Method for direct mineral uranium fixation from acidic hexavalent uranium solution

An acidic, solution-based technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve problems such as inability to form stable uranium compounds, and achieve good curing effect, low cost, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

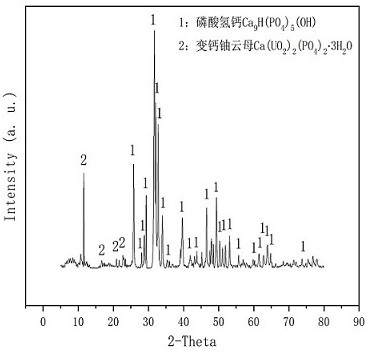

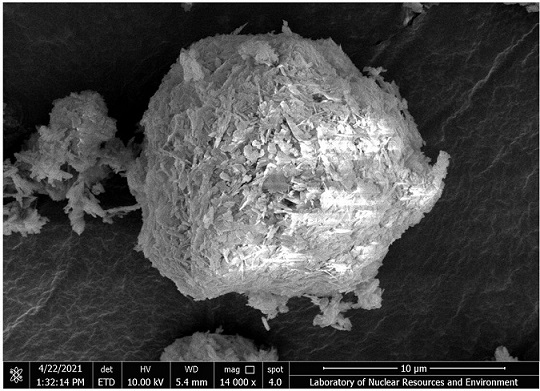

[0028] Such as figure 1 As shown, the method for direct mineral fixation of uranium from acidic hexavalent uranium solution includes: adding 100mL acidic hexavalent uranium solution (wherein the hexavalent uranium content is 83.2mg / L, pH is 1.07) according to the solid-liquid Add 0.25g of calcium phosphate salt (calcium hydrogen phosphate) at a ratio of 2.5:1g / L, and react for 4 minutes at a temperature of 60°C to fix the uranium in the mineral, so that the hexavalent uranium in the solution is adsorbed on the surface of the calcium phosphate salt particles and passes through the ore. The phase transformation is fixed to the target mineral, calcium-uranium mica, and after the reaction, the slurry is filtered, washed, and dried to obtain the calcium-uranium mica product.

[0029] The content of uranium detected in the filtrate obtained by filtering in this embodiment is almost 0, and the removal rate of uranium can reach 100%.

[0030] The present embodiment obtains the XRD fi...

Embodiment 2

[0032] Such as figure 1As shown, the method for direct mineral fixation of uranium from acidic hexavalent uranium solution includes: adding 100mL acidic hexavalent uranium solution (wherein the hexavalent uranium content is 83.2mg / L, pH is 1.07) according to the solid-liquid Add 0.25g of calcium phosphate salt (calcium hydrogen phosphate) at a ratio of 2.5:1g / L, and react for 4 minutes at a temperature of 90°C, so that the hexavalent uranium in the solution is adsorbed on the surface of the calcium phosphate salt particles and undergoes mineral phase transformation. The target mineral is fixed as the calcium uranium mica, and after the reaction, the slurry is filtered, washed and dried to obtain the calcium uranium mica product.

[0033] The content of uranium detected in the filtrate obtained by filtering in this embodiment is almost 0, and the removal rate of uranium can reach 100%.

Embodiment 3

[0035] Such as figure 1 As shown, the method for direct mineral fixation of uranium from acidic hexavalent uranium solution includes: adding 100mL acidic hexavalent uranium solution (wherein the hexavalent uranium content is 83.2mg / L, pH is 1.07) according to the solid-liquid Add 0.4g of calcium phosphate salt (calcium hydrogen phosphate) at a ratio of 4:1g / L, and react for 4 minutes at a temperature of 60°C, so that the hexavalent uranium in the solution is adsorbed on the surface of calcium phosphate salt particles and fixed by mineral phase transformation The target mineral is calcium uranium mica, and after the reaction, the slurry is filtered, washed and dried to obtain the calcium uranium mica product.

[0036] The content of uranium detected in the filtrate obtained by filtering in this embodiment is almost 0, and the removal rate of uranium can reach 100%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com