Photographic fixing roller, fixing device and image forming device

A technology of fixing roller and elastic layer, which is applied in the field of fixing roller, can solve the problems of expansion of difference, accelerated deterioration of heating belt, deformation of heating belt, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

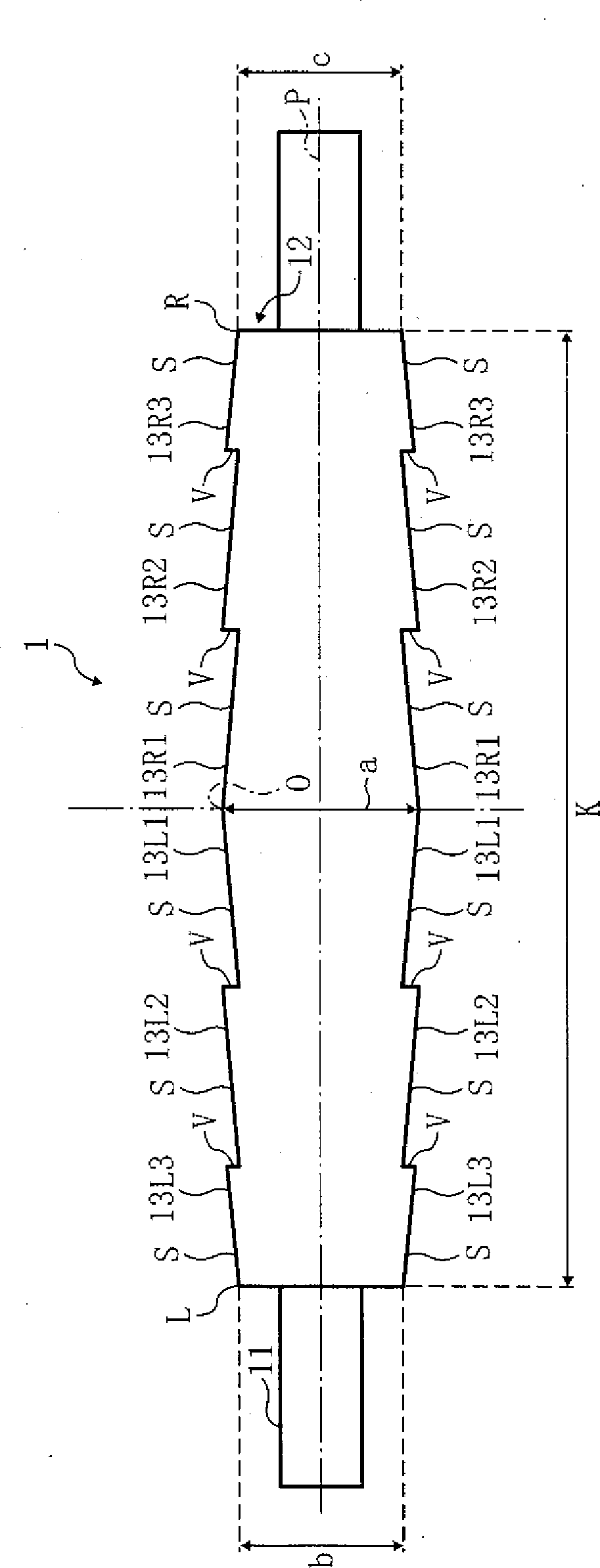

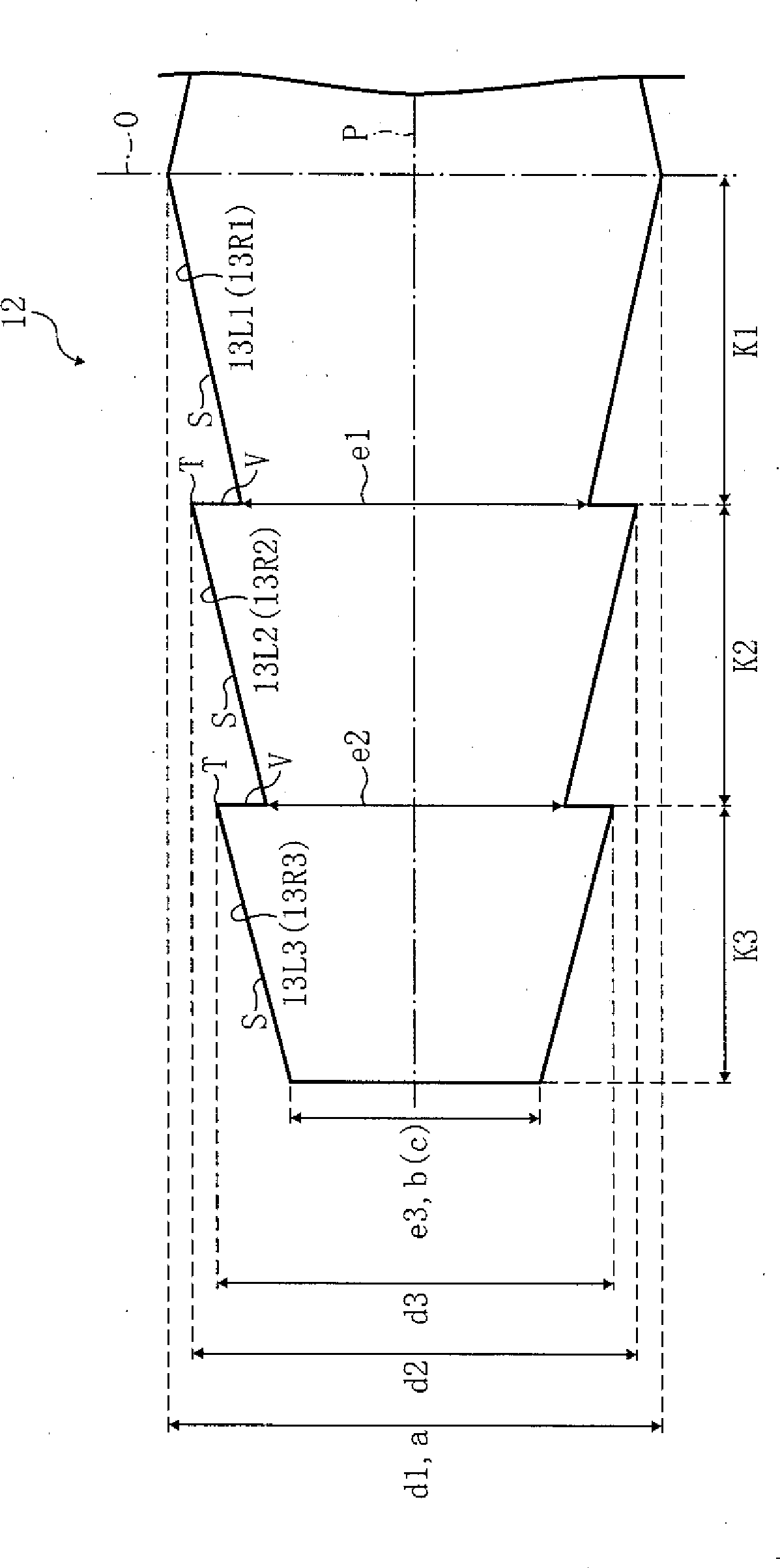

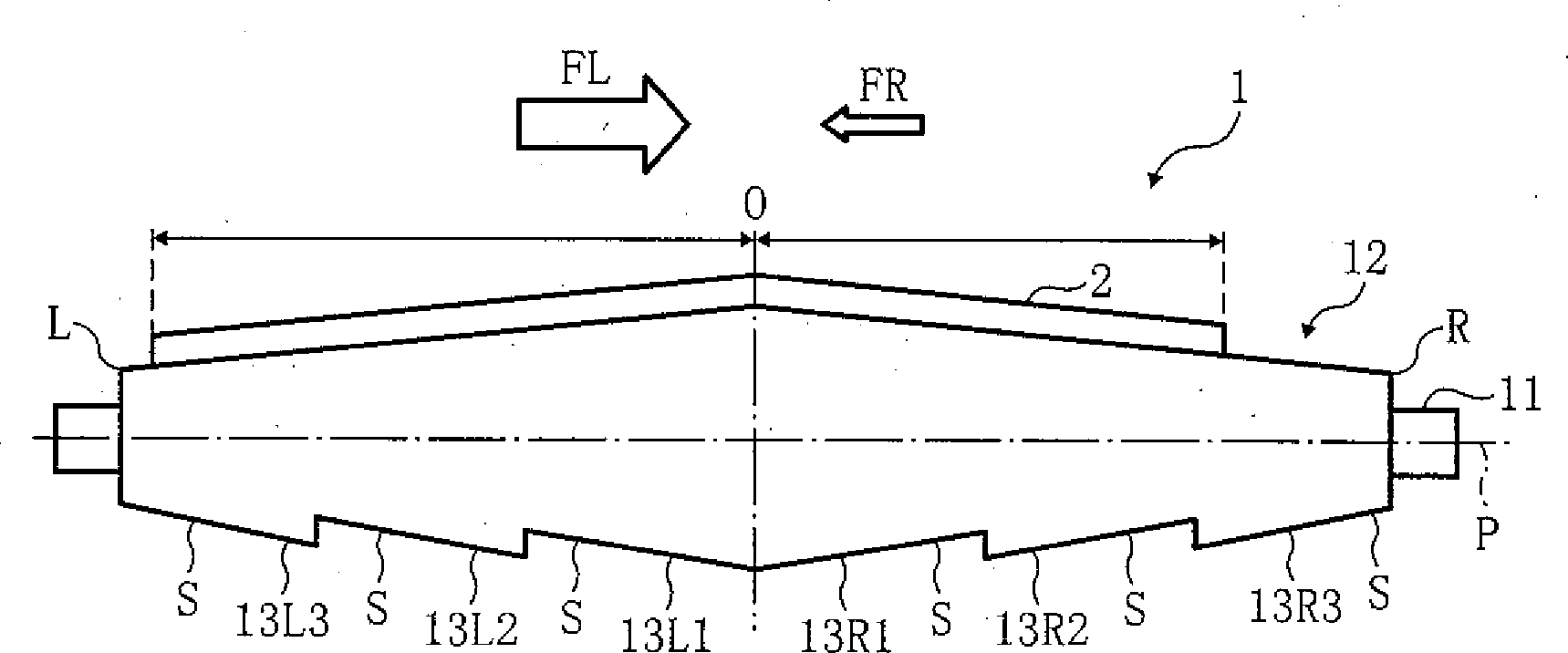

[0085] Below, refer to figure 1 Referring to FIG. 3 , a first embodiment of the fixing roller according to the present invention will be described.

[0086] figure 1 The illustrated fixing roller 1 includes a mandrel 11 and an elastic layer 12 . The mandrel 11 may be made of iron to form a hollow cylindrical shape. The mandrel 11 is installed in a fixing device 116 described later so as to be rotatable about its axis. The elastic layer 12 can be made of an elastic member such as foamed silicone rubber, is formed in a cylindrical shape, is closely overlapped in the outer peripheral surface of the mandrel 11 , and is arranged coaxially with the mandrel 11 . Such as figure 1 , figure 2 As shown, in the outer peripheral surface (surface portion) of the elastic layer 12, a plurality of protrusions 13 (13L1-13L3, 13R1-13R3) protruding in the outward direction are provided.

[0087] Each of these protrusions 13 is provided with a right conical surface S which is high on the...

no. 2 approach

[0115] A second embodiment of the fixing roller according to the present invention will be described below. Since the fixing roller of the second embodiment has the same shape as that of the first embodiment, only the dimensions of each part are different, so refer to the description of the above-mentioned first embodiment. figure 1 , figure 2 .

[0116] In the fixing roller 1 of the second embodiment, the shapes of the right conical surfaces S of all the convex portions 13 ( 13L1 - 13L3 , 13R1 - 13R3 ) are the same. Specifically, the right conical step differences Ht1-Ht3 in the right conical surface S of each convex portion 13 are the same, and the total lengths K1, K2, and K3 of the convex portions 13 are all the same.

[0117] In this way, by making the shape of the right conical surface S of all the protrusions 13, that is, the angle with respect to the axial direction of the elastic layer in the right conical surface S and the length of the generatrix of the right co...

no. 3 approach

[0121] Below, refer to Figure 4-Figure 6 A third embodiment of the fixing roller according to the present invention will be described.

[0122] Figure 4 The illustrated fixing roller 1A includes a mandrel 11 and an elastic layer 12A. The formation of the mandrel 11 is the same as that of the first embodiment described above. The elastic layer 12A may be made of an elastic member such as foamed silicon, and is formed in a cylindrical shape, closely overlapped on the outer peripheral surface of the mandrel 11 and arranged coaxially with the mandrel 11 . Such as Figure 4 , Figure 5 As shown, in the outer peripheral surface (surface portion) of the elastic layer 12A, a plurality of protrusions 14 ( 14L1 - 14L3 , 14R1 - 14R3 ) protruding outward are provided.

[0123] Each of these protrusions 14 is provided with a right conical surface S that is high on the center O side in the axial direction P of the elastic layer 12A and is low on the end L, R sides. Among the plurali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com