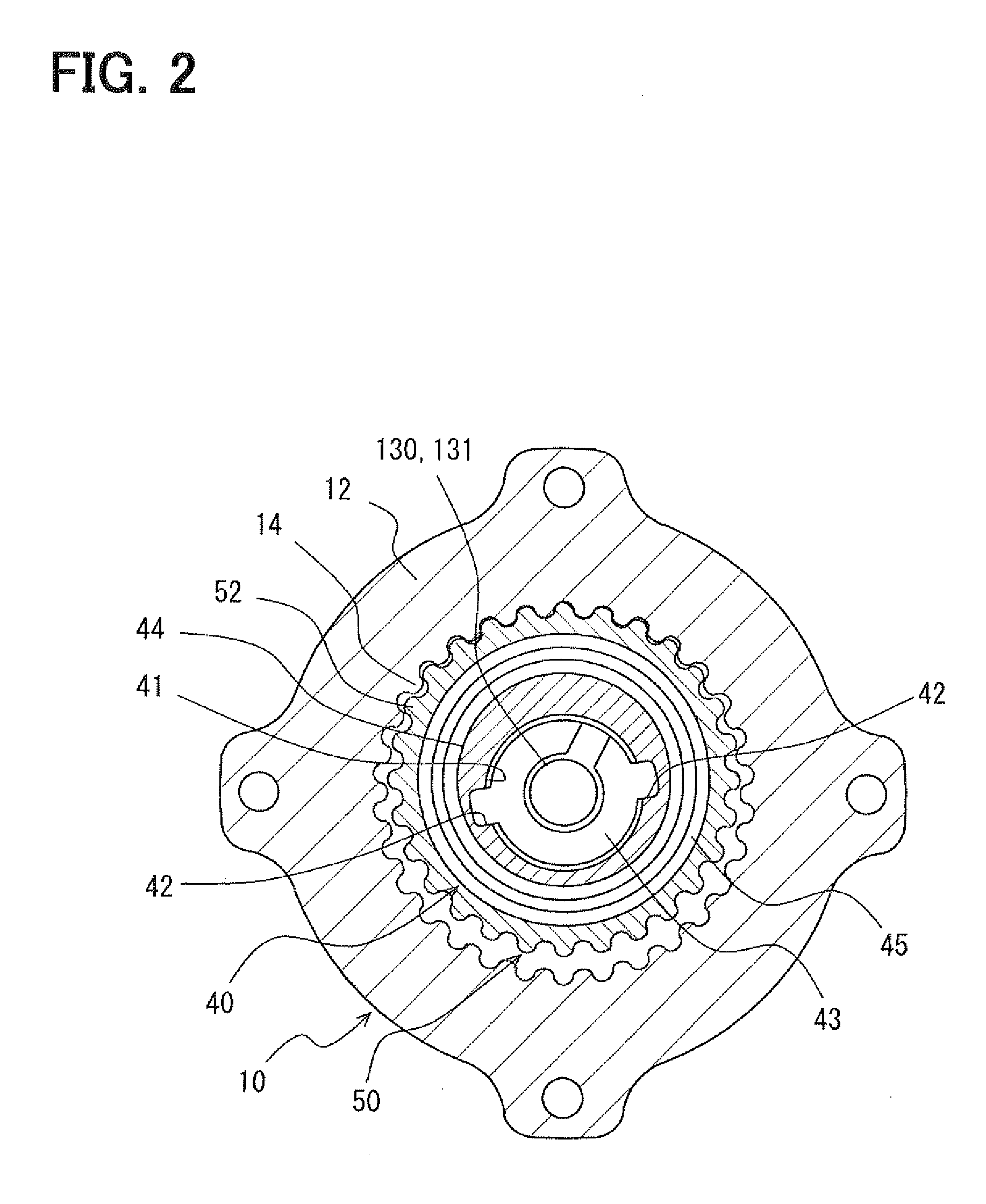

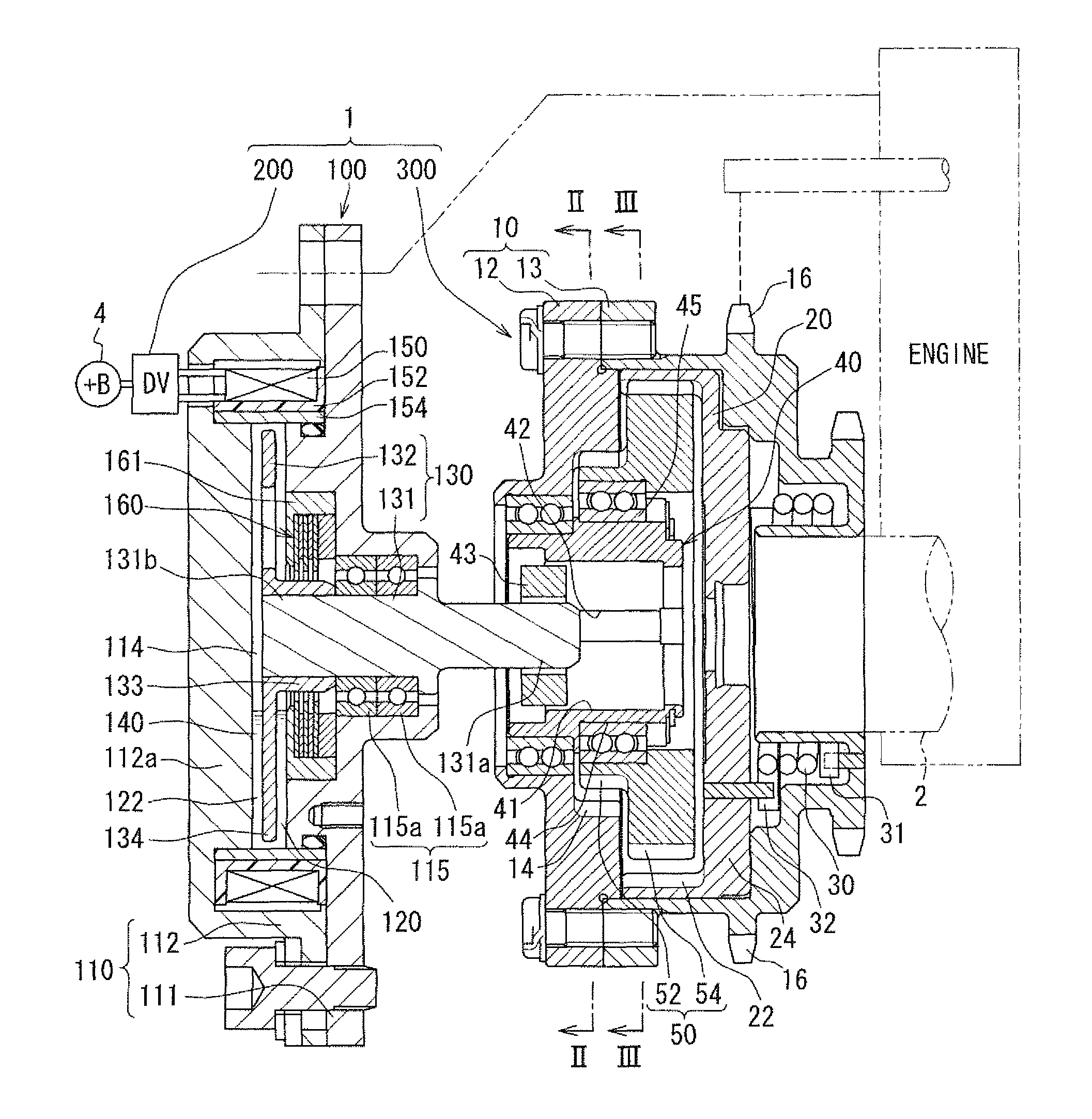

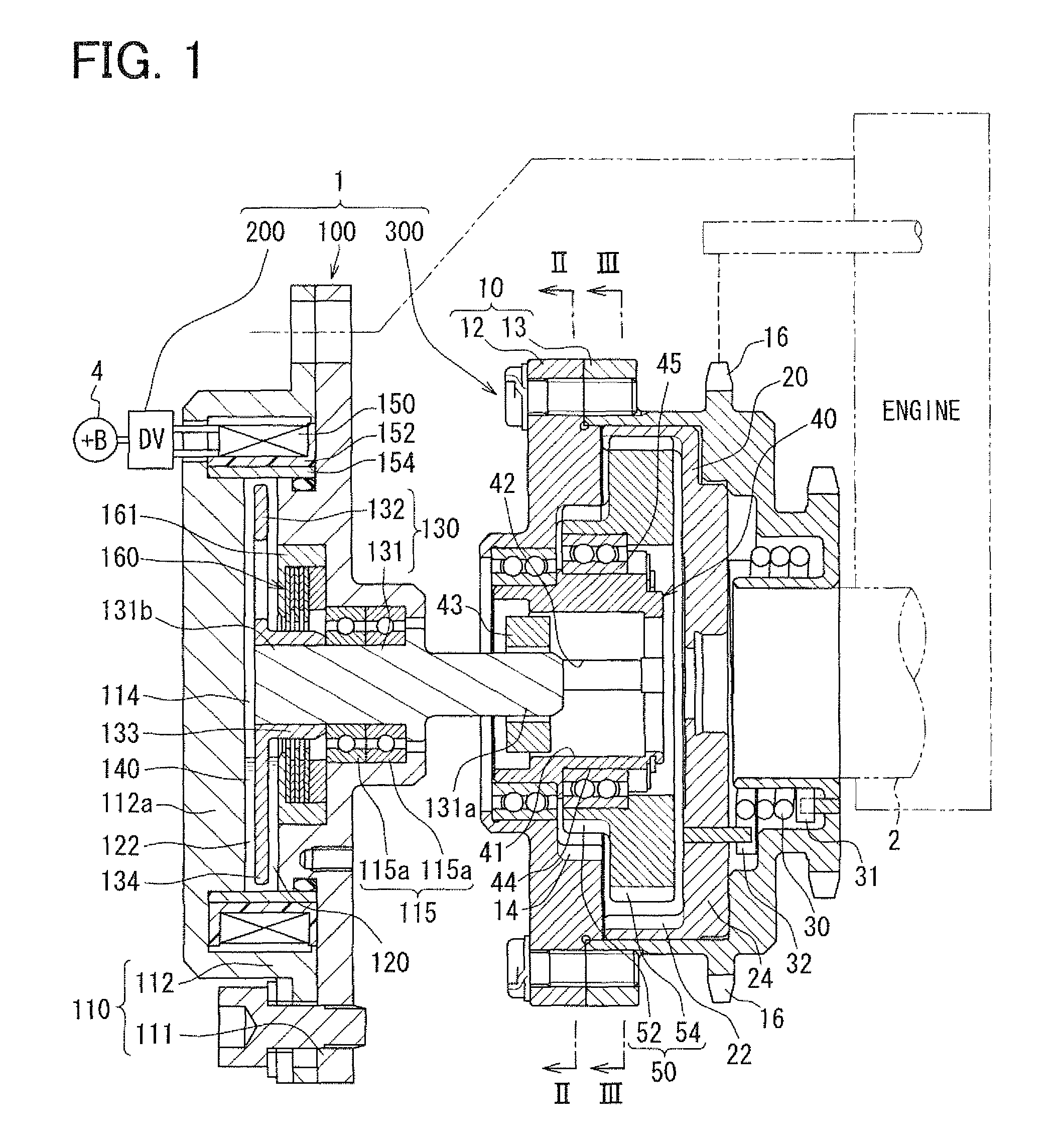

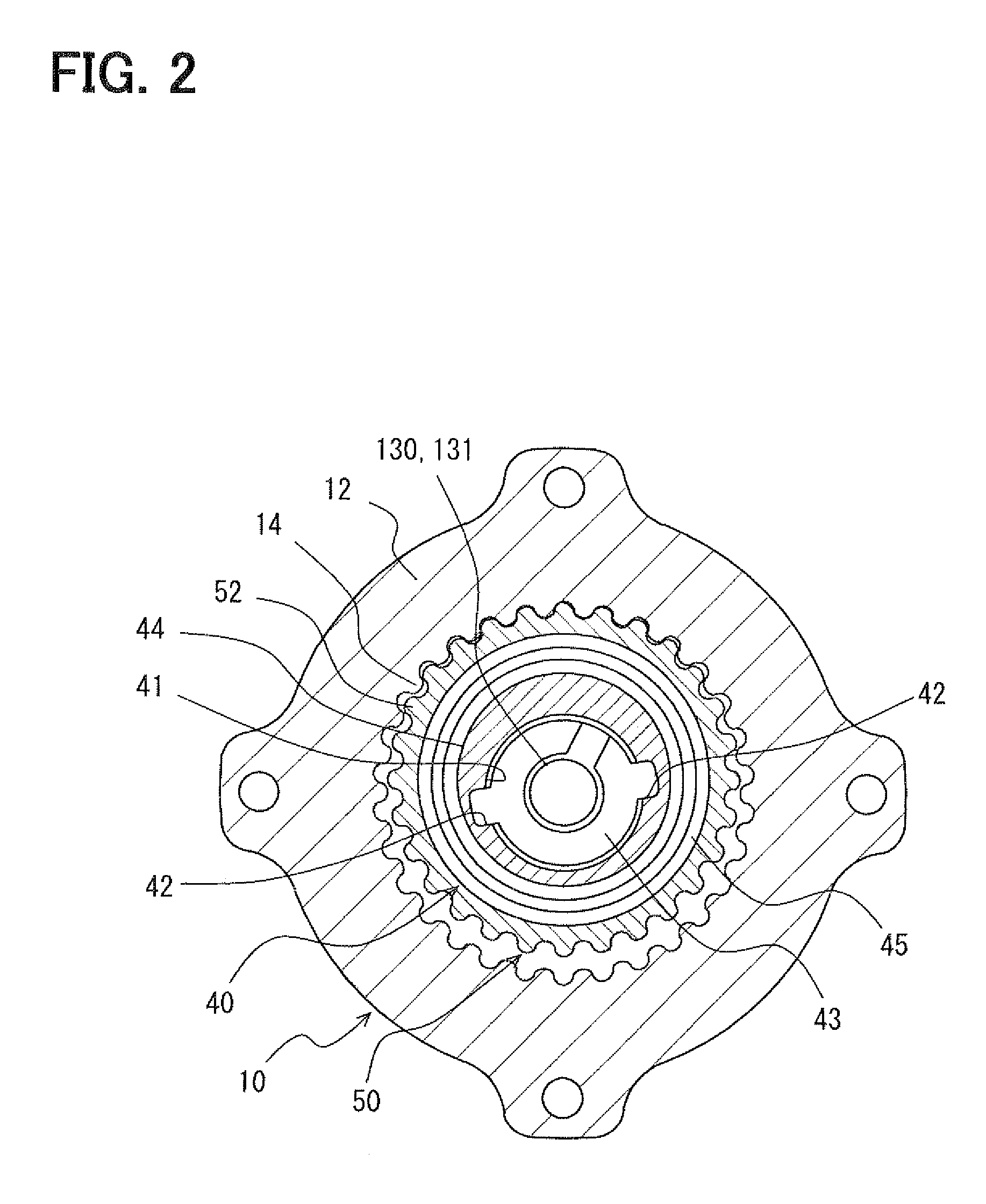

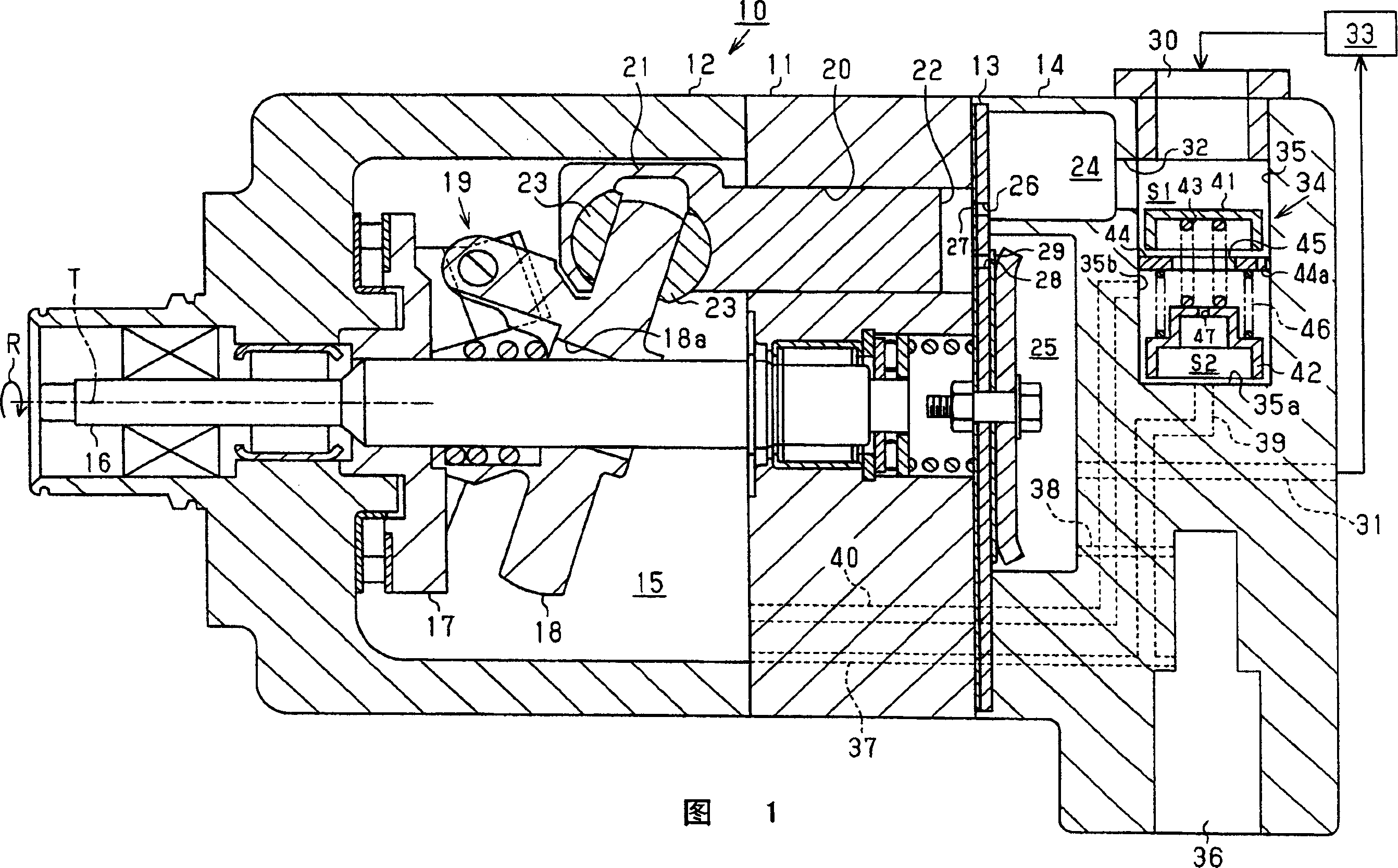

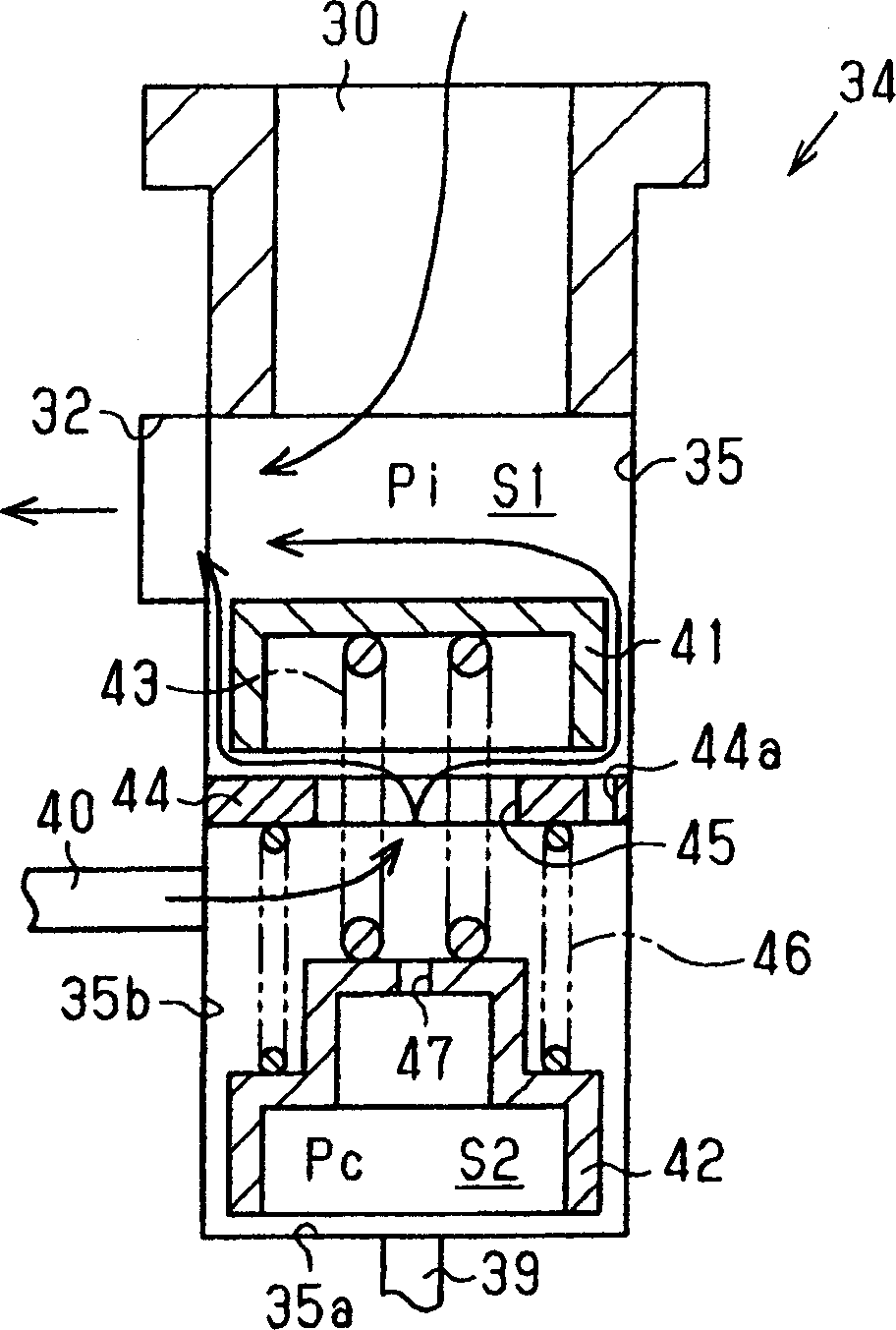

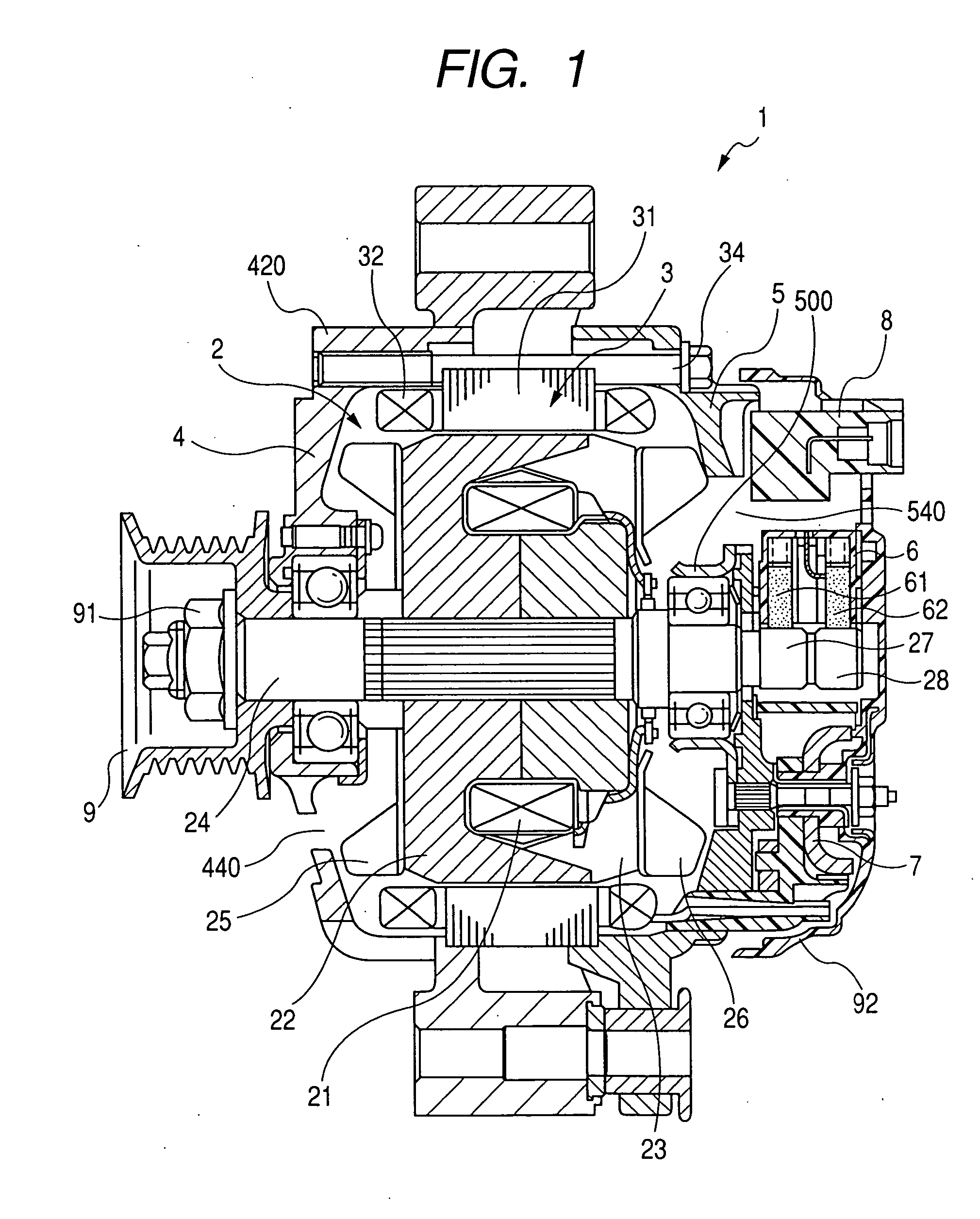

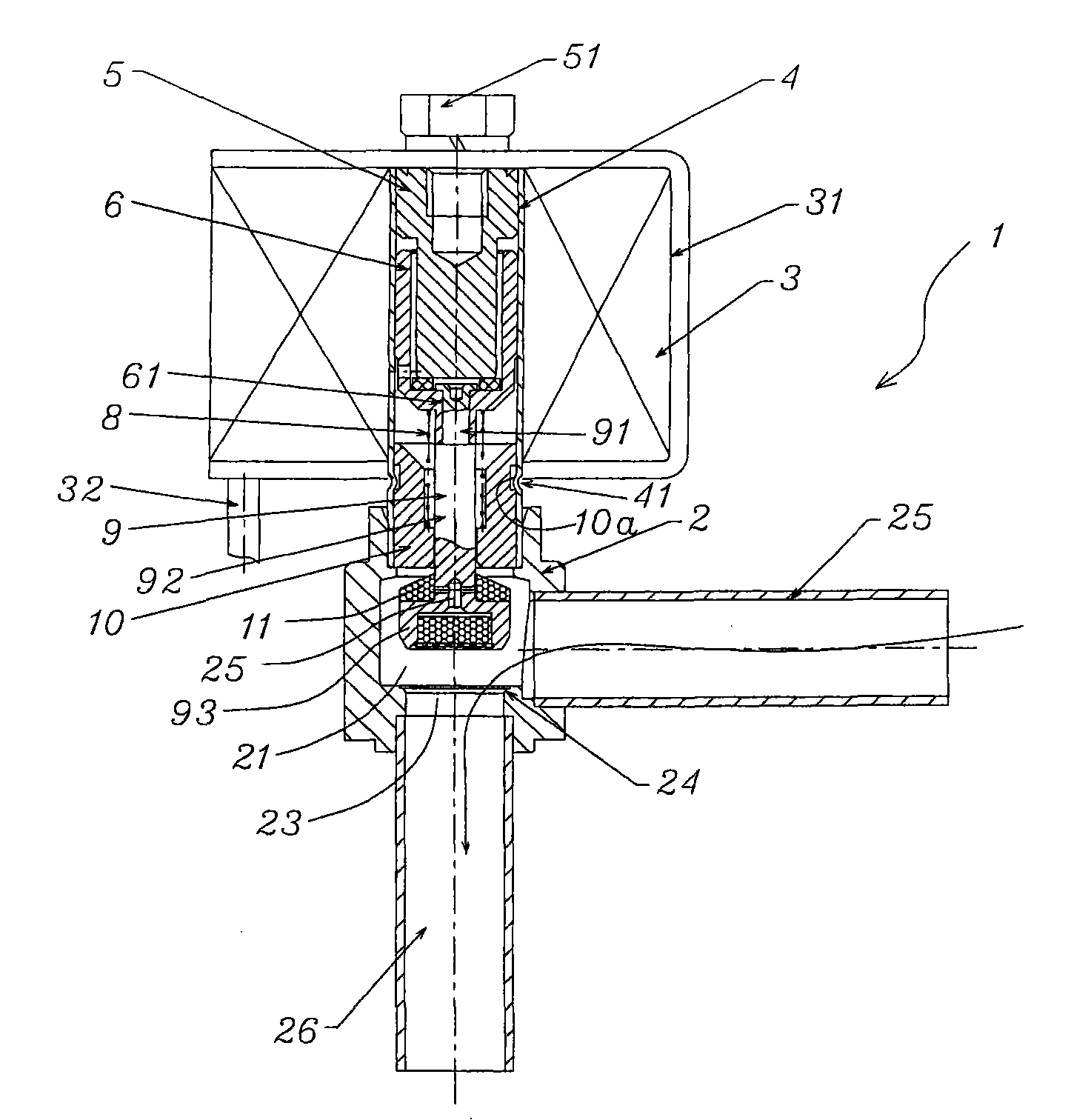

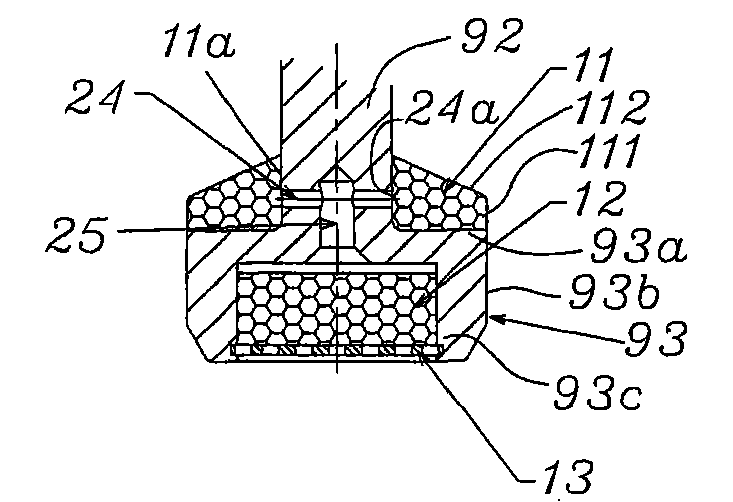

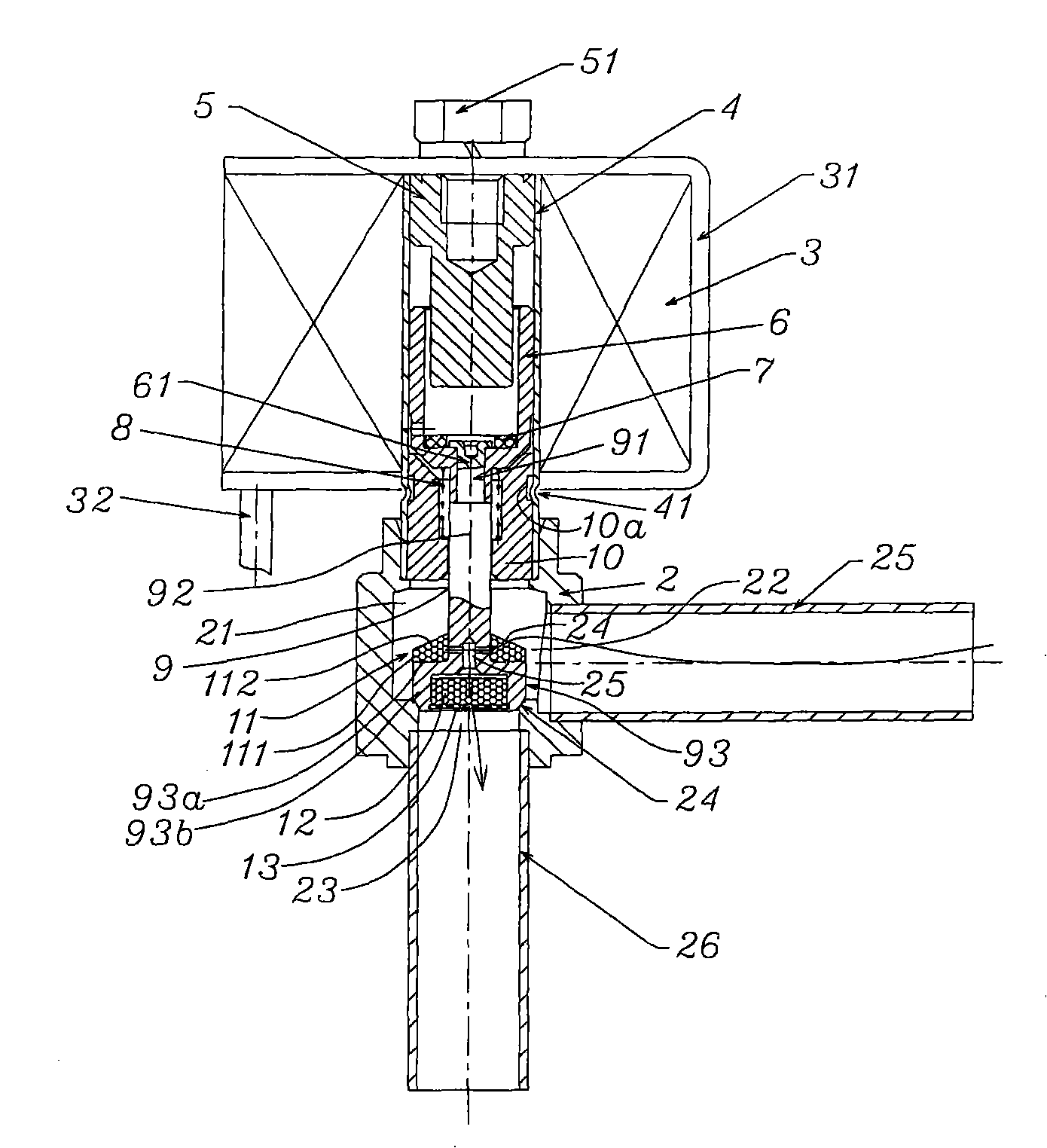

Variable valve timing apparatus

ActiveUS20100095920A1Avoid changeContainment leakValve arrangementsYielding couplingInternal pressureVariable valve timing

A variable valve timing apparatus has a case, a rotor, and a magneto-rheological fluid. The magneto-rheological fluid gives variable braking force to the rotor. The rotor is connected with a phase adjusting mechanism. The phase adjusting mechanism adjusts a phase of an internal combustion engine according to braking force. A sealing device is disposed between the case and the rotor. In one embodiment, the sealing device has a magnet and a plurality of flux guide members. In other embodiment, a diaphragm which acts as a damper mechanism for absorbing an internal pressure change is disposed on a fluid chamber in which the magneto-rheological fluid is kept.

Owner:DENSO CORP

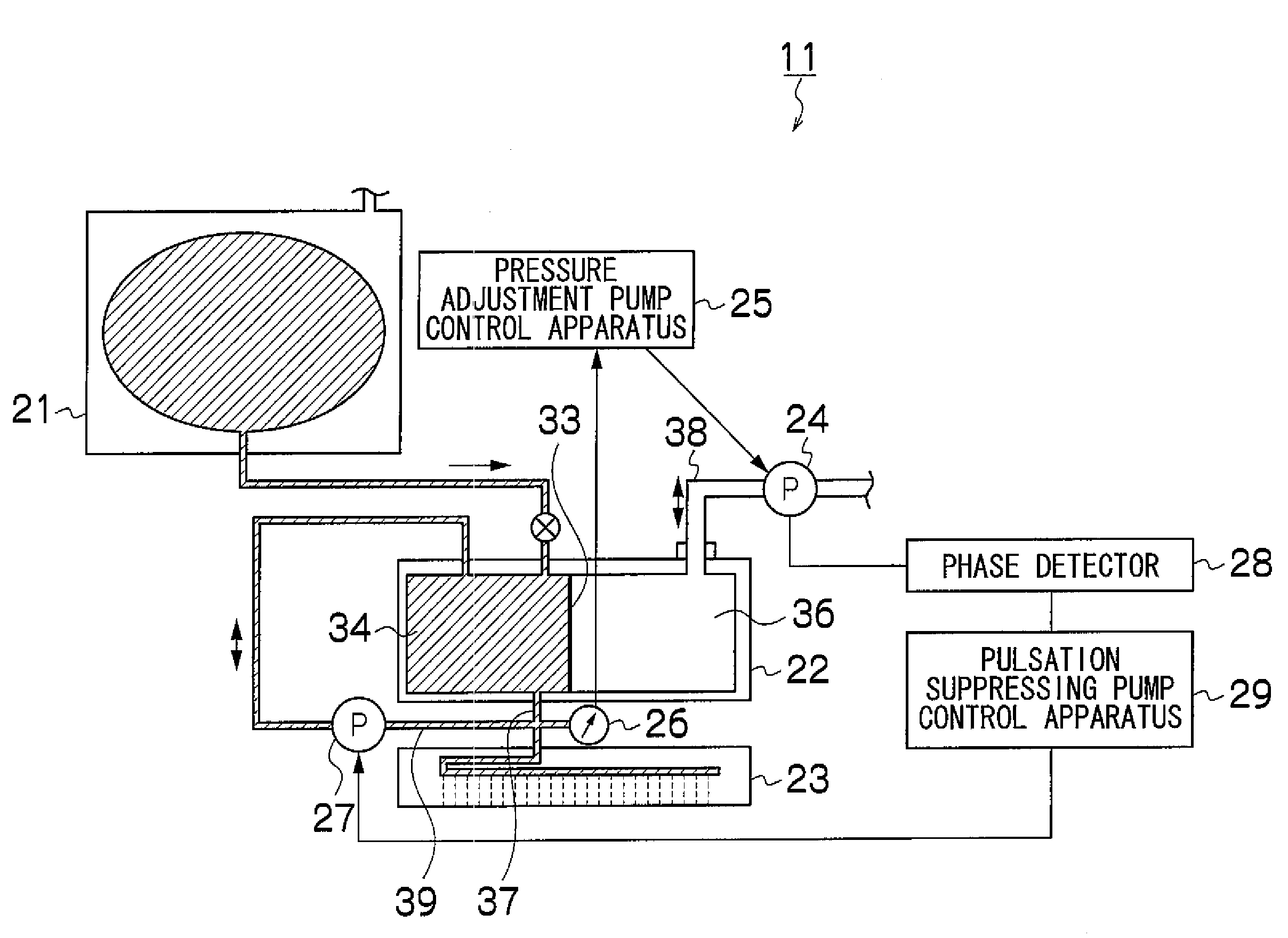

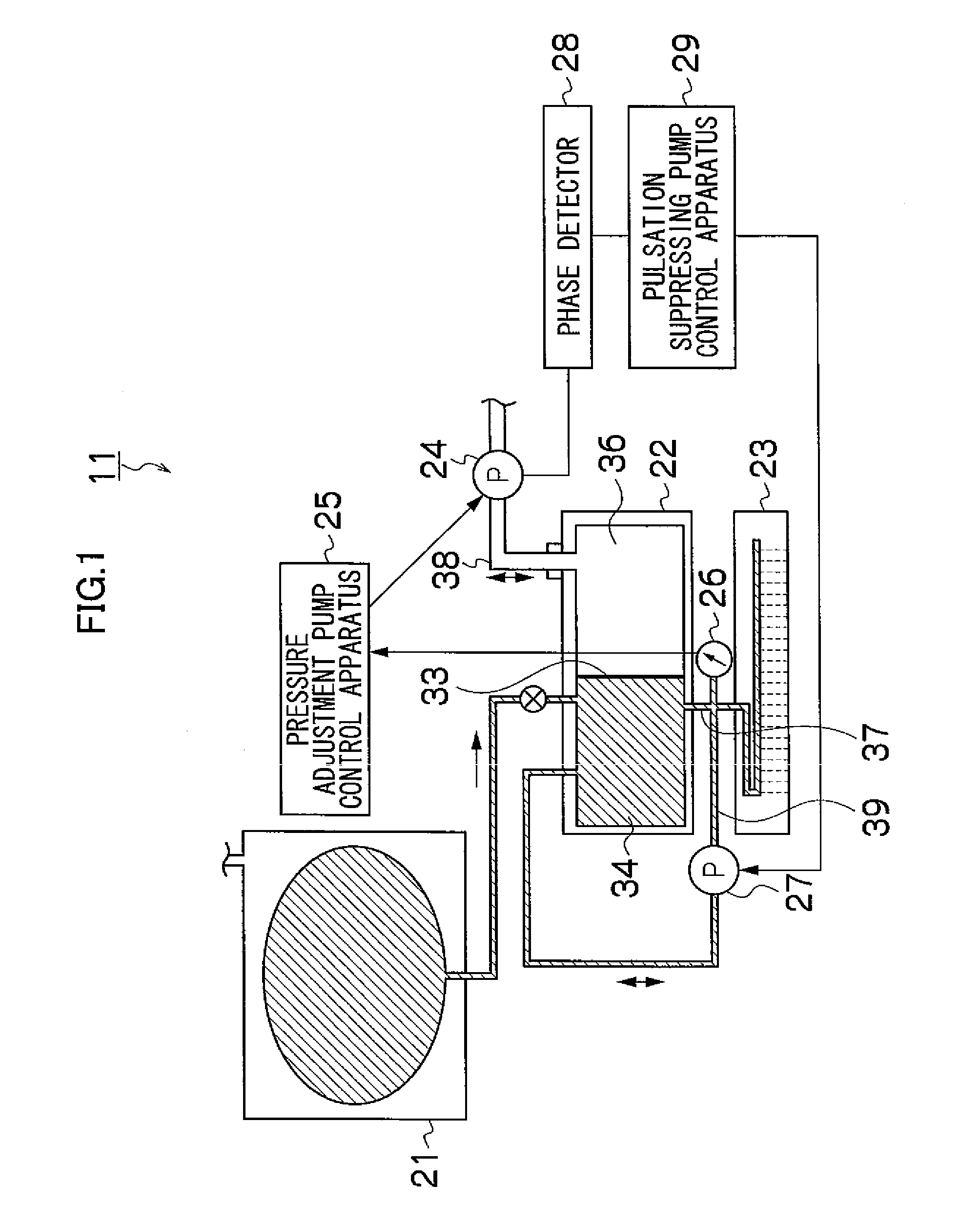

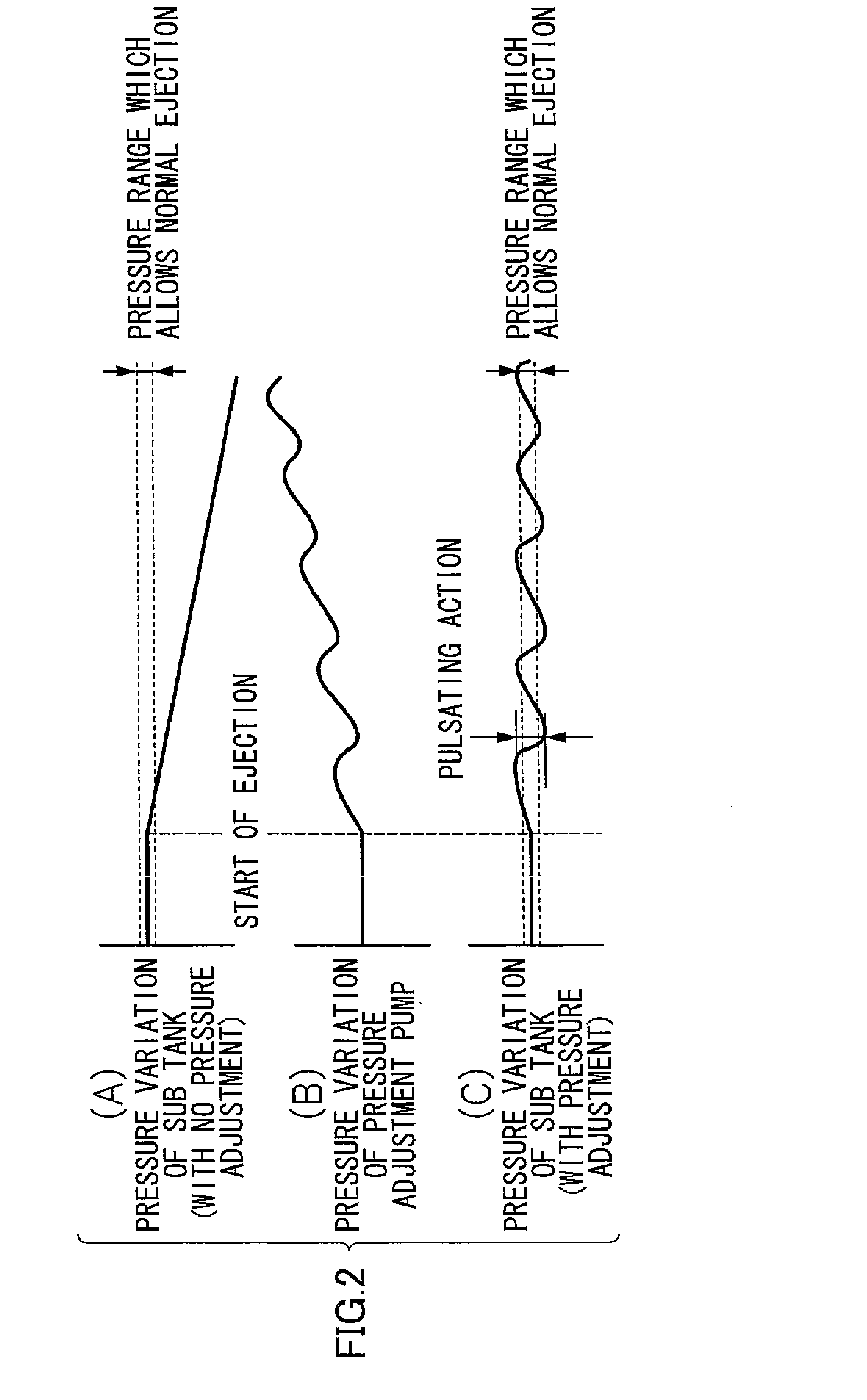

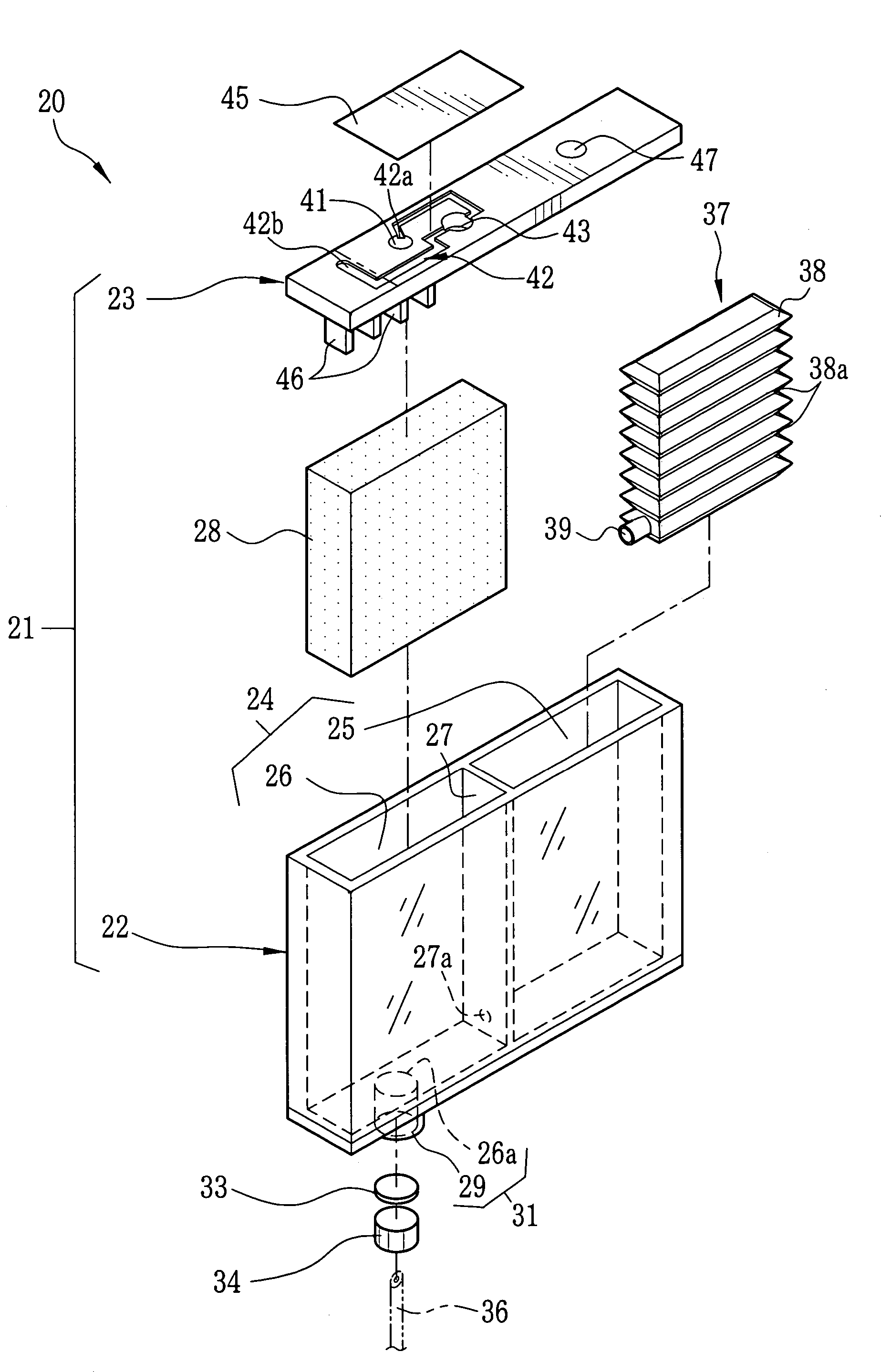

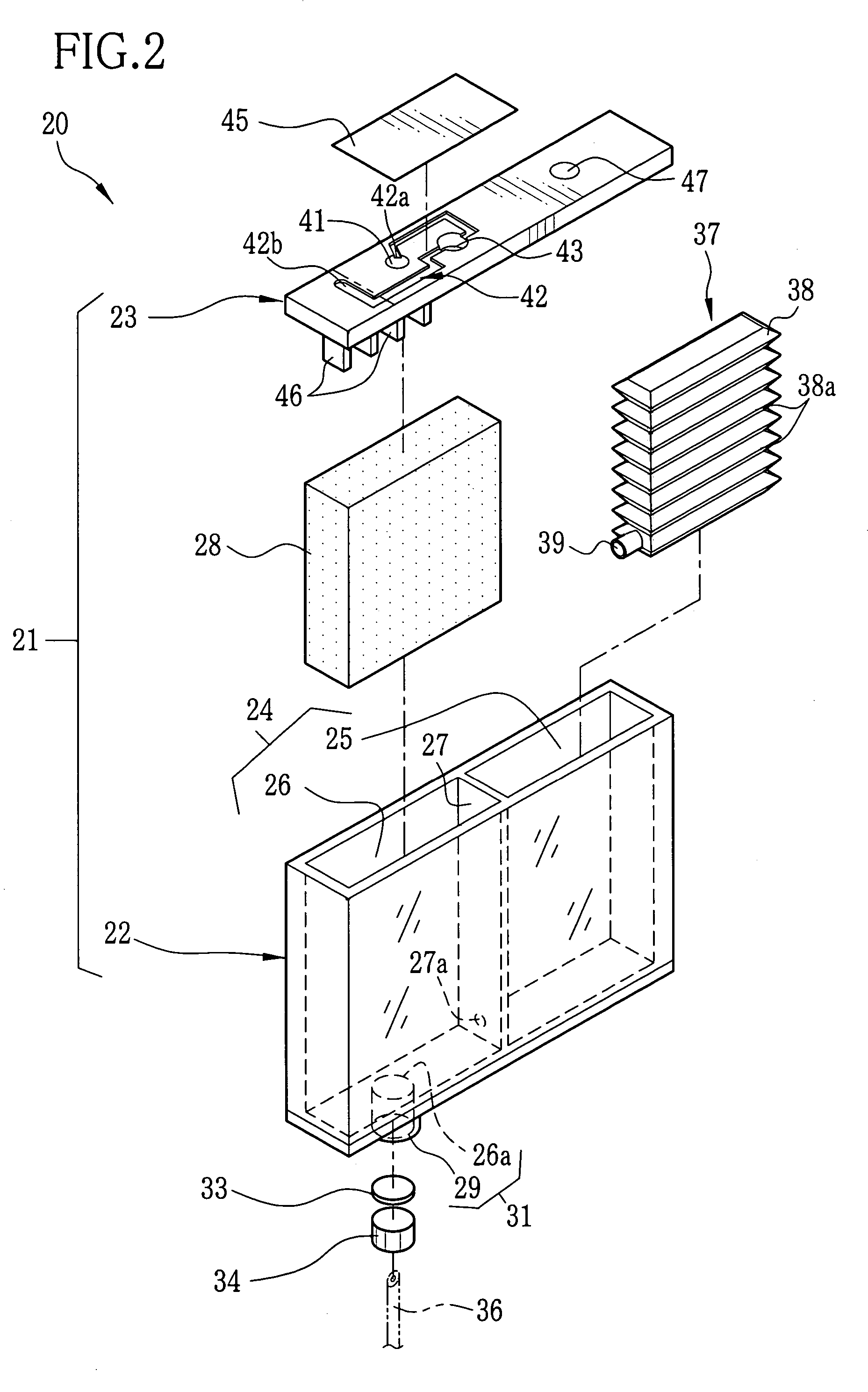

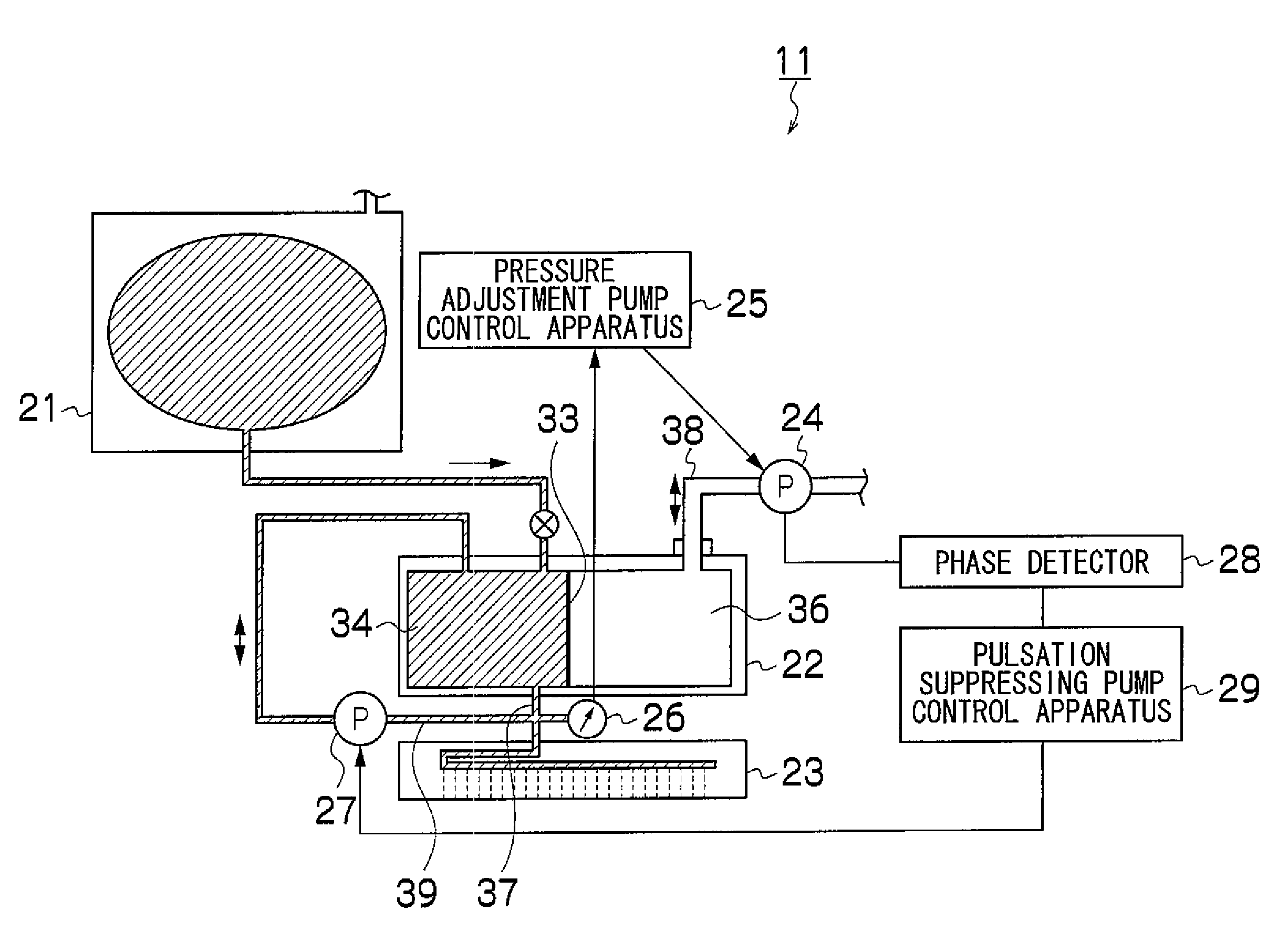

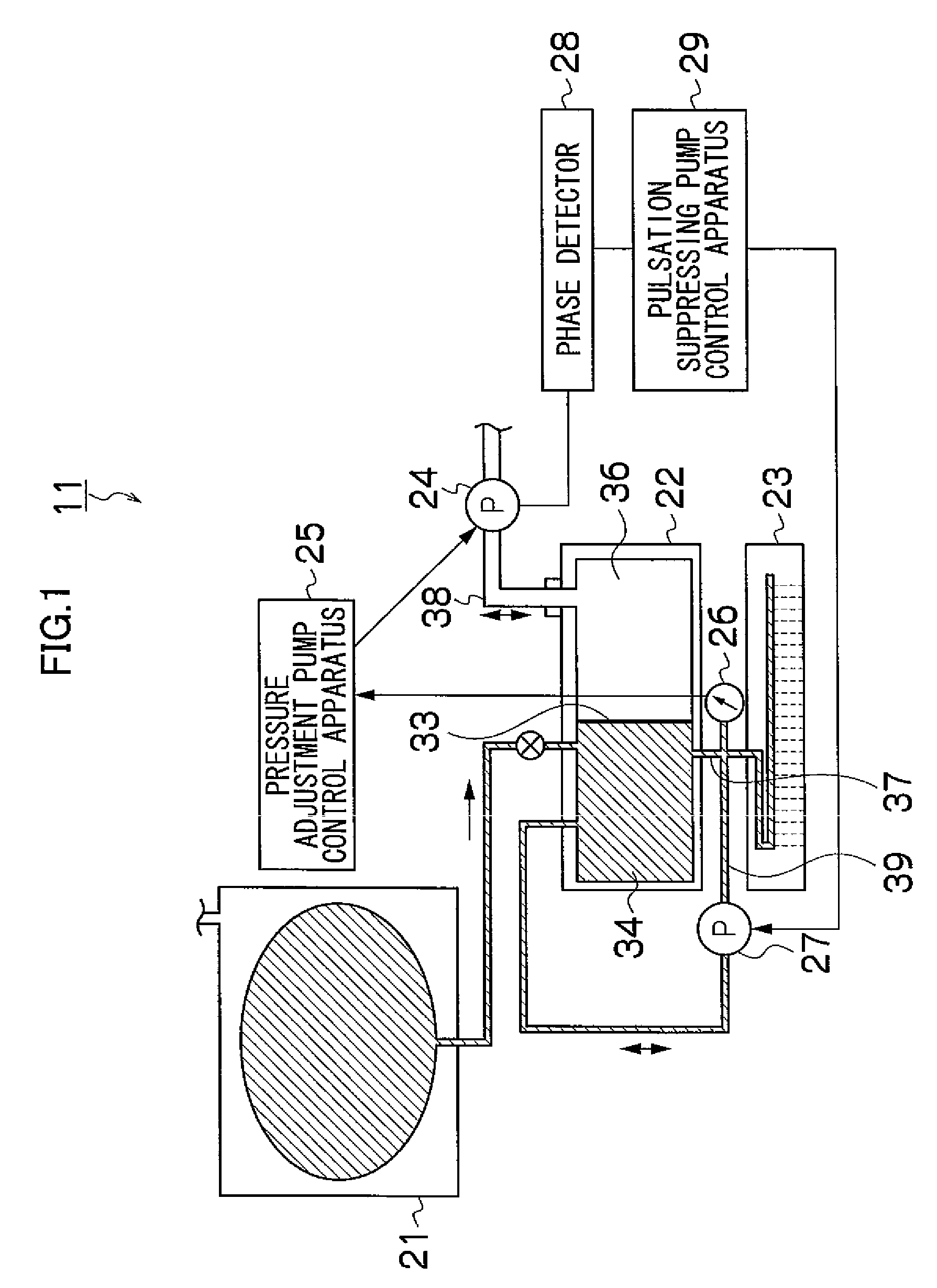

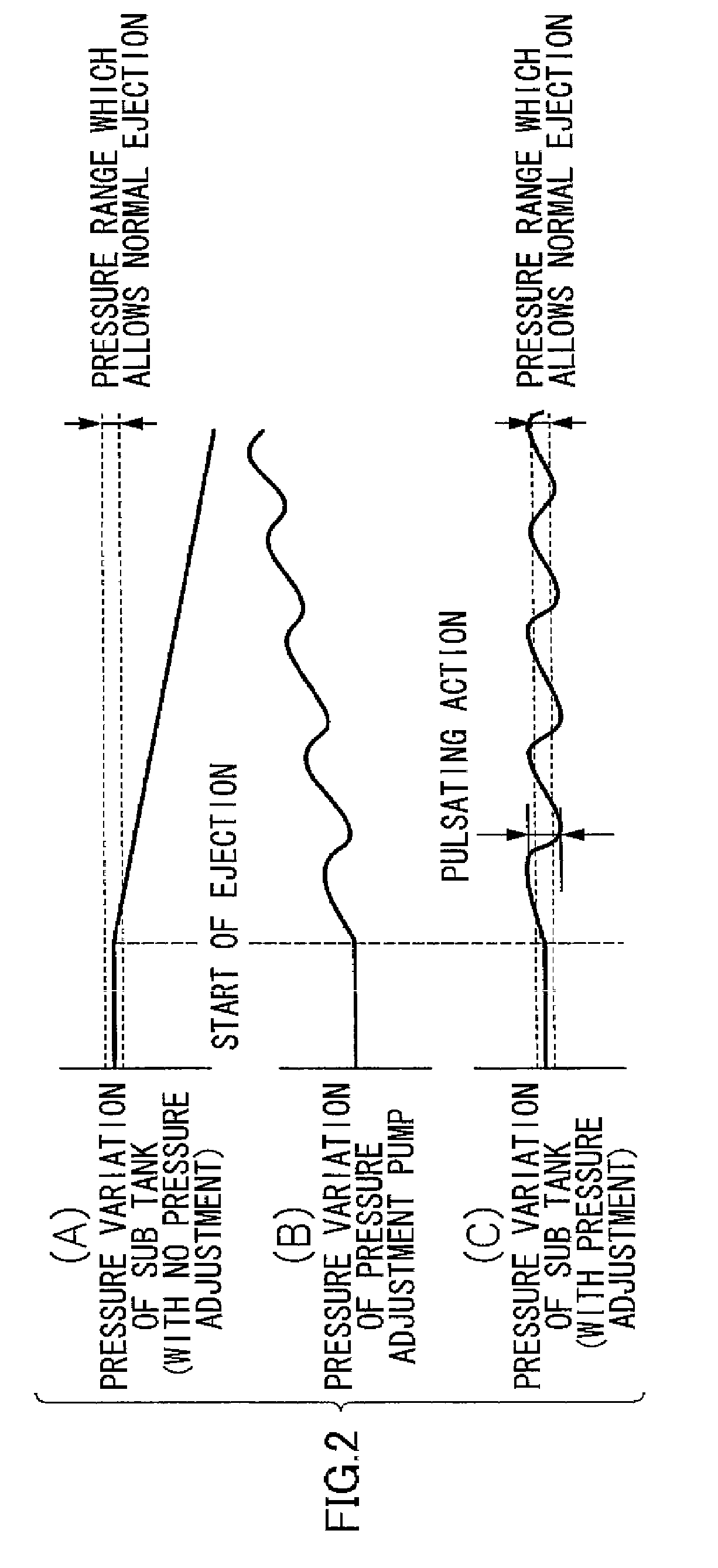

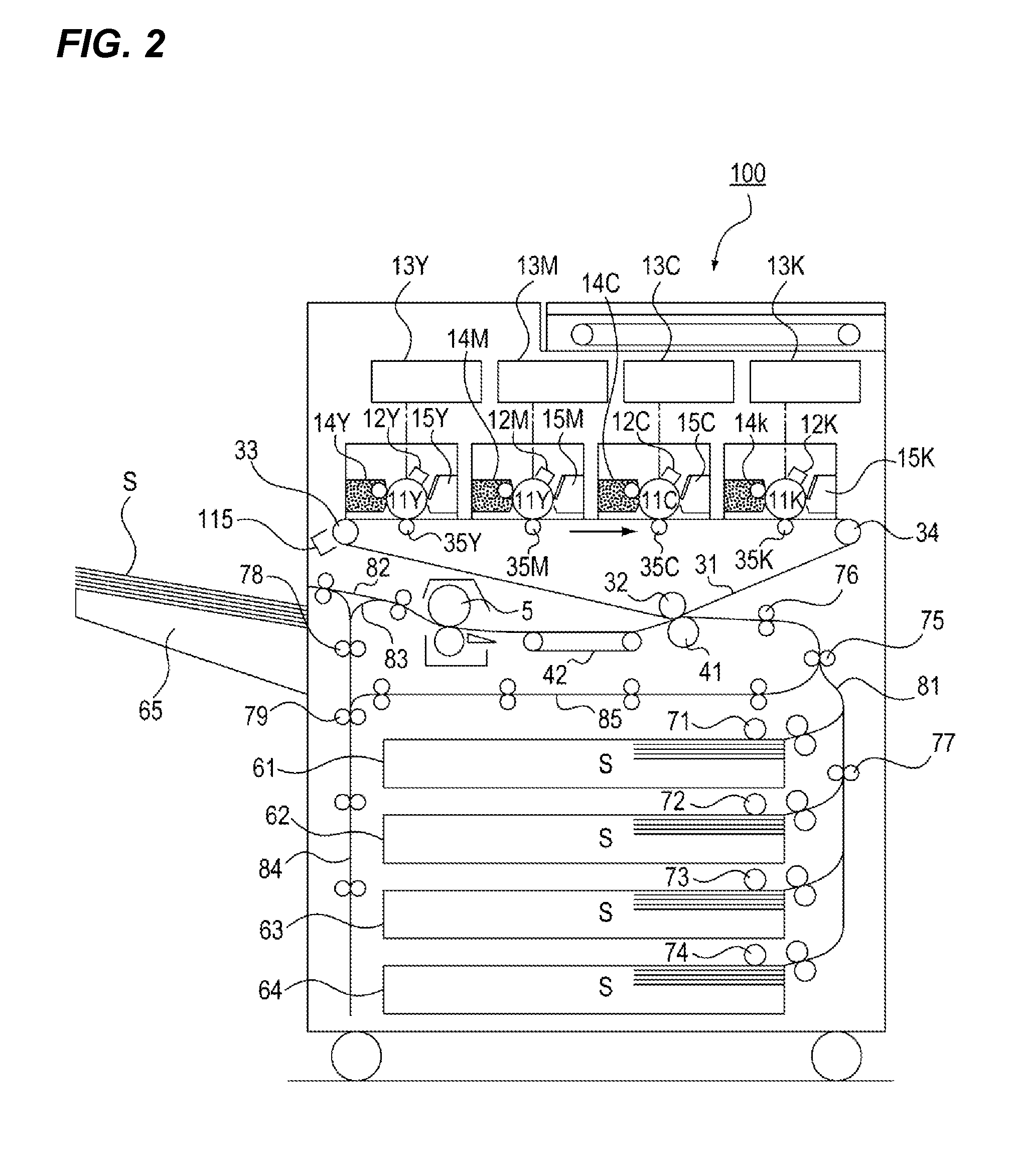

Liquid ejection apparatus and recording apparatus

InactiveUS20080211841A1Suppress pressure variationMaintain responsivenessOther printing apparatusRecording headEngineering

The liquid ejection apparatus includes: a recording head which ejects an ejection liquid; a liquid container which accommodates air and the ejection liquid; a recording head connection flow channel which leads from the liquid container to the recording head; a pressure determination device which determines pressure of the ejection liquid accommodated in the liquid container; a first pressure supply device which drives a rotating body to remove or introduce the air from or to the liquid container so as to keep pressure of the air in the liquid container constant; a phase determination device which determines a phase of the rotating body; a second pressure supply device which is disposed in a pulsation suppressing flow channel that connects the liquid container with the recording head connection flow channel and which removes and introduces the ejection liquid from or to the liquid container; and a control device which controls rotation speed of the second pressure supply device in accordance with the phase of the rotating body determined by the phase determination device so as to cancel out variation of the pressure of the ejection liquid caused by the first pressure supply device.

Owner:FUJIFILM CORP

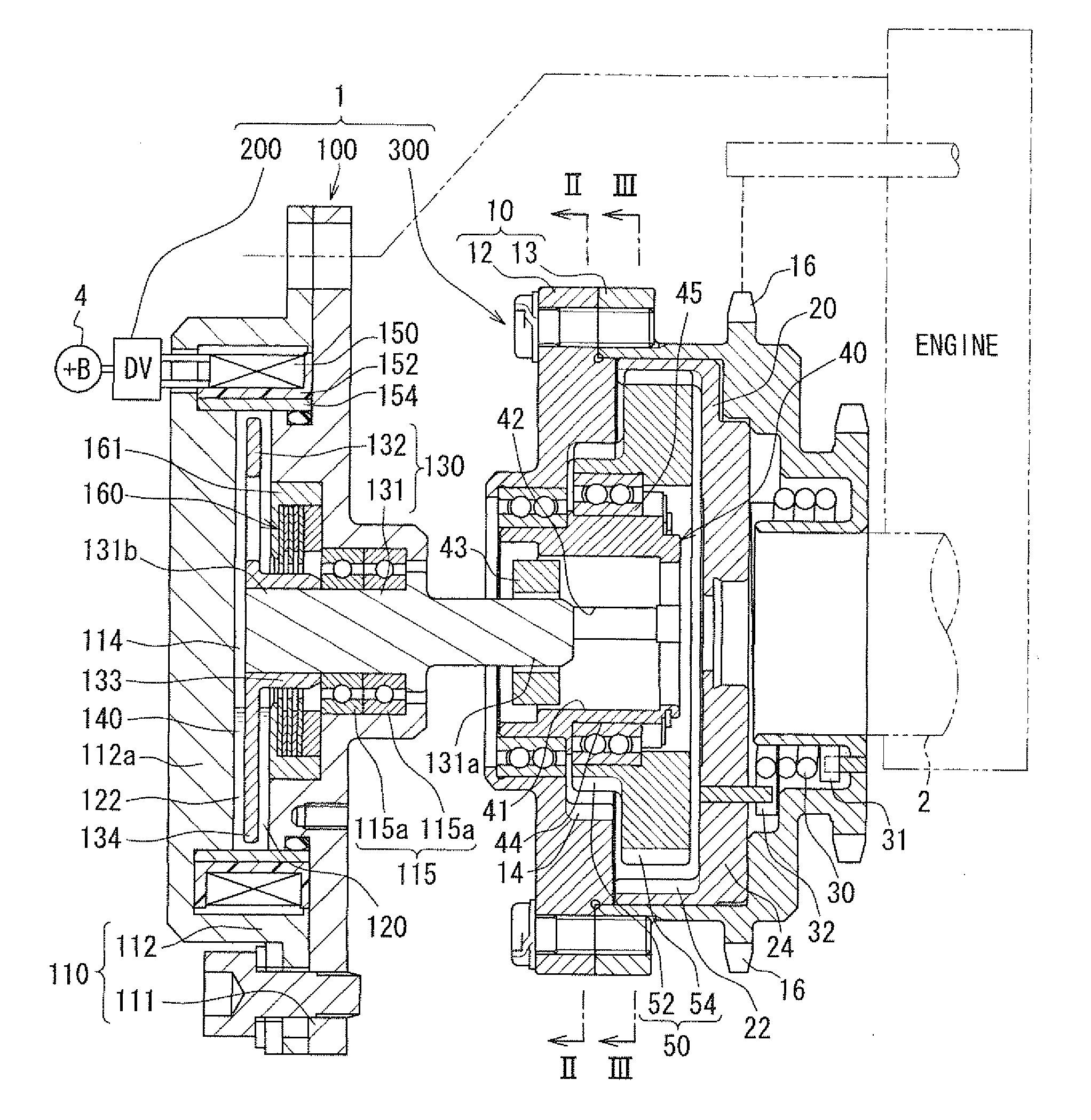

Variable valve timing apparatus

ActiveUS8245679B2Avoid changeContainment leakValve arrangementsYielding couplingInternal pressureVariable valve timing

A variable valve timing apparatus has a case, a rotor, and a magneto-rheological fluid. The magneto-rheological fluid gives variable braking force to the rotor. The rotor is connected with a phase adjusting mechanism. The phase adjusting mechanism adjusts a phase of an internal combustion engine according to braking force. A sealing device is disposed between the case and the rotor. In one embodiment, the sealing device has a magnet and a plurality of flux guide members. In other embodiment, a diaphragm which acts as a damper mechanism for absorbing an internal pressure change is disposed on a fluid chamber in which the magneto-rheological fluid is kept.

Owner:DENSO CORP

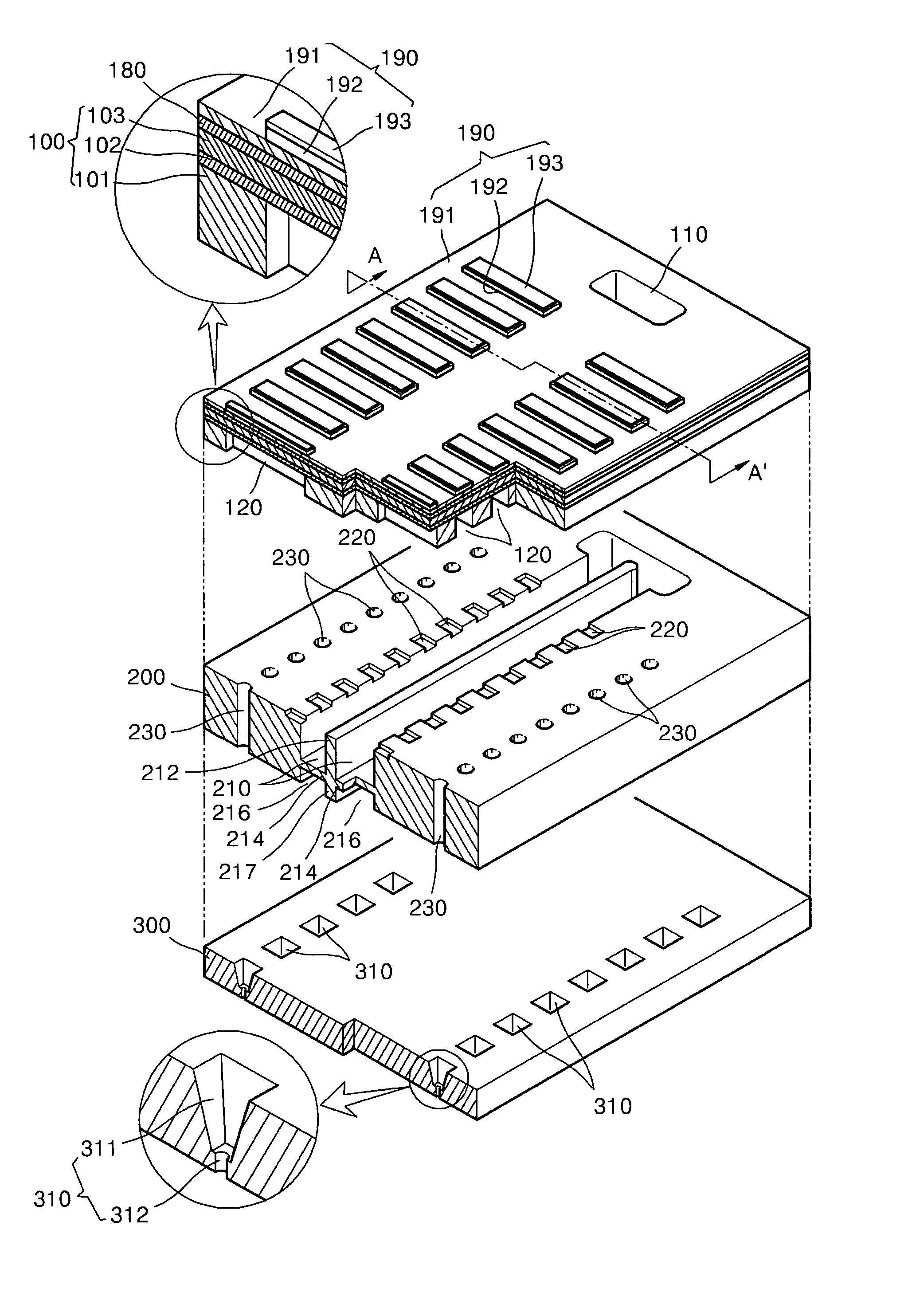

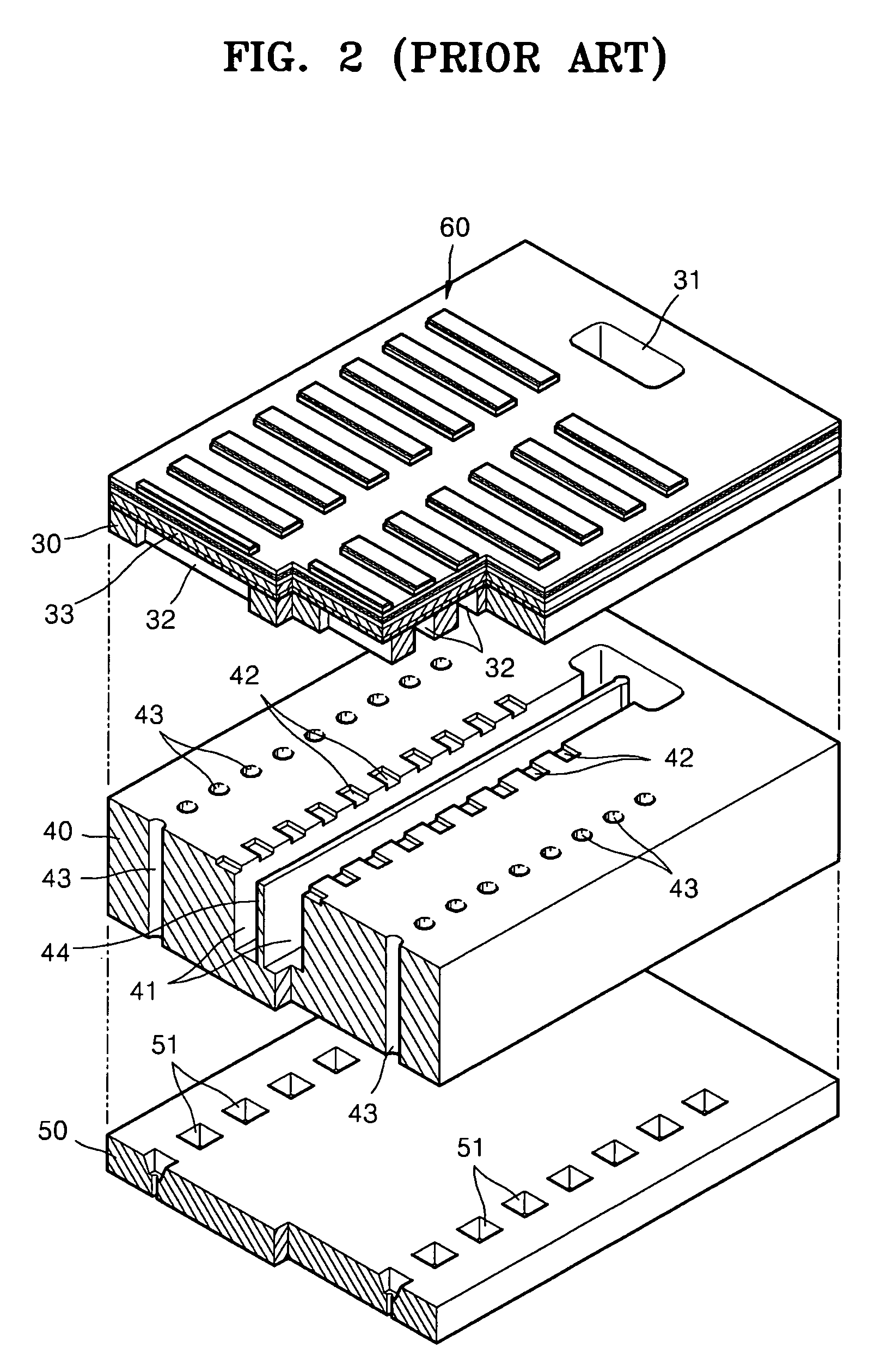

Piezoelectric inkjet printhead and method of manufacturing the same

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

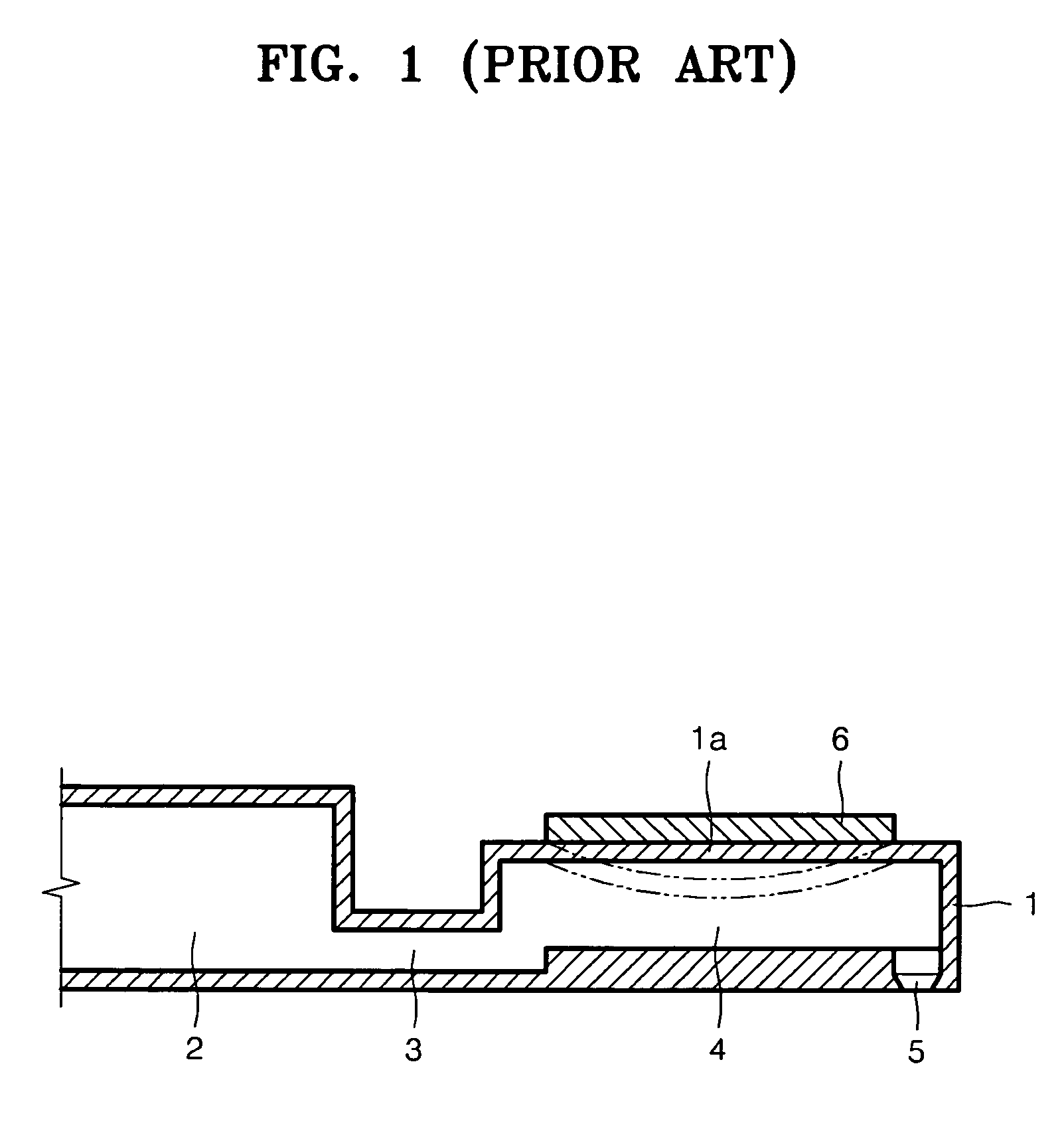

Ink container and ink jet recording apparatus

An ink cartridge is partitioned into a negative pressure generator chamber containing a negative pressure generator and a storage chamber containing an ink bag. The ink bag stores ink and supplies the ink to the negative pressure generator chamber through an ink port. The negative pressure generator absorbs and holds the ink by its capillary force, to keep pressure inside nozzles of a recording head negative to atmospheric pressure. Through a first air introduction hole, the air is introduced into the negative pressure generator chamber as the ink in the negative pressure generator chamber decreases. Through a second air introduction hole, the air is introduced into the storage chamber as the ink in the ink bag decreases. So variations in pressure inside the nozzles are suppressed, which makes ink discharge from the nozzles stable.

Owner:FUJIFILM CORP

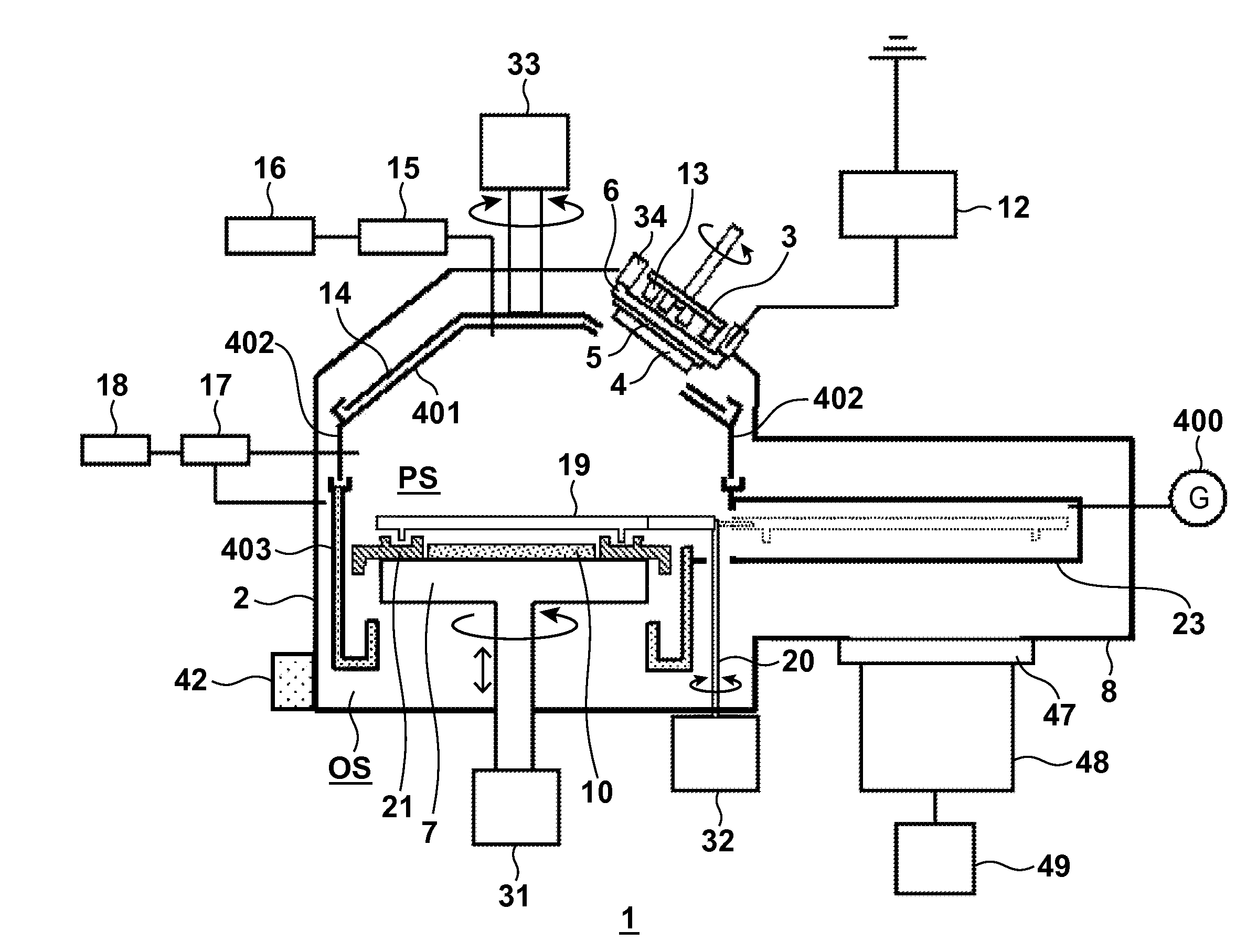

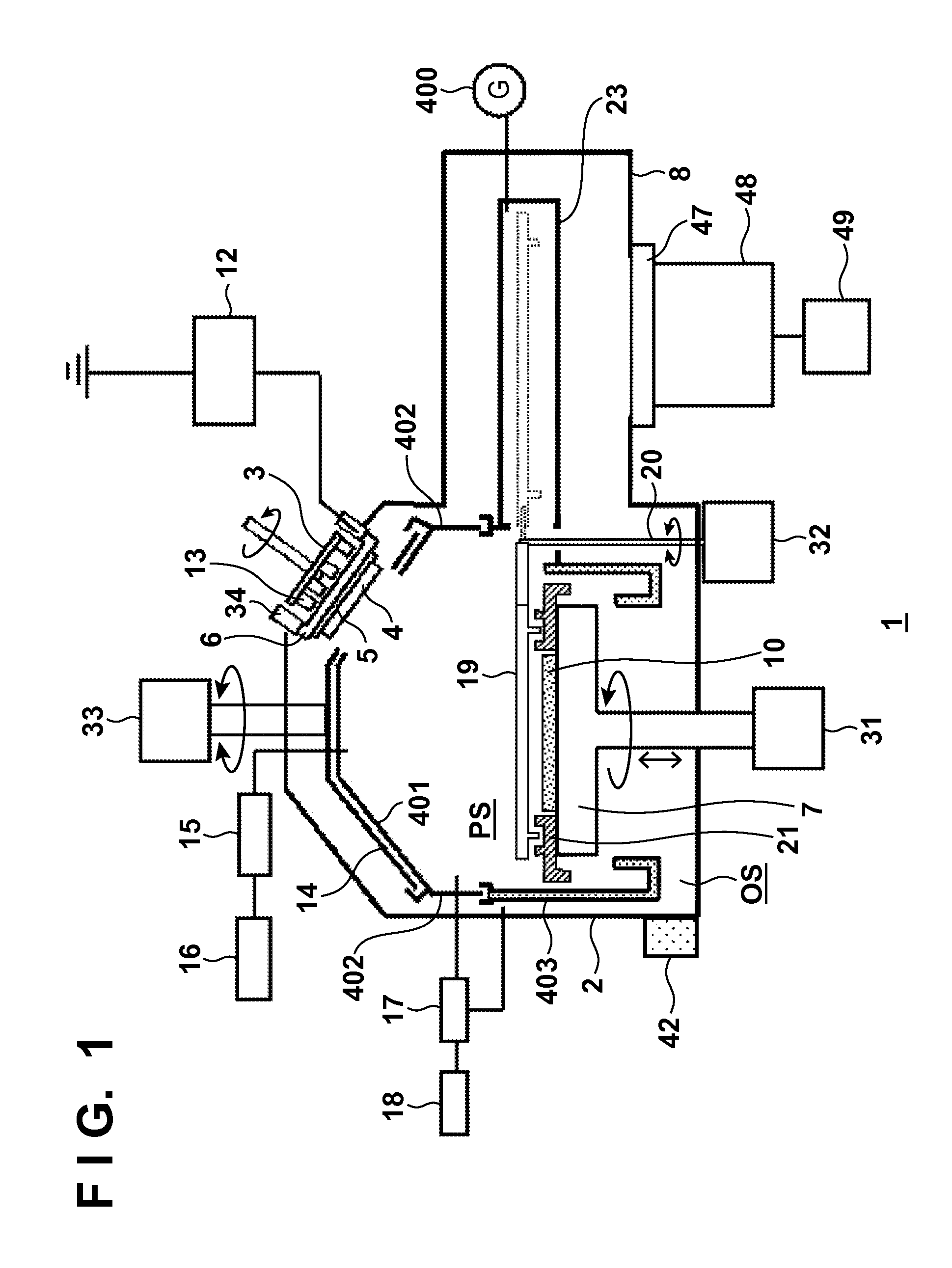

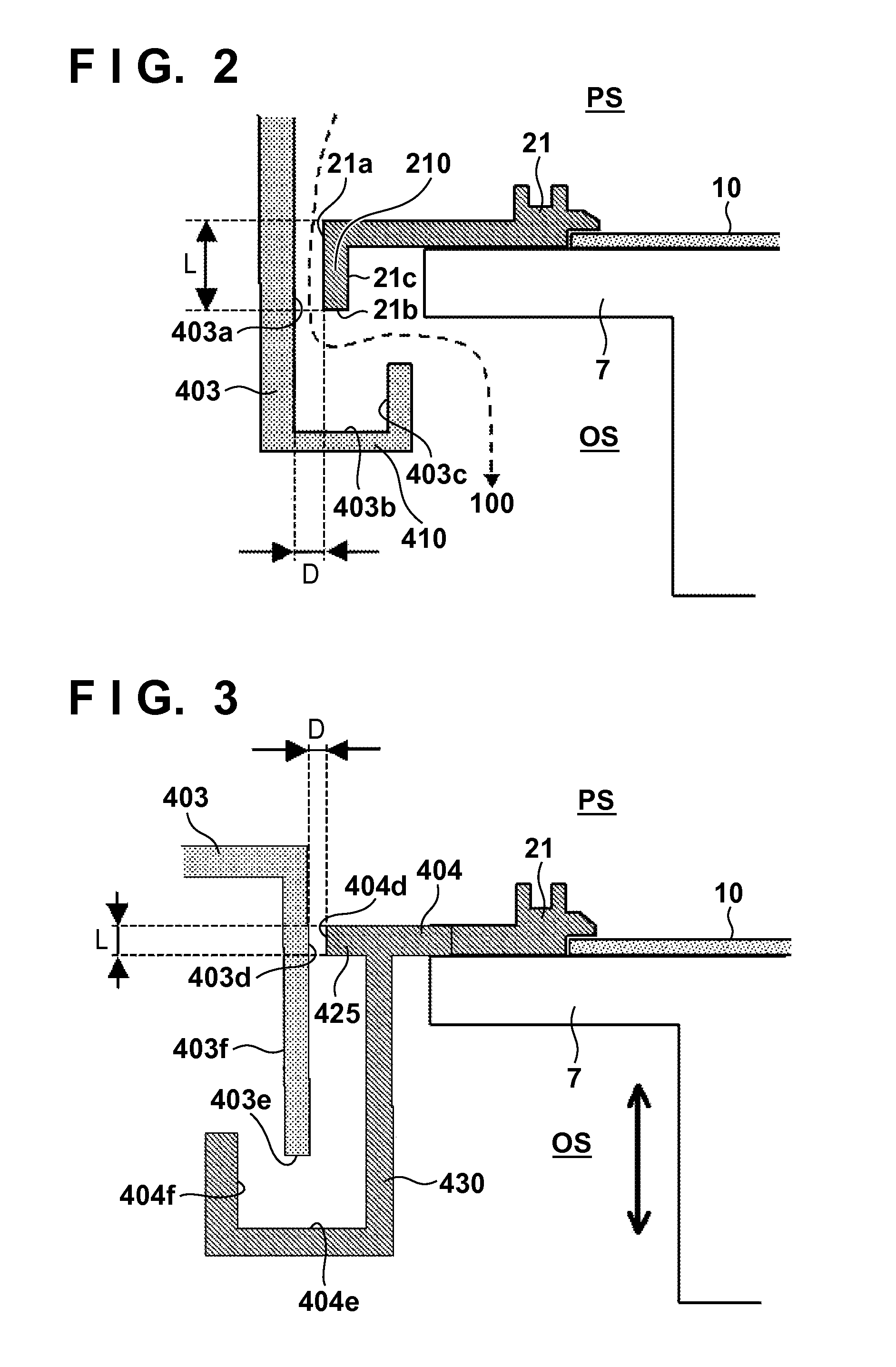

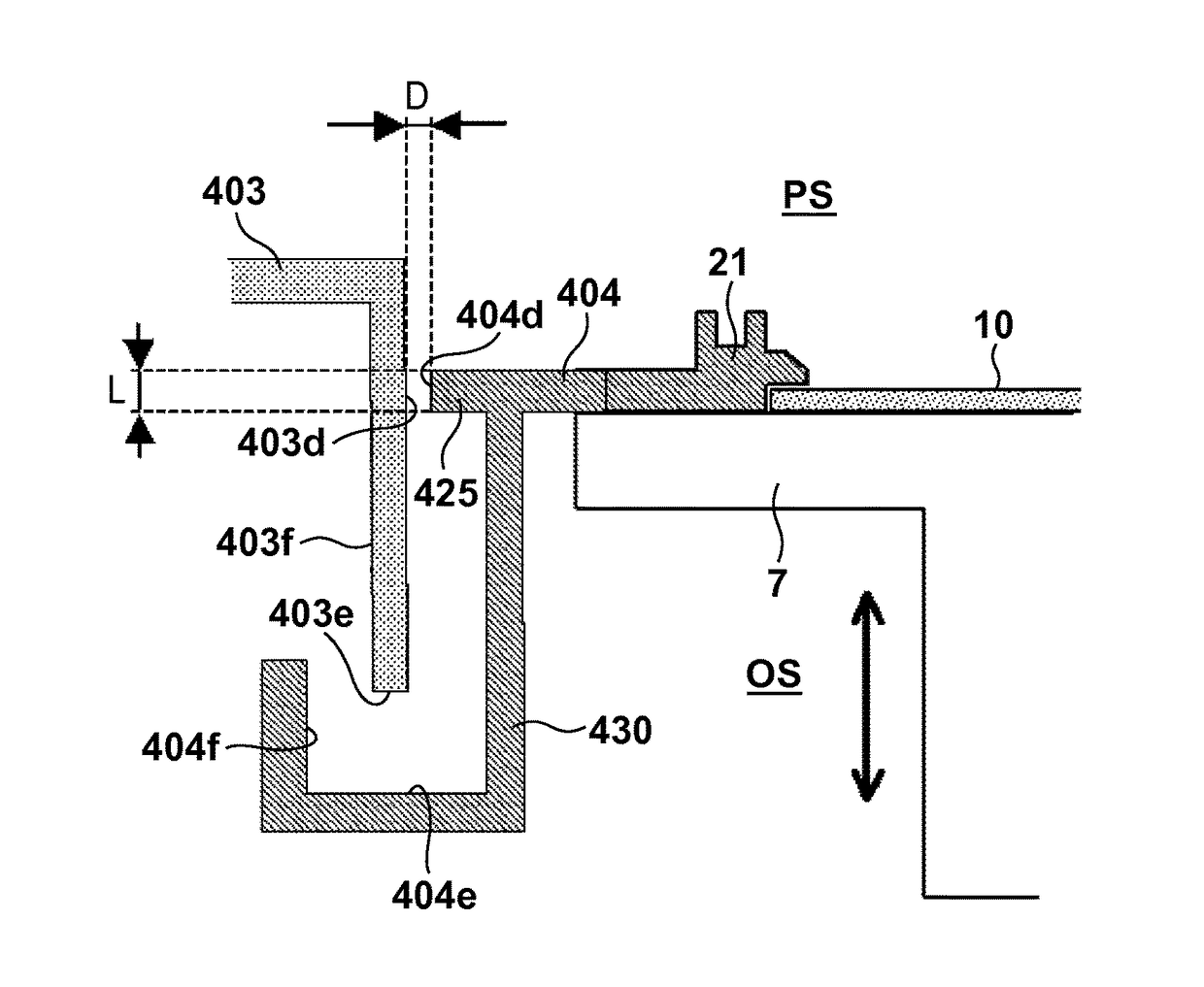

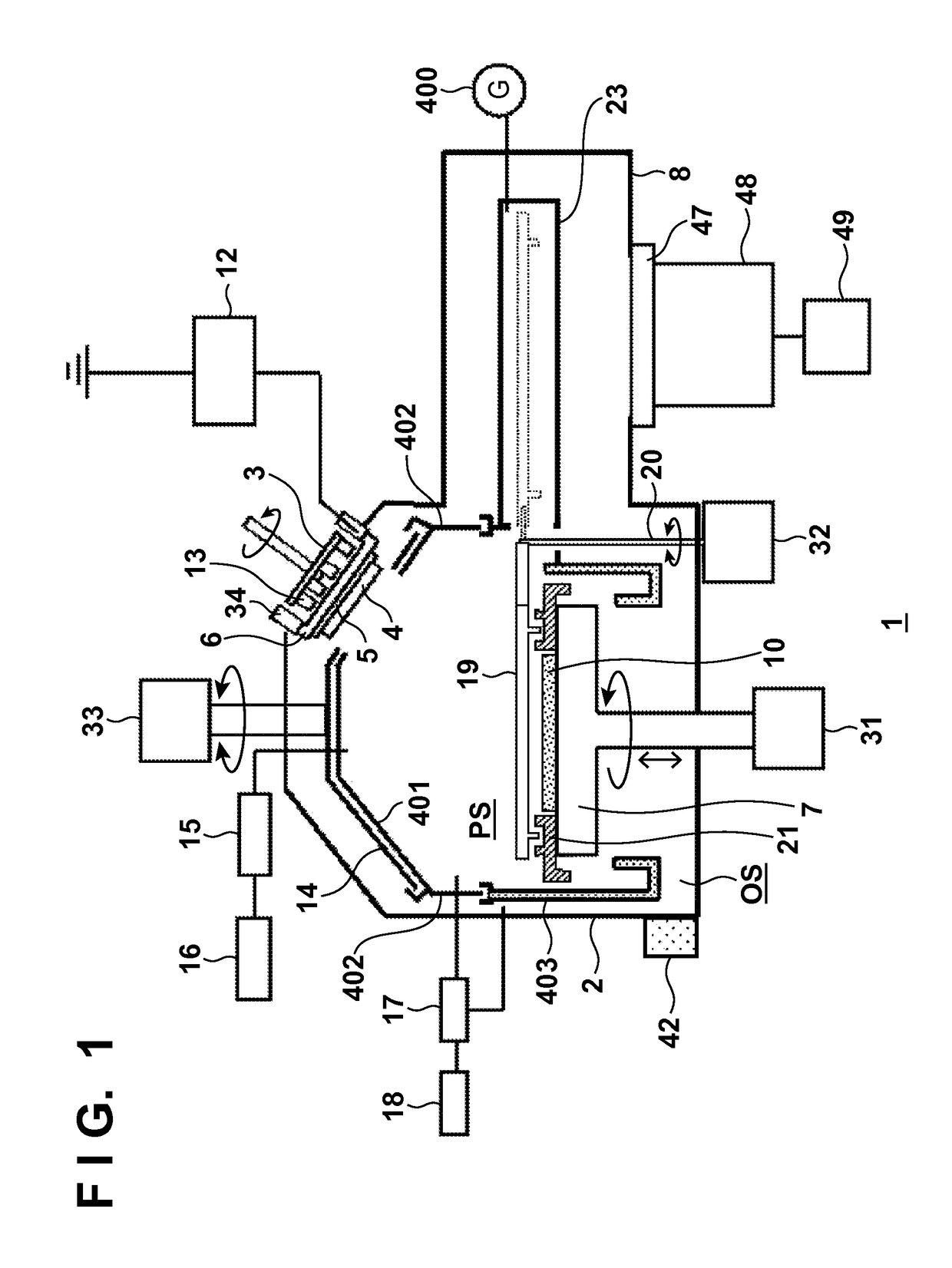

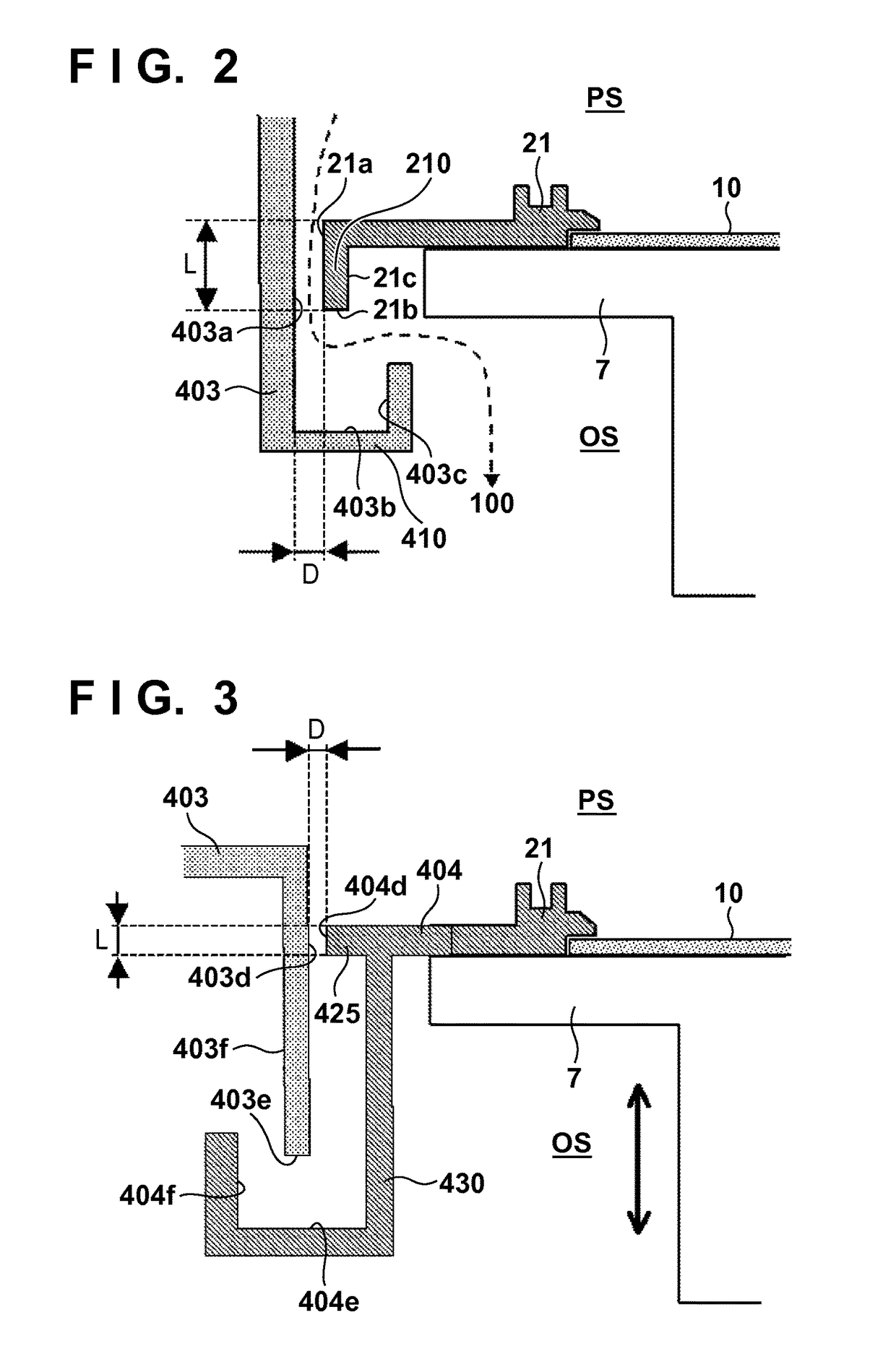

Substrate processing apparatus

ActiveUS20150294845A1Suppress pressure changesHigh-quality thin filmCellsElectric discharge tubesEngineeringOuter space

An apparatus includes a process chamber, a substrate holder arranged in the process chamber, a first shield provided on the peripheral portion of the substrate holder, and a second shield provided inside the process chamber. The internal space of the process chamber is partitioned into an outer space and a process space to process the substrate, by at least the first shield, the second shield, and the substrate holder. The substrate holder can be driven along a driving direction perpendicular to a substrate holding surface. The length, in a direction parallel to the driving direction, of a minimum gap portion having a minimum size in a direction perpendicular to the driving direction between the first and second shields does not change even if the substrate holder is driven in the driving direction.

Owner:CANON ANELVA CORP

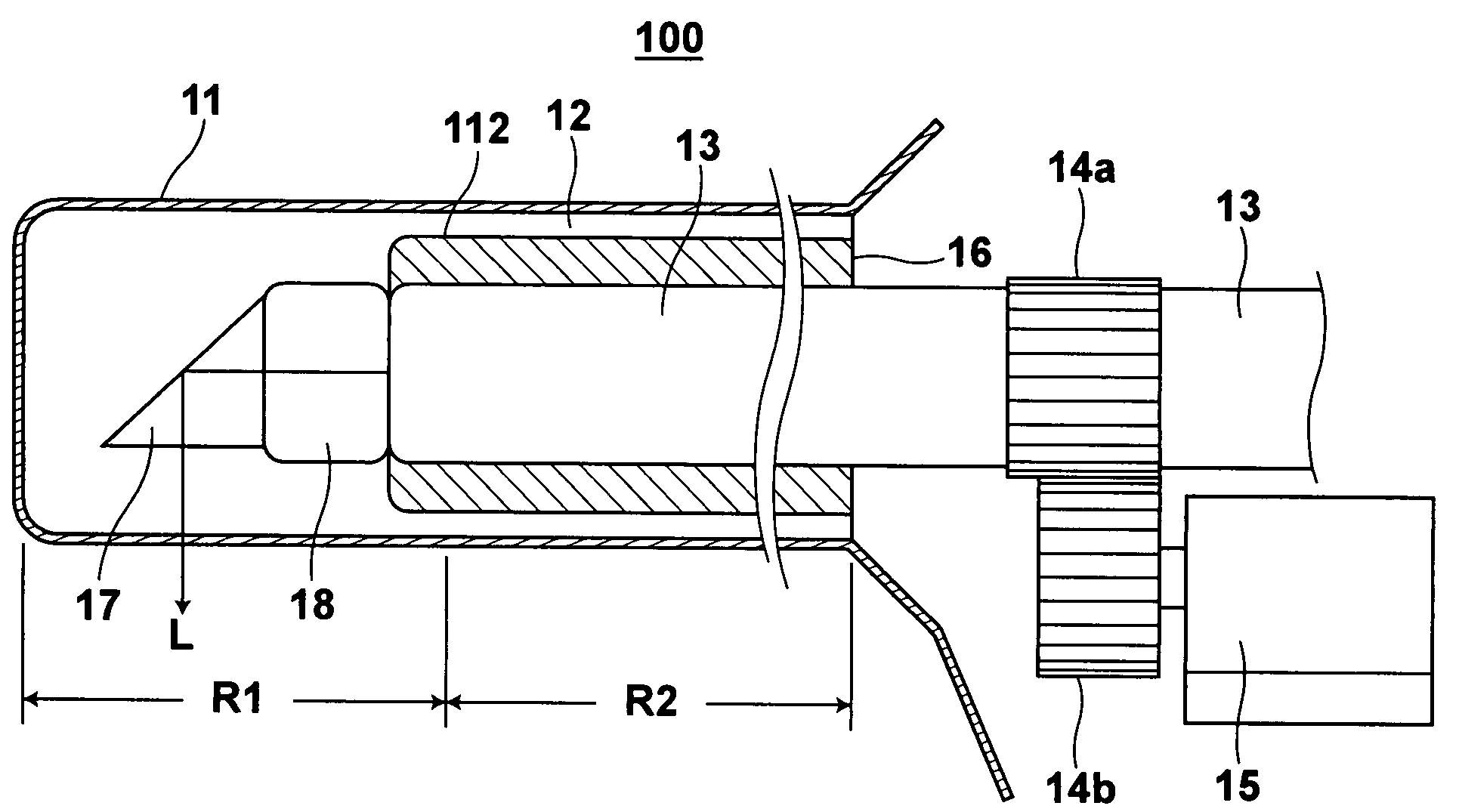

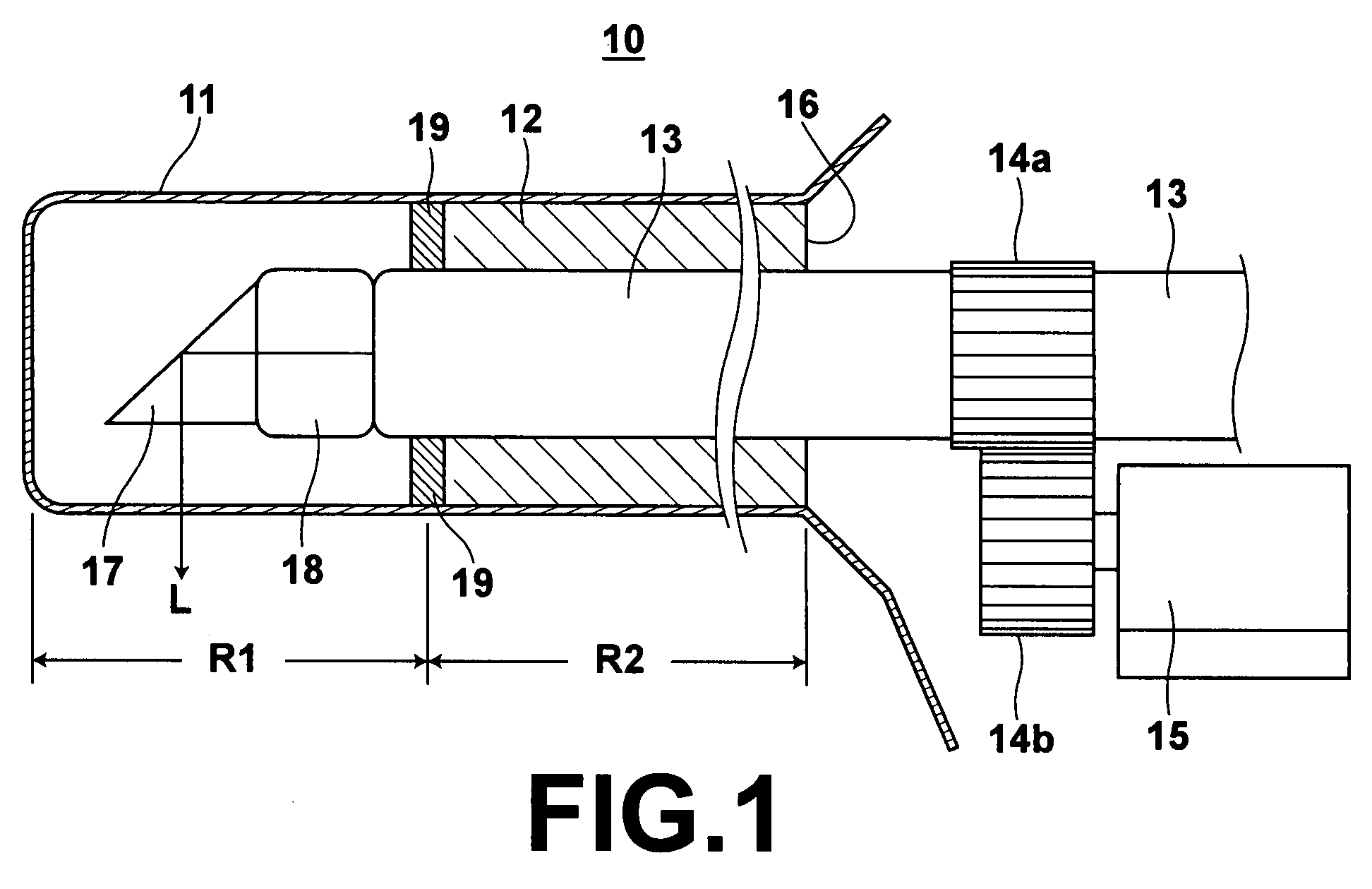

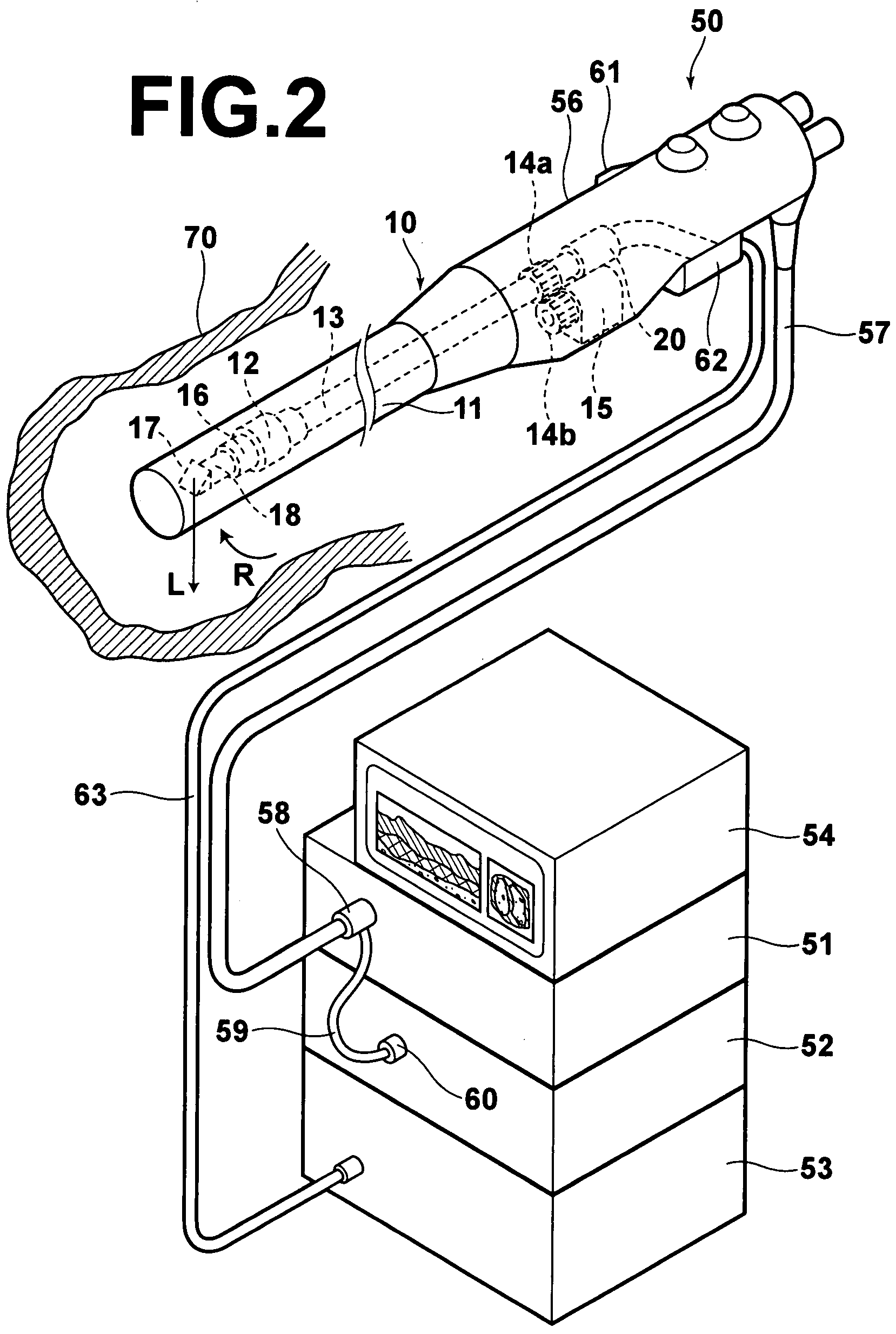

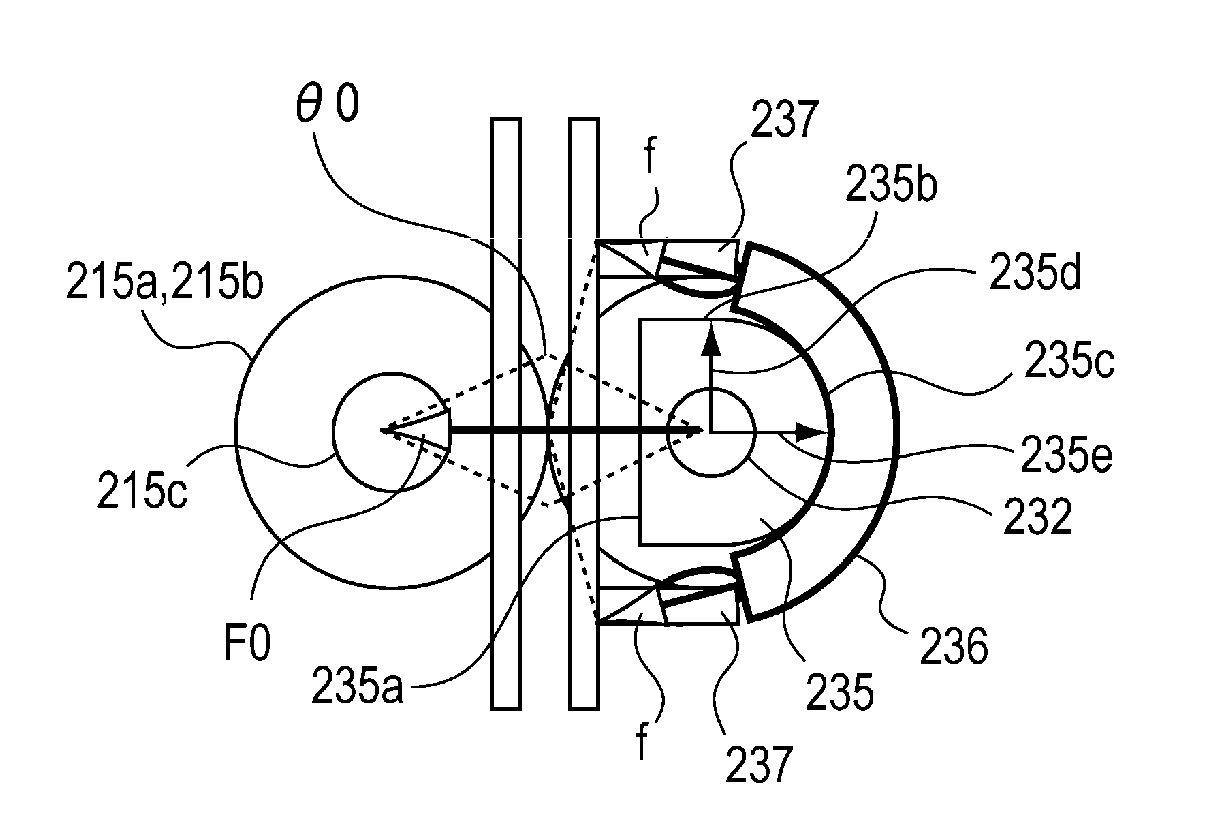

Probe and optical tomography system

InactiveUS7551817B2Suppress deterioration in measuring accuracyLarge heat capacityCatheterDiagnostic recording/measuringOptical tomographyPhysics

An optical fiber is disposed in the direction of axis of the outer envelope inside a tubular outer envelope. Light emitted from the front end of the optical fiber is collected and projected on a body-to-be-scanned disposed externally of the outer envelope, and converged on the body-to-be-scanned. The outer envelope is filled with liquid so that the optical fiber is in the liquid.

Owner:FUJIFILM CORP

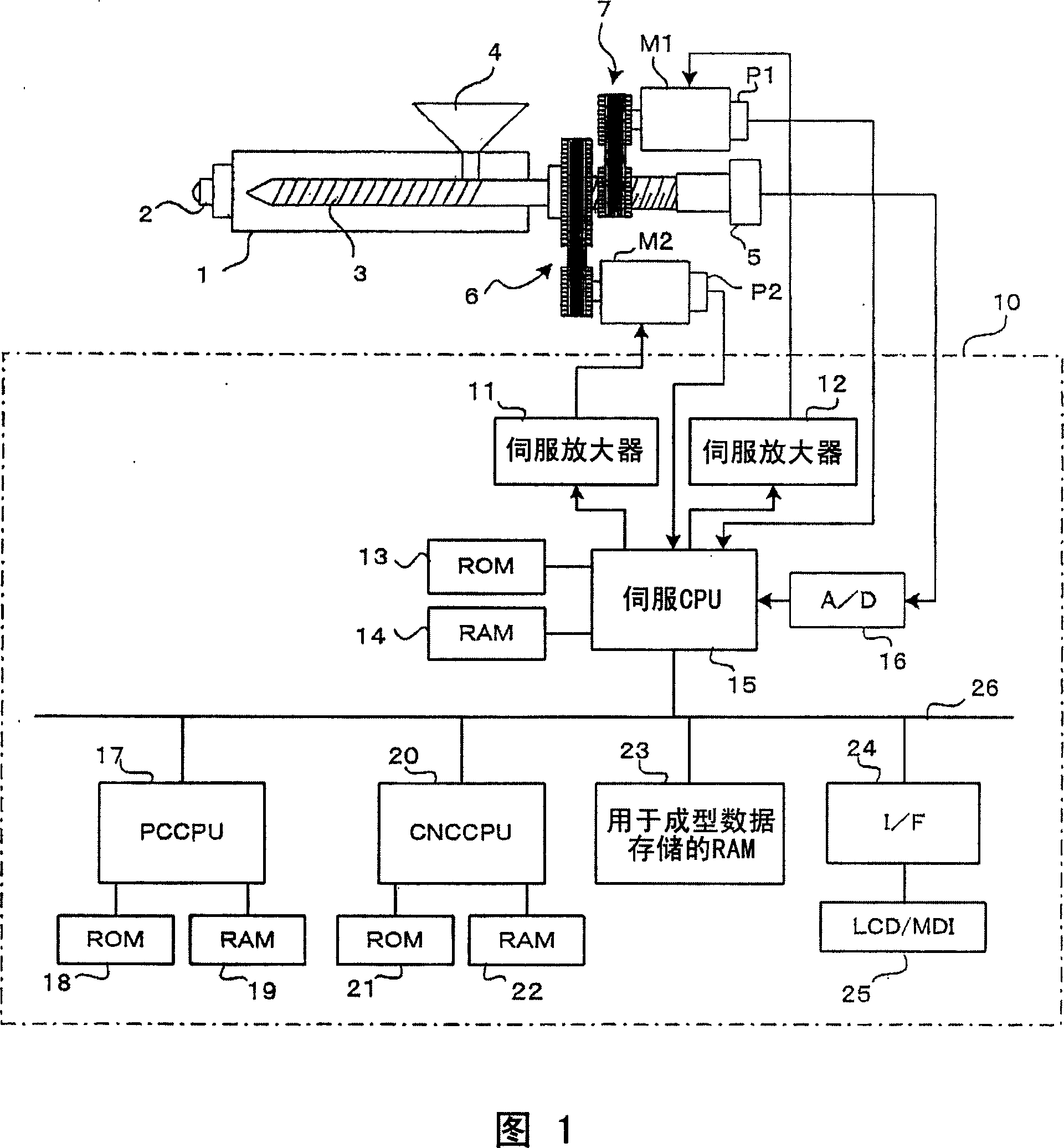

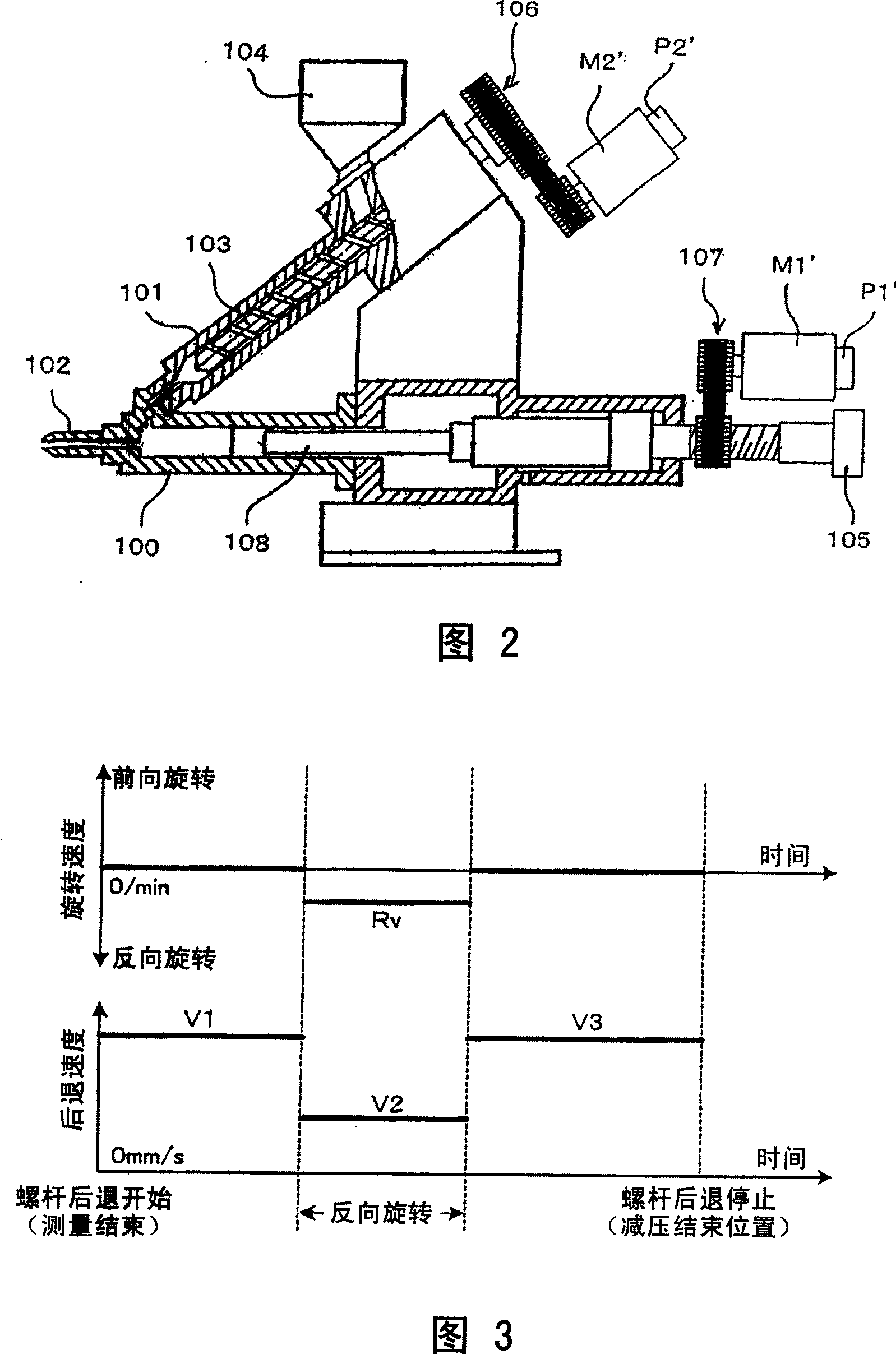

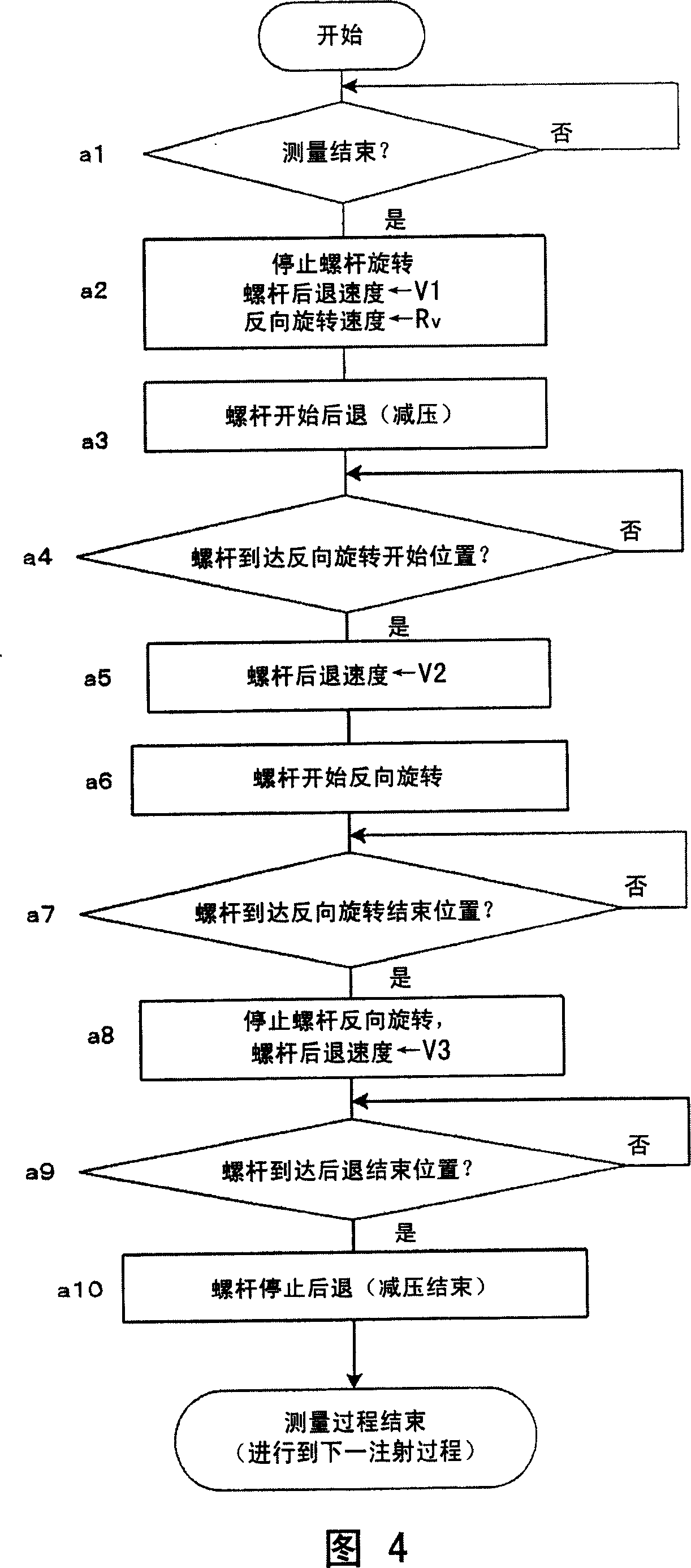

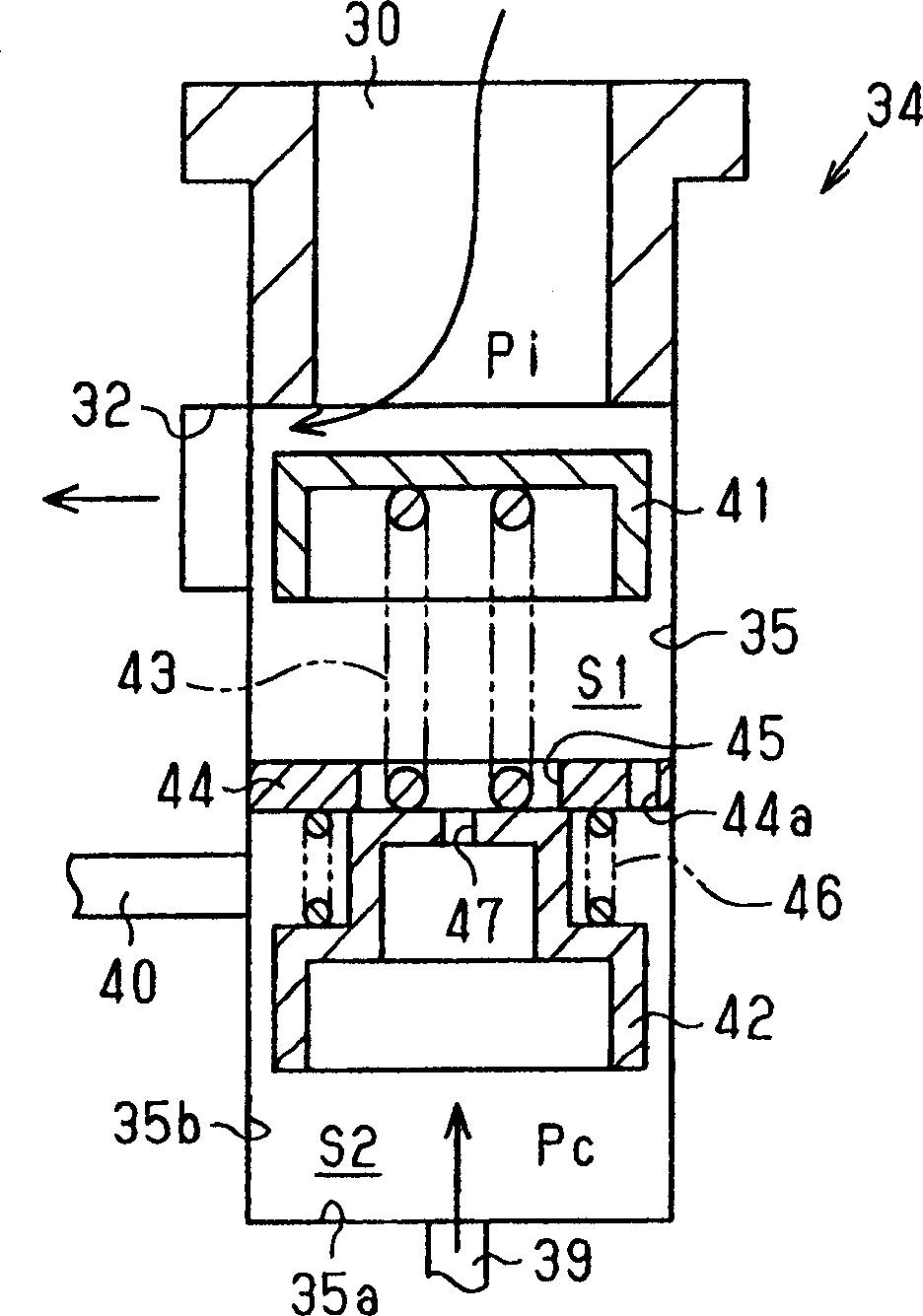

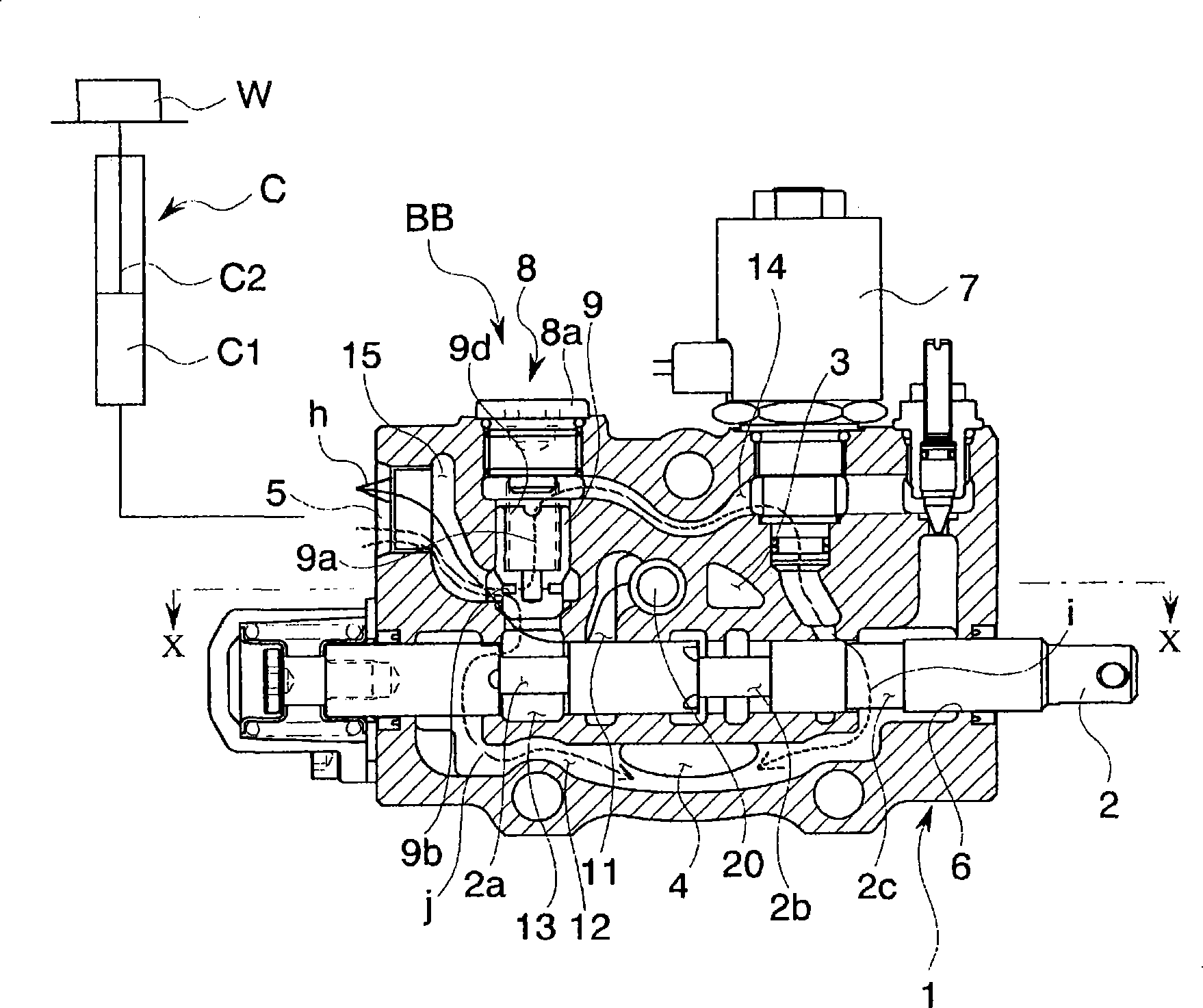

Controller of injection molding machine

A control pillar of injection molding machine, which can diminish the increase of cycle time while the screw rod is falling back after be measured, more accuracy and unity numerical magnitude can be obtained, and the condition of measurement can be determined in a short time. After the measuring, screw rod stop circumgyrate and fall back by the first velocity V1. In the enactment zone, the screw rod reverse rotation by the preset velocity Rv. Then, screw rod fall back at he second velocity V2 which is lower than the first velocity V1, While stopped in the reverse rotation zone, screw rod stop circumgyrate and fall back to the enactment stop position by the third velocity V3. Therefore, compared to the circs of screw rod fall back and reverse rotation, cycle time can be shorten. When the screw rod reverse rotation the fall back speed of screw rod is low, which can inhibit the sudden change of drang. as a consequence of adjust the conditional of screw rod reverse rotation and retrogressive autocephaly, it can be adjust to optimum conditions in a short time.

Owner:FANUC LTD

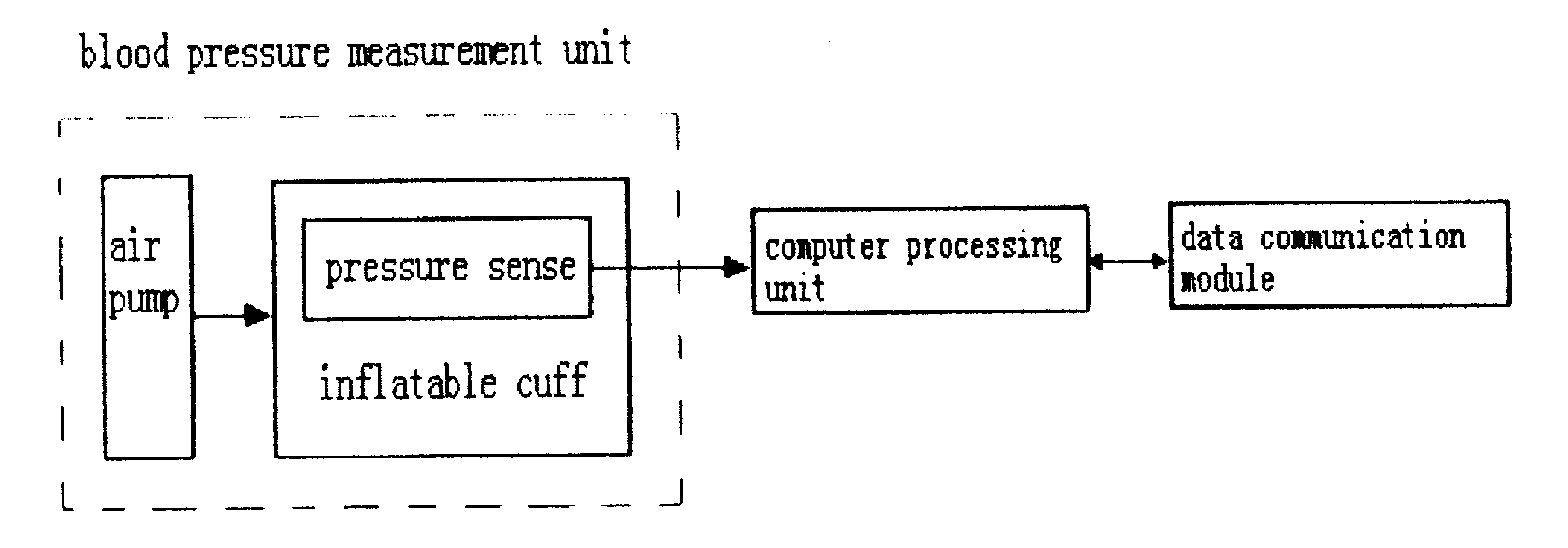

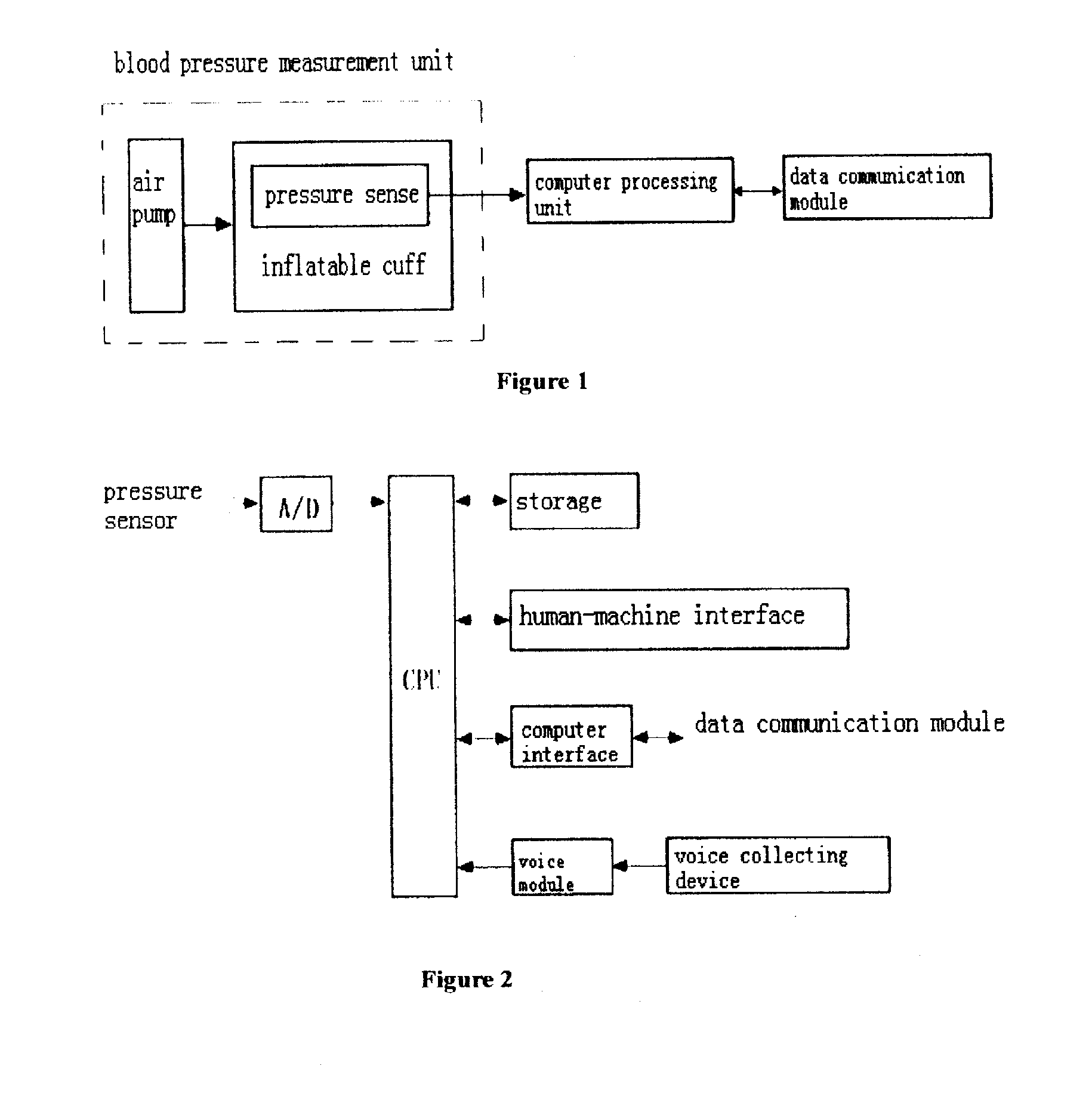

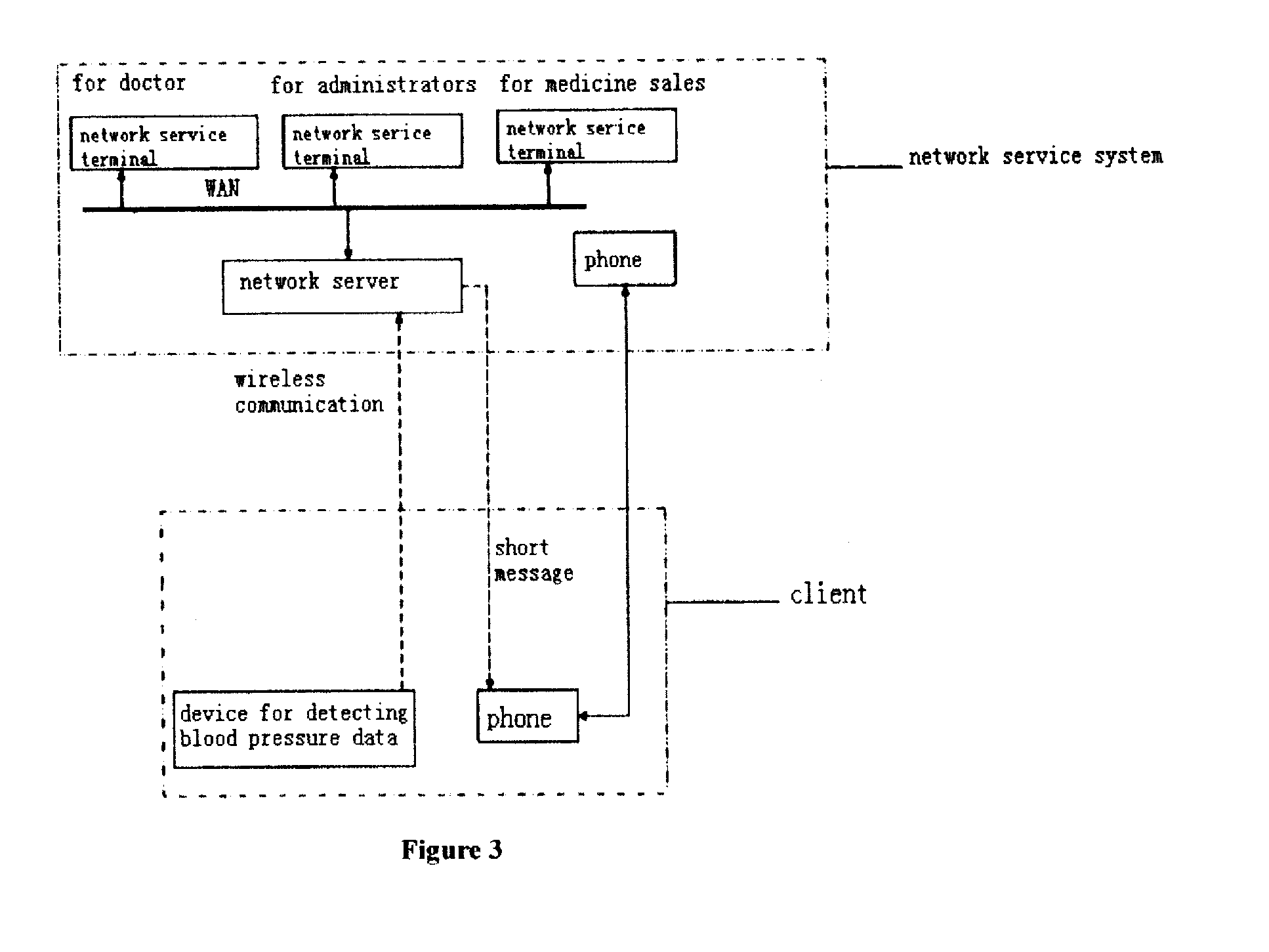

Blood pressure detection method and an apparatus therefor

InactiveUS20120143070A1Successful treatment regimenEasy to operateTelemedicineEvaluation of blood vesselsCommunication interfaceVoice data

Owner:YAO YIMING

Variable displacement compressor

InactiveCN1818383AEasy to startSuppress pressure changesPositive displacement pump componentsWorking fluid for enginesRefrigerantPressure reduction

Refrigerant gas is introduced into the suction chamber through the suction line. Refrigerant gas can flow from the crank chamber to the suction chamber through the outlet line. The opening degree regulating valve (34) has a first valve body for adjusting the opening degree of the suction pipeline and a second valve body for adjusting the opening degree of the outlet pipeline. The first valve body and the second valve body are connected to each other. The first valve body moves in such a way that when the difference between the pressure in the suction chamber and the pressure in the crank chamber decreases, the opening of the suction line increases; when the difference between the pressure in the suction chamber and the pressure in the crank chamber When the difference between them increases, reduce the opening of the suction line. Therefore, variation in gas pressure is reliably suppressed while maintaining good start performance of the compressor.

Owner:TOYOTA IND CORP

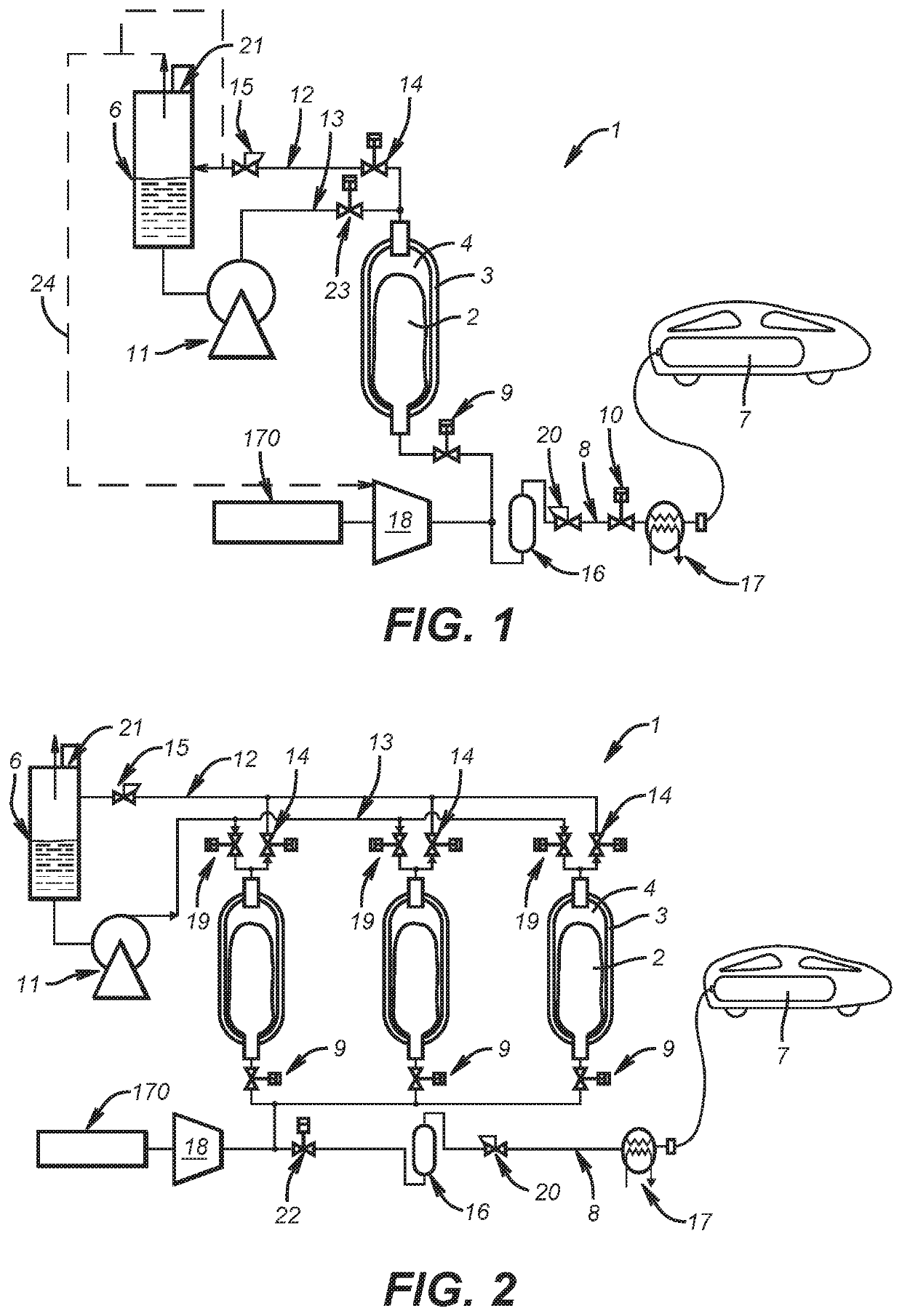

Station and method for filling a tank with a fuel gas

ActiveUS10753539B2Limit number of necessaryNecessity to effect cascade filling canGas handling applicationsGas handling/storage effectsEngineeringControl valves

The invention relates to a station and method for filling a tank with a fuel gas. Said station includes at least one fuel gas source store and a gas transfer system having a first upstream end connected to the source store(s) and a second downstream end that is in fluid communication with the tank. The gas transfer system includes at least one control valve, characterized in that the at least one source store includes a rigid outer wall and a flexible sealing wall that is arranged inside the space defined by the rigid outer wall. The flexible wall defines a storage space for the fuel gas. The first upstream end of the system is connected to the storage space defined by the flexible wall. The at least one control valve is also characterized in that the space located between the flexible wall and the outer wall is connected to a system for transferring liquid into the source store in order to fill or extract the liquid in the source store and control the pressure in the store when filling and / or extracting fuel gas within the sealing wall.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

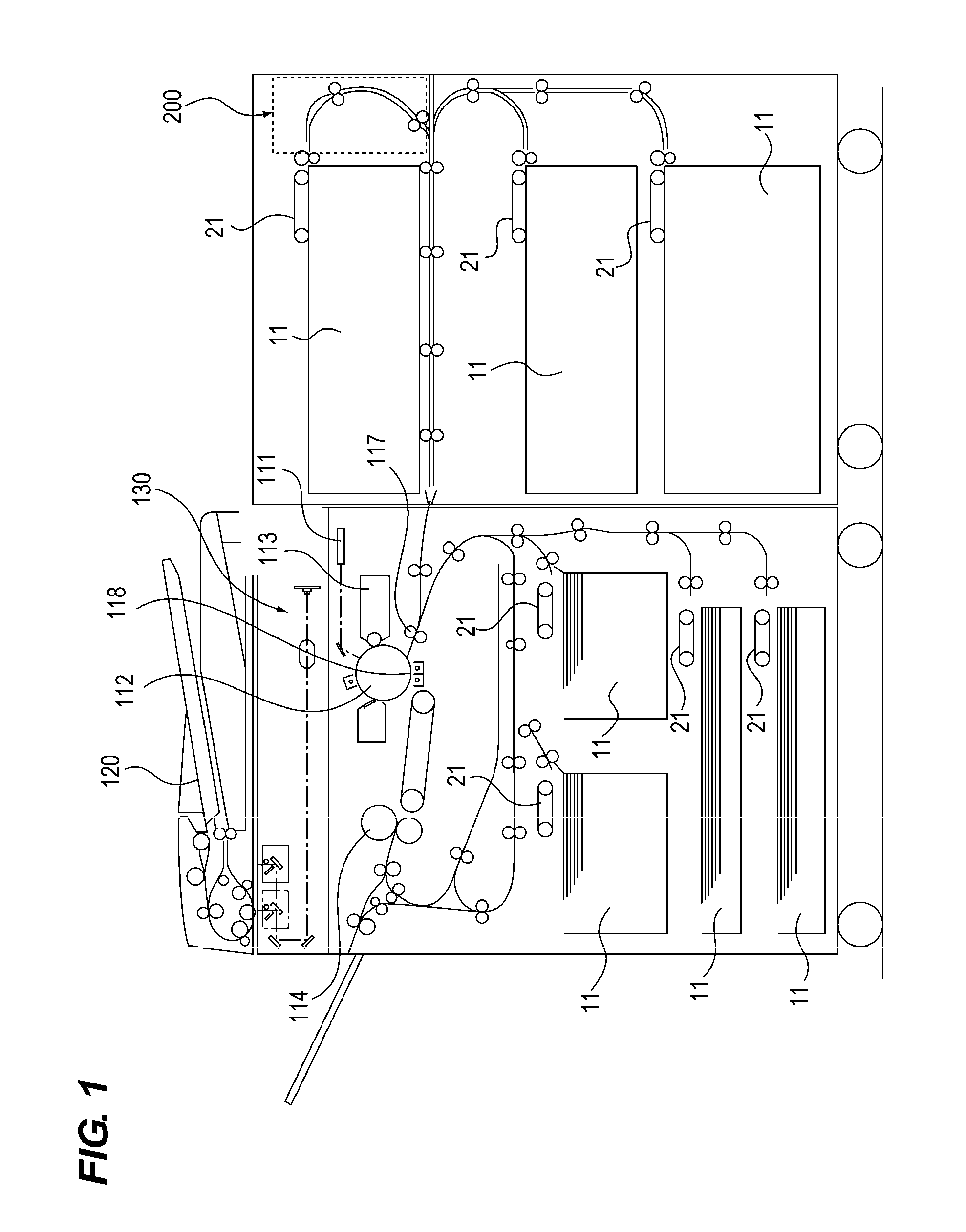

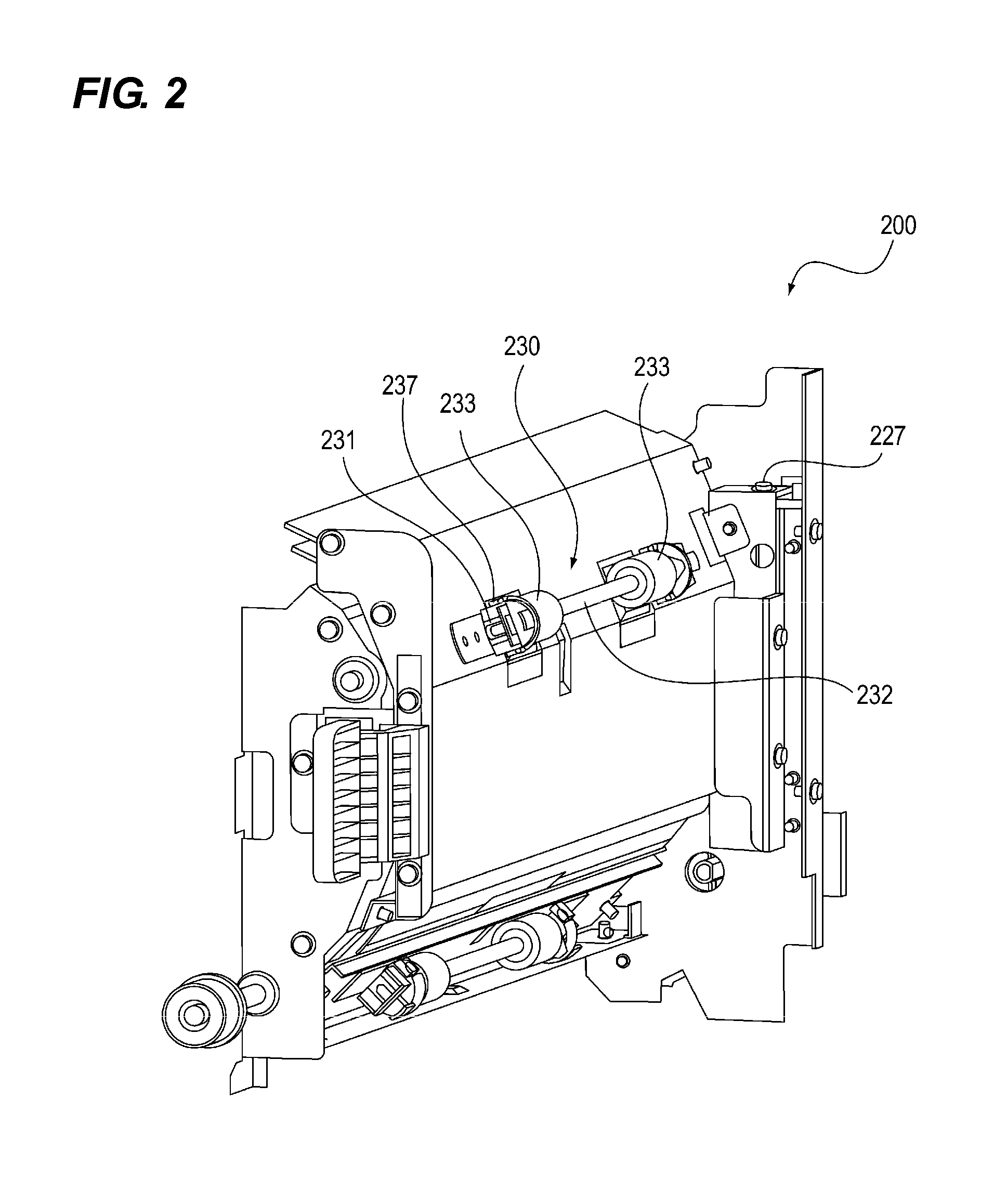

Sheet conveying apparatus and image forming apparatus

Owner:CANON KK

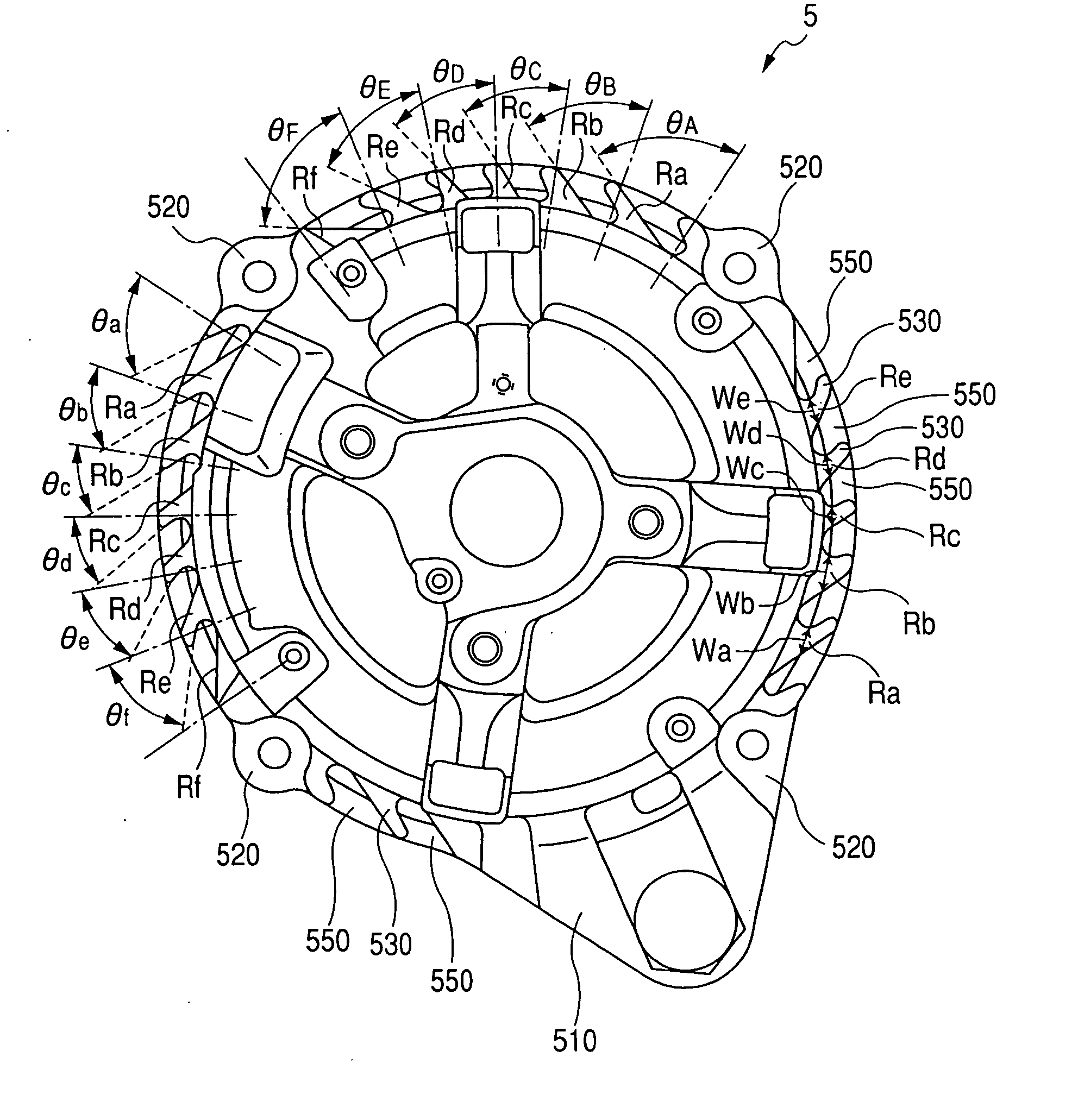

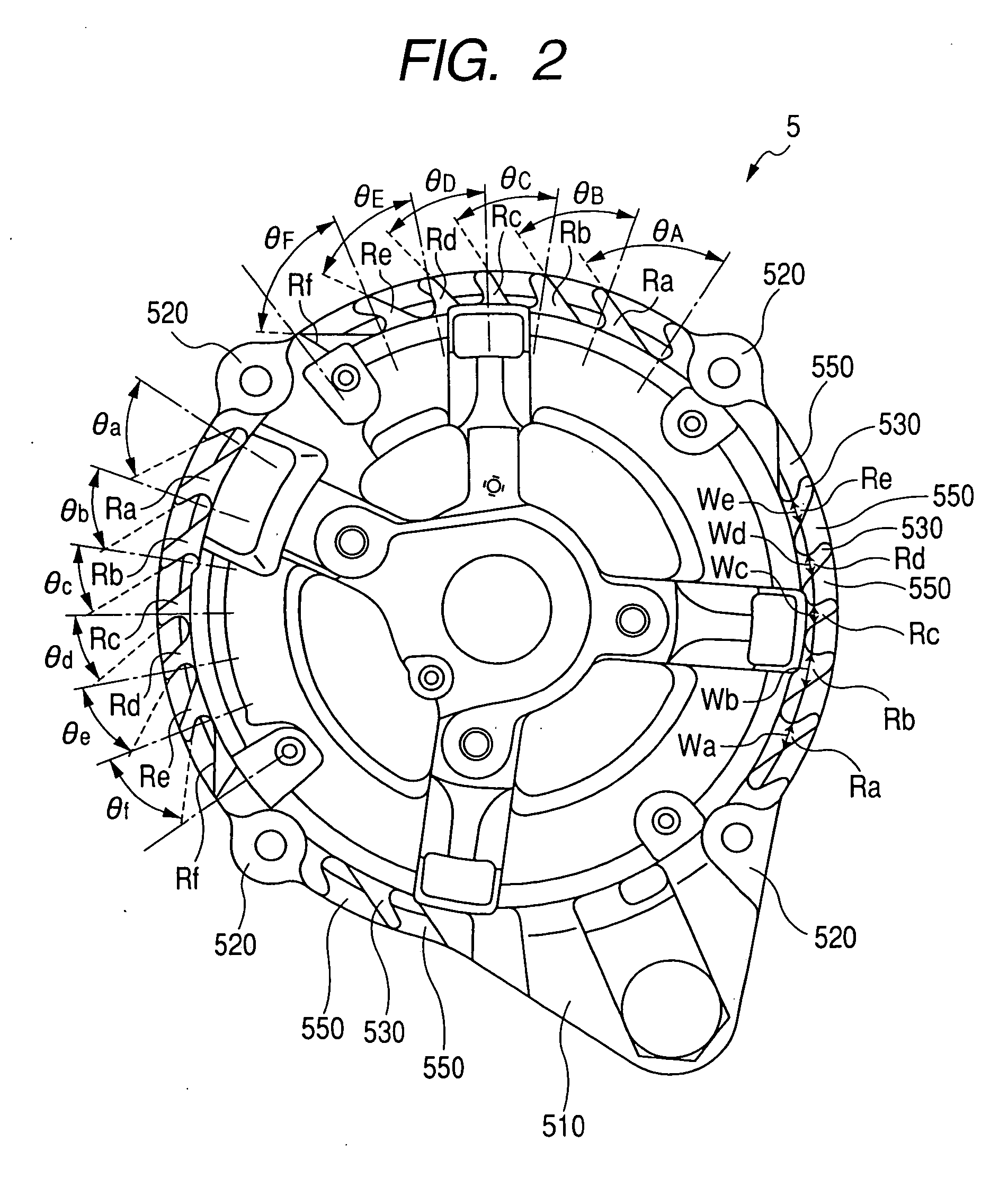

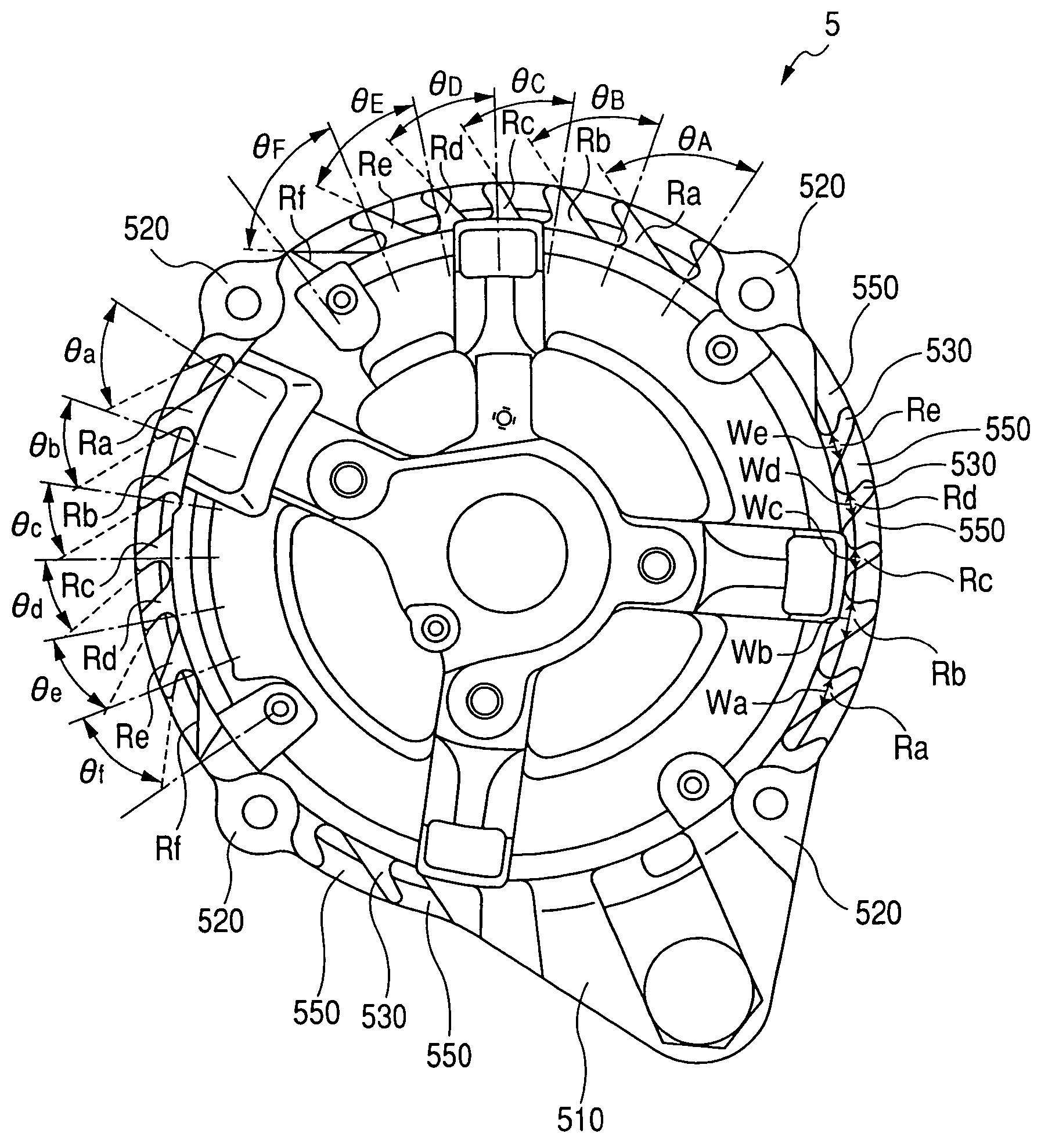

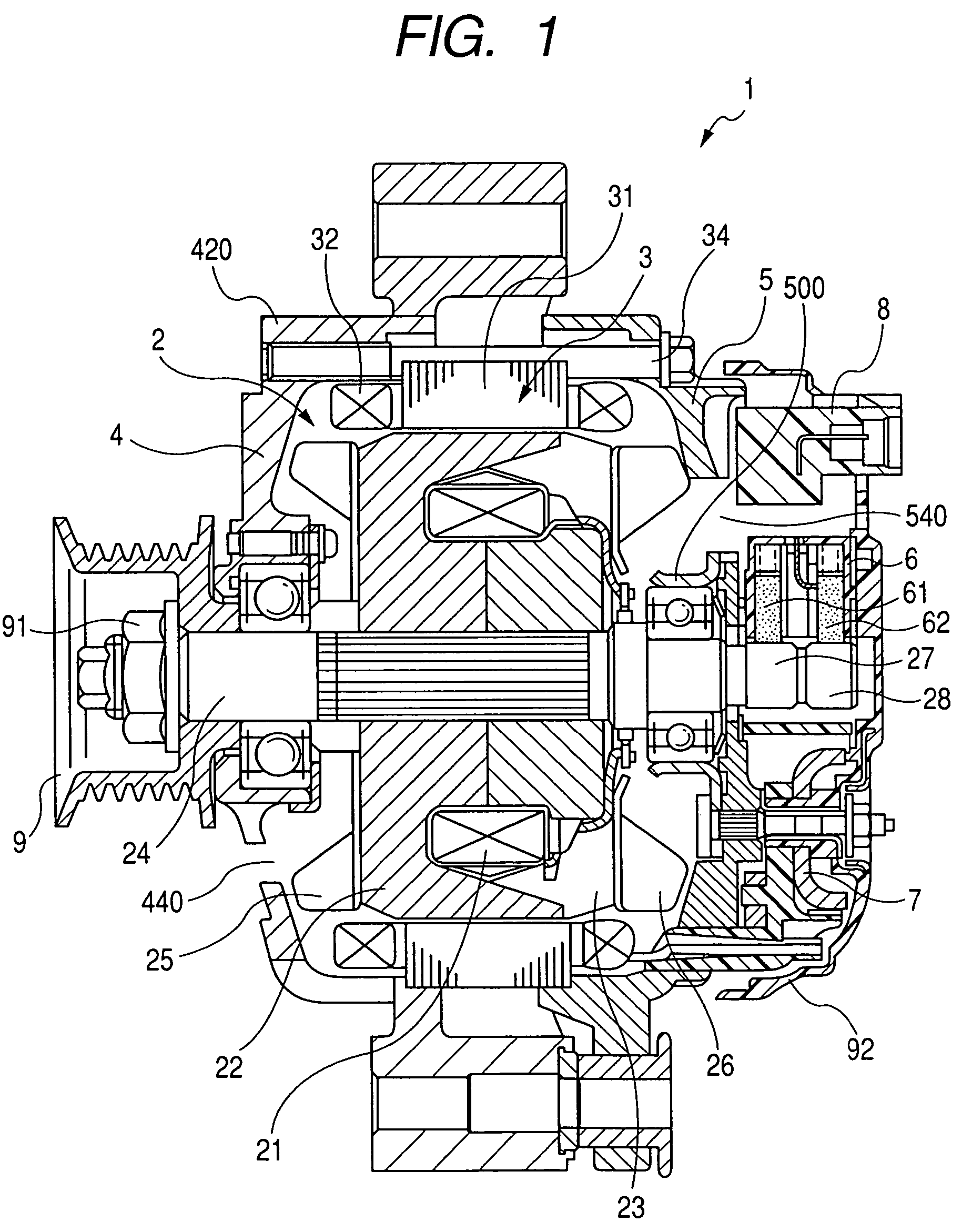

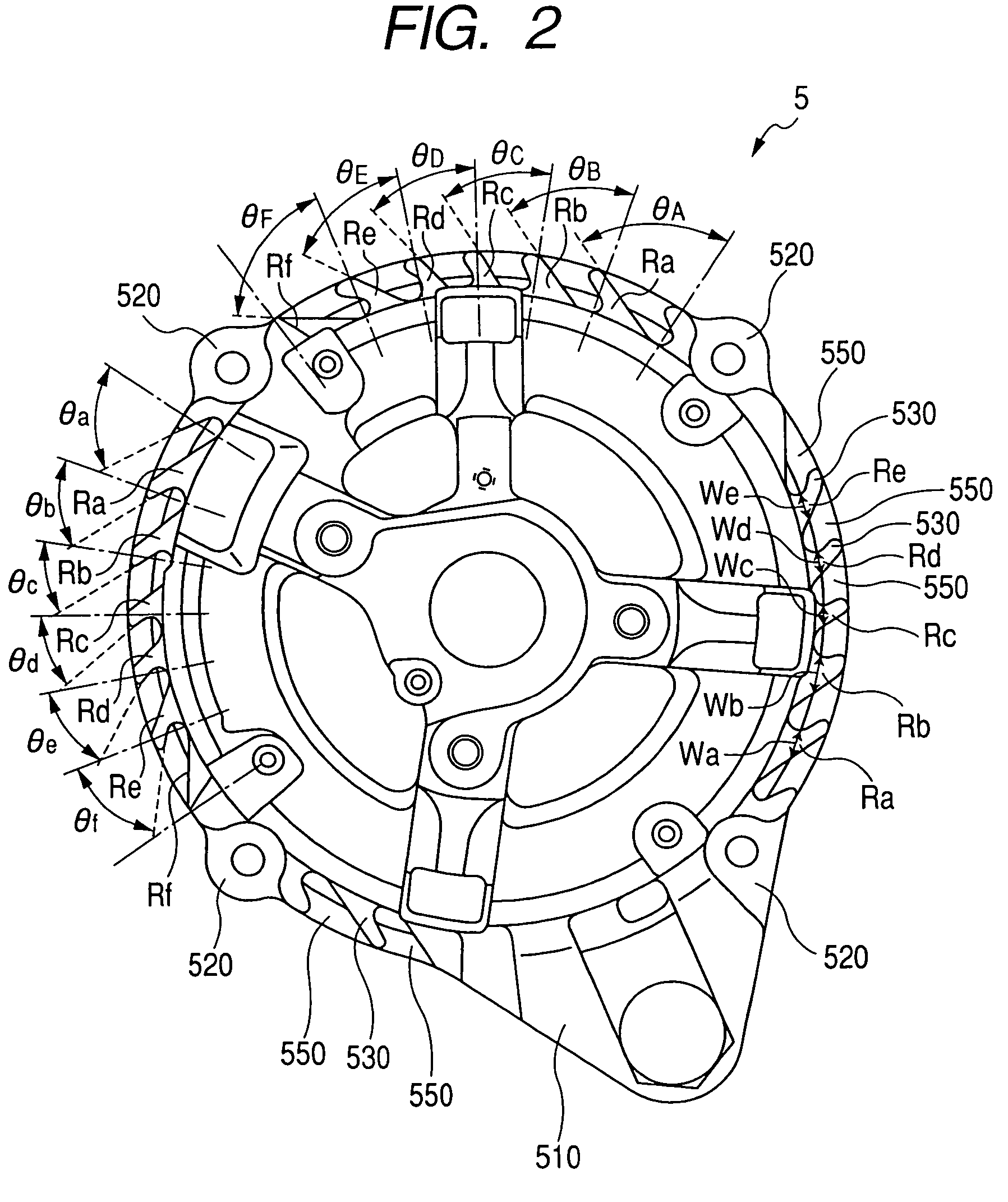

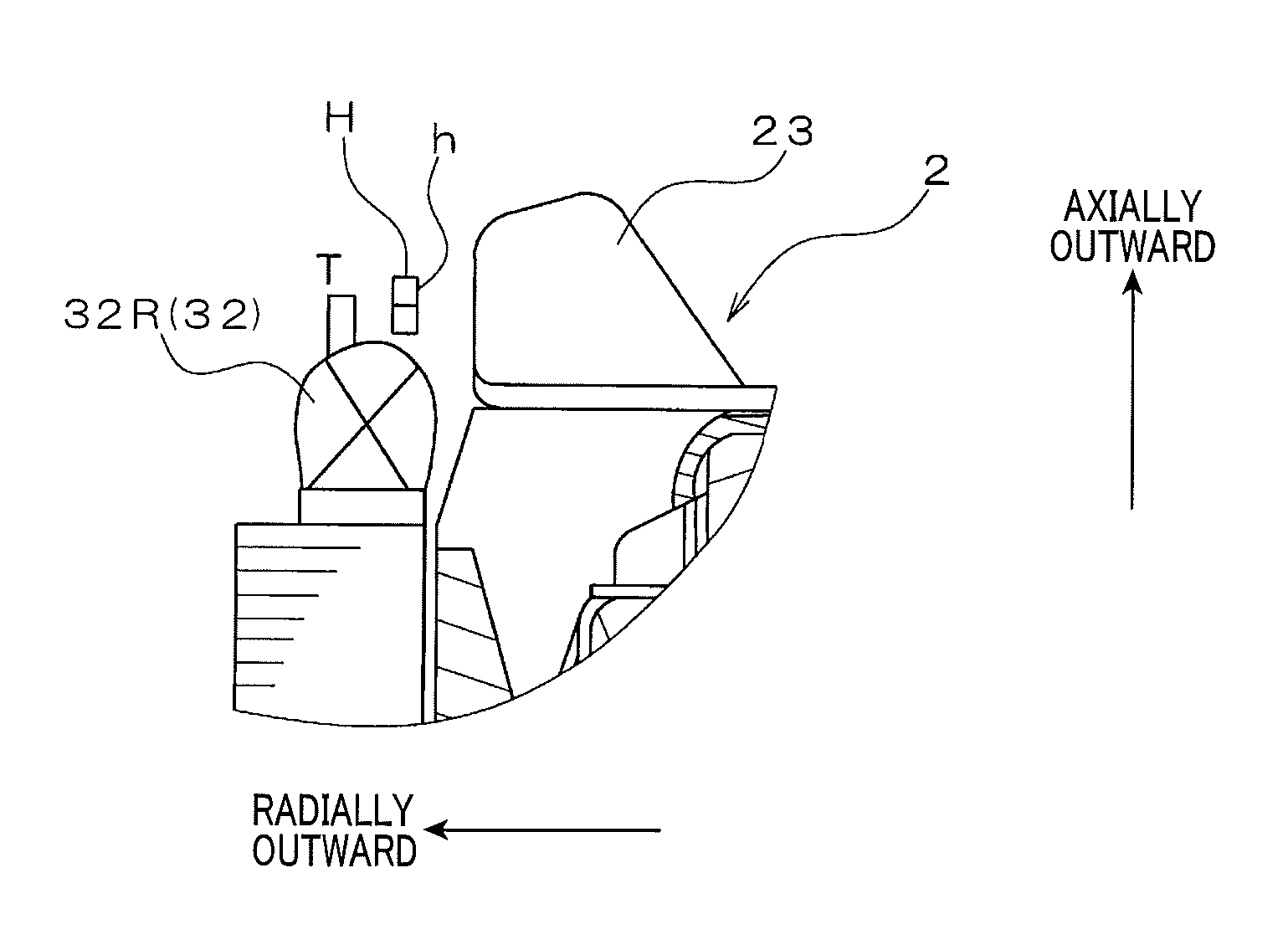

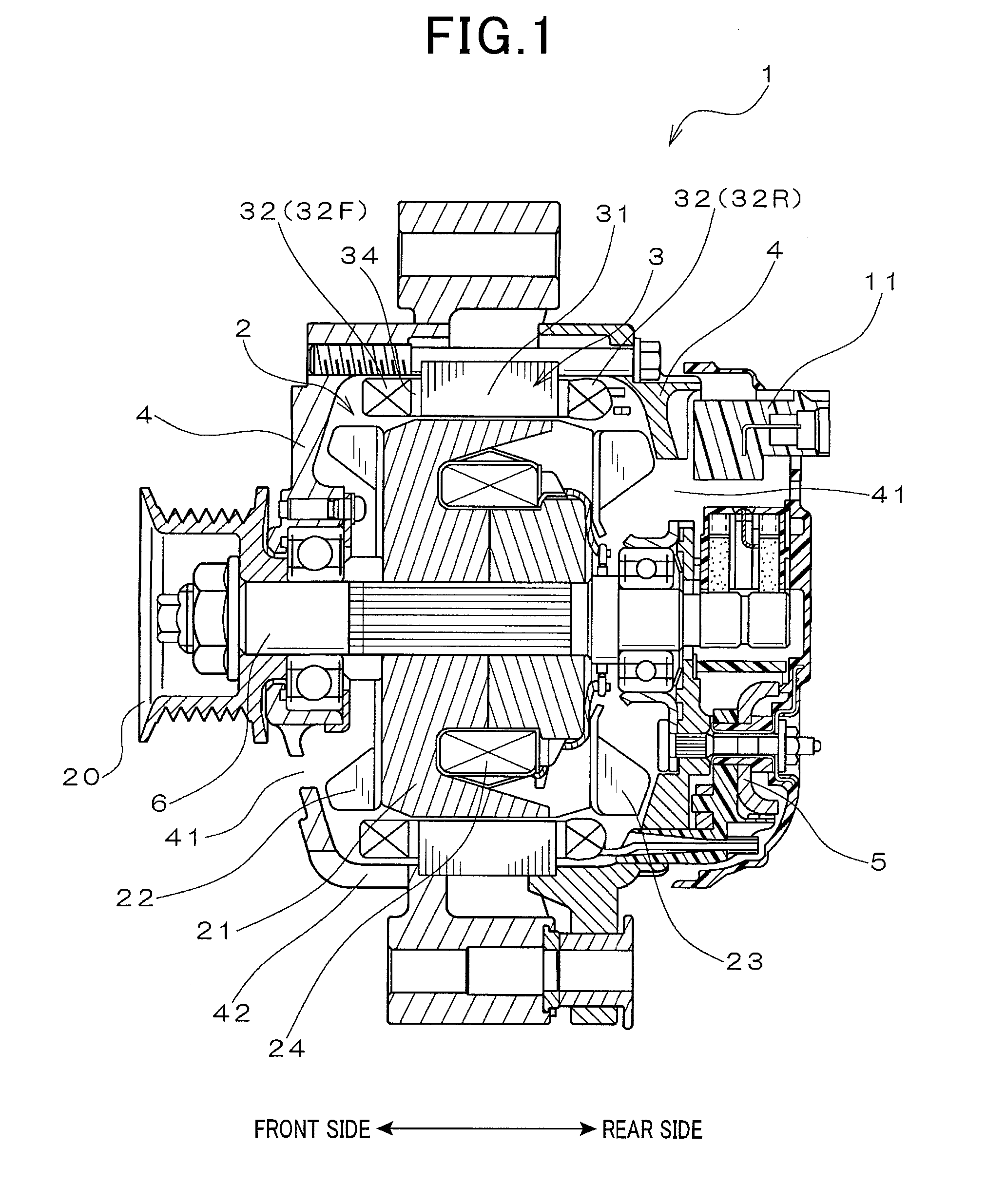

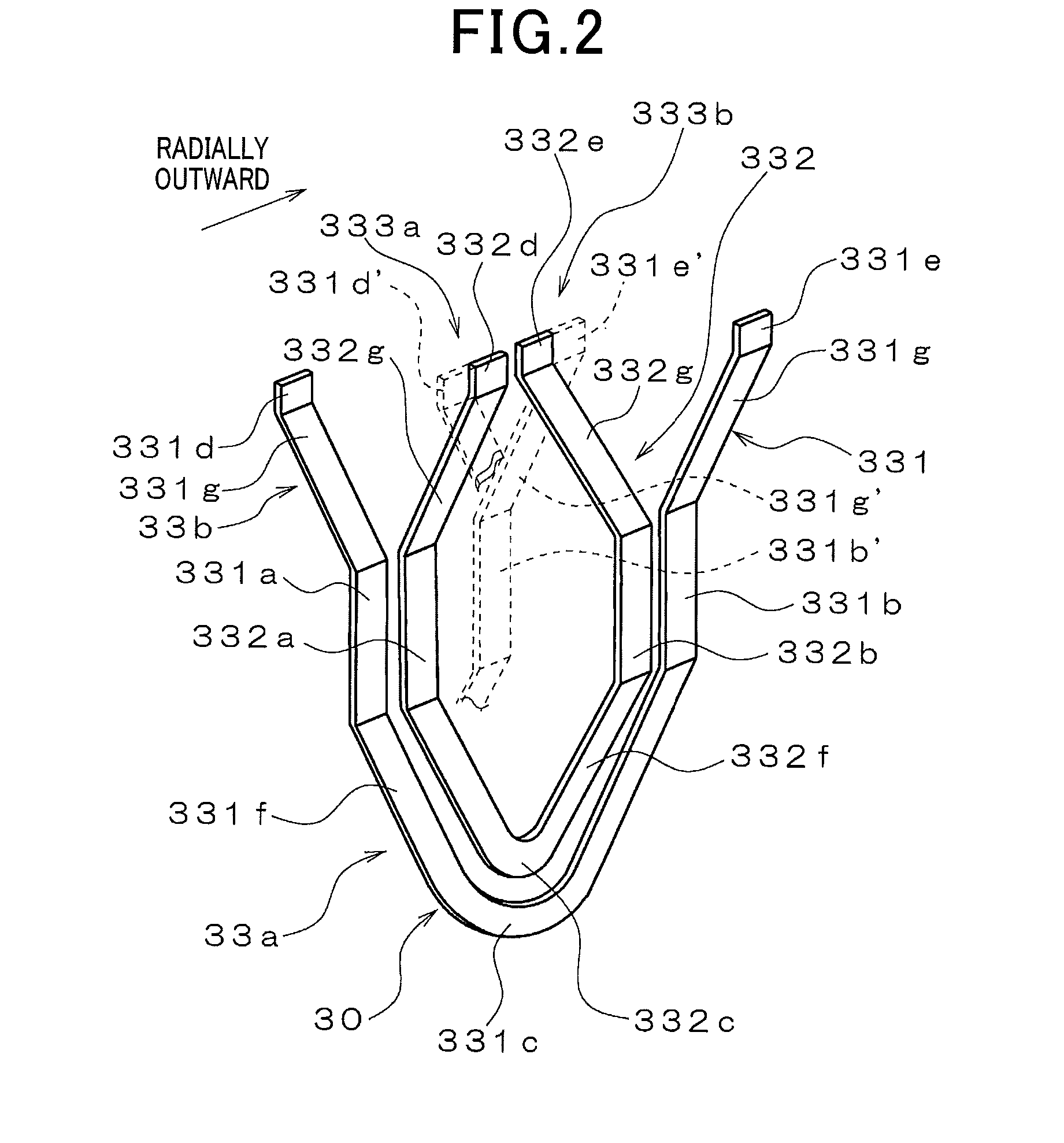

Vehicle-use alternator

InactiveUS20070138879A1Suppressor mutationReduce fan noiseMagnetic circuit rotating partsPump componentsAlternatorEngineering

The vehicle-use alternator includes a cooling fan rotating in one with a rotating shaft thereof to generate cooling air diffusing substantially in a radial direction of the rotating shaft, to thereby cool a stator thereof. A housing thereof rotatably supporting the rotating shaft and housing the rotor is provided with a plurality of supporting members circumferentially spaced on a periphery thereof to which the stator is secured, and a plurality of ribs formed on the periphery which are circumferentially arranged between the supporting members so as to form a plurality of cooling air discharge windows circumferentially arranged on the periphery. The ribs are inclined towards a downstream side with respect to a rotational direction of the rotor, and shaped that their inclination angles towards the downstream side between two adjacent ones of the supporting members reduce with increasing distance from a closer one of the two adjacent ones of the supporting members.

Owner:DENSO CORP

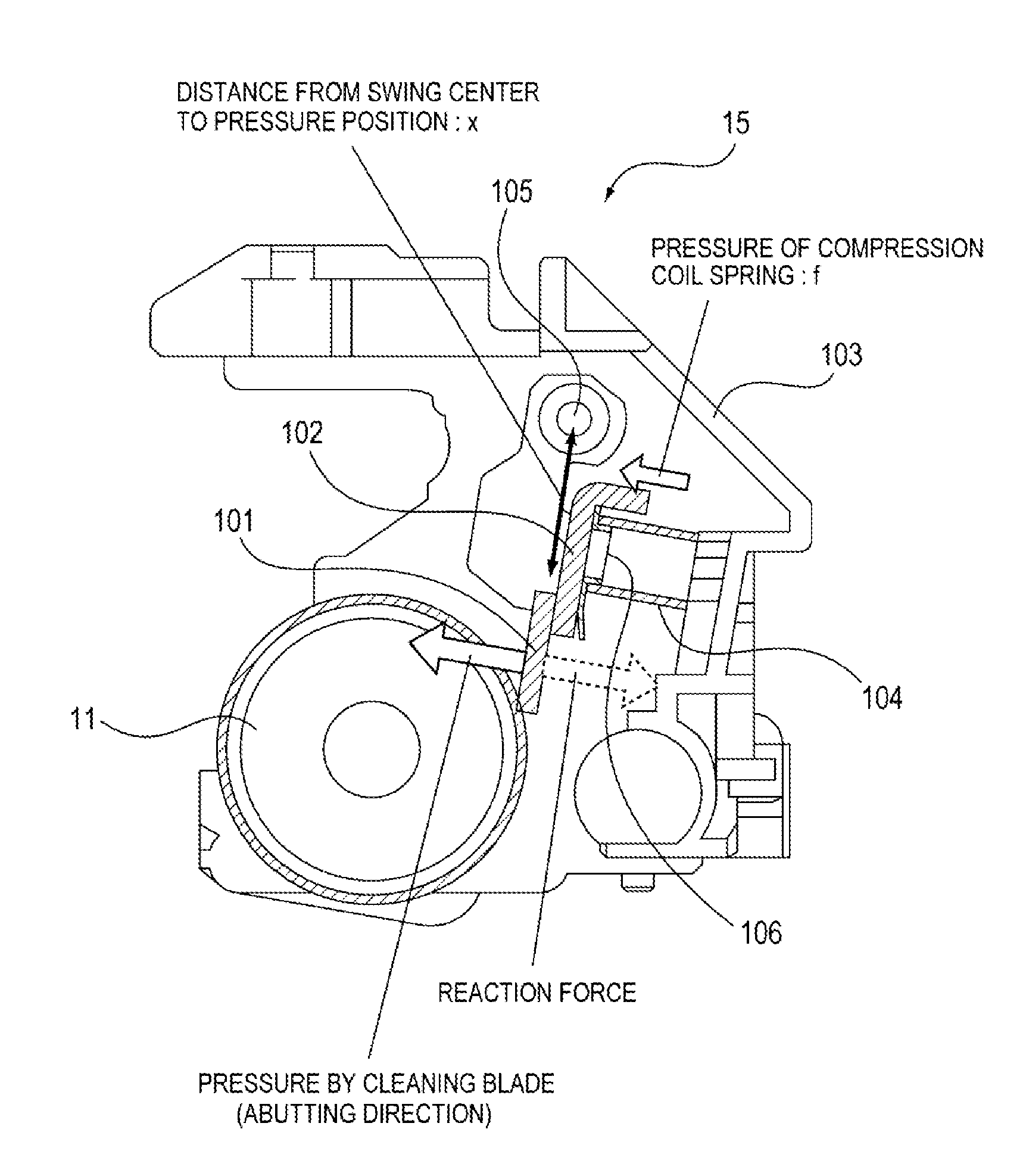

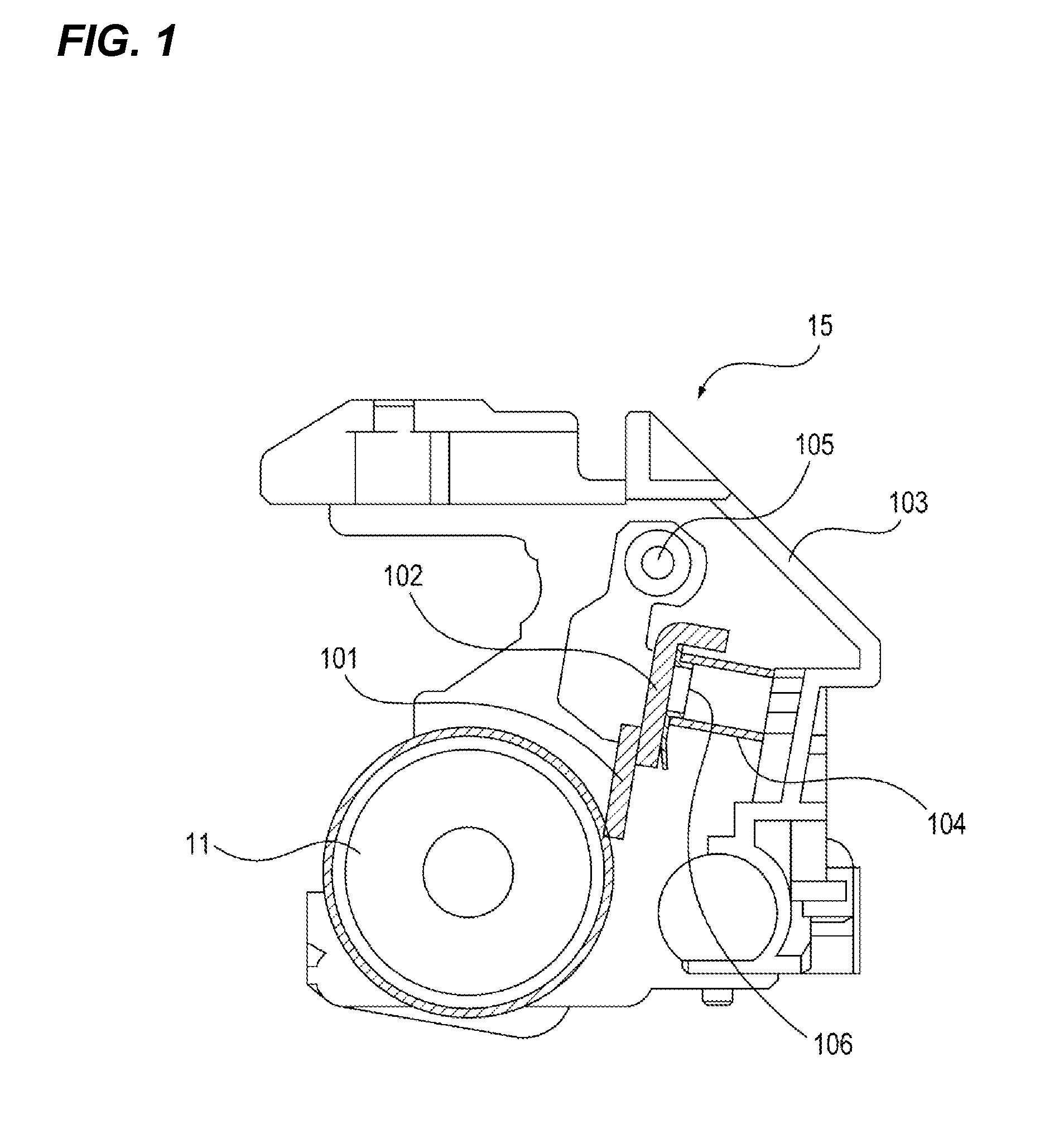

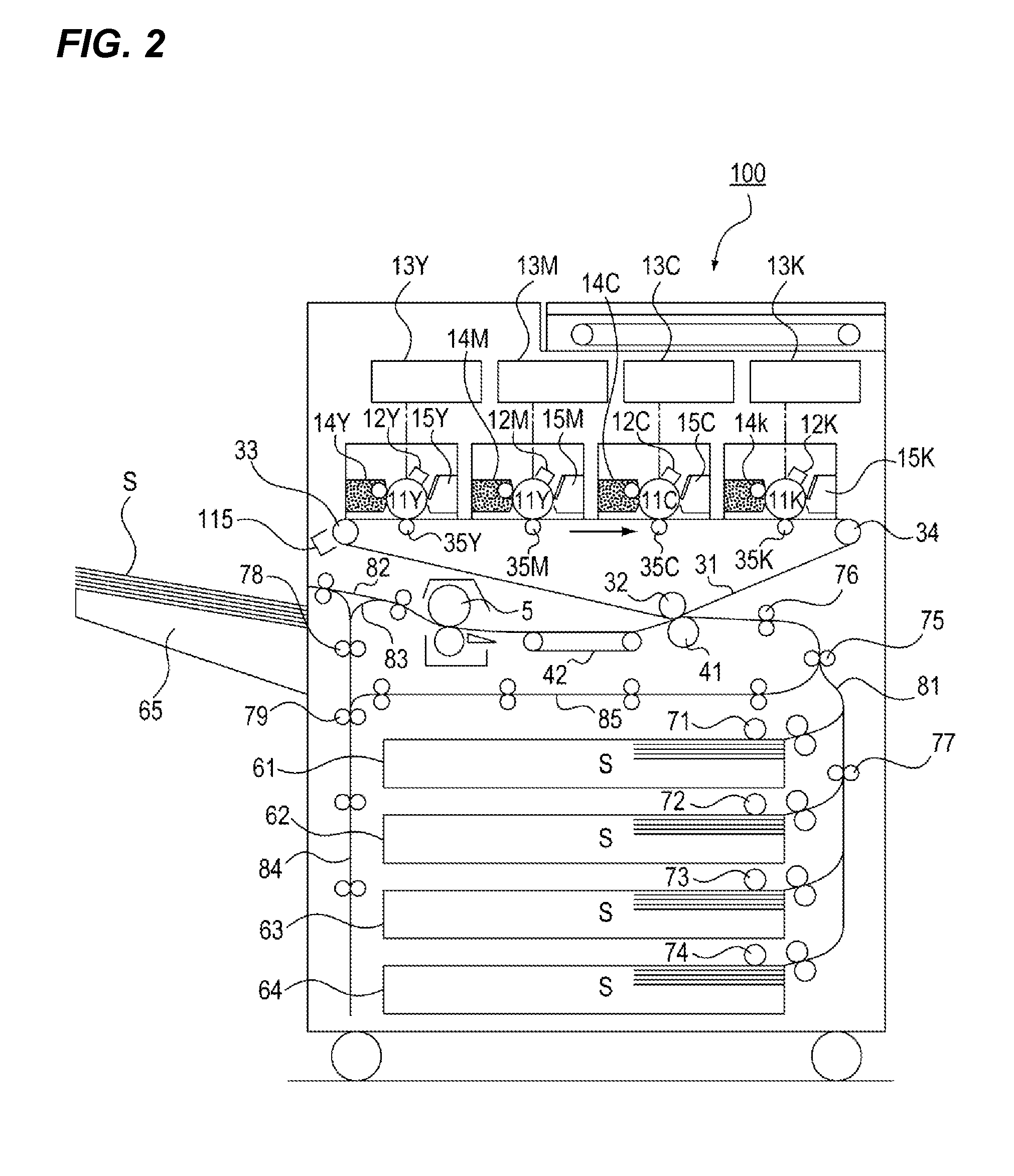

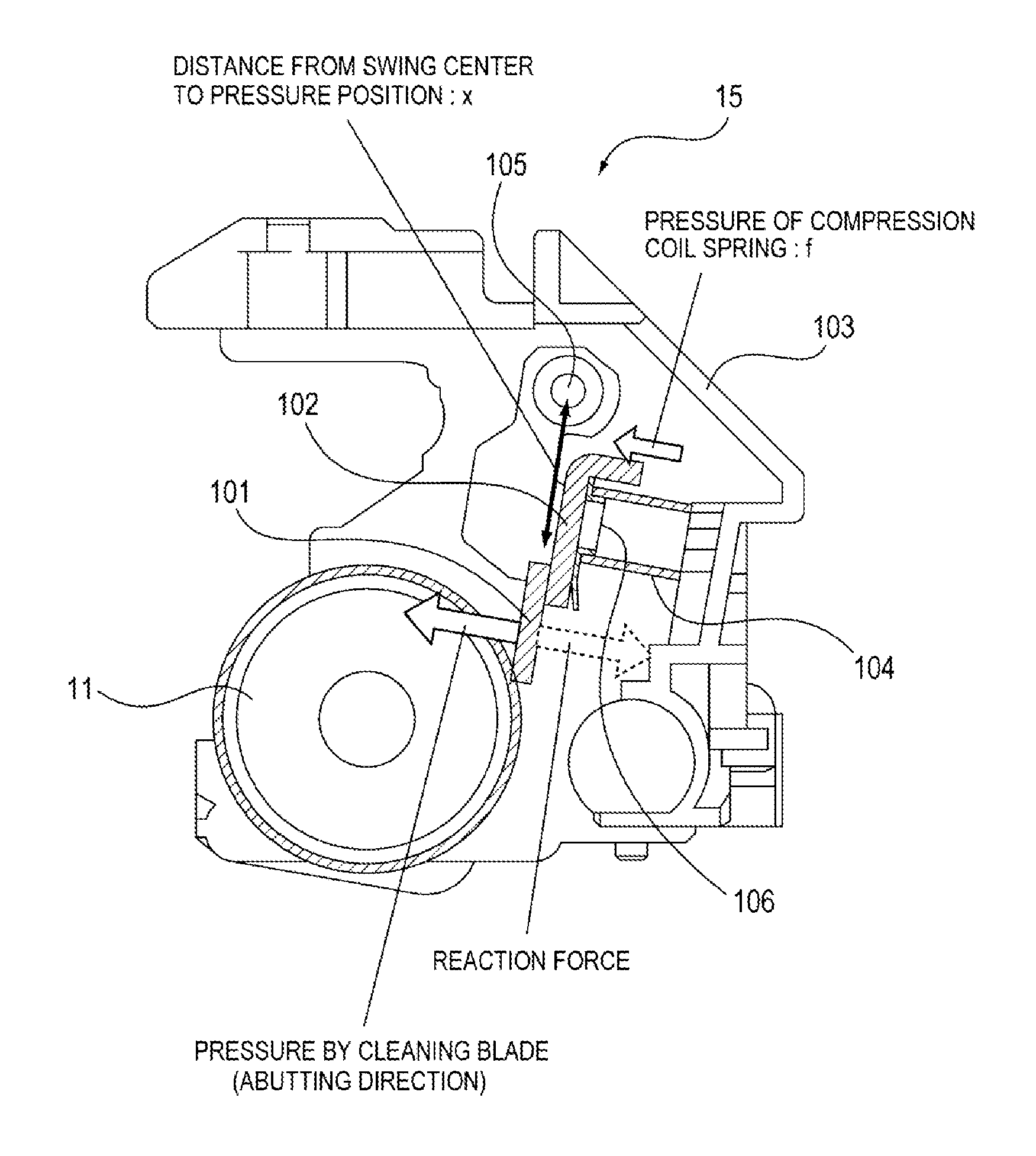

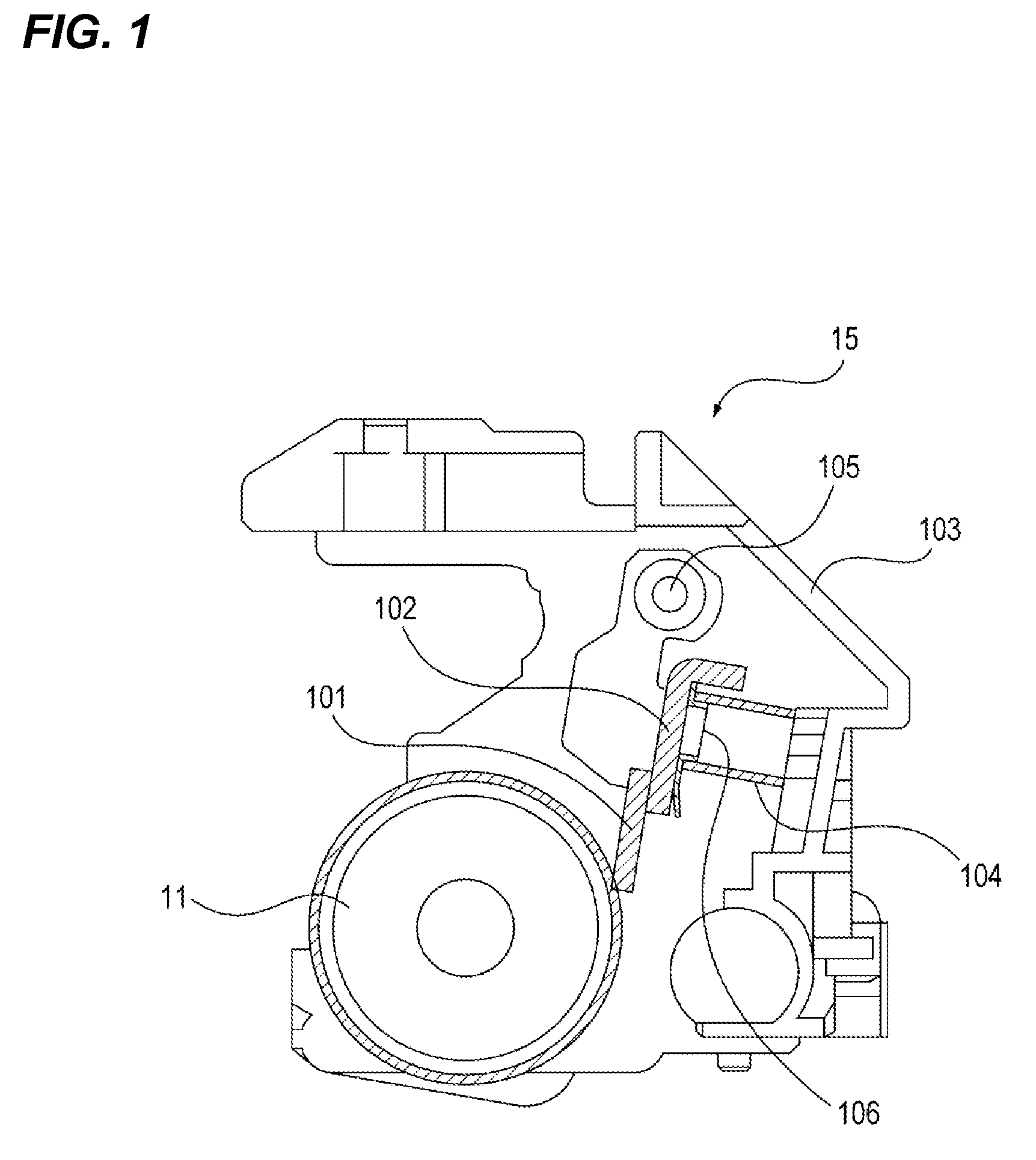

Cleaning device and image forming apparatus

A representative configuration of a cleaning device and an image forming apparatus according to the present invention includes: a photosensitive drum which bears a toner image; a cleaning blade which abuts against the photosensitive drum and removes a toner remained in the photosensitive drum; a compression coil spring which is compressed to pressurize the cleaning blade against the photosensitive drum; and a positioning boss which is arranged to face the compression coil spring, with a predetermined gap being provided therebetween, allows a movement in a direction perpendicular to a compression direction of the compression coil spring, and regulates a movement of the compression coil spring such that the compression coil spring is not moved by more than a predetermined amount in the direction perpendicular to the compression direction of the compression coil spring.

Owner:CANON KK

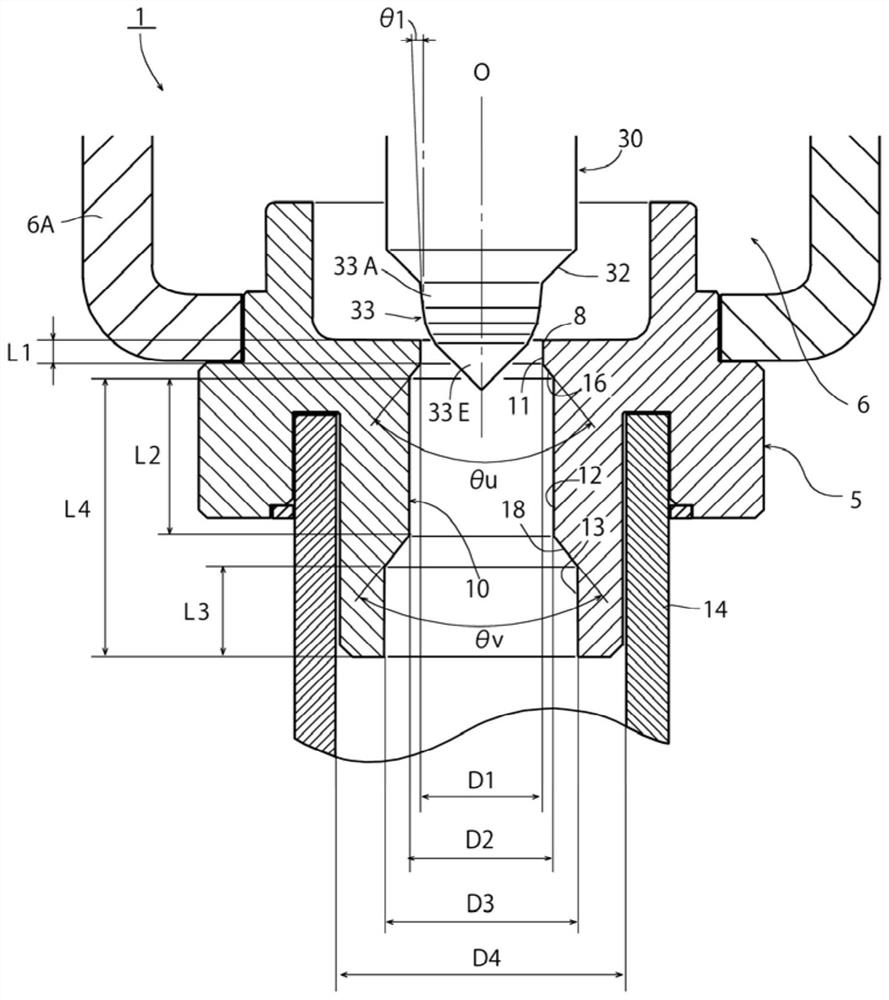

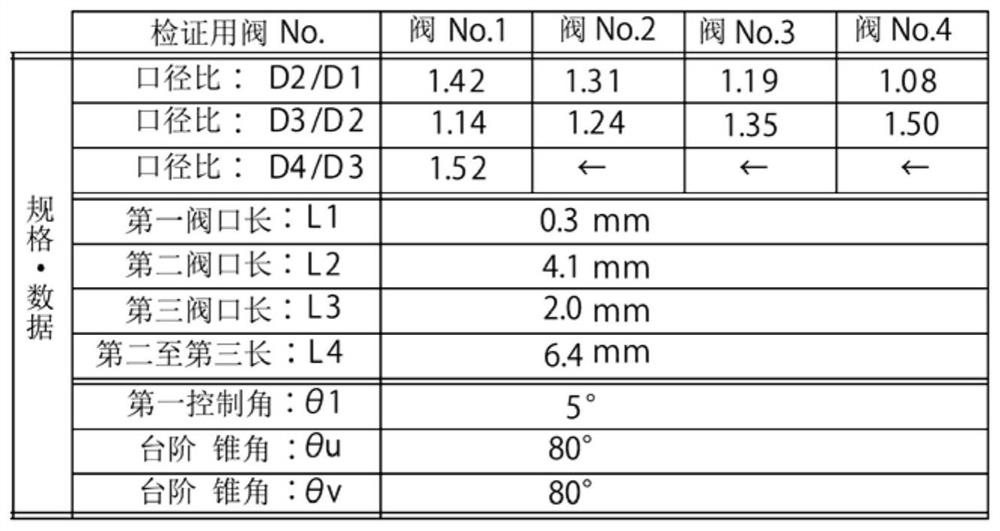

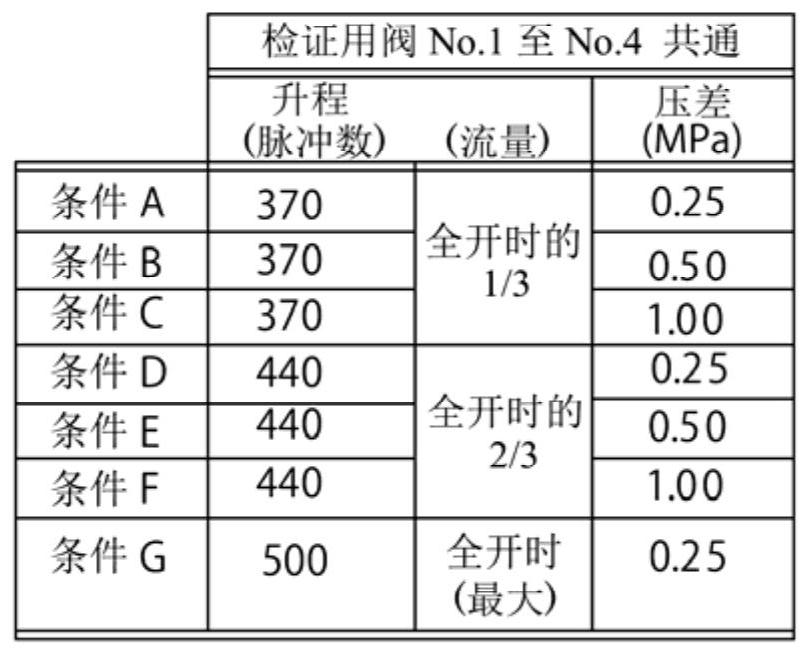

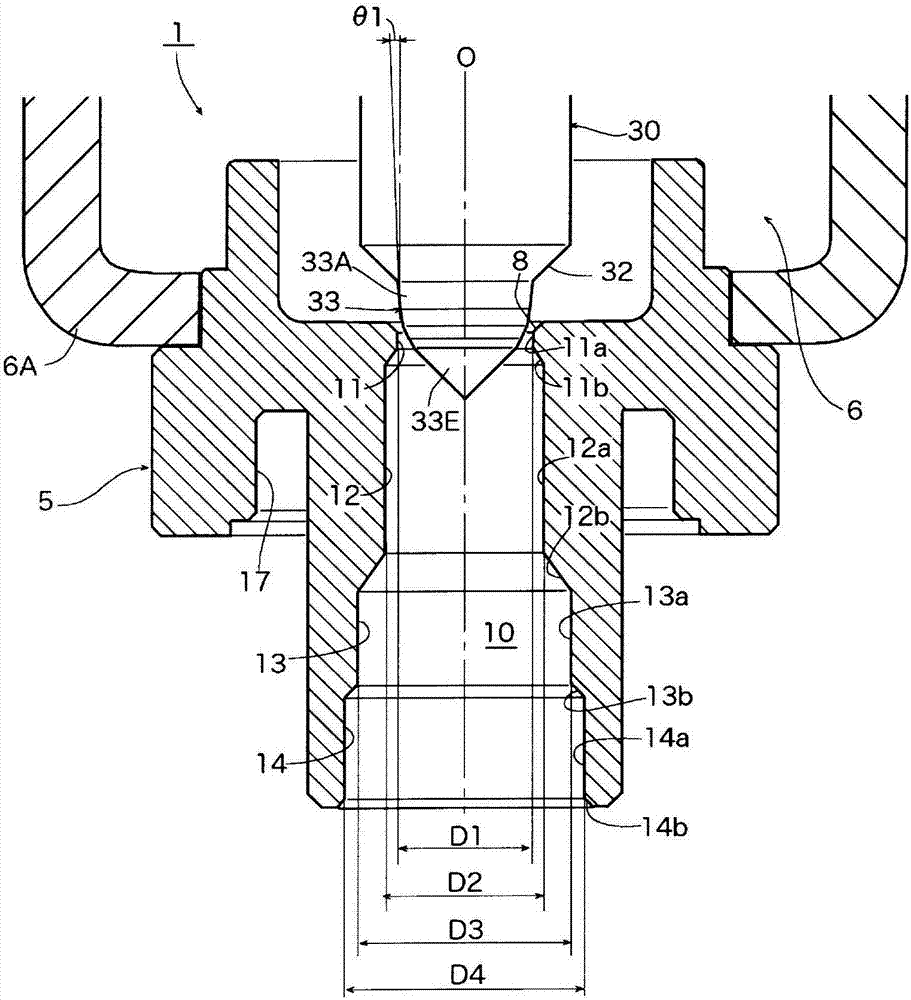

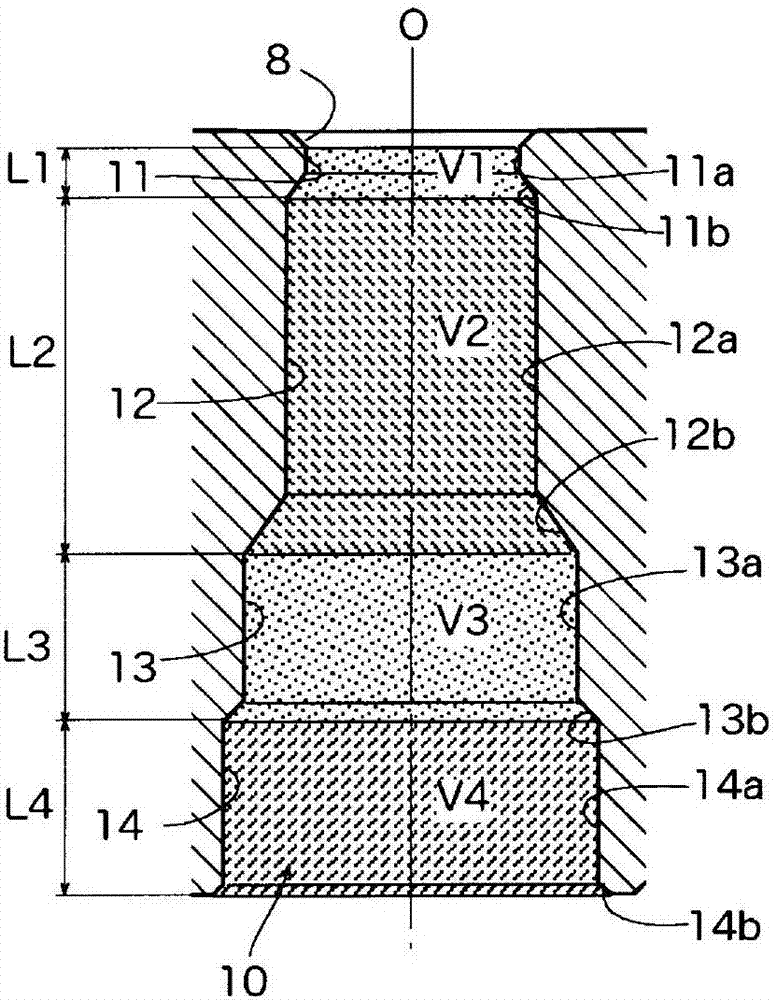

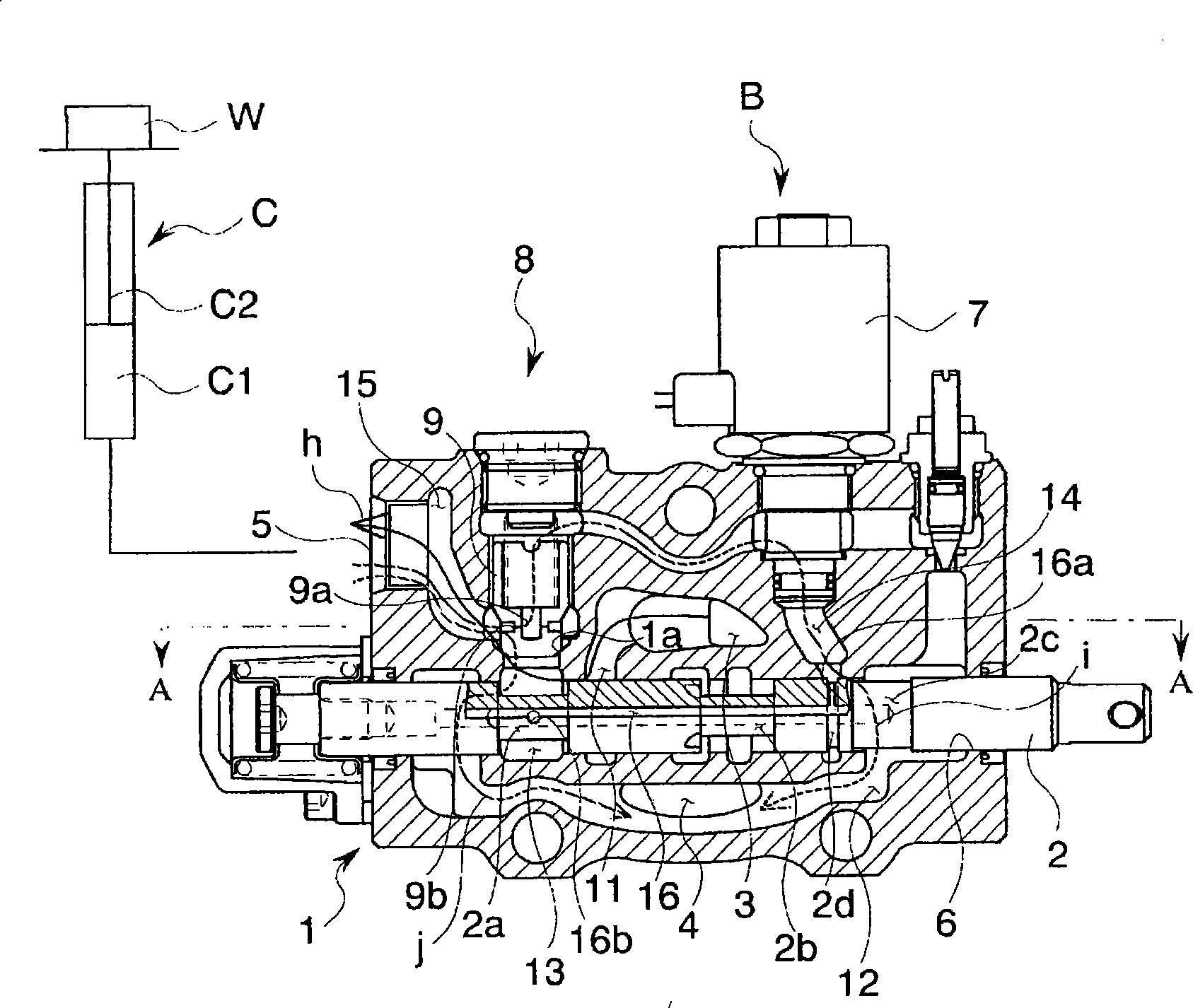

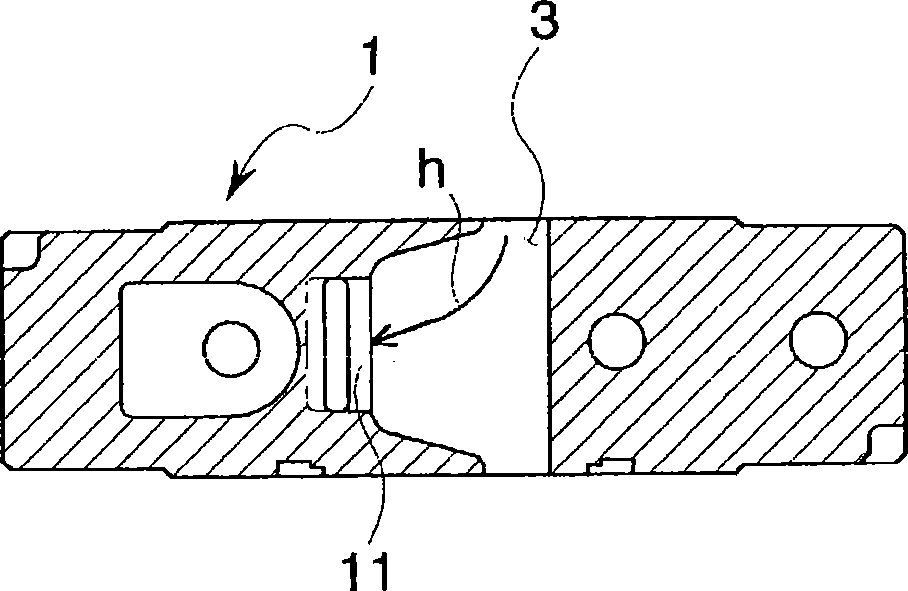

Flow regulating valve

ActiveCN111609154ASuppress pressure changesRealize rectificationValve members for absorbing fluid energyRefrigeration componentsRefrigerantVALVE PORT

The invention provides a flow regulating valve which can effectively reduce the noise generated due to a pressure fluctuation and a refrigerant separation phenomenon during passage through a valve port, and can achieve reduction of a pressure loss and so forth. The flow regulating valve 1 comprises a valve body 5 provided with a valve chamber 6 and a valve port 10, and a valve element 30 having acurved surface part 33 which changes the flow rate of fluid flowing through the valve port 10 according to a lift amount, in which the curvature or the control angle of the curved surface part 33 is continuously or stepwisely increased according as getting close to the end. The diameter of the valve port 10 is increased sequentially in three stages or more according as being separated from the valve chamber 6. Specifically, sequentially from the valve chamber 6 side, a first valve port part 11 having a diameter D1, a second valve port part 12 of diameter D2 (>D1) and a third valve port part 13of a diameter D3 (>D2) are provided. More preferably, D1, D2 and D3 are set such that (a valve port ratio: D2 / D1) and (a valve port ratio: D3 / D2) fall in a specific range.

Owner:FUJIKOKI MFG CO LTD

Flow control valve

ActiveCN107420632ASuppress pressure changesRealize rectificationValve members for absorbing fluid energyFluid circulation arrangementMechanical engineeringEngineering

Provided is a flow control valve that can effectively reduce the generation of noise due to fluctuations in the pressure or a refrigerant separation phenomenon that may occur while a refrigerant passes through the valve orifice, and also reduces the pressure loss and the like. The flow control valve (1) includes a valve body (5) including a valve chamber (6) and a valve orifice (10); and a valve element (30) with a curved surface portion (33) adapted to change the flow rate of a fluid through the valve orifice (10) in accordance with the lift amount of the valve element (30), the curved surface portion (33) having a curvature or a control angle that is increased continuously or in stages toward the tip end of the curved surface portion (33). The orifice diameter of the valve orifice (10) is sequentially increased in four or more stages in a direction away from the valve chamber (6). Further preferably, V2 > V4 > V3 > V1, where the volumes of the first valve orifice portion (11), the second valve orifice portion (12), the third valve orifice portion (13), and the fourth valve orifice portion 14 are V1, V2, V3, and V4, respectively.

Owner:FUJIKOKI MFG CO LTD

Liquid ejection apparatus and recording apparatus

InactiveUS7669954B2Maintain responsivenessSuppress pressure changesOther printing apparatusEngineeringRecording head

The liquid ejection apparatus includes: a recording head which ejects an ejection liquid; a liquid container which accommodates air and the ejection liquid; a recording head connection flow channel which leads from the liquid container to the recording head; a pressure determination device which determines pressure of the ejection liquid accommodated in the liquid container; a first pressure supply device which drives a rotating body to remove or introduce the air from or to the liquid container so as to keep pressure of the air in the liquid container constant; a phase determination device which determines a phase of the rotating body; a second pressure supply device which is disposed in a pulsation suppressing flow channel that connects the liquid container with the recording head connection flow channel and which removes and introduces the ejection liquid from or to the liquid container; and a control device which controls rotation speed of the second pressure supply device in accordance with the phase of the rotating body determined by the phase determination device so as to cancel out variation of the pressure of the ejection liquid caused by the first pressure supply device.

Owner:FUJIFILM CORP

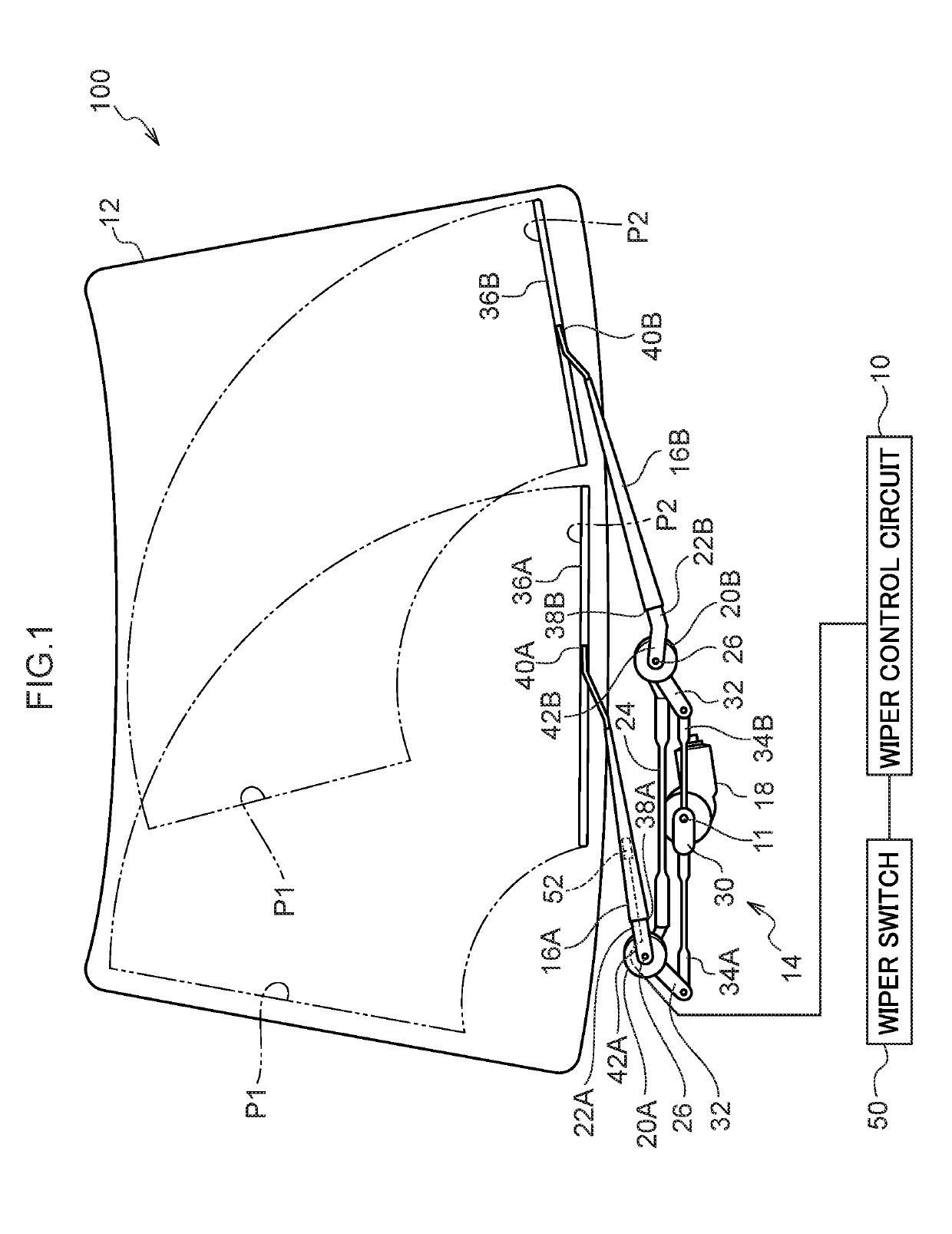

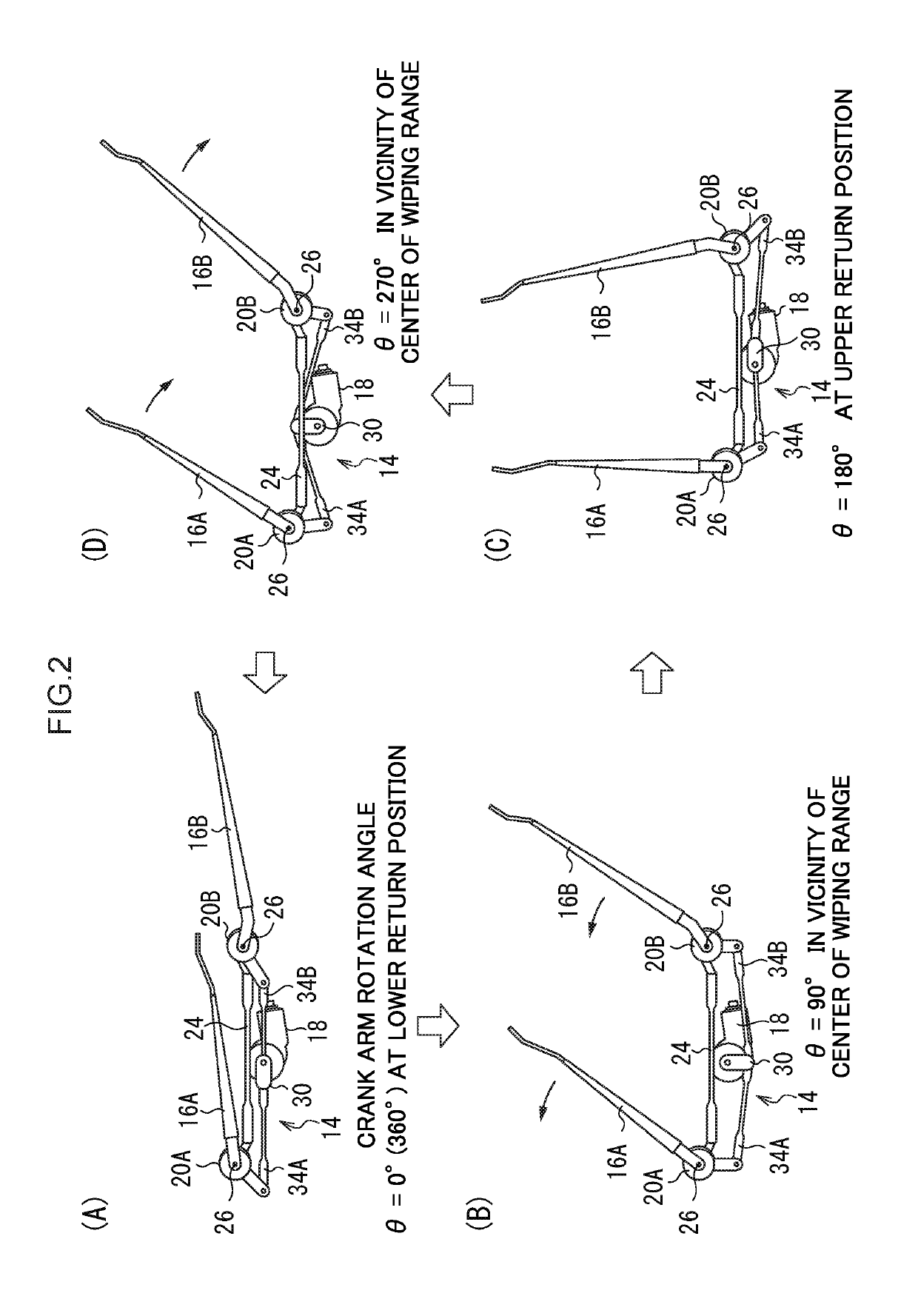

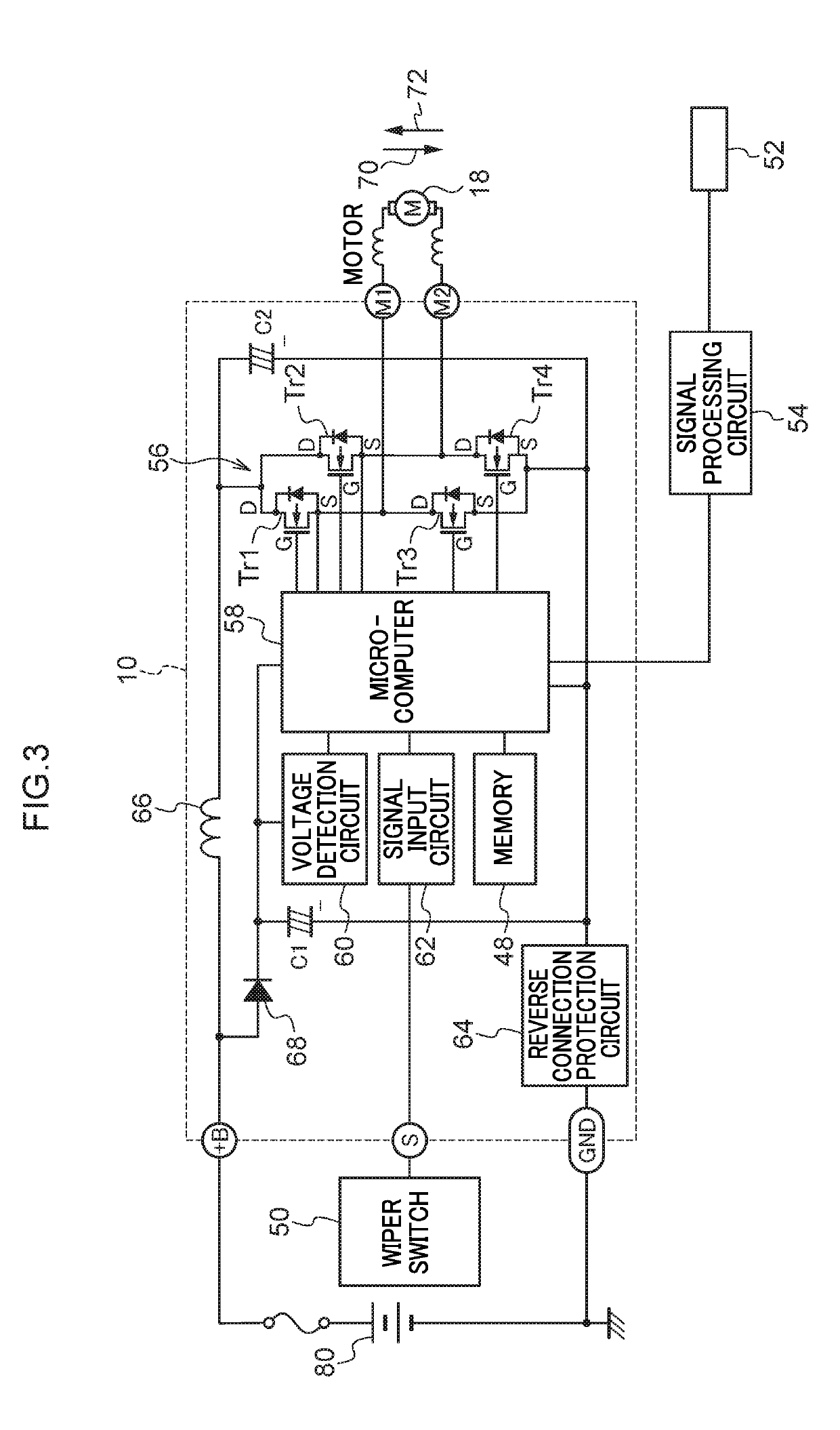

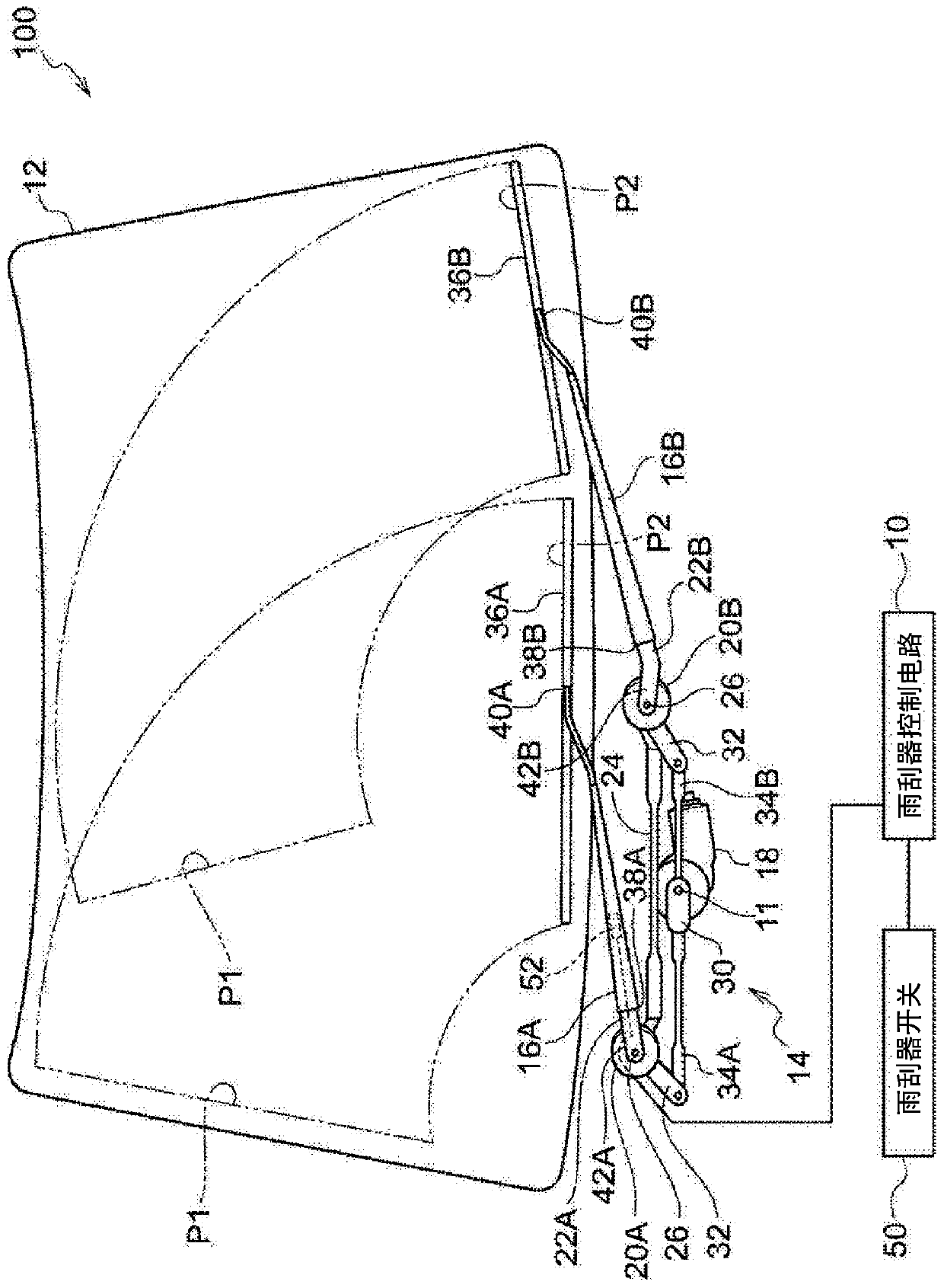

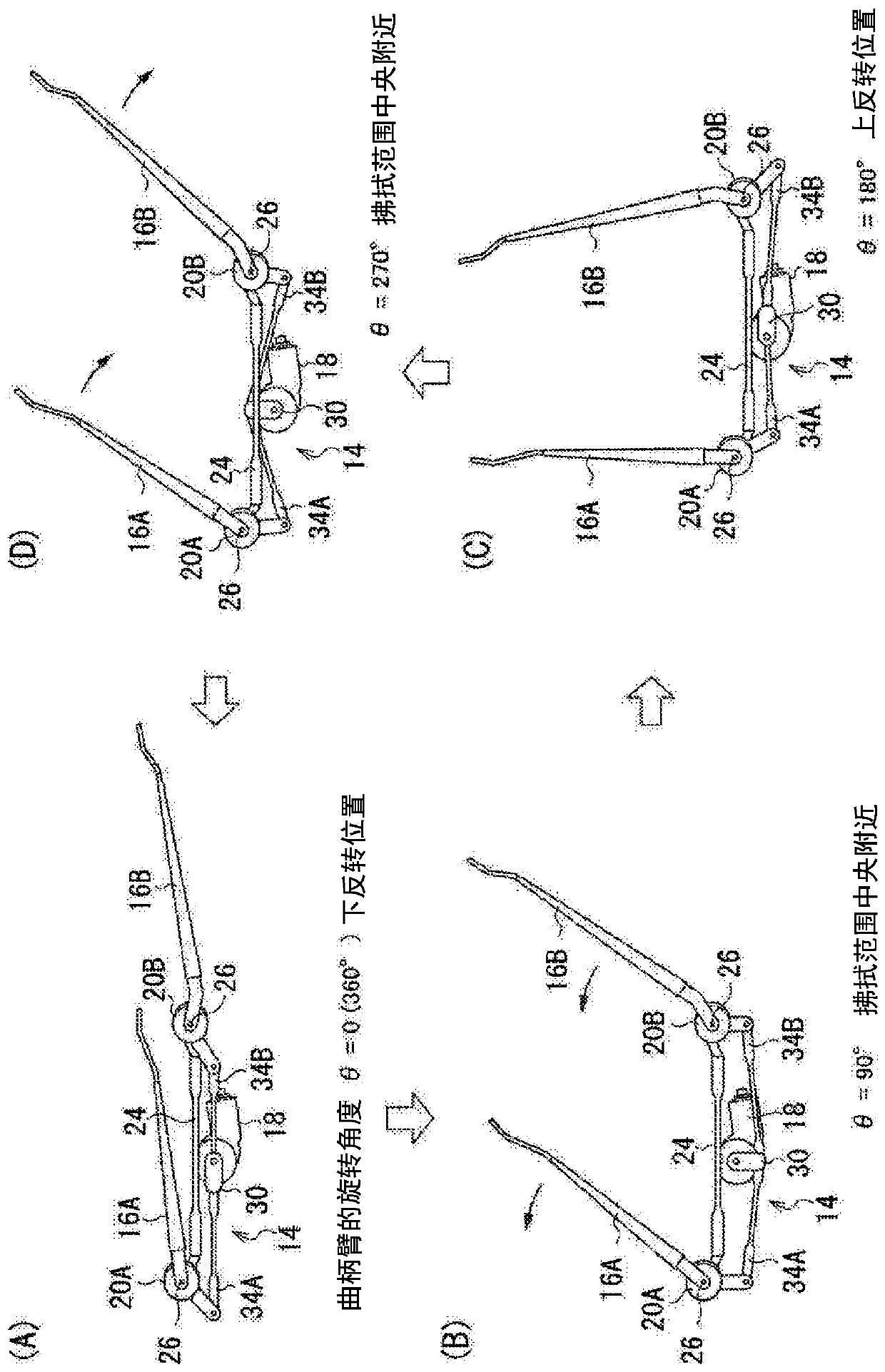

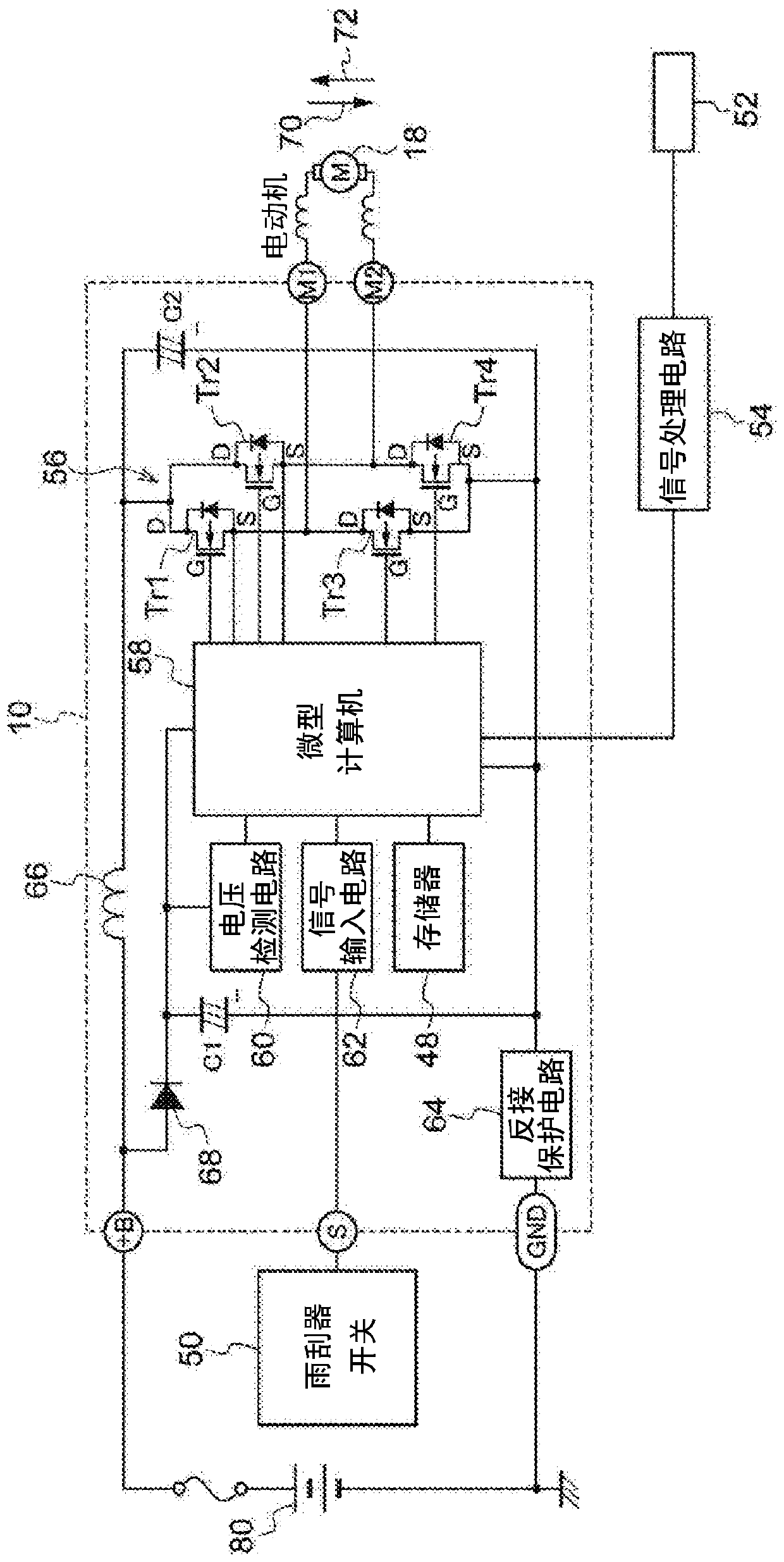

Wiper device

InactiveUS20190329735A1Easy to detectSuppress pressure changesVehicle cleaningEngineeringControl circuit

A wiper device includes a wiper arm that includes a recess and that is swung due to rotation of a wiper motor, the wiper arm causes a wiper blade coupled to a leading end portion of the wiper arm to perform a wiping operation across a surface of a windshield glass, an acceleration sensor that is installed in the recess of the wiper arm, a drive circuit that generates a voltage to be applied to the wiper motor, and a control circuit that controls the drive circuit such that a voltage to reduce a change in acceleration of the wiper arm, detected by the acceleration sensor, is applied to the wiper motor.

Owner:DENSO CORP

Substrate processing apparatus

ActiveUS9779921B2Suppress pressure changesHigh-quality thin filmElectric discharge tubesVacuum evaporation coatingEngineering

An apparatus includes a process chamber, a substrate holder arranged in the process chamber, a first shield provided on the peripheral portion of the substrate holder, and a second shield provided inside the process chamber. The internal space of the process chamber is partitioned into an outer space and a process space to process the substrate, by at least the first shield, the second shield, and the substrate holder. The substrate holder can be driven along a driving direction perpendicular to a substrate holding surface. The length, in a direction parallel to the driving direction, of a minimum gap portion having a minimum size in a direction perpendicular to the driving direction between the first and second shields does not change even if the substrate holder is driven in the driving direction.

Owner:CANON ANELVA CORP

Electromagnetic valve

ActiveCN101865323BReduce refrigerant flow soundStable throttlingOperating means/releasing devices for valvesFluid circulation arrangementEngineeringRefrigerant

The invention provides an electromagnetic valve. A valve core can be close to or far away from a valve seat part formed on a valve body through an electromagnetic coil, the valve body is provided with an inflow side channel and an outflow side channel, the valve core is provided with a conical first porous member and a disk-shaped second porous member, wherein the conical first porous member is arranged on the periphery of the valve core opposite to the inflow side channel, and the disk-shaped second porous member is kept in the valve core opposite to the outflow side channel. In the electromagnetic valve, because the periphery of the valve core formed to be a refrigerant inflow side is configured with the conical first porous member, the first porous member can subdivide air bubbles in refrigerants by utilizing a reduced conical part facing to the valve core, and the inflow air-liquid two-phase refrigerants can gradually diffuse to the porous member, which can diffusedly pass through the porous member. As a result, the first porous member can also be used as a constitution member for inhibiting pressure changes while being used as a constitution member for subdividing the air bubbles of the refrigerants.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

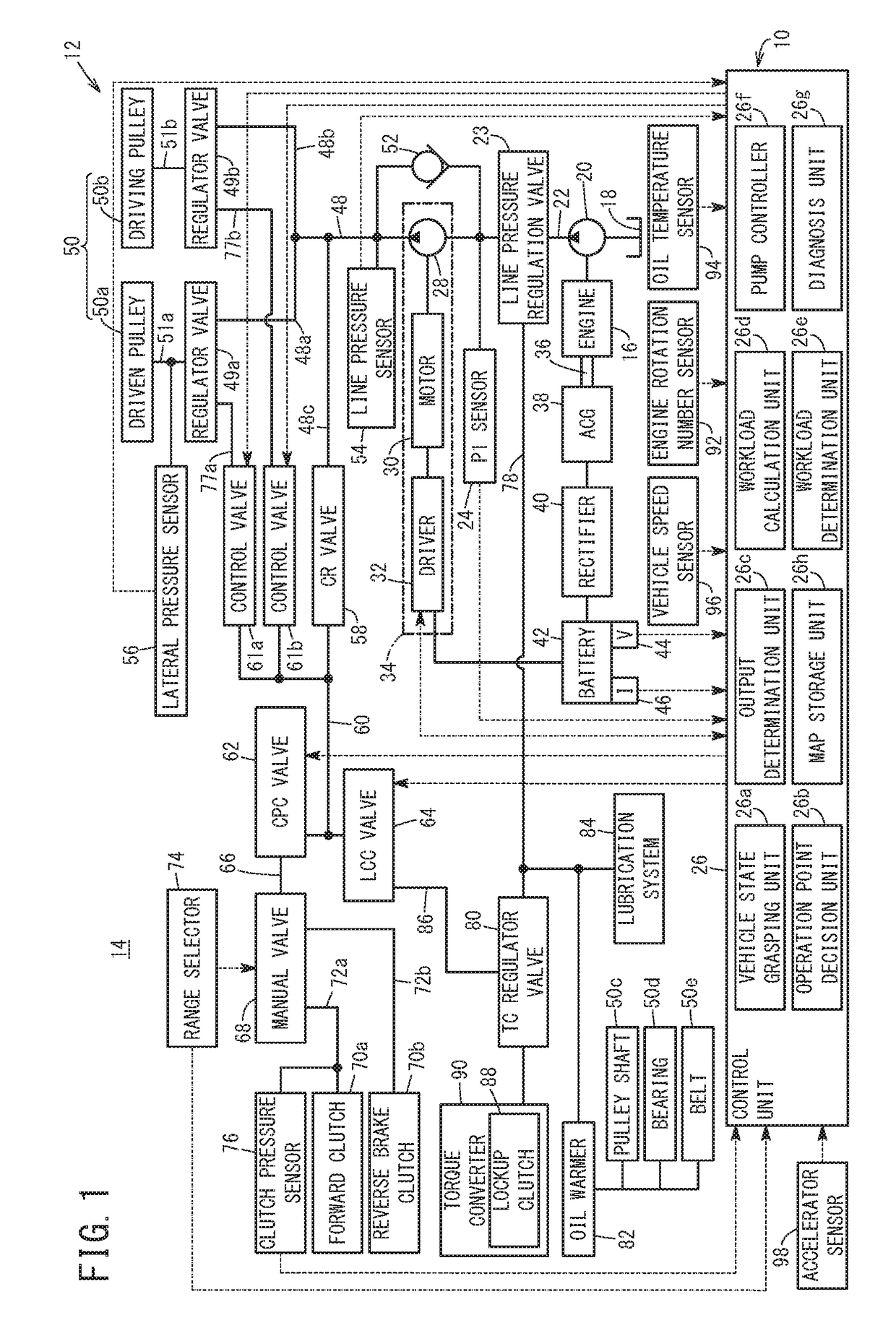

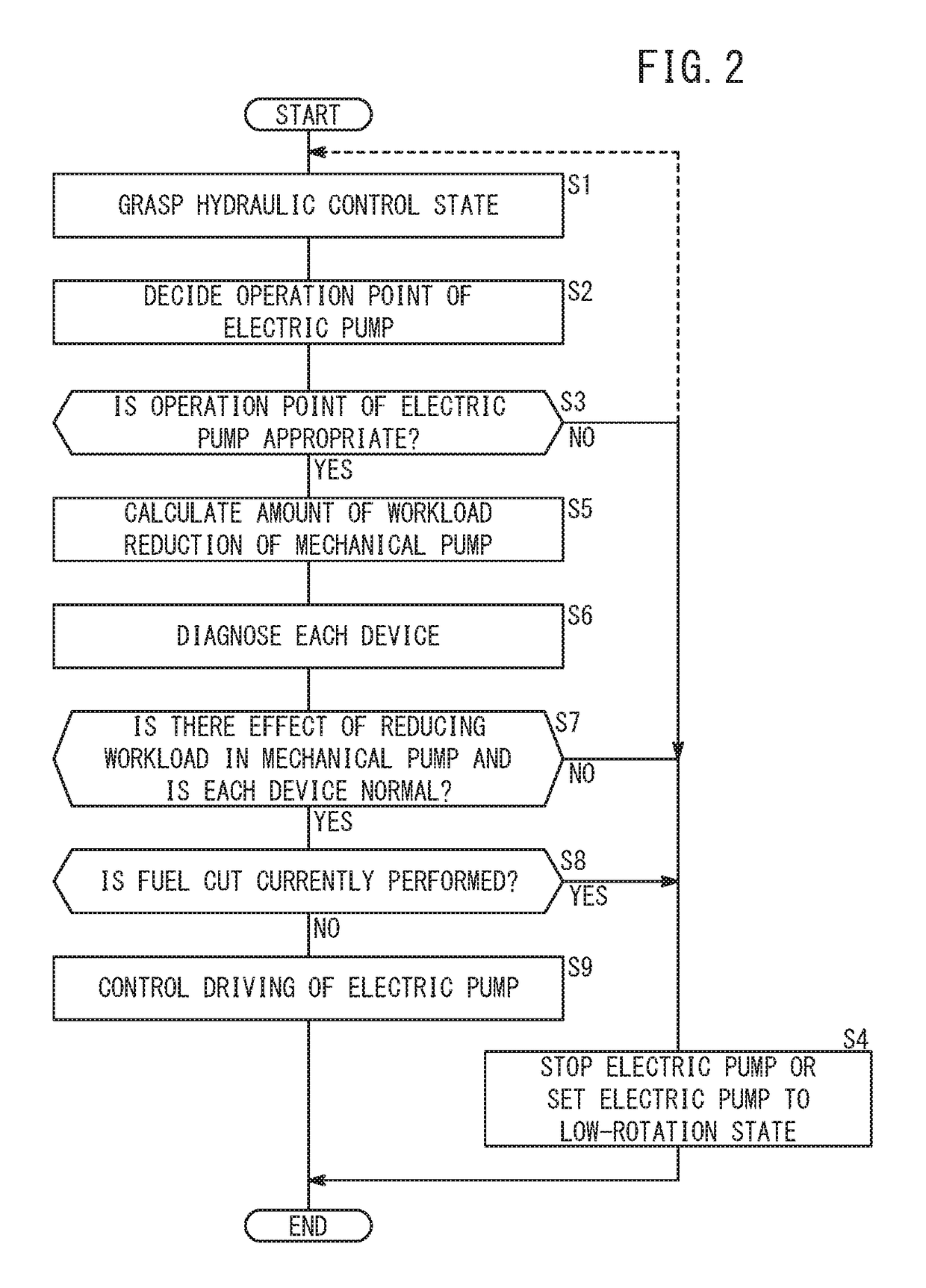

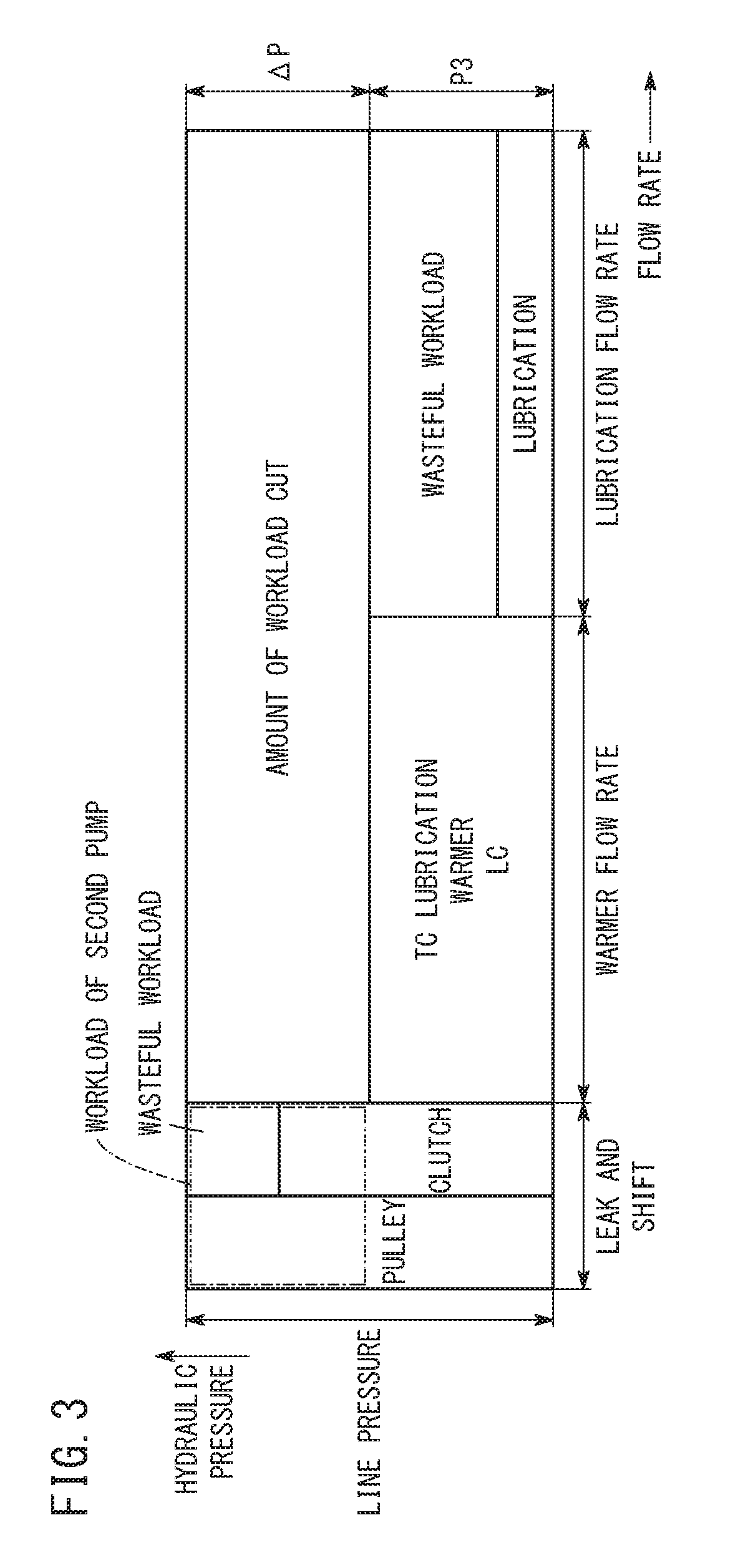

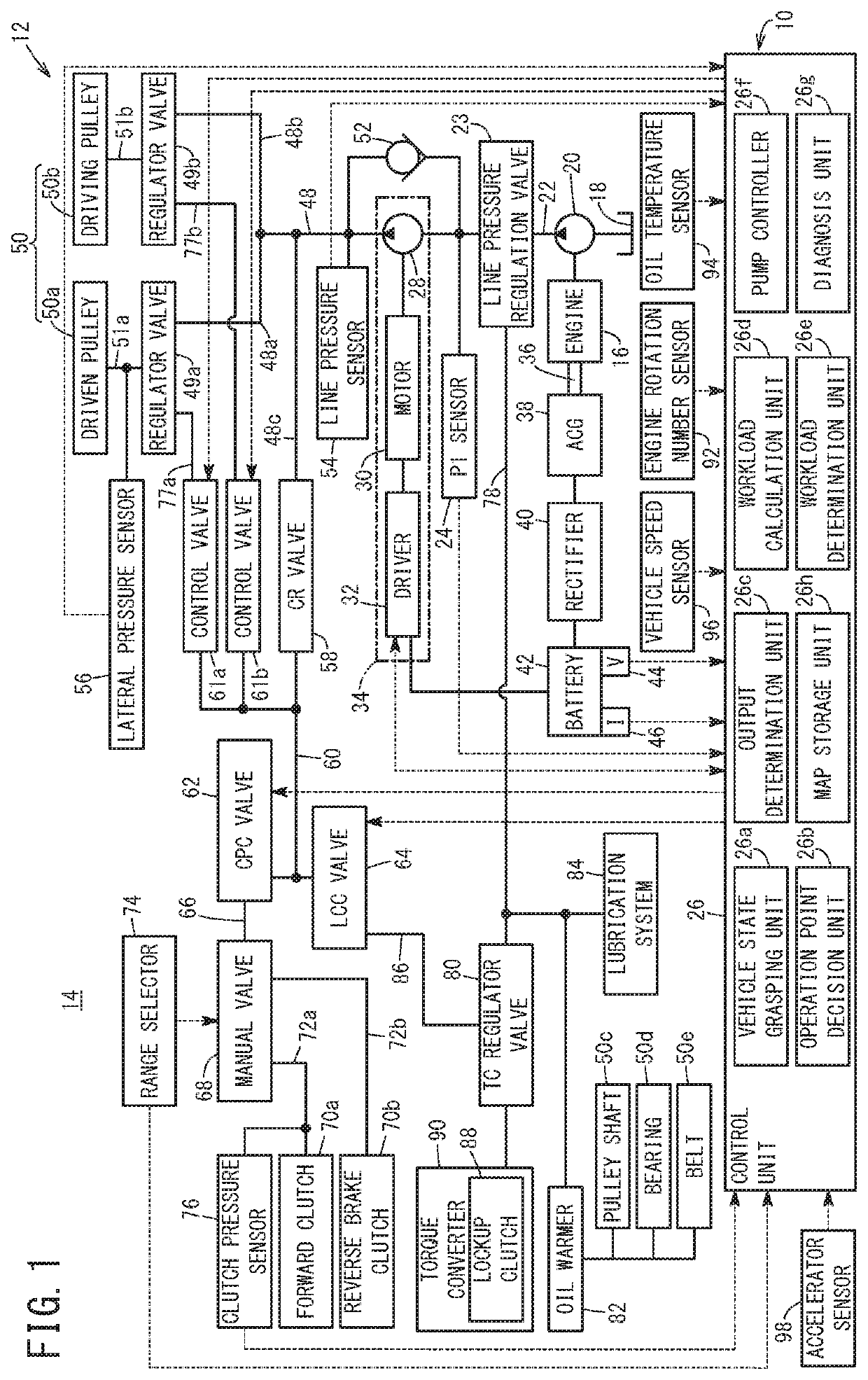

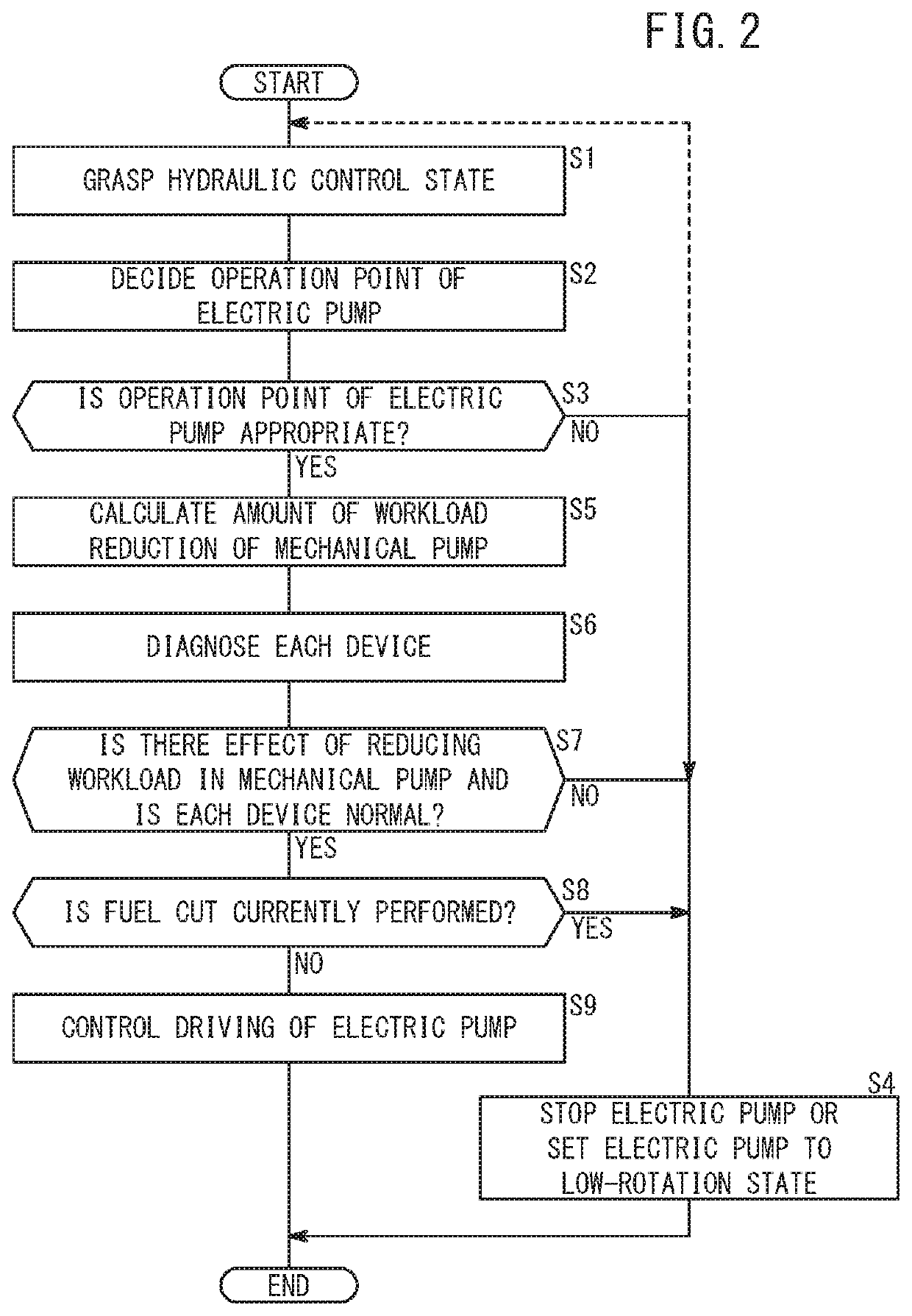

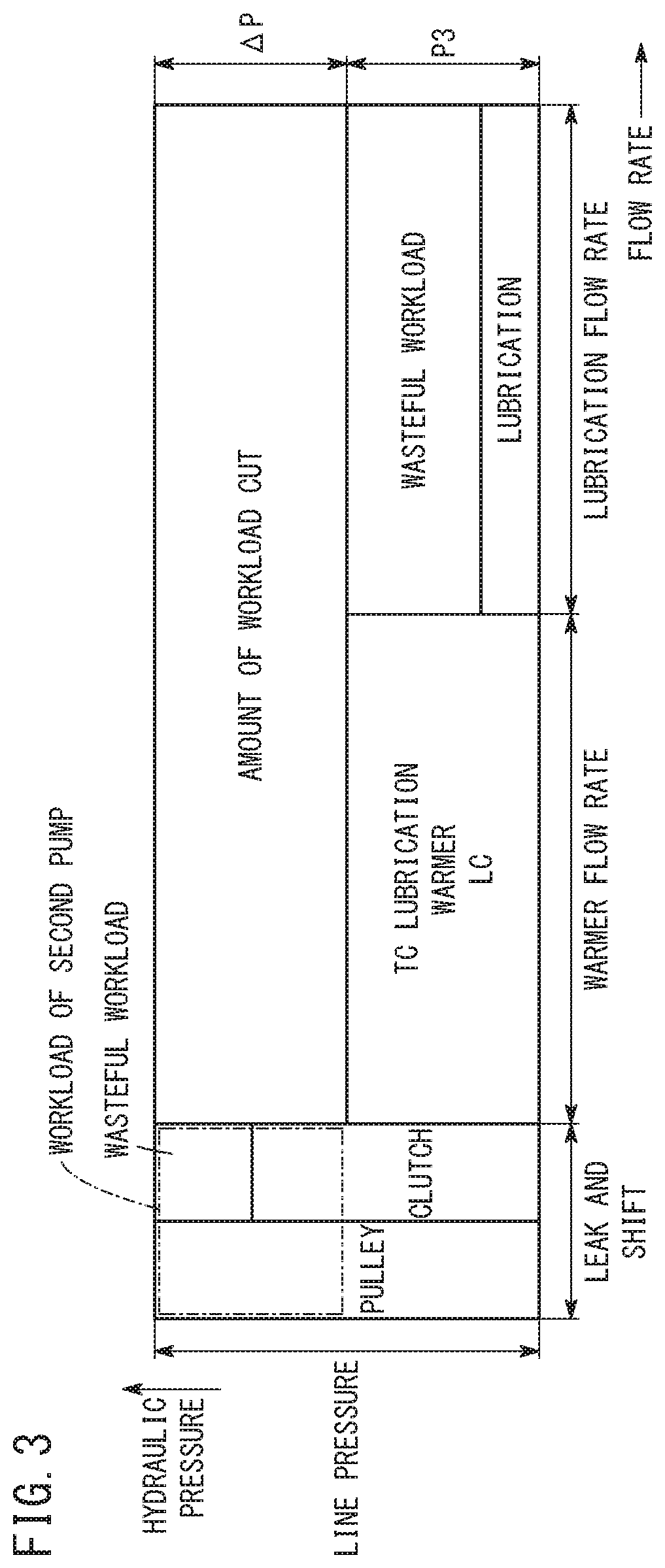

Hydraulic control device

ActiveUS20190048868A1Fuel efficiency deterioratesPrevent huntingServomotorsGearing controlEngineeringOperation point

In a control unit of a hydraulic control device, a vehicle state grasping unit grasps a vehicle state of a vehicle, and an output determination unit determines whether an operation point depending on the vehicle state that is decided by an operation point decision unit is over a discharging capability limit line. A pump controller stops a second pump or decreases a rotation number if the output determination unit determines that the operation point is over the discharging capability limit line.

Owner:HONDA MOTOR CO LTD

Vehicle-use alternator

InactiveUS7633196B2Suppressor mutationSuppress pressure changesMagnetic circuit rotating partsPump componentsAlternatorMechanical engineering

Owner:DENSO CORP

Hydraulic control device

ActiveUS10760681B2Avoid deterioration in fuel efficiency of vehiclePrevent huntingServomotorsGearing controlControl engineeringControl cell

Owner:HONDA MOTOR CO LTD

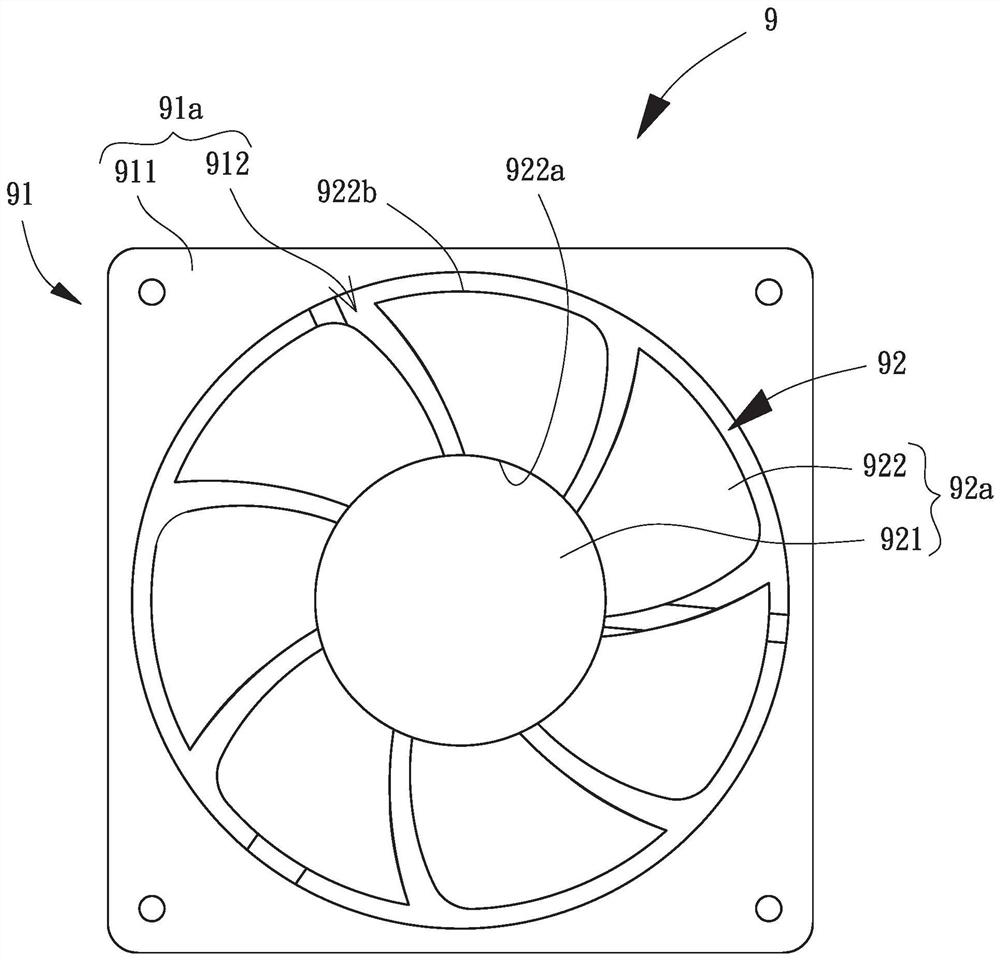

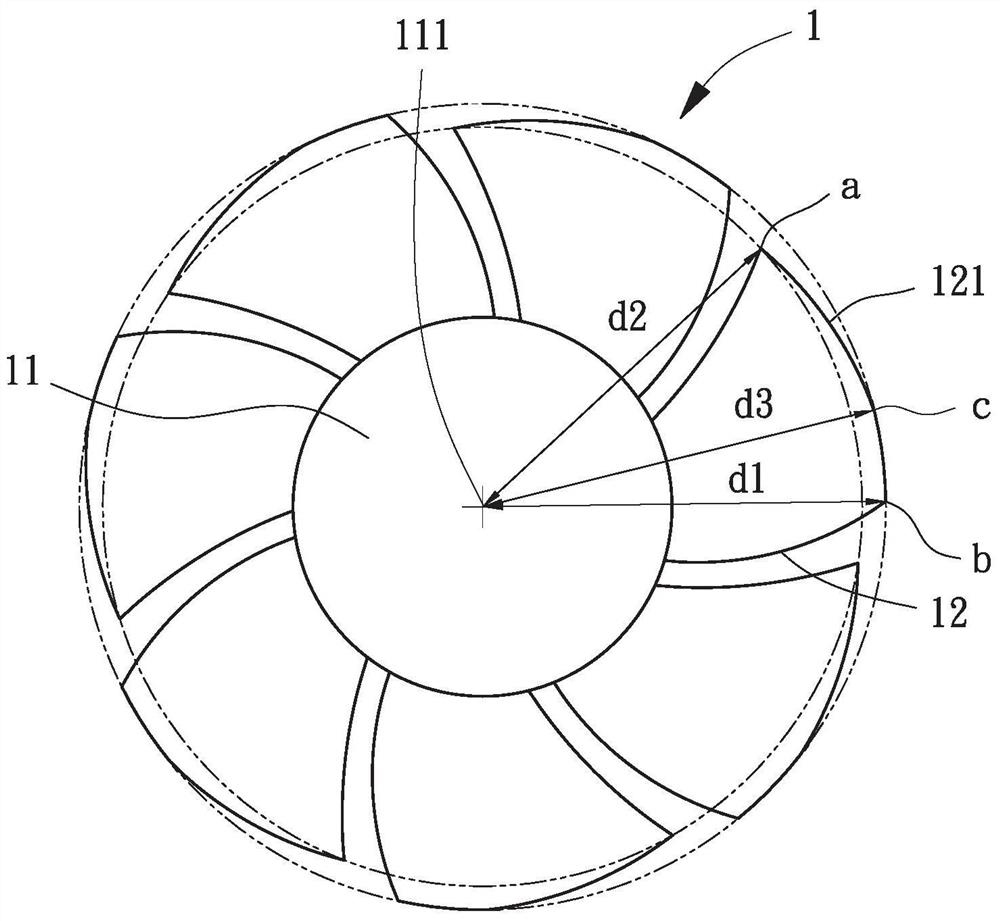

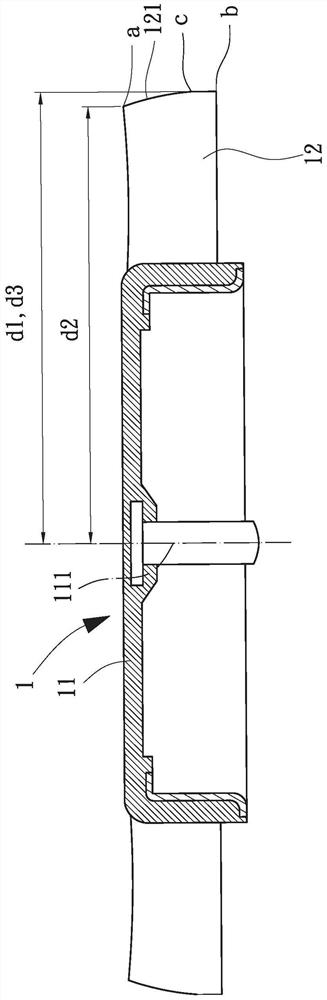

Axial fan

ActiveCN106812722BSignificant effect of pressure changesReduce running noisePump componentsPump installationsRotational axisImpeller

The invention provides an axial flow type fan and fan wheel thereof for the higher problem of axial flow fan running noise is commonly used in the solution. This axial flow fan's impeller contains a wheel hub and several flabellum. This wheel hub has a rotation axis. The several flabellum combines in abovementioned wheel hub, and respectively this flabellum upwards has a lateral border in the footpath of this impeller, and this lateral border is an inlet air extreme point and an air-out extreme point at the ascending both ends of axle of this impeller. Wherein, abovementioned lateral border more has a convergent and plays the initial point, and the distance that this convergent plays the supreme rotation axis of stating of initial point is greater than the distance of above -mentioned inlet air extreme point to this rotation axis.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

Photographic fixing roller, fixing device and image forming device

InactiveCN102279549BInhibition biasInhibit deteriorationElectrographic process apparatusImage formationEngineering

Owner:RICOH KK

Cleaning device and image forming apparatus

ActiveUS9014612B2Suppress pressure changesElectrography/magnetographyCoil springElectrical and Electronics engineering

A representative configuration of a cleaning device and an image forming apparatus according to the present invention includes: a photosensitive drum which bears a toner image; a cleaning blade which abuts against the photosensitive drum and removes a toner remained in the photosensitive drum; a compression coil spring which is compressed to pressurize the cleaning blade against the photosensitive drum; and a positioning boss which is arranged to face the compression coil spring, with a predetermined gap being provided therebetween, allows a movement in a direction perpendicular to a compression direction of the compression coil spring, and regulates a movement of the compression coil spring such that the compression coil spring is not moved by more than a predetermined amount in the direction perpendicular to the compression direction of the compression coil spring.

Owner:CANON KK

Fluid control valve

ActiveCN101506532BSuppress pressure changesSuppress pressure lossServomotor componentsServomotorsFluid controlEngineering

A fluid control valve wherein a main valve body includes: a high-pressure passage providing communication between a suction port and a sleeve in which a spool is fitted; a tank passage providing communication between a discharge port and the sleeve; a lift lock poppet located between the sleeve and a cylinder port and assuming an open position for providing communication between the sleeve and the cylinder port; a hydraulic fluid discharge passage providing communication between a back-pressure chamber provided within the lift lock poppet and the sleeve; a hydraulic fluid delivery passage located between the sleeve and the lift lock poppet; a cylinder passage located between the lift lock poppet and the cylinder port that communicates with the hydraulic fluid delivery passage when the lift lock poppet is in the open position, and a communication passage providing communication between the hydraulic fluid discharge passage and the hydraulic fluid delivery passage.

Owner:SHIMADZU SEISAKUSHO CO LTD

Windshield wiper device

InactiveCN109963755AAvoid damageSuppress pressure changesVehicle cleaningControl circuitDriving circuit

A windshield wiper device includes: a wiper arm which has a recess, is swung according to the rotation of a wiper motor, and allows a wiper blade coupled to the leading end thereof to wipe clean the surface of a windshield; an acceleration sensor which is mounted in the recess of the wiper arm; a drive circuit which generates a voltage to be applied to the wiper motor; and a control circuit whichcontrols the drive circuit so that a voltage which decreases the change in the acceleration of the wiper arm detected by the acceleration sensor is applied to the wiper motor.

Owner:DENSO CORP

Stator for rotating electric machine

ActiveUS9461513B2Improve environmental resistanceSuppress pressure changesWindings insulation shape/form/constructionCooling/ventillation arrangementElectric machineStator coil

A stator includes an annular stator core, a stator coil and at least one protective wall. The stator core has a plurality of slots formed therein. The slots are spaced from one another in a circumferential direction of the stator core. The stator coil is comprised of a plurality of windings mounted on the stator core. The windings are connected in a predetermined manner to form a plurality of connection portions therebetween. The connection portions are located outside the slots of the stator core on one axial side of the stator core. The at least one protective wall is provided radially inside the connection portions of the stator coil so as to shield the connection portions from the radially inside of the stator.

Owner:DENSO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com