Piezoelectric element, ink jet head, angular velocity sensor, manufacturing method thereof, and ink jet type recording apparatus

a piezoelectric element and ink jet technology, applied in the field of piezoelectric elements, can solve the problems of increasing the cost of piezoelectric elements, and thus the cost of ink jet heads using piezoelectric elements, and the difficulty of obtaining a well-oriented film having a desirable crystallinity in the film formation process,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 2

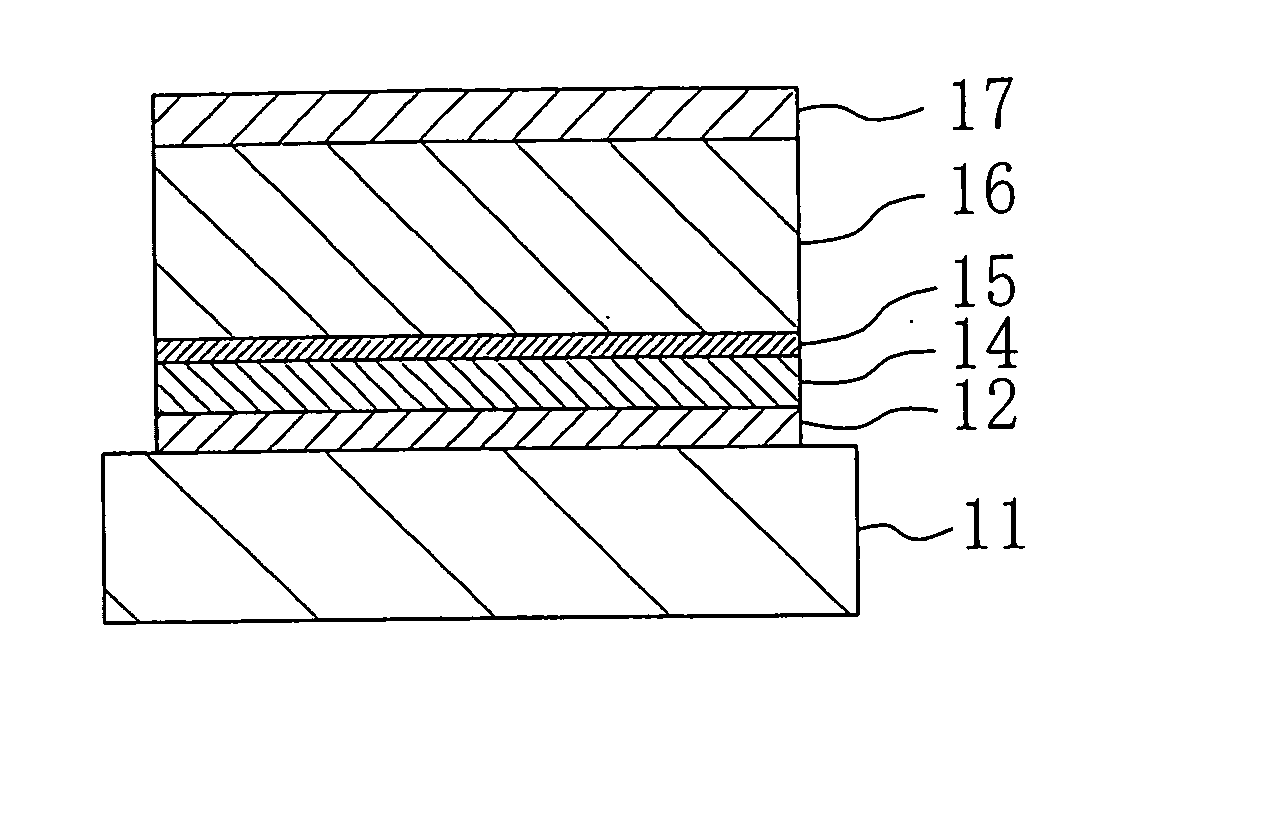

[0127] In Example 2, a 4-inch stainless steel (SUS304) having a thickness of 0.25 mm was used as the substrate, a tantalum (Ta) film having a thickness of 0.01 .mu.m was used as the adhesive layer, a Pt film having a thickness of 0.25 .mu.m and containing 8 mol % of titanium oxide was used as the first electrode layer, a PLT film (to which 3 mol % of magnesium was added) having a thickness of 0.03 .mu.m and containing 17 mol % of lanthanum in which the lead content was 6 mol % in excess of the stoichiometric composition was used as the orientation control layer, a PZT film (Zr / Ti=40 / 60) having a thickness of 2.7 .mu.m was used as the piezoelectric layer, and a Pt film having a thickness of 0.1 .mu.m was used as the second electrode layer.

[0128] The adhesive layer was obtained by using a Ta target and applying a high-frequency power of 100 W thereto for 1 minute while heating the substrate to 500.degree. C. in an argon gas at 1 Pa.

[0129] The first electrode layer was obtained by usin...

example 3

[0139] In Example 3, a barium borosilicate glass having a thickness of 0.5 mm (size: 100 mm.times.100 mm) was used as the substrate, a nickel (Ni) film having a thickness of 0.005 .mu.m was used as the adhesive layer, an iridium (Ir) film having a thickness of 0.15 .mu.m and containing 18 mol % of titanium was used as the first electrode layer, a PLT film (to which 1 mol % of manganese was added) having a thickness of 0.02 .mu.m and containing 8 mol % of lanthanum in which the lead content was 16 mol % in excess of the stoichiometric composition was used as the orientation control layer, a PZT film (Zr / Ti=60 / 40) having a thickness of 2.6 .mu.m was used as the piezoelectric layer, and a Pt film having a thickness of 0.01 .mu.m was used as the second electrode layer.

[0140] The adhesive layer was obtained by using an Ni target and applying a high-frequency power of 200 W thereto for 1 minute while heating the substrate to 300.degree. C. in an argon gas at 1 Pa.

[0141] The first electrod...

example 4

[0151] In Example 4, a 4-inch silicon wafer having a thickness of 0.5 mm was used as the substrate, a titanium film having a thickness of 0.01 .mu.m was used as the adhesive layer, an Ir film having a thickness of 0.25 .mu.m and containing 5 mol % of titanium oxide was used as the first electrode layer, a PLT film having a thickness of 0.05 .mu.m and containing 10 mol % of lanthanum in which the lead content was 10 mol % in excess of the stoichiometric composition was used as the orientation control layer, a PZT film (Zr / Ti=52 / 48) having a thickness of 3.2 .mu.m was used as the piezoelectric layer, and a Pt film having a thickness of 0.01 .mu.m was used as the second electrode layer.

[0152] The adhesive layer was obtained by using an Ti target and applying a high-frequency power of 100 W thereto for 1 minute while heating the substrate to 500.degree. C. in an argon gas at 1 Pa.

[0153] The first electrode layer was obtained by using a Ti target and an Ir target and applying high-freque...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Nanoscale particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Adhesion strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com