Controller of injection molding machine

A technology for injection molding machines and controllers, applied in the field of injection molding machines, can solve problems such as increased injection pressure dispersion or minimum buffer volume, difficult control, and inability to inject molten resin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

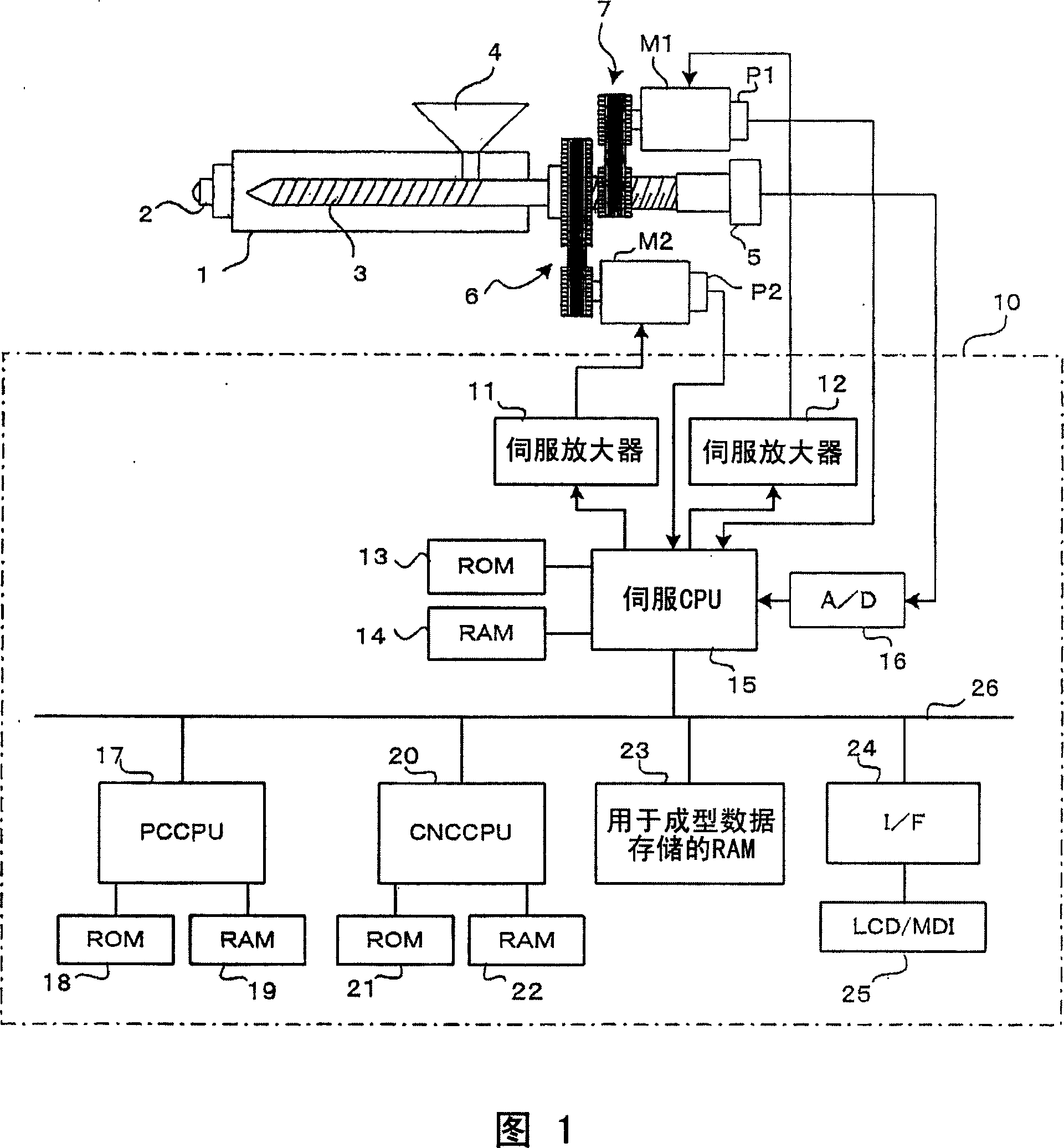

[0033] FIG. 1 shows the main components of an injection molding machine according to an embodiment of the present invention. The nozzle part 2 is pasted on the end of the injection barrel 1, and the screw 3 passes through the injection barrel 1. The screw 3 has a pressure sensor 5 such as a load cell for detecting the resin pressure acting on the screw 3 . A servo motor M2 for screw rotation rotates the screw 3 through a transmission mechanism 6 (consisting of pulleys, conveyor belts, etc.). Further, the servo motor M1 used for the forward and backward movement of the screw drives the screw 3 to move in its axial direction through the transmission mechanism 7, which includes a pulley, a conveyor belt, a ball screw / nut mechanism, and a mechanism for converting rotational motion into linear motion. some other agencies. Symbol P1 represents a position / speed detector that detects the shaft position and speed of the screw 3 by detecting the position / speed of the servo motor M1 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com