Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Stable stockpile" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

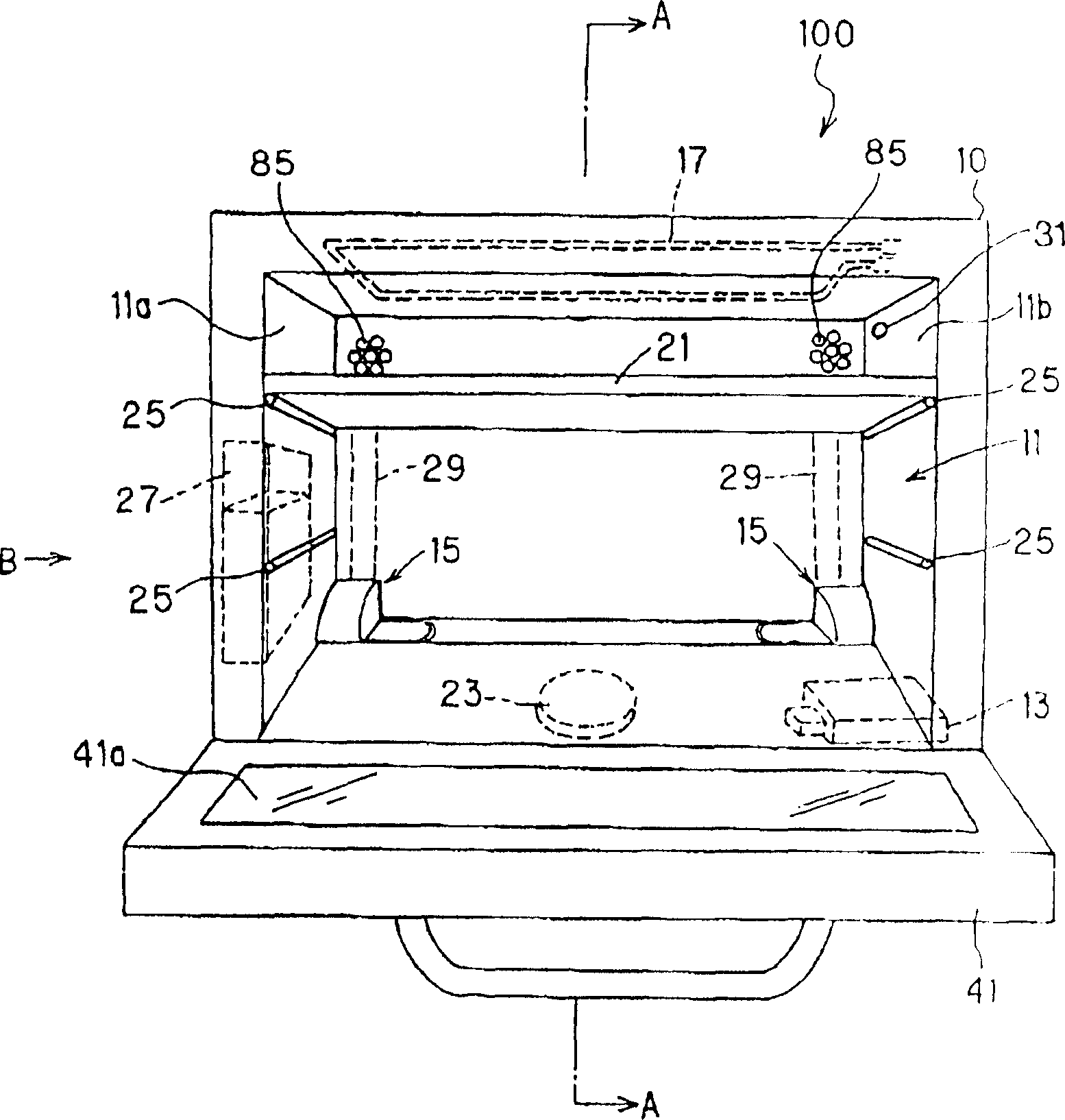

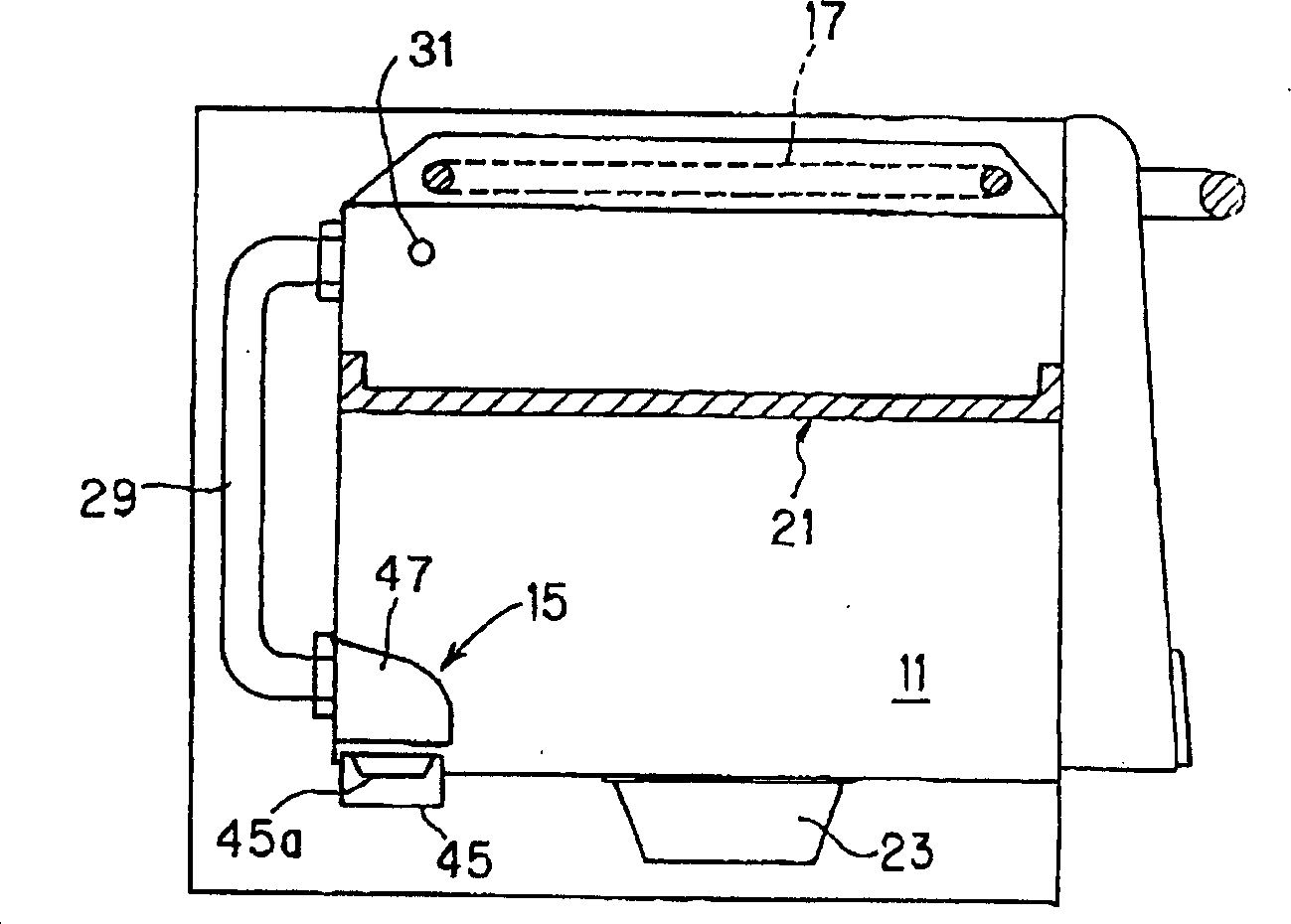

High frequency heating apparatus having a steam generating function

InactiveCN1811277AAvoid distractionHigh frequency supplyDomestic stoves or rangesLighting and heating apparatusEngineeringLower face

The invention provides a high-frequency heating cooking-vessel which can lead heated objects to be rapidly heated up to a preset heating temperature and can effectively utilize steam to heat a cooking with high efficiency. The high-frequency heating cooking-vessel (10) is provided with a high-frequency generating portion (13) and a steam generating portion (15) which produces steam in a heated heating room (11), which can feed any one in the high frequency and steam to the heating room (11), thereby heating and processing a heated object which. The invention is provided with a carrier (21) which is carried to the heated object, is divided with a set interval with the lower face of the heating room (11), and is allocated on the upper portion of the lower face of the heating room to cut the space in the heating room (11) through a mode which can be freely dismounted, a stream delivering device (29) which supplies steam which is produced by the steam generating portion (15) to the upper space on the upper portion of the carrier (21) and a preheating device (17) which leads the integral temperature in the heating room to go up.

Owner:PANASONIC CORP

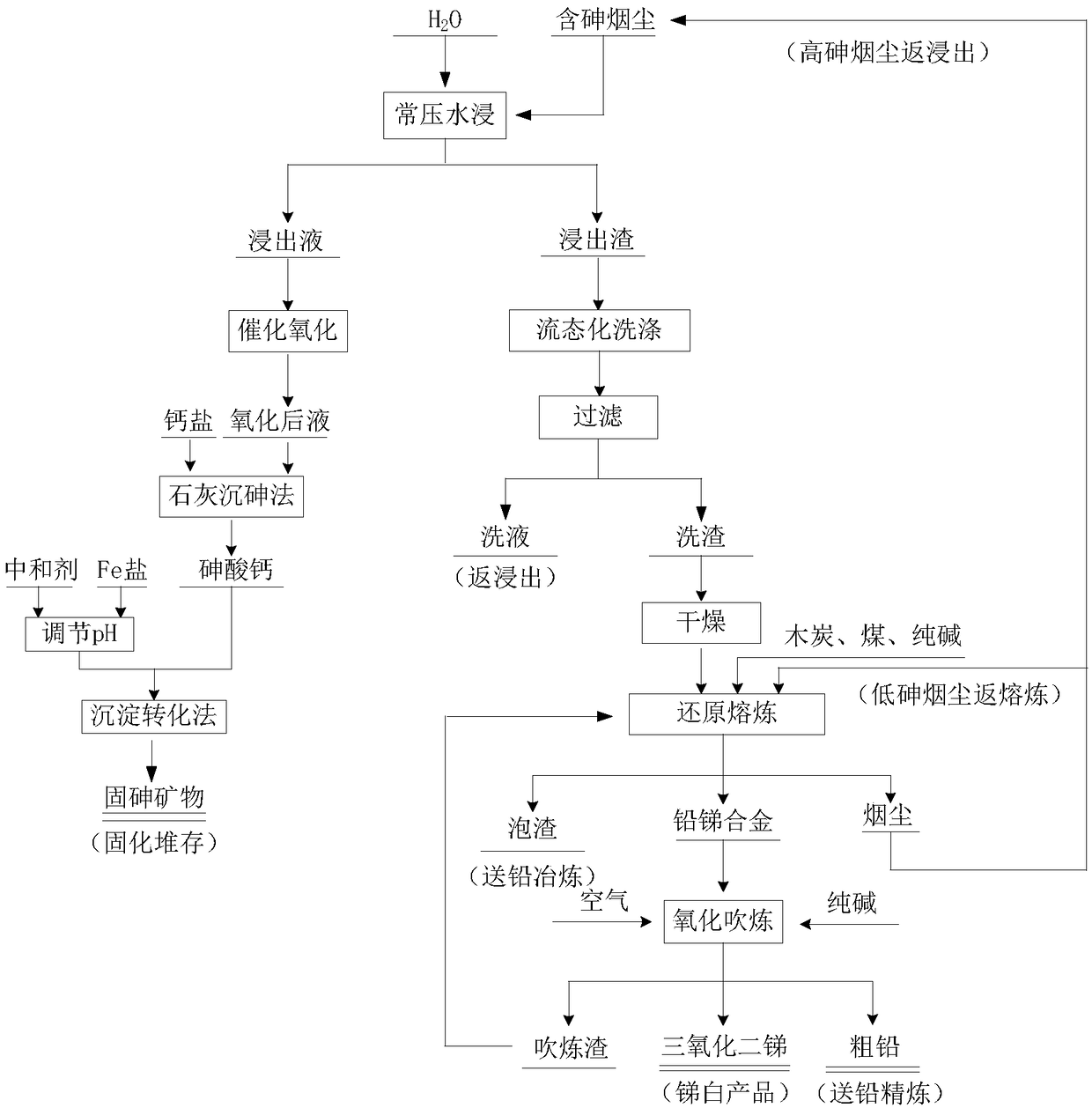

Method for arsenic removal of arsenic-containing dust and comprehensive recycling of valuable elements

ActiveCN106834716AReduce contentImplement resourcesProcess efficiency improvementCatalytic oxidationZinc smelting

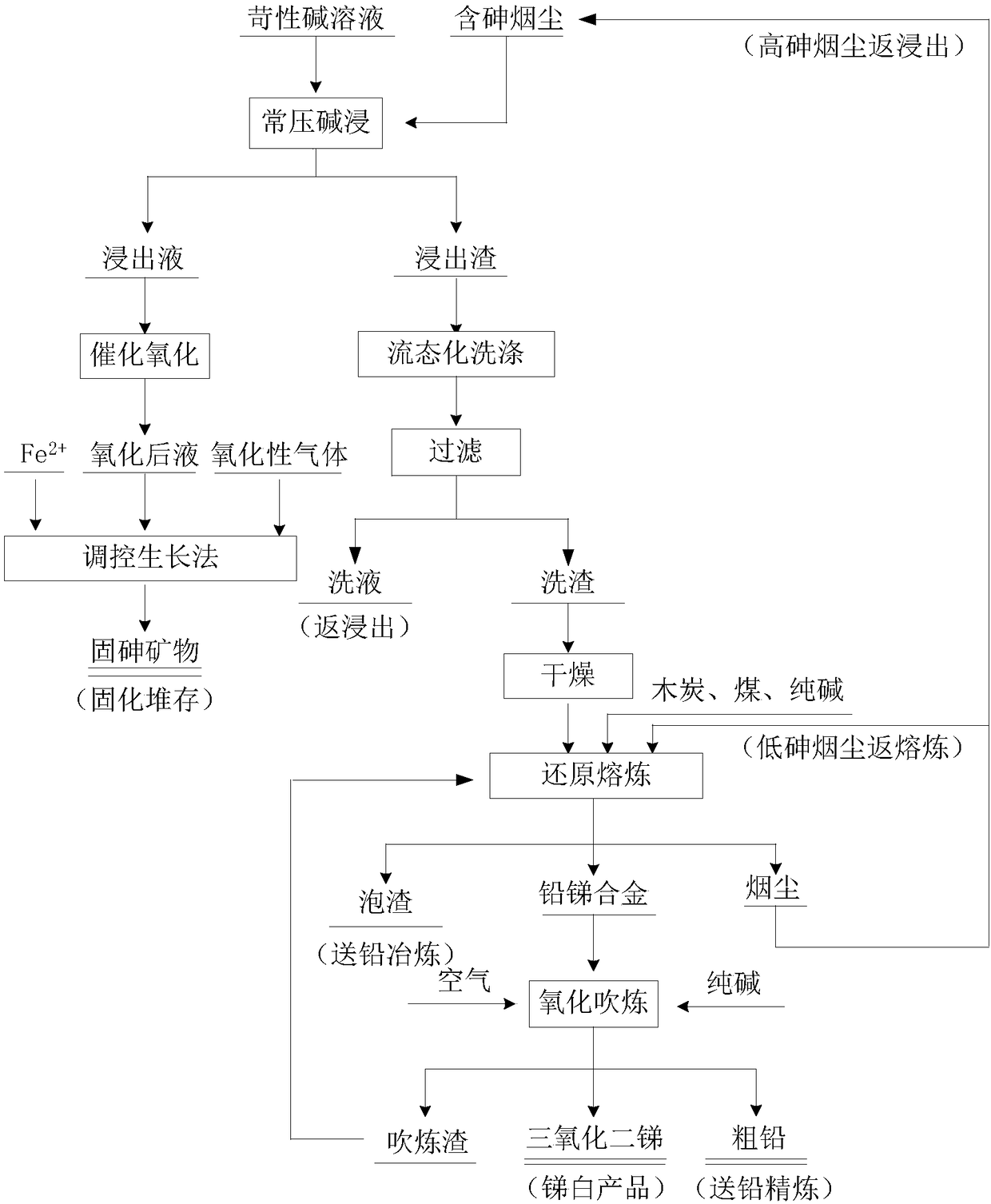

The invention relates to a method for arsenic removal of arsenic-containing dust and comprehensive recycling of valuable elements. According to the method, production of comprehensive recovery of valuable metals such as arsenic, antimony, lead, bismuth and the like from smelting dust containing the arsenic, the antimony and the lead is performed, accumulation of the arsenic in the system is reduced, and harmless treatment is performed on the arsenic. With the method, through normal pressure alkaline leaching, soluble arsenic in the dust is removed, after trivalent arsenic in a leaching solution becomes pentavalent arsenic through catalytic oxidation, stable arsenic-fixing minerals are synthesized with the method for arsenic precipitation with lime and the precipitation transforming method and are solidified through piling, leaching residues are subjected to procedures of washing, reduction smelting, oxidizing blowing and the like, and the various valuable elements are recycled to the maximum extent. With the method, the arsenic is removed from the dust, the antimony, the lead, the bismuth and the like are left in the arsenic-removed residues as much as possible, and separation and harmless treatment of the arsenic and the valuable metals can be realized. According to the method, the comprehensive utilization rate of resources is high, the raw material application range is wide, the problem of pollution in the extraction process of the traditional technology is solved, and the method has the more obvious advantages for the dust produced in the lead and zinc smelting process particularly.

Owner:CENT SOUTH UNIV

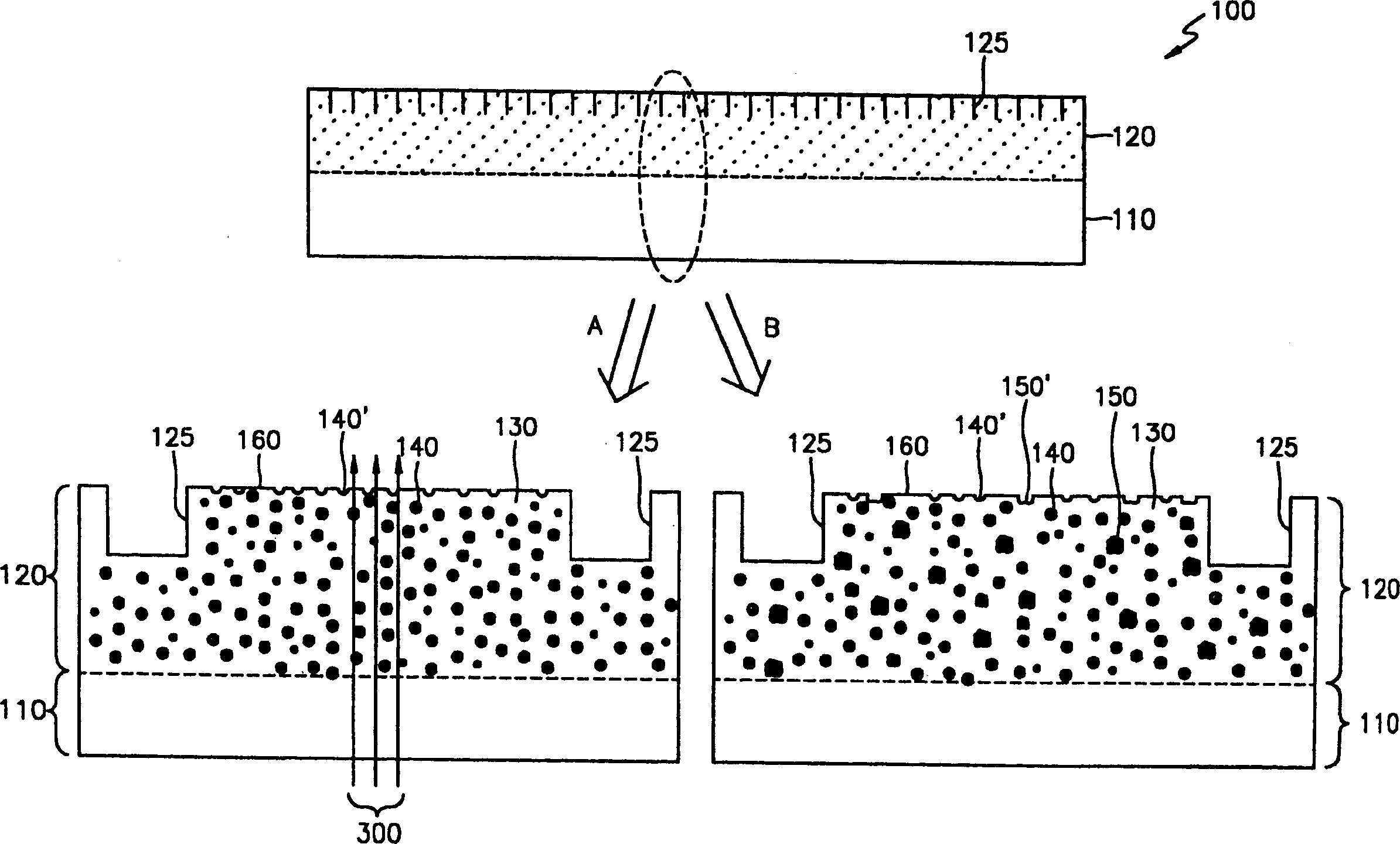

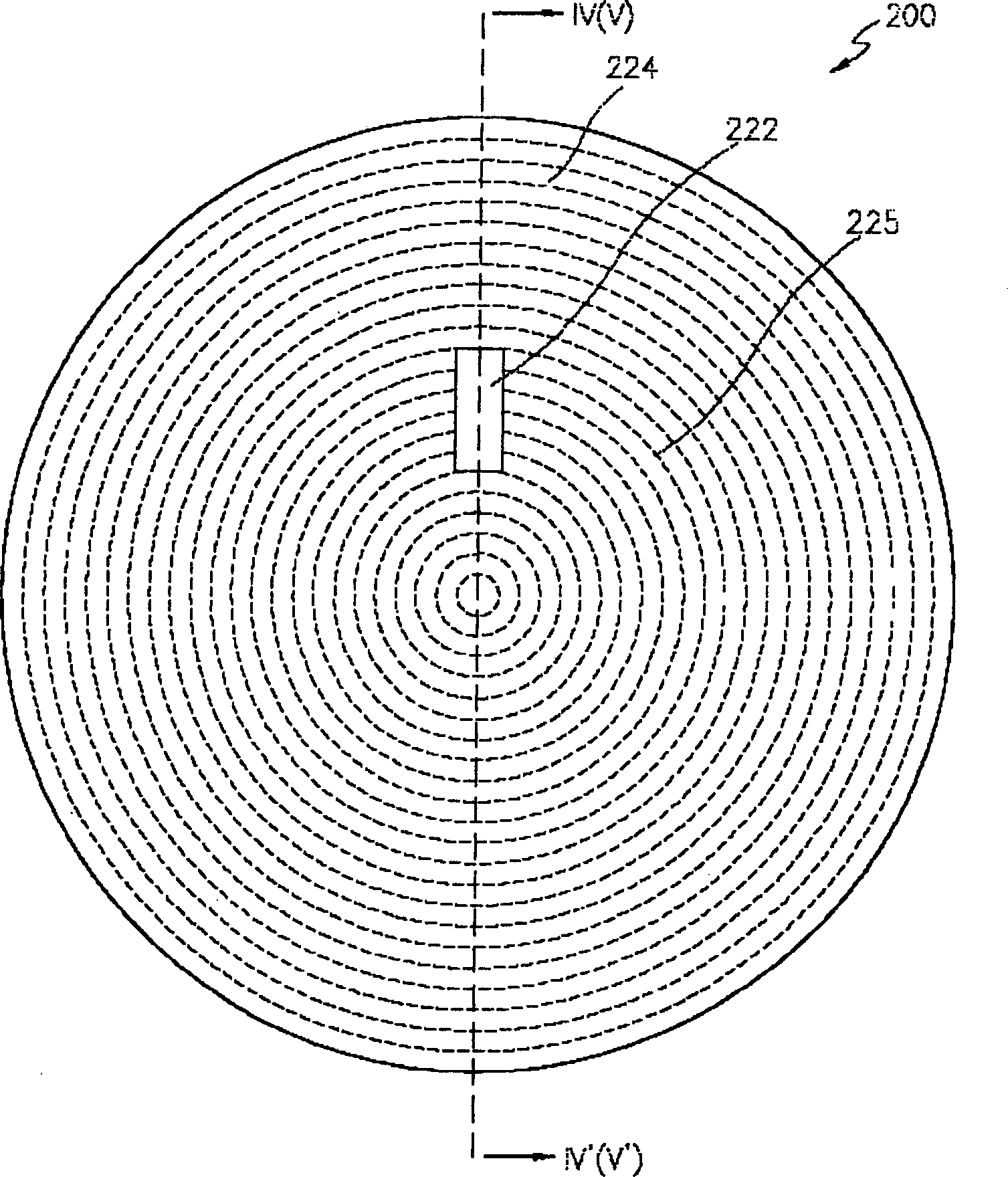

Integrated grinding pad and its mfg. method

InactiveCN1494986AImprove planarization efficiencyUniform physical propertiesLapping machinesAbrasion apparatusAdhesiveHardness

An integral polishing pad includes an elastic support layer and a polishing layer, which is formed on the elastic support layer and has a higher hardness than the elastic support layer. The elastic support layer and the polishing layer are made from materials chemically compatible with each other so that a structural border between the elastic support layer and the polishing layer does not exist. In addition, the integral polishing pad also includes a transparent region, which is transparent to a light source used to detect the surface state of an object being polished and integrated with the other elements of the integral polishing pad. The integral polishing pad has high planarization efficiency and uniform properties, and thus can be reliably used for polishing. In addition, the integral polishing pad prevents a congestion of a polishing slurry and facilitates delivery of the polishing slurry. The integral polishing pad does not need an adhesive for connecting elements or a process for bonding the elements, thereby simplifying manufacturing processes.

Owner:KPX CHEM

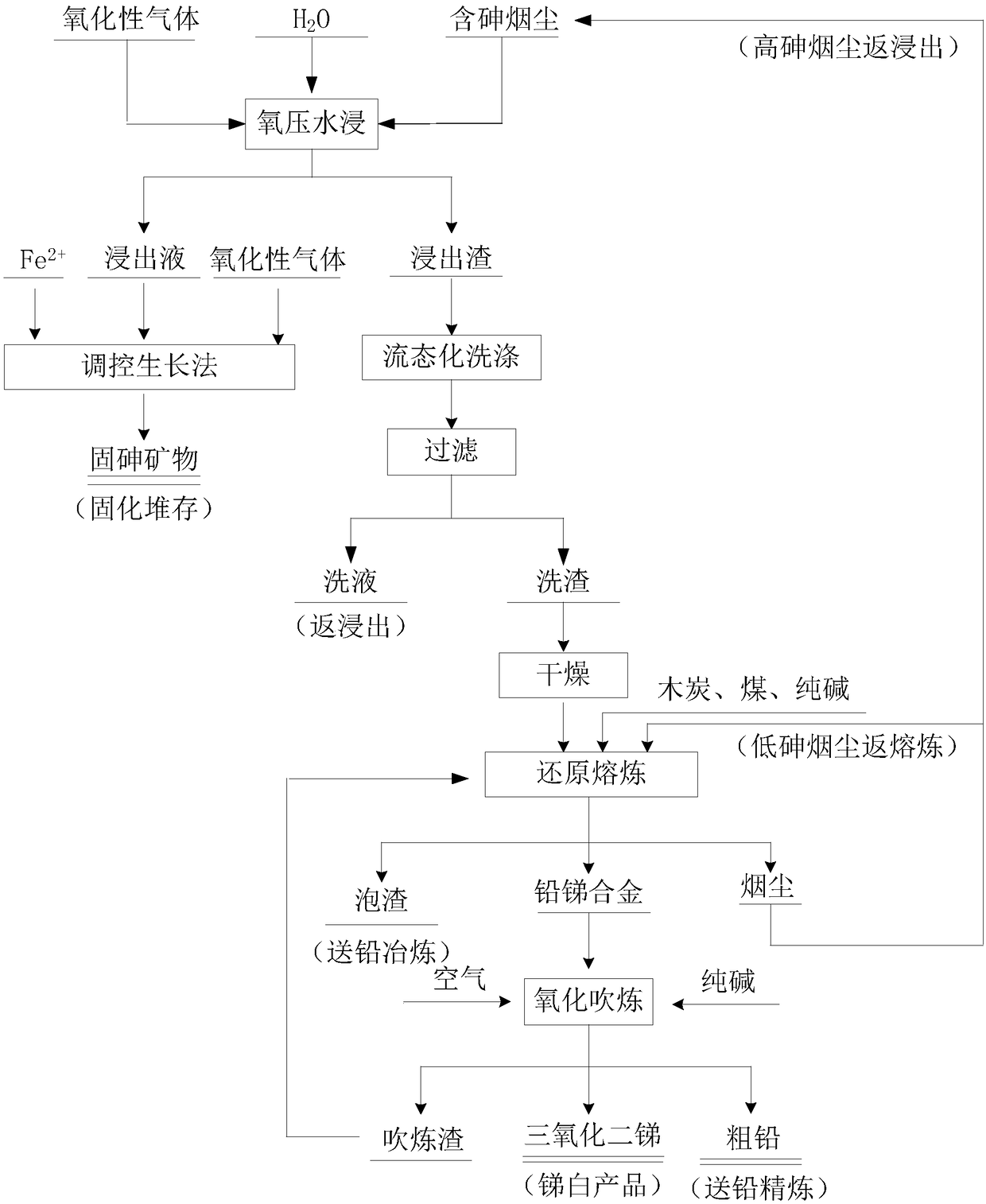

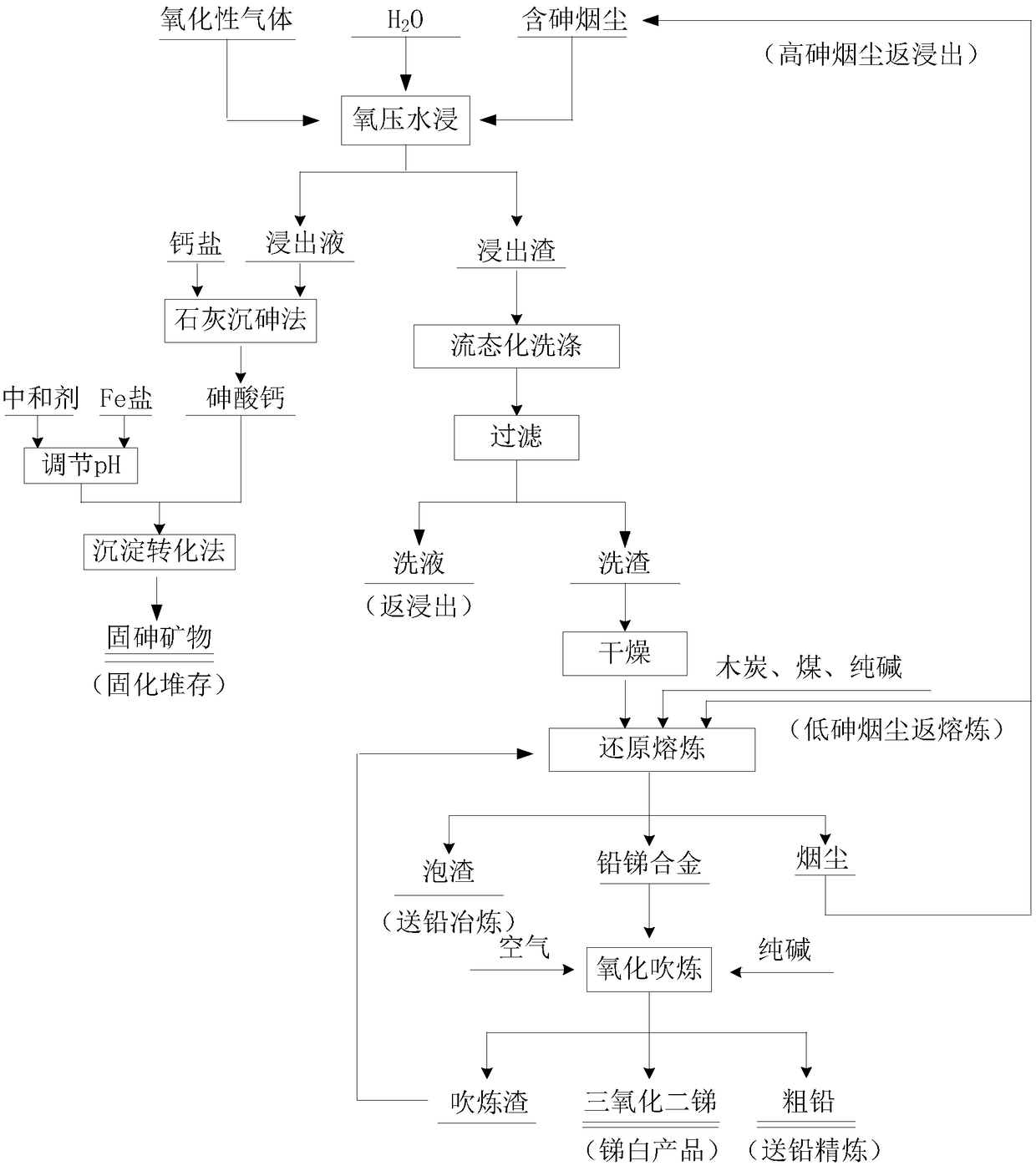

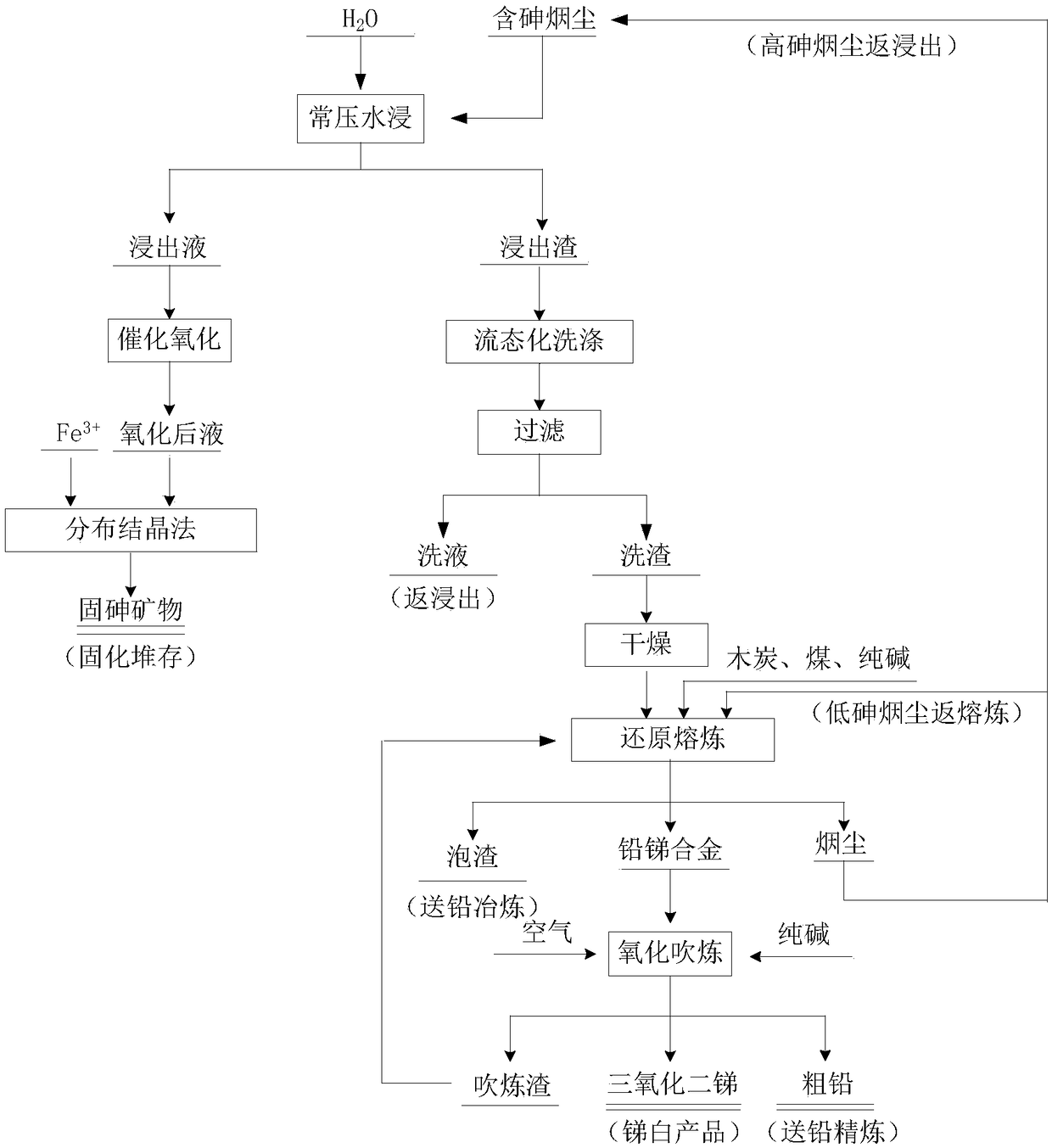

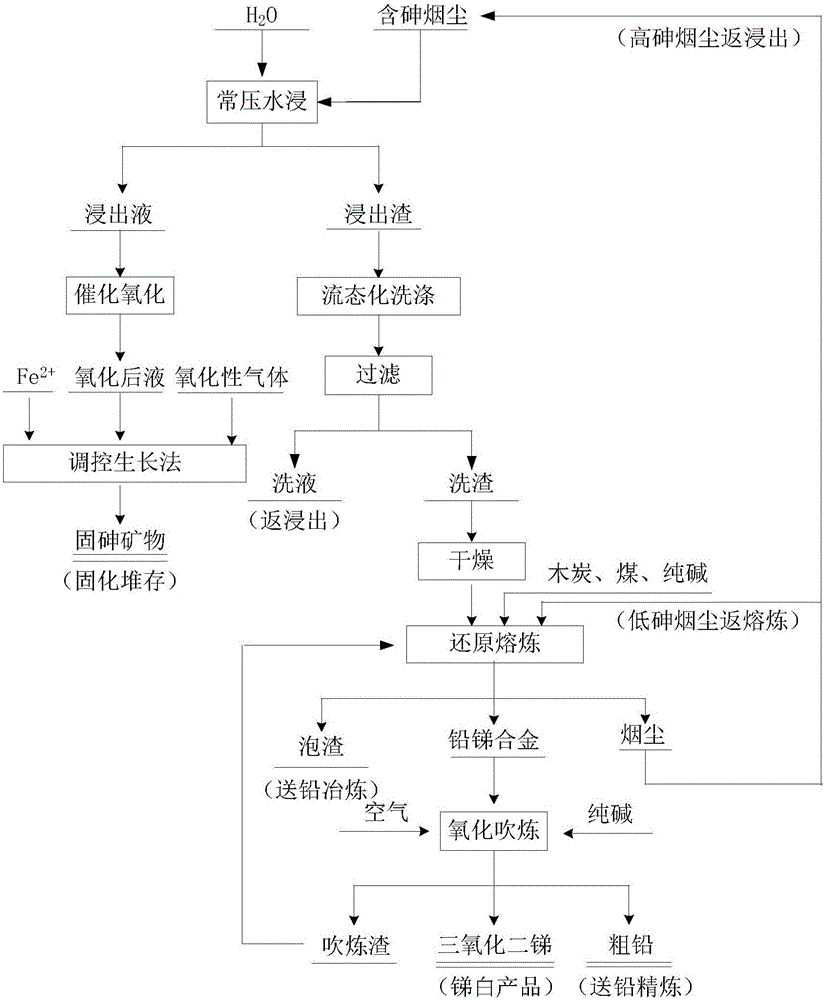

Method for comprehensively treating arsenic-contained smoke and synthesizing arsenic fixing minerals by control growth method

ActiveCN106834720AComprehensive utilization of resources is highRaw material adapts to a wide rangeProcess efficiency improvementSmelting processBismuth

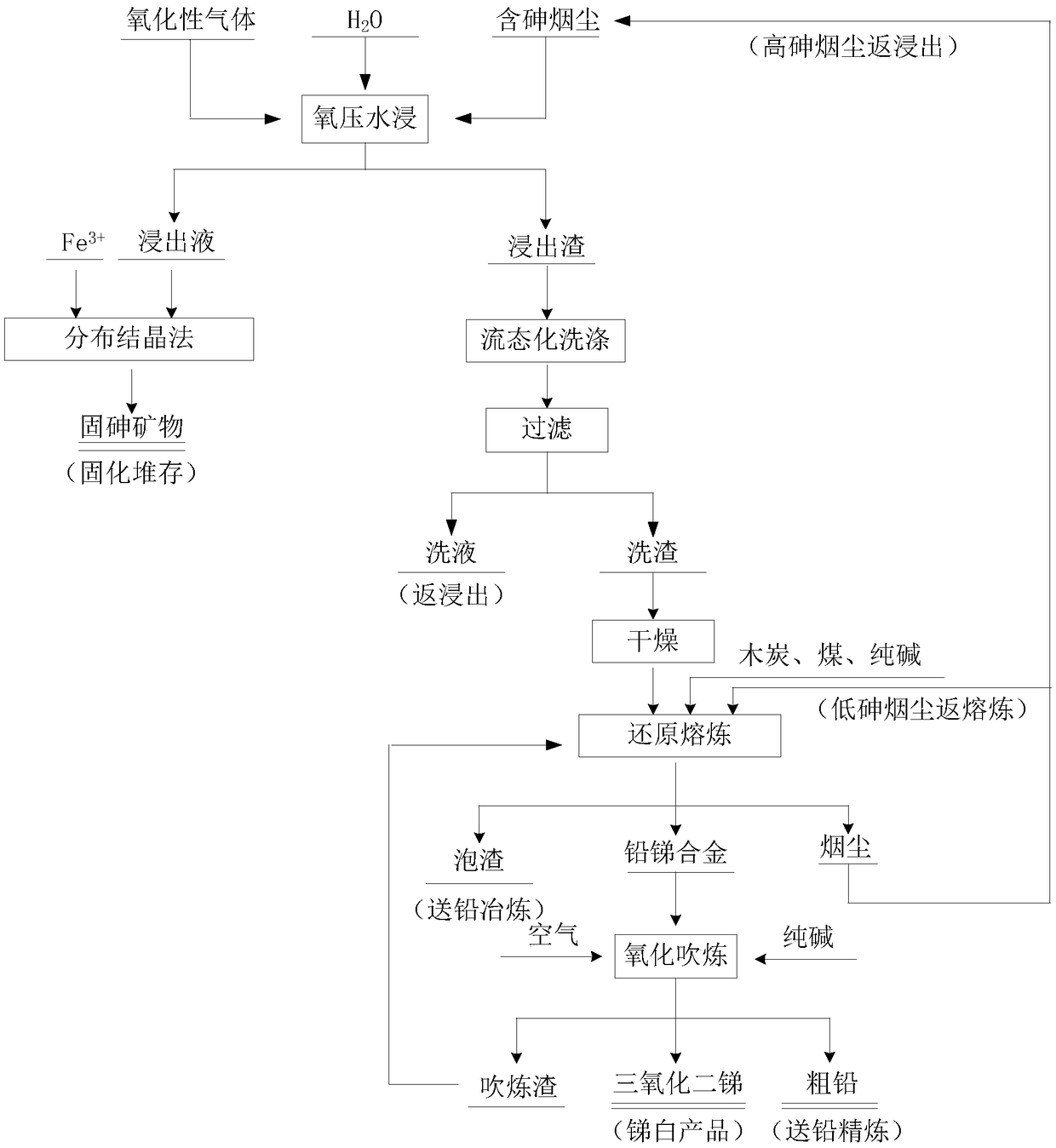

The invention belongs to the technical field of metallurgy, and in particular, relates to a method for comprehensively treating arsenic-contained smoke and synthesizing arsenic fixing minerals by a control growth method. The method comprises four steps of oxygen pressure water leaching, leaching liquid arsenic fixation, leaching slag washing and recovery of valuable metal from washing slag in sequence; the method uses the oxygen pressure water leaching for removing solvable arsenic in the smoke; arsenic in leaching liquid is synthesized as high-stability arsenic fixing minerals by the control growth method; and then, the arsenic fixing minerals are cured by a stockpiling mode. All valuable elements are recycled from leaching slag to the greatest extent by such procedures as washing, reduction smelting and oxidation blowing. The method removes arsenic from the smoke and synthesizes the stable arsenic fixing minerals, but retains antimony, lead, bismuth and the like in the leaching slag as far as possible, and realizes separation of arsenic from the valuable metal and harmlessness. The method is high in resource comprehensive utilization rate and wide in raw material application range, solves the pollution problem in the traditional extracting process, in particular the smoke generated in the lead-zinc smelting process, and is more obvious in advantages.

Owner:CENT SOUTH UNIV

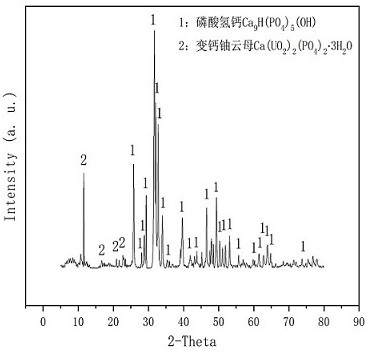

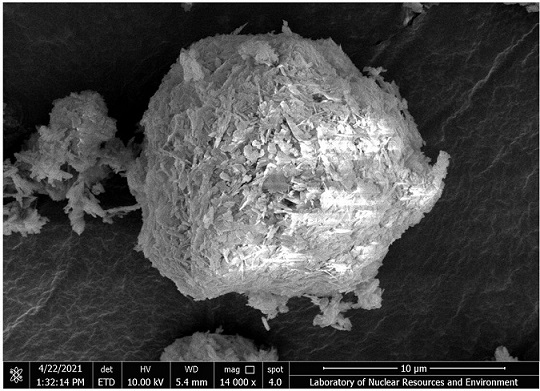

Method for direct mineral uranium fixation from acidic hexavalent uranium solution

ActiveCN113321196ALow costSimple processPhosphorus compoundsCalcium biphosphatePregnant leach solution

The invention relates to a method for direct mineral uranium fixation from an acidic hexavalent uranium solution, and belongs to the technical field of uranium-containing wastewater treatment. The method comprises the following steps: adding calcium phosphate into an acidic hexavalent uranium solution according to a solid-to-liquid ratio of (0.5-5.0): 1 g / L, and conducting reacting for 1-100 minutes at the temperature of 30-90 DEG C, so as to adsorb hexavalent uranium in the solution on the surfaces of particles of the calcium phosphate and fix the hexavalent uranium into a target mineral, namely calcium-changed uranium mica through mineral phase transformation; and after the reaction is finished, filtering the slurry, and conducting washing and drying to prepare a mixed product of the calcium-variable uranium mica and the calcium phosphate. According to the invention, TCLP toxic leaching with the pH being 4.98 is carried out on the mixed product, the result shows that the uranium-containing solid product has high leaching stability, the uranium concentration in the leachate is lower than 0.1 mg / L, and the uranium-containing solid waste safe stockpiling standard in the uranium mining and metallurgy facility decommissioning environment management technical regulation (GB 14586-93) can be met.

Owner:EAST CHINA UNIV OF TECH +1

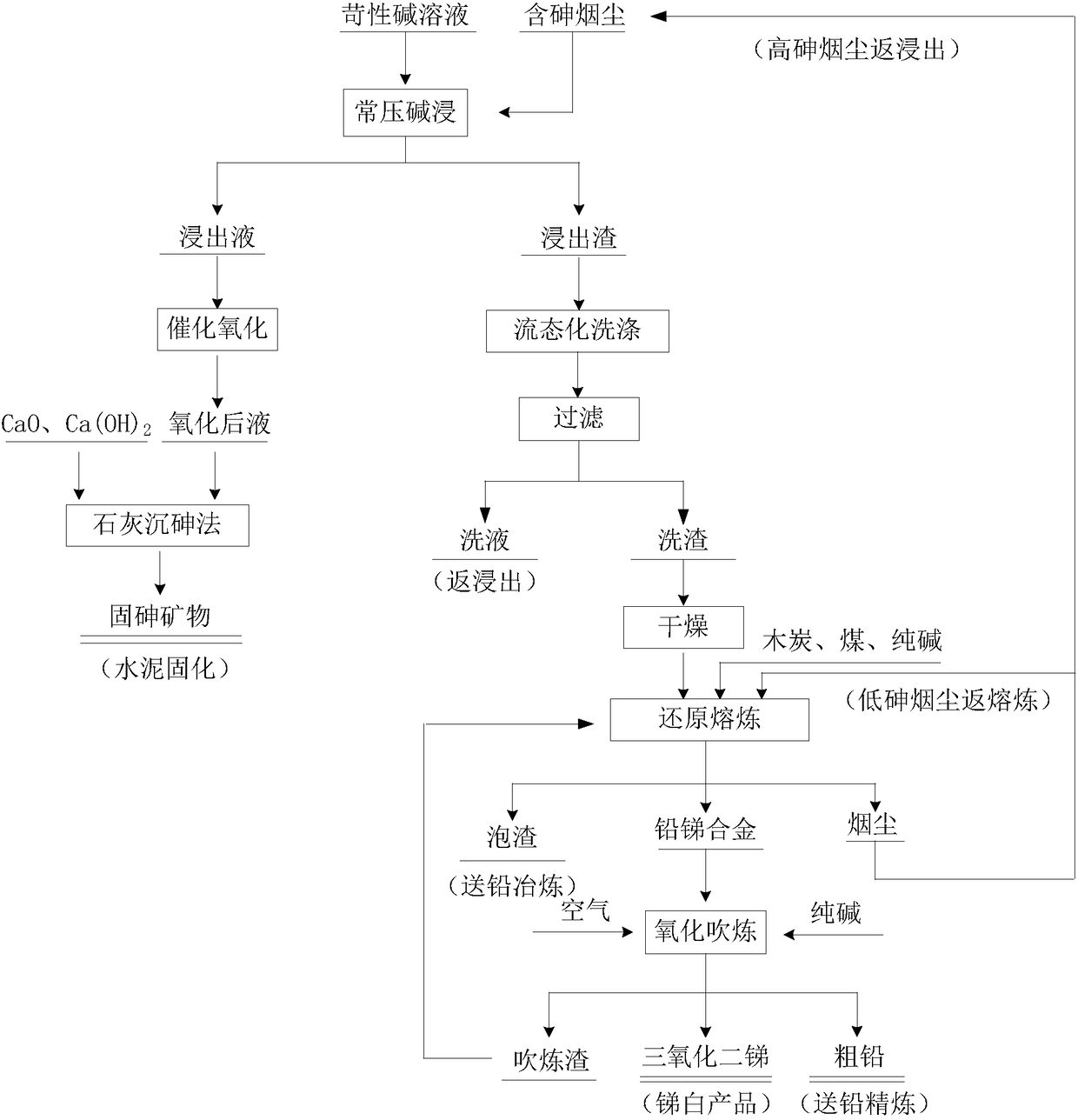

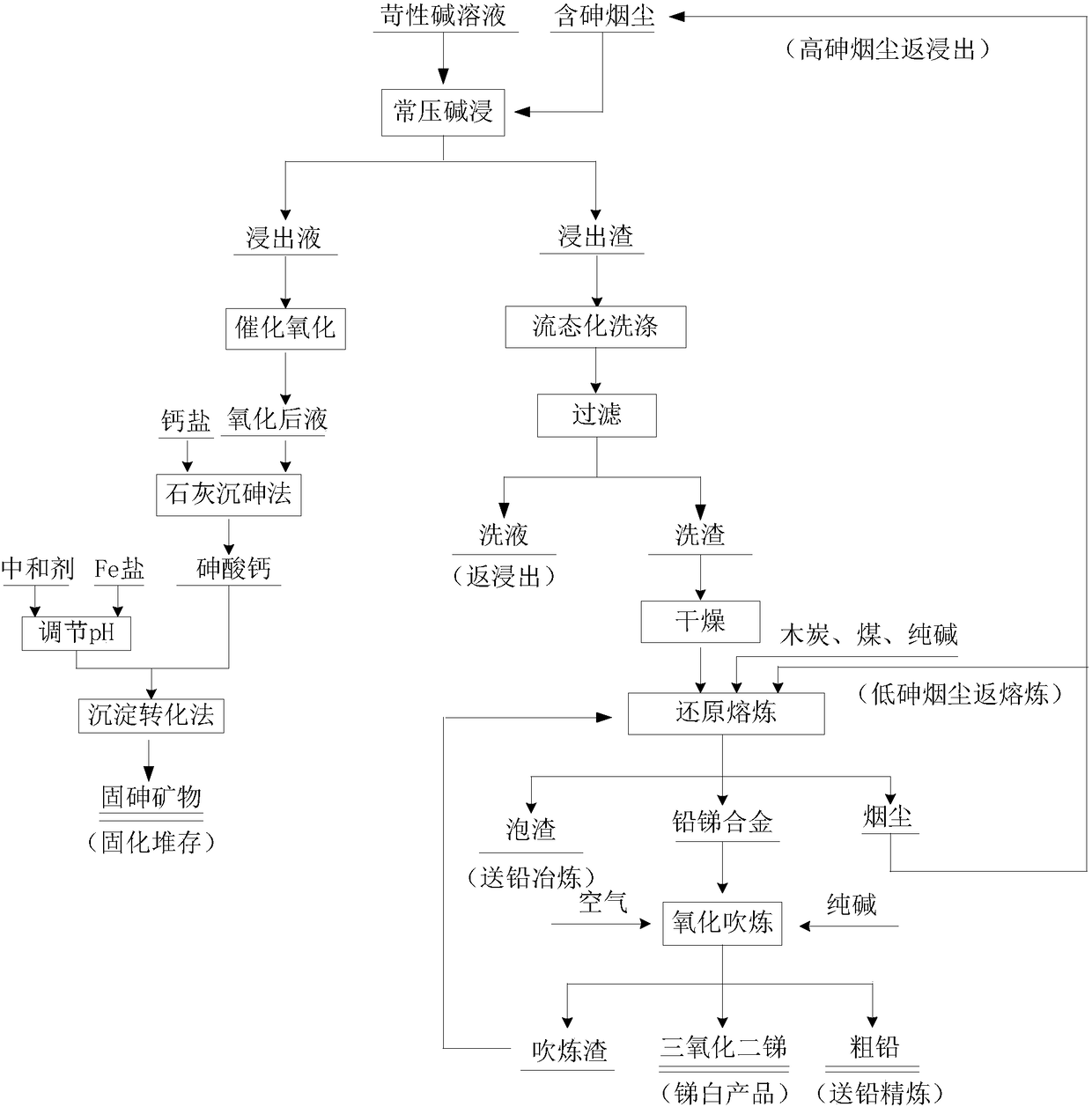

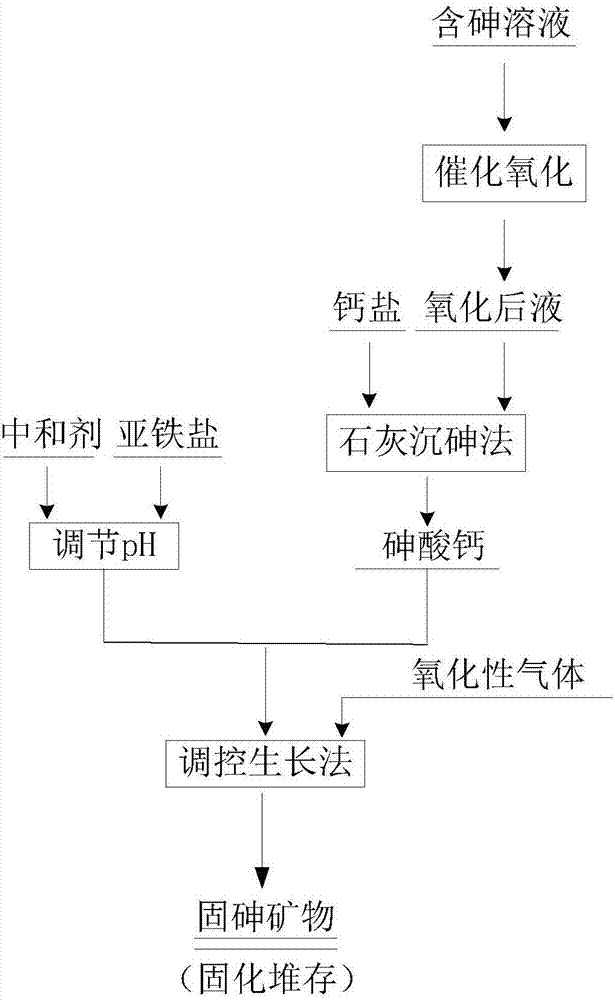

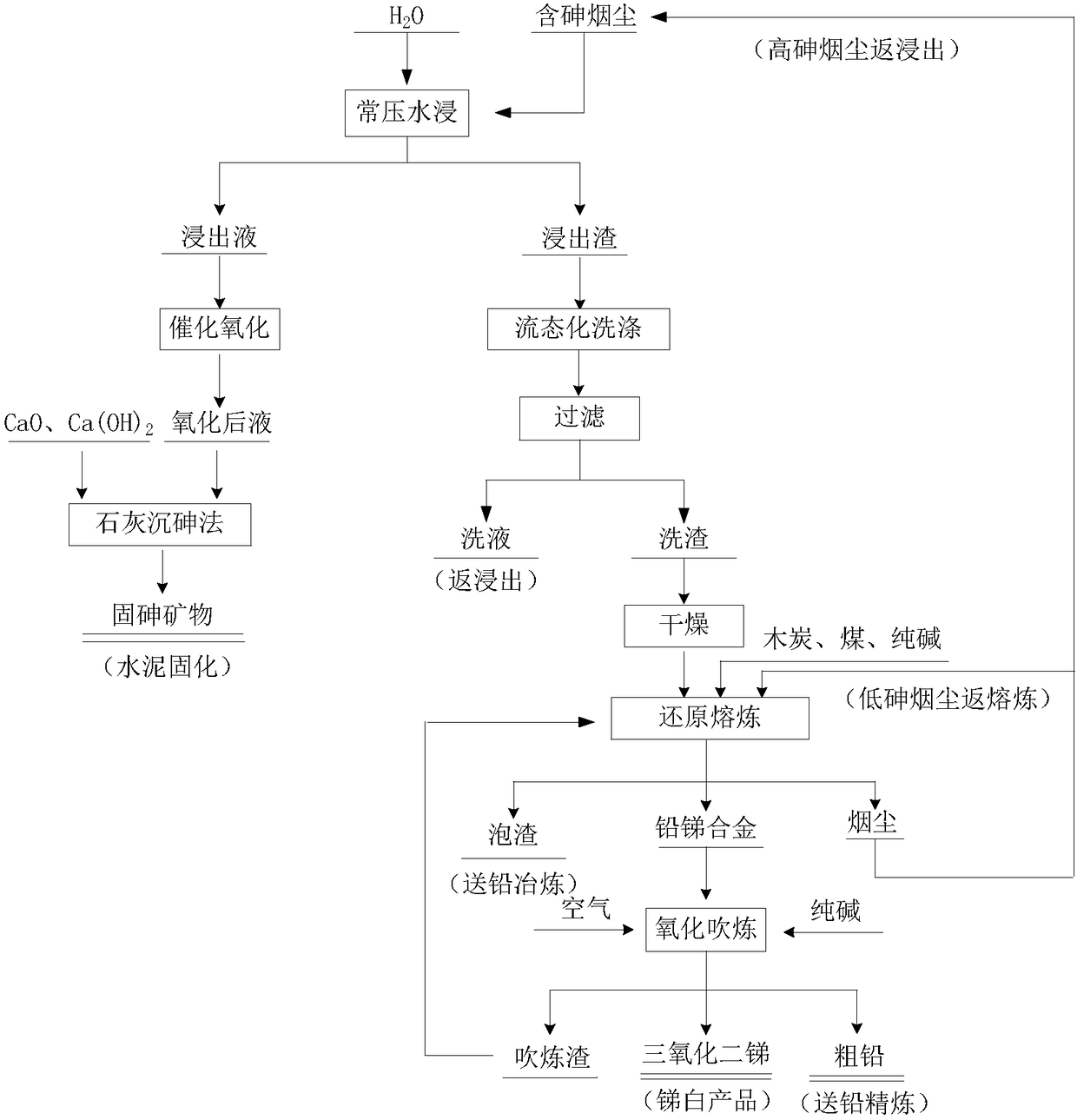

Safe treatment method for recycling valuable metals and arsenic from arsenic-containing smoke

ActiveCN106834717AReduce contentReduce arsenic levelsProcess efficiency improvementCatalytic oxidationZinc smelting

The invention relates to a safe treatment method for recycling valuable metals and arsenic from arsenic-containing smoke. The safe treatment method comprises the following steps: carrying out water leaching under normal pressure; carrying out catalytic oxidation on leachate; after oxidization, solidifying arsenic in the leachate; washing leaching residues; and recycling valuable metals from the washed residues. According to the method, soluble arsenic is removed from the smoke through normal-pressure water leaching; trivalent arsenic is oxidized into pentavalent arsenic after a catalytic oxidation procedure is carried out on the leachate; after oxidation, high-stability solid arsenic minerals are obtained by synthesizing the leachate by a lime arsenic precipitation process, and then, cementation treatment is carried out; and after the leaching residues are treated by the procedures of washing, reduction smelting and oxidization blowing, all valuable elements are recycled and utilized. The method has the advantages that the arsenic is removed from the smoke and solidified, the valuable elements, such as stibium, lead and bismuth, are kept in the leaching residues as much as possible, and the harmless separation of the arsenic from the valuable metals is realized. The comprehensive utilizing rate of the resources is high, the application range of the raw materials is wide, and a pollution problem in the extracting process of a traditional technology is solved. The method has more remarkable advantages over smoke produced in lead and zinc smelting processes.

Owner:CENT SOUTH UNIV

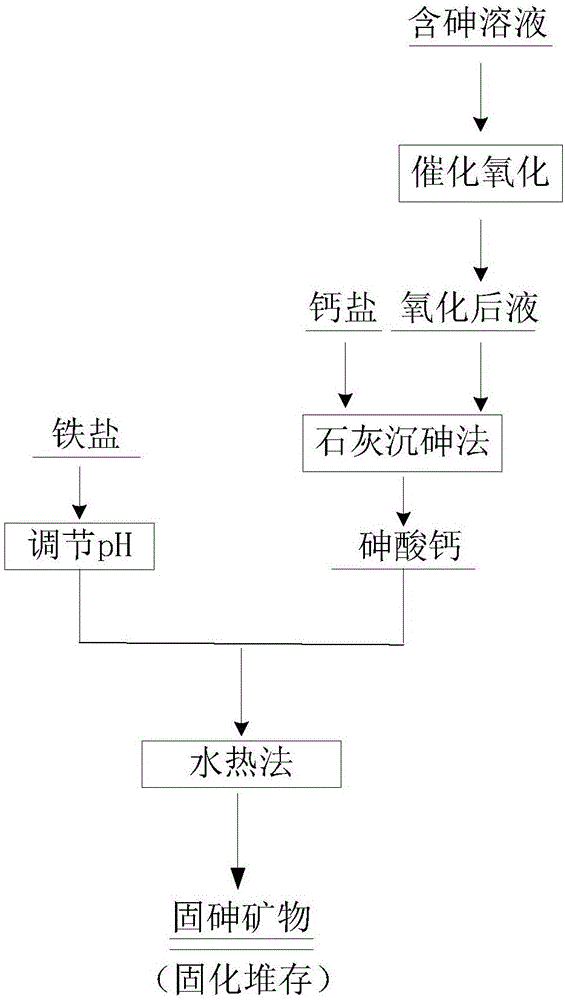

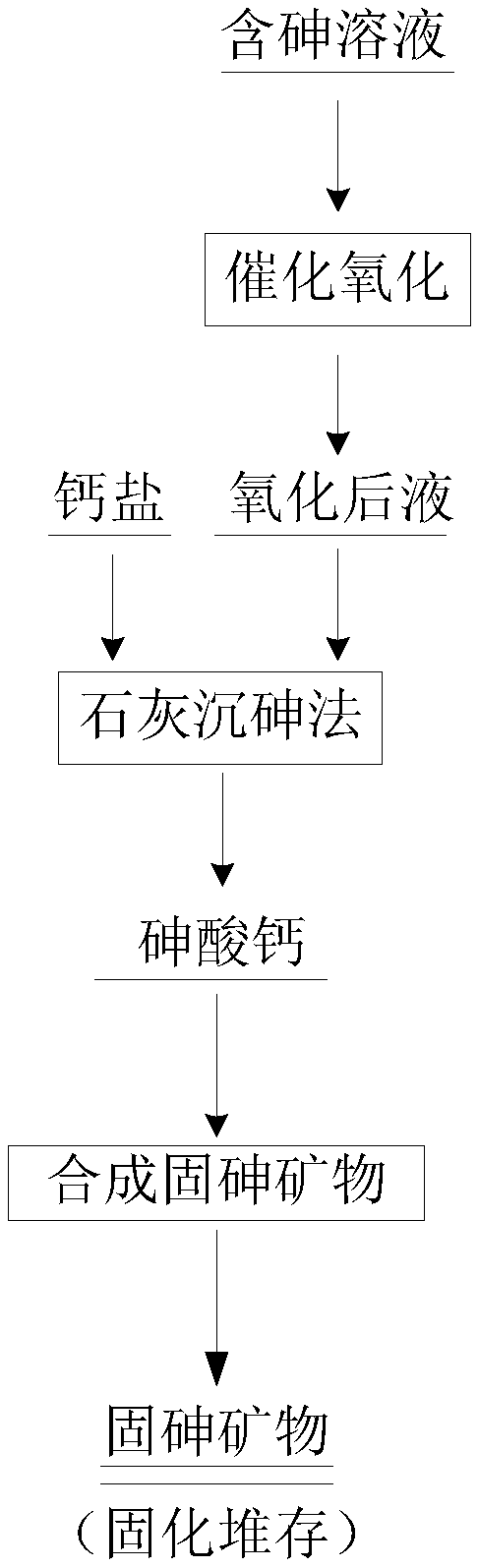

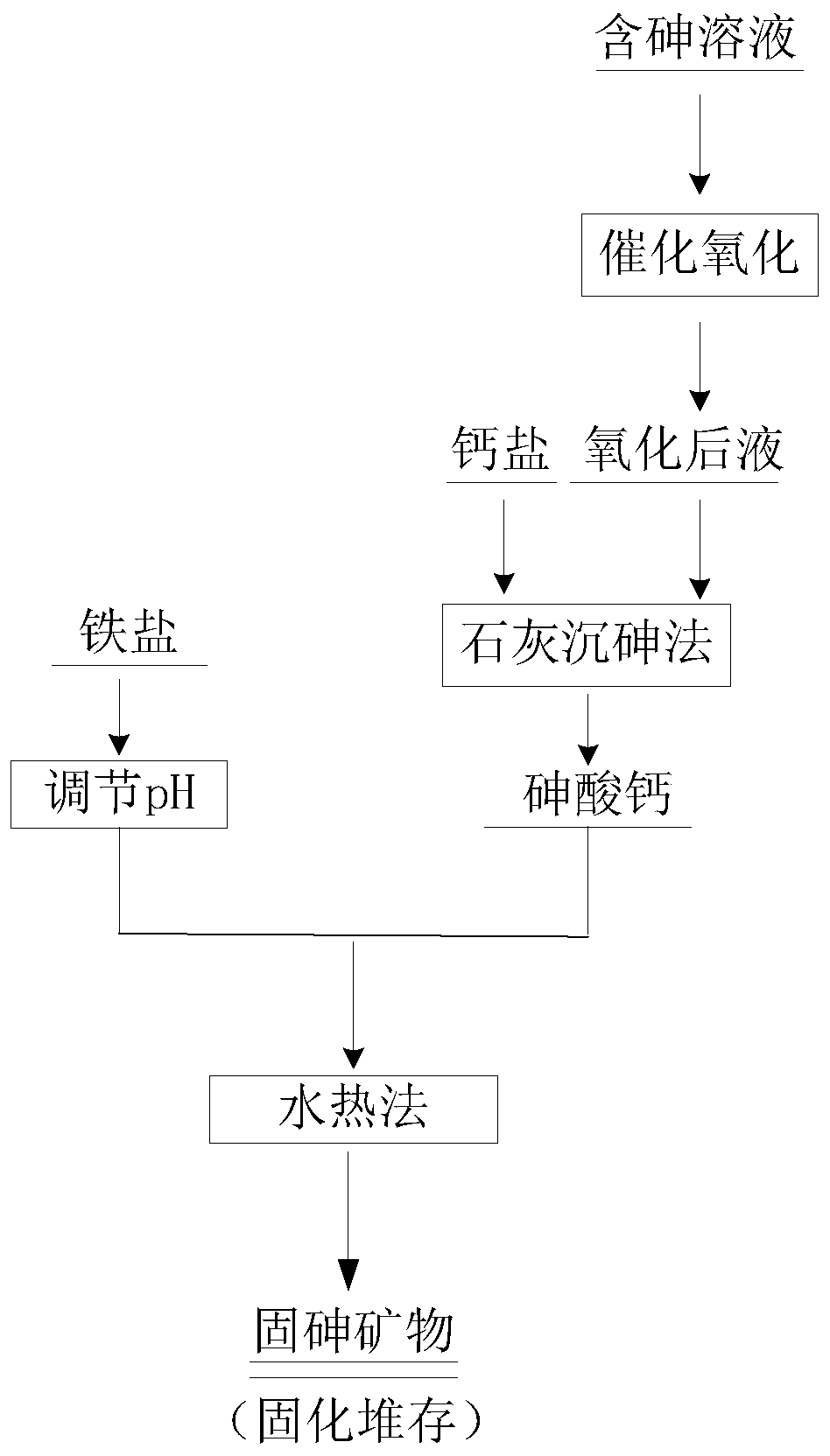

Method for preparing high-stability solid arsenic minerals by hydrothermal process

The invention relates to a method for preparing high-stability solid arsenic minerals by a hydrothermal process. Arsenic is removed from a high-arsenic solution and solidified, and harmless treatment is carried out on the arsenic-containing solution. According to the method, trivalent arsenic in the arsenic-containing solution is changed into pentavalent arsenic through catalytic oxidation; and after oxidation, the high-stability solid arsenic minerals are obtained by synthesizing the solution by a lime arsenic precipitation process and the hydrothermal process, and the high-stability solid arsenic minerals can be directly stacked. First, calcium arsenate is obtained by the lime arsenic precipitation process, and then, the calcium arsenate is converted to the high-stability solid arsenic minerals by adopting the hydrothermal process. Toxicity extraction meets the Identification Standards for Solid Wastes and Identification Standards for Extraction Toxicity GB5085.3-2007. The technical process is short, and the arsenic precipitation effect is great. After the arsenic is precipitated, the solution can be directly discharged, and the stability of the synthesized solid arsenic minerals is high. The solid arsenic minerals can be stably stacked in a wide pH value range which is between 2 and 11 under a strong reduction condition.

Owner:CENT SOUTH UNIV

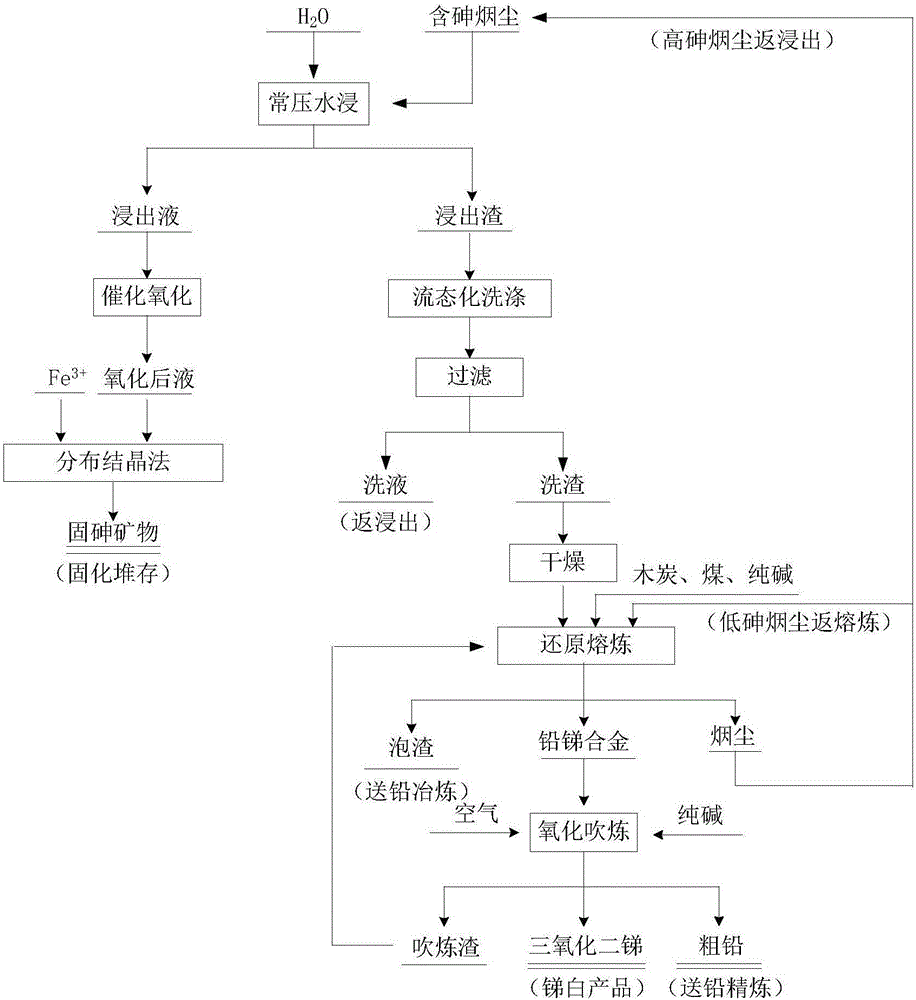

Comprehensive treatment method of arsenic-containing materials

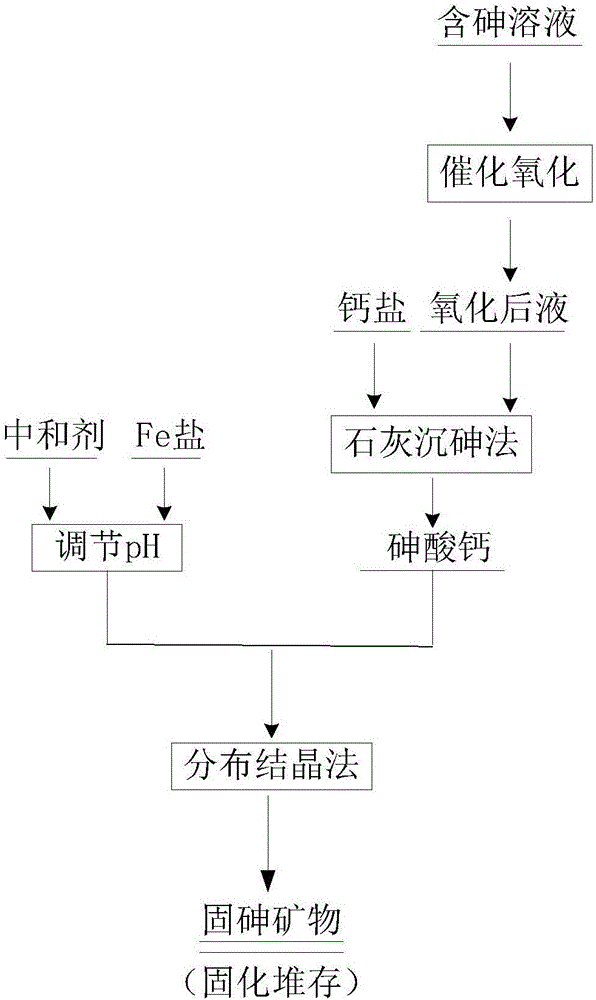

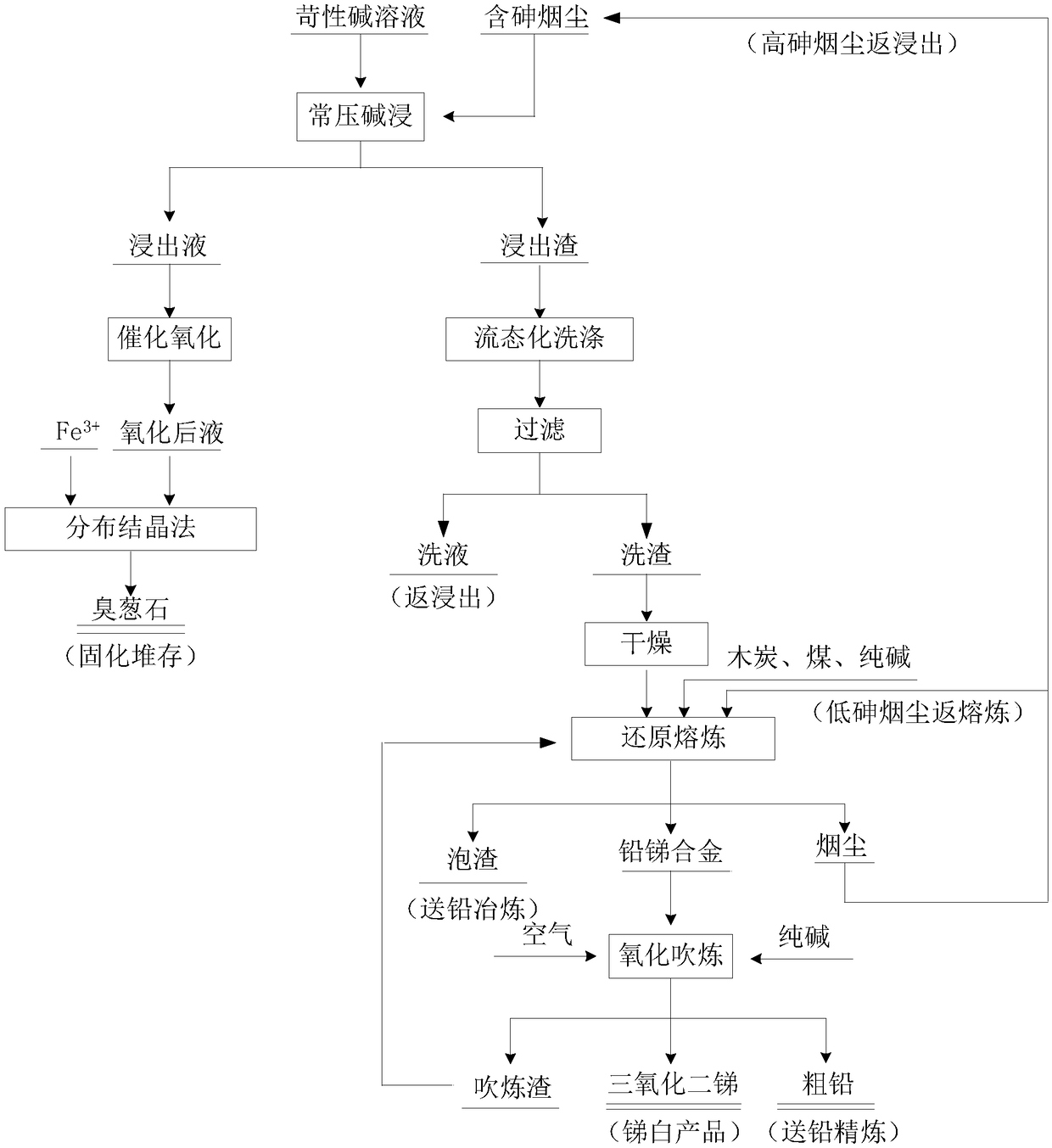

ActiveCN106834714AHarmlessAchieve recyclingProcess efficiency improvementCatalytic oxidationZinc smelting

The invention relates to a comprehensive treatment method of arsenic-containing materials. According to the method, production of comprehensive recovery of valuable metals such as arsenic, antimony, lead, bismuth and the like from smelting dust containing the arsenic, the antimony and the lead is performed, accumulation of the arsenic in the system is reduced, and harmless treatment is performed on the arsenic. With the method, through normal pressure alkaline leaching, soluble arsenic in the dust is removed, trivalent arsenic in a leaching solution becomes pentavalent arsenic through catalytic oxidation, stable arsenic-fixing minerals are synthesized with the fractional crystallization method and then are solidified through stockpiling, leaching residues are subjected to procedures of washing, reduction smelting, oxidizing blowing and the like, and various valuable elements are recycled to the maximum extent. With the method, the arsenic is removed from the dust, the antimony, the lead, the bismuth and the like are left in the arsenic-removed residues as much as possible, and separation and harmless treatment of the arsenic and the valuable metals can be realized. According to the method, the comprehensive utilization rate of resources is high, the raw material application range is wide, the problem of pollution in the extraction process of the traditional technology is solved, and the method has the more obvious advantages for the dust produced in the lead and zinc smelting process particularly.

Owner:CENT SOUTH UNIV

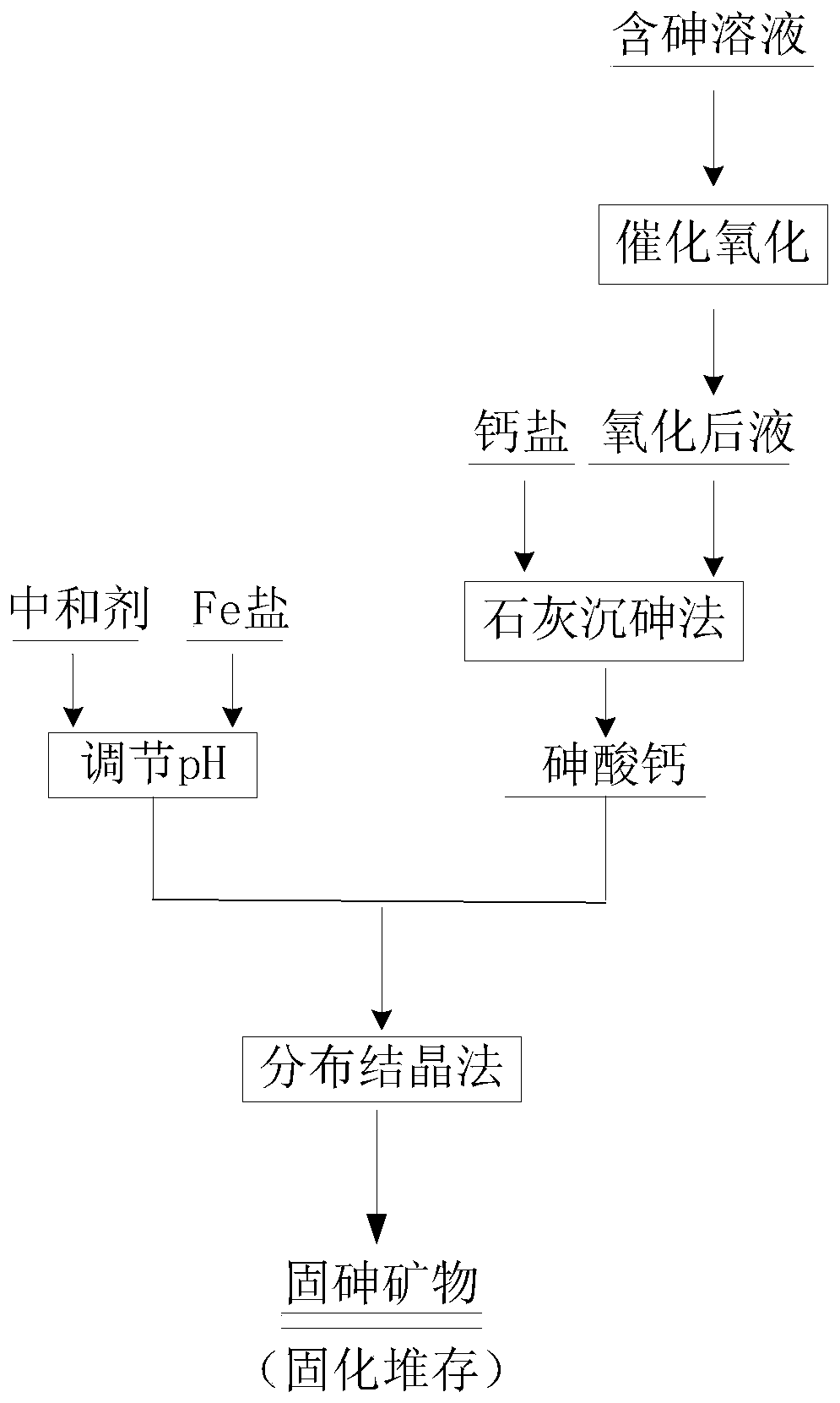

Method for preparing high-stability solid arsenic minerals through distributed crystallization method

ActiveCN106823233ASimple processEasy to operateChemical protectionCatalytic oxidationReduced properties

The invention relates to a method for preparing high-stability solid arsenic minerals through a distributed crystallization method. The method comprises the following steps: removing arsenic from a high-arsenic-content solution and curing the solution, so as to carry out harmless treatment on the arsenic-containing solution. According to the method disclosed by the invention, trivalent arsenic in the arsenic-containing solution is catalytically oxidized into pentavalent arsenic; and the oxidized solution is synthesized into the high-stability solid arsenic minerals through a lime arsenic settling method and the distributed crystallization method, and the high-stability solid arsenic minerals can be directly stockpiled. Calcium arsenate is obtained firstly through the lime arsenic settling method, and then the calcium arsenate is turned into the high-stability solid arsenic minerals through the distributed crystallization method; and toxicity extraction meets the specifications of GB5085.3-2007 (solid waste authentication standard-extraction toxicity authentication). The method is short in technological flow and good in arsenic settling effect; the solution subjected to arsenic settling can be directly discharged, and the synthesized solid arsenic minerals are high in stability and can be stably stockpiled within a wide pH range of 2 to 11 and under a strong reducing property condition.

Owner:CENT SOUTH UNIV

A kind of preparation method of highly stable arsenic-fixing mineral

The invention relates to a preparing method for high-stability solid arsenic mineral. A high-arsenic containing solution is subjected to arsenic removal and is cured, and the arsenic containing solution is subjected to harmless treatment. After trivalent arsenic in the arsenic containing solution is converted into pentavalent arsenic through catalytic oxidation, after oxidization, liquid is synthesized into the high-stability solid arsenic mineral through combination of the lime arsenic deposition method and one of the distribution crystallization method, the regulation and control growth method and the hydrothermal method, and the solid arsenic mineral can be directly stacked. Calcium arsenate is obtained through the lime arsenic deposition method firstly and then is converted into the high-stability solid arsenic mineral through one of the distribution crystallization method, the regulation and control growth method and the hydrothermal method, and toxicity leaching conforms to the GB5085.3-2007(solid waste distinguishing standard-leaching toxicity identification) rule. According to the preparing method, the technology process is short, the arsenic deposition effect is good, the liquid can be directly discharged after arsenic deposition, and the synthesized solid arsenic mineral is high in stability and can be stably stacked within the wide pH value range of 2-11 and under the strong reducing condition.

Owner:CENT SOUTH UNIV

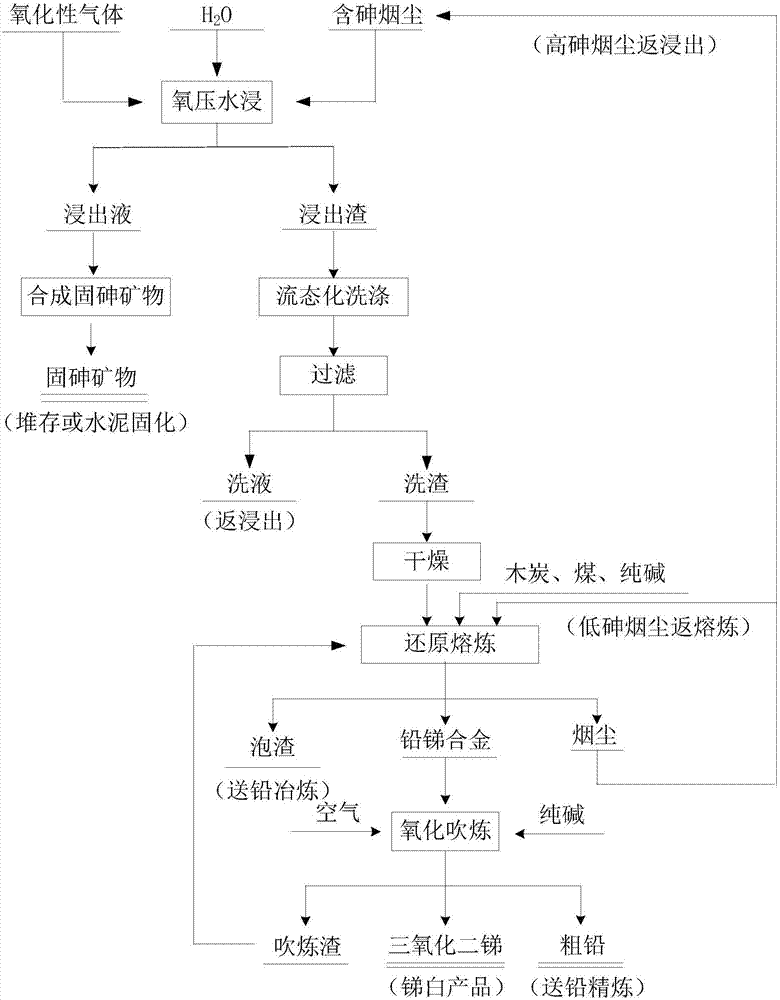

Method for comprehensively using arsenic-containing smoke dust and synthesizing solid arsenic minerals through precipitate conversion method

ActiveCN106834709ASeparation and detoxificationImprove resource utilizationProcess efficiency improvementResource utilizationSoot

The invention relates to the technical field of metallurgy, in particular to a method for comprehensively using arsenic-containing smoke dust and synthesizing solid arsenic minerals through a precipitate conversion method. The method comprises 5 steps of oxygen pressure water leaching, obtaining of solid arsenic in leach liquor, precipitate conversion, leaching residues washing and residue washing to recycling valuable metals: by the oxygen pressure water leaching, removing dissolvable arsenic from the smoke dust, synthesizing stable solid arsenic minerals through lime arsenic settling and precipitate conversion, curing the solid arsenic minerals by adopting a stockpiling mode, and carrying out procedures of washing, reducing smelting, oxidizing blowing and the like on leaching residues, so as to recycle and use all valuable elements to the maximum extent. According to the method, arsenic is removed from the smoke dust and synthesized into the stable solid arsenic minerals, and antimony, lead and bismuth are retained in arsenic-removed residues as much as possible, so that separation and harmlessness of the arsenic and the valuable metals can be realized. The method is high in comprehensive resource utilization rate and wide in raw material application range; the problem of pollution in an extraction process of a conventional technology is solved, and particularly soots produced in lead-zinc smelting process can be avoided. The method has a better advantage.

Owner:CENT SOUTH UNIV

Method for preparing high-stability arsenic fixing minerals through adjusted and controlled growth process

The invention relates to a method for preparing high-stability arsenic fixing minerals through an adjusted and controlled growth process. The method comprises the step of removing arsenic from a high-arsenic solution and curing the high-arsenic solution, thereby realizing innocent treatment on an arsenic containing solution. According to the method, after trivalent arsenic in the arsenic-containing solution is converted into pentavalent arsenic through catalytic oxidation, the oxidized solution is synthesized into high-stability arsenic fixing minerals through a lime arsenic precipitation process-adjusted and controlled growth process, and the high-stability arsenic fixing minerals can be directly piled up. Calcium arsenate is firstly obtained through the lime arsenic precipitation process, and then calcium arsenate is converted into high-stability arsenic fixing minerals through the adjusted and controlled growth process, so that toxicity leaching meets regulations of GB5085.3-2007(solid waste identification standards-leaching toxicity identification). The method is short in technological process and is good in arsenic precipitation effect; the arsenic-precipitated solution can be directly exhausted, and the synthesized arsenic fixing minerals are high in stability, and can be stably piled up within a wide pH value range of 2-11 under strong reducing conditions.

Owner:CENT SOUTH UNIV

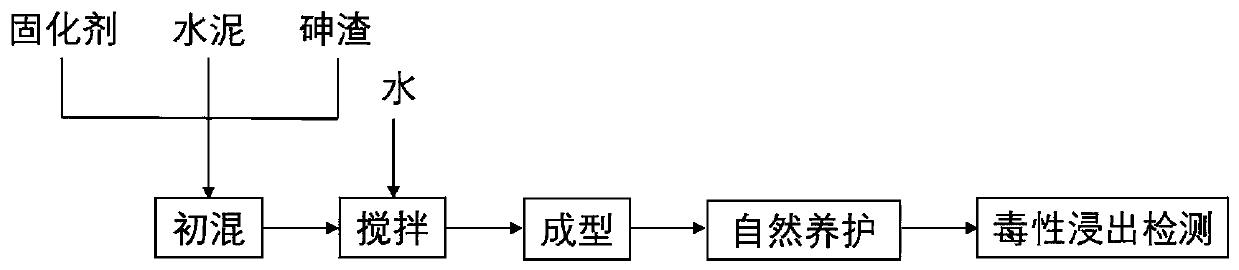

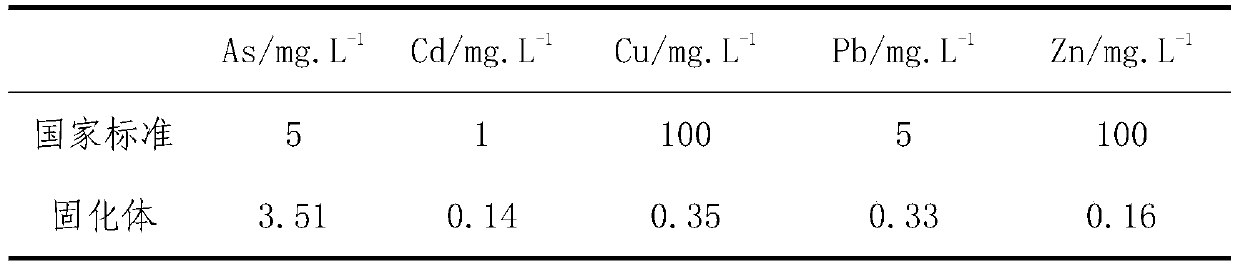

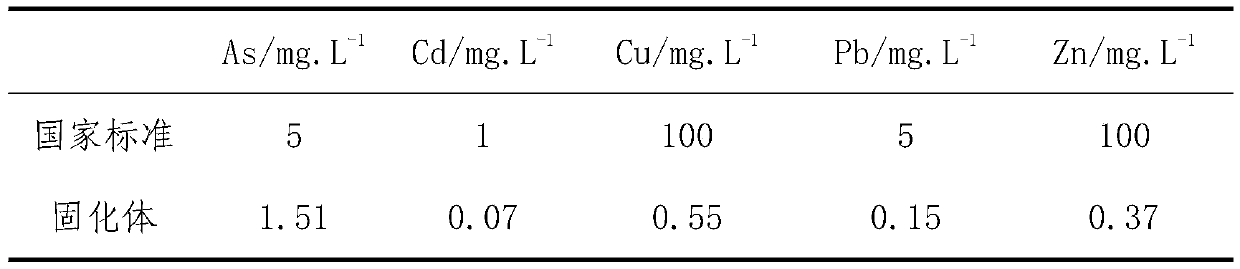

Arsenic-iron slag cement solidifying method with humic acid serving as additive

InactiveCN110090850AStable stockpileWill not bring pollution problemsTransportation and packagingSolid waste disposalEnvironmental effectSlag

The invention discloses an arsenic-iron slag cement solidifying method with humic acid serving as an additive. The process comprises the steps that arsenic-iron slag, cement and the additive are mixedaccording to the mass percent ratio of 100:(15-25):(1-3); a mixture and water are fully mixed uniformly, obtained slurry is poured into a mould, vibration forming is performed, and demoulding is performed after 24 hours of natural curing; and a demoulded solidified body is subjected to 15-45 days of natural curing under the room temperature. The arsenic-iron slag cement solidifying method with humic acid serving as the additive has the advantages that the process is simple, operation is convenient, the arsenic slag solidifying efficiency is high, the treatment cost is low, and a reagent is nontoxic, and a remarkable social and environmental effect can be achieved while the cost is saved.

Owner:WESTERN MINING CO LTD +1

A method for comprehensive treatment of arsenic-containing smoke and dust and the method of synthesizing arsenic-fixed minerals by regulating the growth method

ActiveCN106834720BReduce contentSolve difficult oxidation problemsProcess efficiency improvementSootPollution

The invention belongs to the technical field of metallurgy, and in particular, relates to a method for comprehensively treating arsenic-contained smoke and synthesizing arsenic fixing minerals by a control growth method. The method comprises four steps of oxygen pressure water leaching, leaching liquid arsenic fixation, leaching slag washing and recovery of valuable metal from washing slag in sequence; the method uses the oxygen pressure water leaching for removing solvable arsenic in the smoke; arsenic in leaching liquid is synthesized as high-stability arsenic fixing minerals by the control growth method; and then, the arsenic fixing minerals are cured by a stockpiling mode. All valuable elements are recycled from leaching slag to the greatest extent by such procedures as washing, reduction smelting and oxidation blowing. The method removes arsenic from the smoke and synthesizes the stable arsenic fixing minerals, but retains antimony, lead, bismuth and the like in the leaching slag as far as possible, and realizes separation of arsenic from the valuable metal and harmlessness. The method is high in resource comprehensive utilization rate and wide in raw material application range, solves the pollution problem in the traditional extracting process, in particular the smoke generated in the lead-zinc smelting process, and is more obvious in advantages.

Owner:CENT SOUTH UNIV

A method for removing arsenic from arsenic-containing smoke and its solidification

ActiveCN106756058BReduce contentSolve difficult oxidation problemsProcess efficiency improvementCatalytic oxidationSoot

The invention relates to a method for removing arsenic from smoke containing arsenic and solidifying arsenic. The method comprises the following steps that production of comprehensive recovering of valuable metal such as arsenic, antimony, lead and bismuth from smelting smoke containing arsenic, antimony and lead is conducted, and arsenic accumulation in a system is reduced to enable arsenic to be harmless. According to the method provided by the invention, through normal-pressure alkaline leaching, soluble arsenic in the smoke is removed, after trivalent arsenic in a leaching agent is changed to pentavalent arsenic through catalytic oxidation, a stable solid arsenic mineral is compounded through a lime arsenic precipitation method, and then the solid arsenic mineral is solidified through a cement solidifying mode; and leaching slag is subjected to the processes such as washing, reduction smelting and oxidizing blowing, and then all valuable elements are recycled to the maximum. According to the method, by removing arsenic from smoke and leaving antimony, lead, bismuth and the like in the arsenic removed slag as far as possible, separation of arsenic and the valuable metal and harmlessness can be achieved; the comprehensive using rate of the resources is high, the application range of raw materials is wide, the pollution problem in the extracting process of a traditional technique is solved, and particularly dust generated in the lead-zinc smelting process is avoided, and the advantage of the method is more obvious.

Owner:CENT SOUTH UNIV

A method for comprehensively recovering valuable metals from arsenic-containing dust and synthesizing arsenic-fixed minerals by regulating growth

ActiveCN106834713BReduce contentStable stockpileProcess efficiency improvementCatalytic oxidationSoot

Owner:CENT SOUTH UNIV

A comprehensive treatment method for arsenic-containing materials

ActiveCN106834714BReduce contentReduce arsenic levelsProcess efficiency improvementCatalytic oxidationPollution

The invention relates to a comprehensive treatment method of arsenic-containing materials. According to the method, production of comprehensive recovery of valuable metals such as arsenic, antimony, lead, bismuth and the like from smelting dust containing the arsenic, the antimony and the lead is performed, accumulation of the arsenic in the system is reduced, and harmless treatment is performed on the arsenic. With the method, through normal pressure alkaline leaching, soluble arsenic in the dust is removed, trivalent arsenic in a leaching solution becomes pentavalent arsenic through catalytic oxidation, stable arsenic-fixing minerals are synthesized with the fractional crystallization method and then are solidified through stockpiling, leaching residues are subjected to procedures of washing, reduction smelting, oxidizing blowing and the like, and various valuable elements are recycled to the maximum extent. With the method, the arsenic is removed from the dust, the antimony, the lead, the bismuth and the like are left in the arsenic-removed residues as much as possible, and separation and harmless treatment of the arsenic and the valuable metals can be realized. According to the method, the comprehensive utilization rate of resources is high, the raw material application range is wide, the problem of pollution in the extraction process of the traditional technology is solved, and the method has the more obvious advantages for the dust produced in the lead and zinc smelting process particularly.

Owner:CENT SOUTH UNIV

A method for removing arsenic from arsenic-containing dust and comprehensively recycling valuable elements

ActiveCN106834716BReduce contentImplement resourcesProcess efficiency improvementCatalytic oxidationZinc smelting

Owner:CENT SOUTH UNIV

A method for comprehensive utilization of arsenic-containing smoke and dust and precipitation conversion method to synthesize arsenic-fixed minerals

ActiveCN106834709BReduce contentSolve difficult oxidation problemsProcess efficiency improvementResource utilizationSoot

The invention relates to the technical field of metallurgy, in particular to a method for comprehensively using arsenic-containing smoke dust and synthesizing solid arsenic minerals through a precipitate conversion method. The method comprises 5 steps of oxygen pressure water leaching, obtaining of solid arsenic in leach liquor, precipitate conversion, leaching residues washing and residue washing to recycling valuable metals: by the oxygen pressure water leaching, removing dissolvable arsenic from the smoke dust, synthesizing stable solid arsenic minerals through lime arsenic settling and precipitate conversion, curing the solid arsenic minerals by adopting a stockpiling mode, and carrying out procedures of washing, reducing smelting, oxidizing blowing and the like on leaching residues, so as to recycle and use all valuable elements to the maximum extent. According to the method, arsenic is removed from the smoke dust and synthesized into the stable solid arsenic minerals, and antimony, lead and bismuth are retained in arsenic-removed residues as much as possible, so that separation and harmlessness of the arsenic and the valuable metals can be realized. The method is high in comprehensive resource utilization rate and wide in raw material application range; the problem of pollution in an extraction process of a conventional technology is solved, and particularly soots produced in lead-zinc smelting process can be avoided. The method has a better advantage.

Owner:CENT SOUTH UNIV

A method for preparing highly stable arsenic-fixed minerals by distribution crystallization

ActiveCN106823233BSimple processEasy to operateChemical protectionCatalytic oxidationReduced properties

Owner:CENT SOUTH UNIV

A method for preparing high-stability solid arsenic minerals by regulating growth method

The invention relates to a method for preparing high-stability arsenic fixing minerals through an adjusted and controlled growth process. The method comprises the step of removing arsenic from a high-arsenic solution and curing the high-arsenic solution, thereby realizing innocent treatment on an arsenic containing solution. According to the method, after trivalent arsenic in the arsenic-containing solution is converted into pentavalent arsenic through catalytic oxidation, the oxidized solution is synthesized into high-stability arsenic fixing minerals through a lime arsenic precipitation process-adjusted and controlled growth process, and the high-stability arsenic fixing minerals can be directly piled up. Calcium arsenate is firstly obtained through the lime arsenic precipitation process, and then calcium arsenate is converted into high-stability arsenic fixing minerals through the adjusted and controlled growth process, so that toxicity leaching meets regulations of GB5085.3-2007(solid waste identification standards-leaching toxicity identification). The method is short in technological process and is good in arsenic precipitation effect; the arsenic-precipitated solution can be directly exhausted, and the synthesized arsenic fixing minerals are high in stability, and can be stably piled up within a wide pH value range of 2-11 under strong reducing conditions.

Owner:CENT SOUTH UNIV

A method for comprehensively recovering valuable metals from arsenic-containing smoke and synthesizing arsenic-fixing minerals by fractional crystallization

ActiveCN106834706BReduce contentStable stockpileProcess efficiency improvementCatalytic oxidationSoot

The invention relates to a method for comprehensively recovering valuable metal from arsenic containing smoke and synthesizing arsenic fixing ore through a fractional crystallization method. The method includes the following steps of ordinary pressure water leaching, leaching agent catalytic oxidation, oxidized liquid arsenic fixing, leaching slag washing and slag washing for recovering the valuable metal. According to the method, through the processes that trivalent arsenic in a leaching agent is catalyzed and oxidized into pentavalent arsenic through ordinary pressure water leaching, oxidized liquid synthesizes the stable arsenic fixing ore through the fractional crystallization method, leaching slag washing is carried out, and leaching slag is subject to reduction smelting, oxidation blowing and the like, all valuable elements are recycled to the greatest extent. According to the method, the arsenic is desorbed from the smoke, stibium, lead, bismuth and the like are left in arsenic removal slag as many as possible, deep separation of the arsenic and other elements is achieved, the high-stability arsenic fixing ore is obtained, and recycling and harmless treatment of the arsenic containing smoke are achieved. The method is high in resource comprehensive utilization rate and wide in raw material application scope, and the problem of pollution in the traditional handicraft extraction process is solved. The beneficial effects of the method are more obvious for the smoke generated in the lead and zinc smelting process particularly.

Owner:CENT SOUTH UNIV

Method for comprehensively recovering valuable metal from arsenic containing smoke and synthesizing arsenic fixing ore through fractional crystallization method

ActiveCN106834706AReduce contentStable stockpileProcess efficiency improvementCatalytic oxidationPollution

The invention relates to a method for comprehensively recovering valuable metal from arsenic containing smoke and synthesizing arsenic fixing ore through a fractional crystallization method. The method includes the following steps of ordinary pressure water leaching, leaching agent catalytic oxidation, oxidized liquid arsenic fixing, leaching slag washing and slag washing for recovering the valuable metal. According to the method, through the processes that trivalent arsenic in a leaching agent is catalyzed and oxidized into pentavalent arsenic through ordinary pressure water leaching, oxidized liquid synthesizes the stable arsenic fixing ore through the fractional crystallization method, leaching slag washing is carried out, and leaching slag is subject to reduction smelting, oxidation blowing and the like, all valuable elements are recycled to the greatest extent. According to the method, the arsenic is desorbed from the smoke, stibium, lead, bismuth and the like are left in arsenic removal slag as many as possible, deep separation of the arsenic and other elements is achieved, the high-stability arsenic fixing ore is obtained, and recycling and harmless treatment of the arsenic containing smoke are achieved. The method is high in resource comprehensive utilization rate and wide in raw material application scope, and the problem of pollution in the traditional handicraft extraction process is solved. The beneficial effects of the method are more obvious for the smoke generated in the lead and zinc smelting process particularly.

Owner:CENT SOUTH UNIV

A method for comprehensive utilization of arsenic-containing smoke and dust and harmless disposal of arsenic

ActiveCN106834718BReduce contentReduce arsenic levelsProcess efficiency improvementPollutionMaterials science

The invention provides a method for the comprehensive utilization of arsenic-containing smoke and the harmless treatment of arsenic. The method adopts the operation of carrying out oxygen pressure water leaching, solidifying arsenic in leachate, washing leaching residues and recycling valuable metals from the washed residues. Soluble arsenic is removed from the smoke through oxygen pressure water leaching. The arsenic in the leachate is synthesized into stable solid arsenic minerals by combining one or more than two of a controlled growth process, a distribution and crystallization process, a lime arsenic precipitation process and a precipitation and converting process. Then, the solid arsenic minerals are solidified by adopting a stacking or cementation manner, and all valuable elements in the leaching residues are recycled and utilized to an utmost extent through the procedures of washing, reduction smelting, oxidization blowing and the like. According to the method, the arsenic is removed from the smoke, stibium, lead, bismuth and the like are kept in the residues from which the arsenic is removed as much as possible, and the harmless separation of the arsenic from the valuable metals is realized. The comprehensive utilizing rate of the resources is high, the application range of the raw materials is wide, and a pollution problem in the extracting process of a traditional technology is solved. The method has more remarkable advantages over smoke produced in lead and zinc smelting processes.

Owner:CENT SOUTH UNIV

A method for recovering valuable metals from arsenic-containing dust and synthesizing arsenic-fixed minerals by precipitation transformation

ActiveCN106756059BReduce contentImplement resourcesProcess efficiency improvementCatalytic oxidationSoot

Owner:CENT SOUTH UNIV

A method for preparing highly stable arsenic-fixed minerals by hydrothermal method

The invention relates to a method for preparing high-stability solid arsenic minerals by a hydrothermal process. Arsenic is removed from a high-arsenic solution and solidified, and harmless treatment is carried out on the arsenic-containing solution. According to the method, trivalent arsenic in the arsenic-containing solution is changed into pentavalent arsenic through catalytic oxidation; and after oxidation, the high-stability solid arsenic minerals are obtained by synthesizing the solution by a lime arsenic precipitation process and the hydrothermal process, and the high-stability solid arsenic minerals can be directly stacked. First, calcium arsenate is obtained by the lime arsenic precipitation process, and then, the calcium arsenate is converted to the high-stability solid arsenic minerals by adopting the hydrothermal process. Toxicity extraction meets the Identification Standards for Solid Wastes and Identification Standards for Extraction Toxicity GB5085.3-2007. The technical process is short, and the arsenic precipitation effect is great. After the arsenic is precipitated, the solution can be directly discharged, and the stability of the synthesized solid arsenic minerals is high. The solid arsenic minerals can be stably stacked in a wide pH value range which is between 2 and 11 under a strong reduction condition.

Owner:CENT SOUTH UNIV

A method for recovering valuable metals from arsenic-containing fumes and safely disposing of arsenic

ActiveCN106834717BReduce contentReduce arsenic levelsProcess efficiency improvementCatalytic oxidationSoot

The invention relates to a safe treatment method for recycling valuable metals and arsenic from arsenic-containing smoke. The safe treatment method comprises the following steps: carrying out water leaching under normal pressure; carrying out catalytic oxidation on leachate; after oxidization, solidifying arsenic in the leachate; washing leaching residues; and recycling valuable metals from the washed residues. According to the method, soluble arsenic is removed from the smoke through normal-pressure water leaching; trivalent arsenic is oxidized into pentavalent arsenic after a catalytic oxidation procedure is carried out on the leachate; after oxidation, high-stability solid arsenic minerals are obtained by synthesizing the leachate by a lime arsenic precipitation process, and then, cementation treatment is carried out; and after the leaching residues are treated by the procedures of washing, reduction smelting and oxidization blowing, all valuable elements are recycled and utilized. The method has the advantages that the arsenic is removed from the smoke and solidified, the valuable elements, such as stibium, lead and bismuth, are kept in the leaching residues as much as possible, and the harmless separation of the arsenic from the valuable metals is realized. The comprehensive utilizing rate of the resources is high, the application range of the raw materials is wide, and a pollution problem in the extracting process of a traditional technology is solved. The method has more remarkable advantages over smoke produced in lead and zinc smelting processes.

Owner:CENT SOUTH UNIV

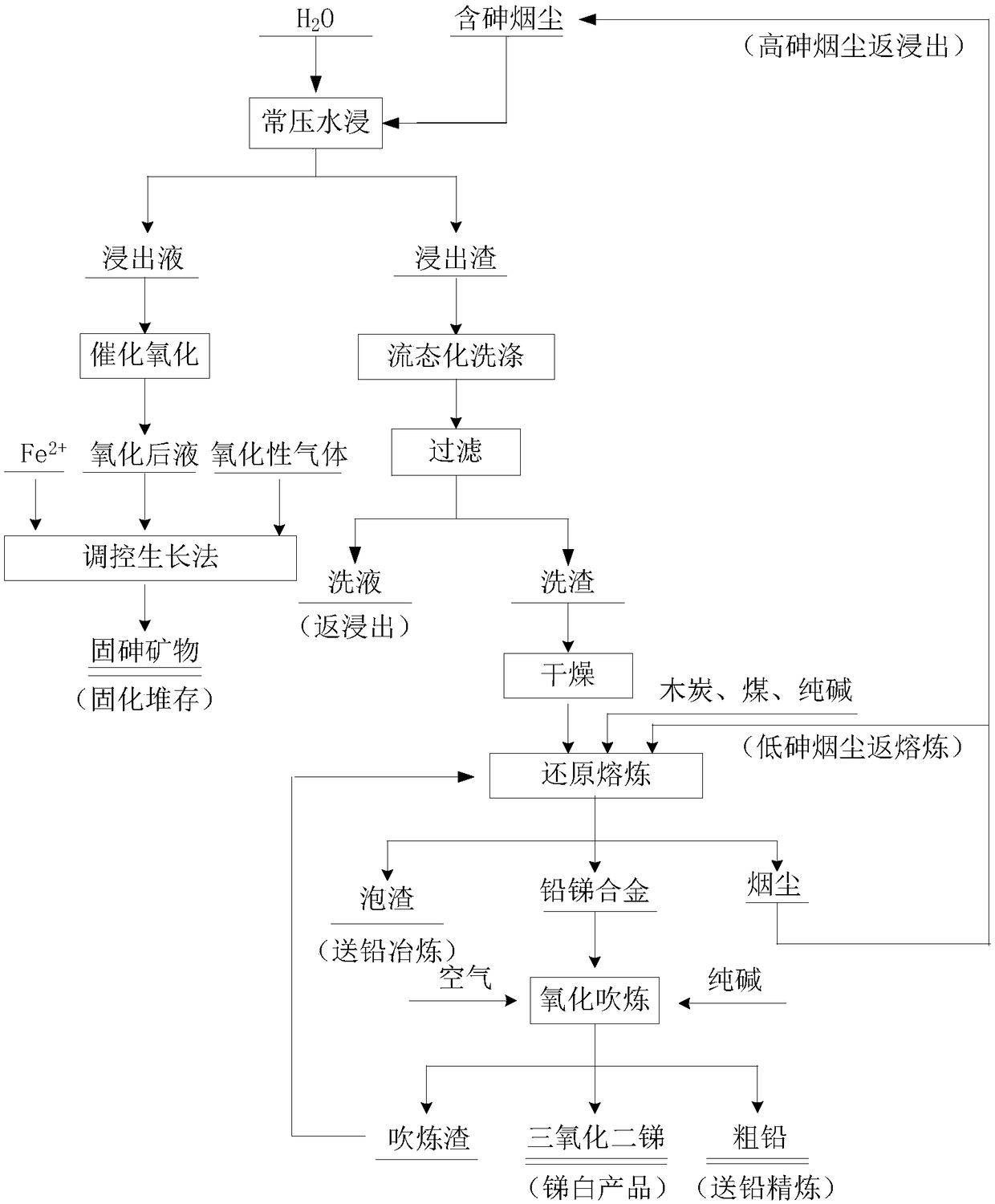

Method for comprehensive recovery of valuable metals from arsenic-containing dust and synthesis of arsenic-fixing minerals with adjusted and controlled growth method

ActiveCN106834713ASeparation and detoxificationImprove resource utilizationProcess efficiency improvementCatalytic oxidationPollution

The invention relates to a method for comprehensive recovery of valuable metals from arsenic-containing dust and synthesis of arsenic-fixing minerals with an adjusted and controlled growth method. The method comprises the steps as follows: normal pressure water leaching, catalytic oxidation of a leaching solution, arsenic fixing of an oxidized solution with the adjusted and controlled growth method, washing of leaching residues and recovery of the valuable metals from washing residues. With the method, various valuable elements are recycled through procedures of normal pressure water leaching, catalytic oxidation of the leaching solution, arsenic fixing of the oxidized solution with the adjusted and controlled growth method, washing of the leaching residues, reduction smelting of the washing residues, oxidizing blowing and the like. With the method, the arsenic is removed from the dust, antimony, lead, bismuth and the like are left in the arsenic-removed residues as much as possible, depth separation of arsenic and antimony is realized, the high-stability arsenic-fixing minerals are obtained, meet national standards and can be piled safely, and recycling and harmless treatment of the arsenic-containing dust are realized. According to the method, the comprehensive utilization rate of resources is high, the raw material application range is wide, the problem of pollution in the extraction process of the traditional technology is solved, and the method has the more obvious advantages for the dust produced in the lead and zinc smelting process particularly.

Owner:CENT SOUTH UNIV

A method for removing arsenic from arsenic-containing smoke and its solidification

ActiveCN106801145BReduce contentReduce arsenic levelsProcess efficiency improvementSmelting processGrowth control

The invention relates to a method for removing arsenic from smoke containing arsenic and curing arsenic. The method comprises production of comprehensively recycling valuable metals such as arsenic, antimony, lead and bismuth from the smelting smoke containing arsenic, antimony and lead, accumulation of arsenic in the system is reduced, and arsenic is made to be harmless. According to the method, through normal-pressure alkaline leaching, soluble arsenic is removed from the smoke, trivalent arsenic in a leaching agent is converted into pentavalent arsenic through catalytic oxidation, stable arsenic fixing minerals are synthesized through a growth control method, then the arsenic fixing minerals are cured through a stockpiling manner, the processes of washing, reduction smelting, oxidation blowing and the like are conducted on leaching residues, and valuable elements are recycled to the maximum extent. By the adoption of the method, arsenic is removed from the smoke, antimony, lead and bismuth are remained in the residues without arsenic as much as possible, and separation of arsenic and the valuable metals can be achieved and is harmless. By the adoption of the method, the comprehensive rate of resources is high, the raw material application range is wide, the pollution problem existing in a traditional process extraction process, especially the pollution caused by smoke generated in a lead-zinc smelting process is solved, and the advantages of the method are more remarkable.

Owner:CENT SOUTH UNIV

A method for arsenic-containing arsenic dust removal and distribution crystallization to synthesize arsenic-fixed minerals

ActiveCN106834712BReduce contentSolve difficult oxidation problemsProcess efficiency improvementZinc smeltingMaceral

The invention belongs to the technical field of metallurgy and particularly relates to a method for arsenic removal of arsenic-containing dust and synthesis of arsenic-fixing minerals with a fractional crystallization method. The method sequentially comprises four steps including oxygen pressure water leaching, arsenic fixing with a leaching solution, washing of leaching residues and recovery of valuable metals from washing residues. According to the method, through oxygen pressure water leaching, soluble arsenic in the dust is removed, the stable arsenic-fixing minerals are synthesized from the leaching solution with the fractional crystallization method, and then the arsenic-fixing minerals are solidified through stockpiling. The leaching residues are subjected to procedures of washing, reduction smelting, oxidizing blowing and the like, and various valuable elements are recycled to the maximum extent. With the method, the arsenic is removed from the dust, the stable arsenic-fixing minerals are synthesized, antimony, lead, bismuth and the like are left in the leaching residues as much as possible, and separation and harmless treatment of the arsenic and the valuable metals are realized. According to the method, the comprehensive utilization rate of resources is high, the raw material application range is wide, the problem of pollution in the extraction process of the traditional technology is solved, and the method has the more obvious advantages for the dust produced in the lead and zinc smelting process particularly.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com