Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Realize automatic drive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

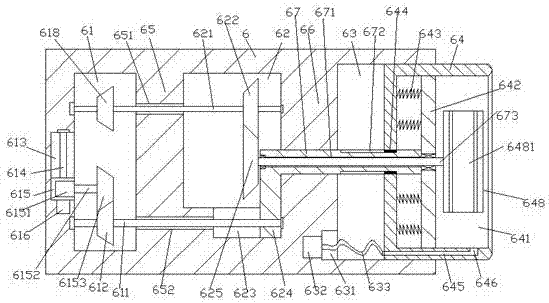

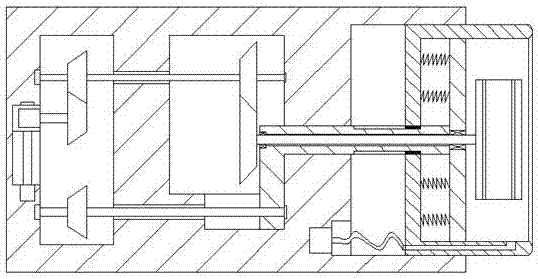

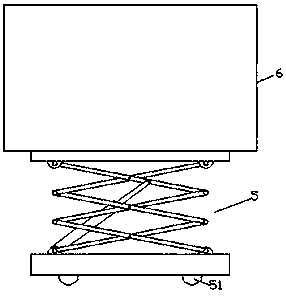

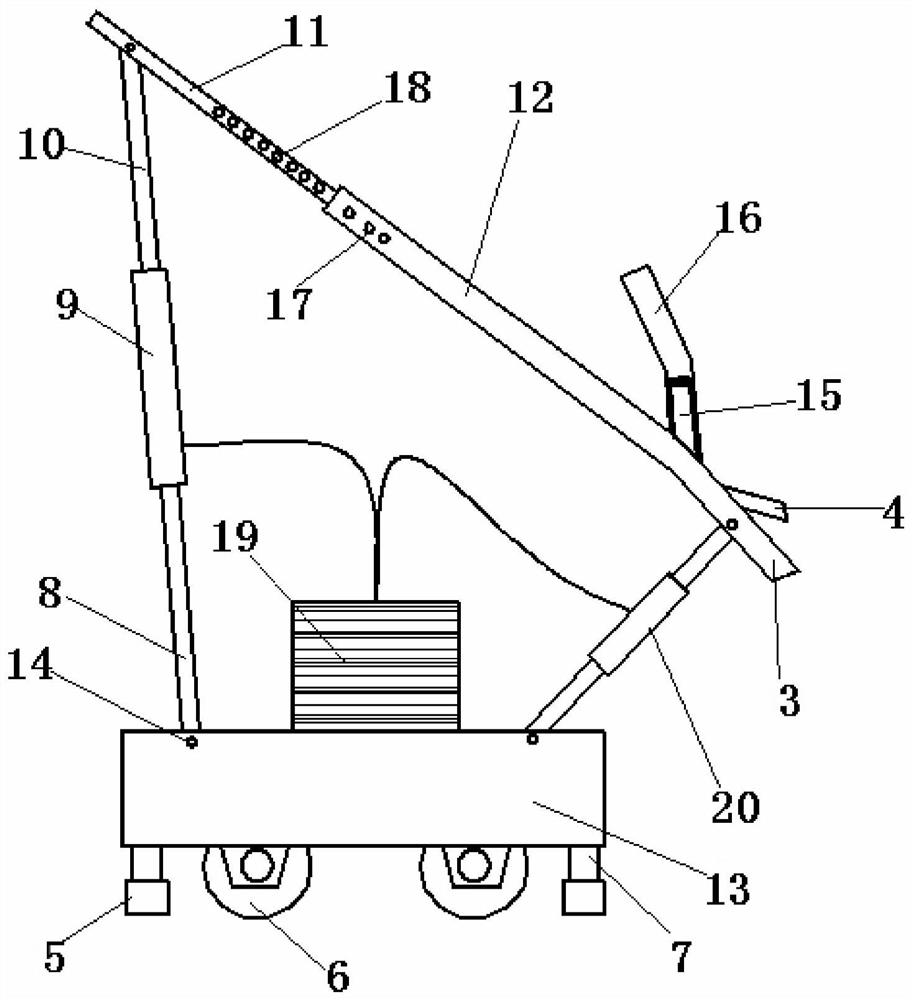

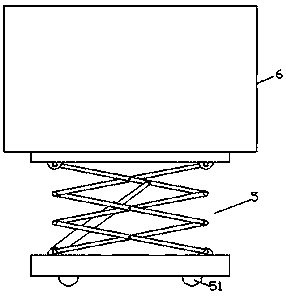

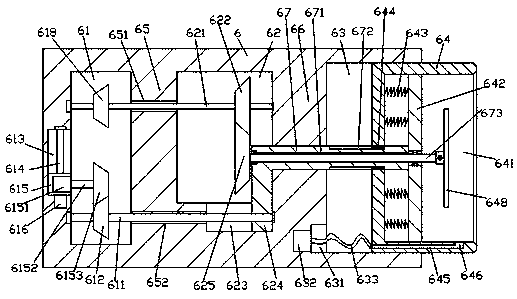

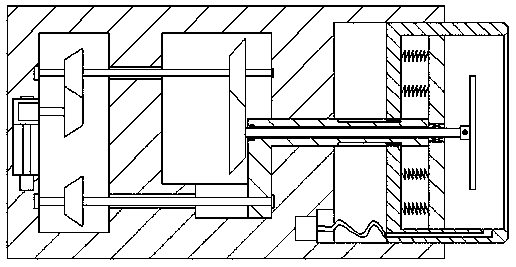

Wall face grinding device for architectural decoration and finishing

InactiveCN107160249AReduce investmentLow costPlane surface grinding machinesGrinding/polishing safety devicesEngineeringBuilding renovation

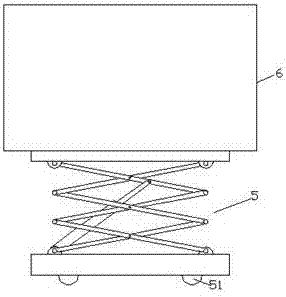

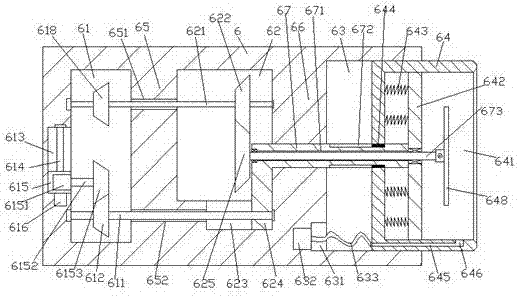

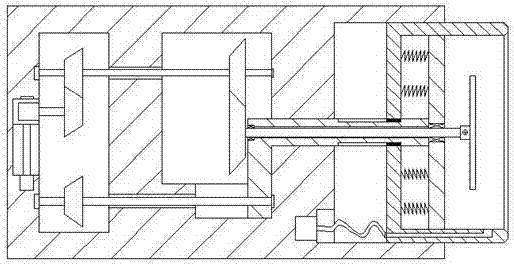

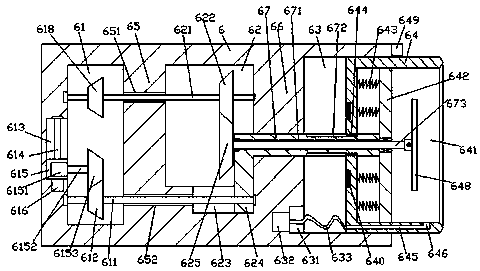

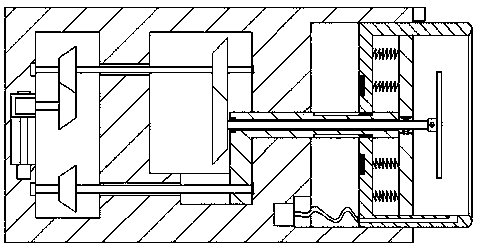

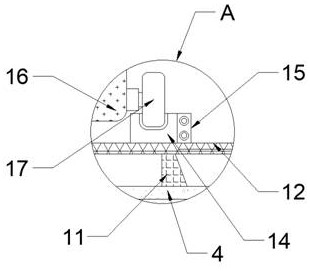

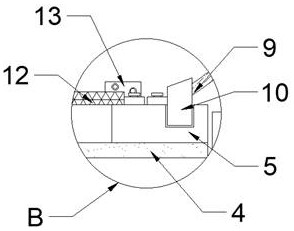

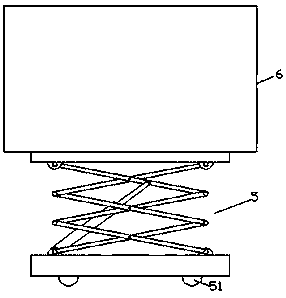

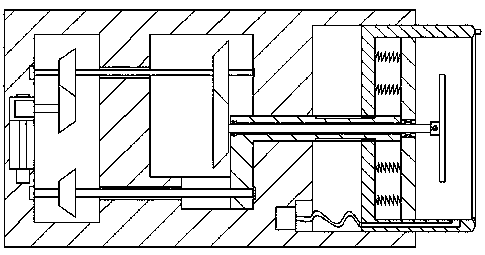

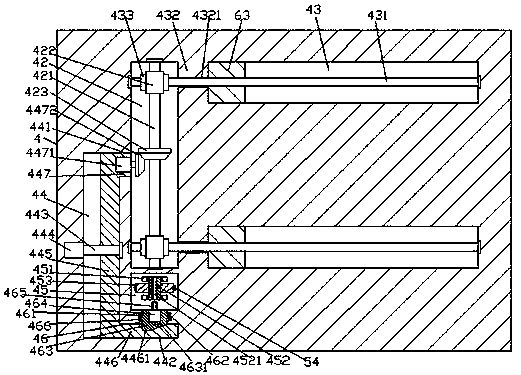

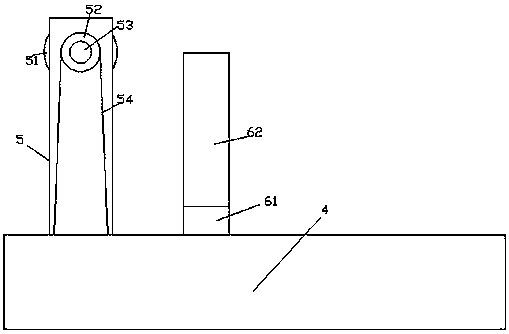

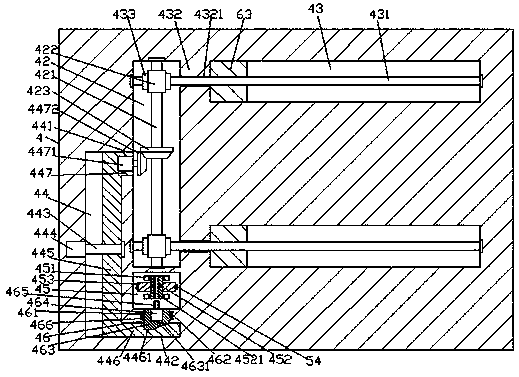

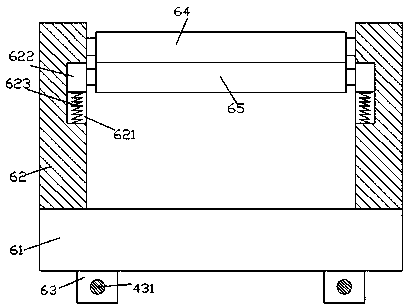

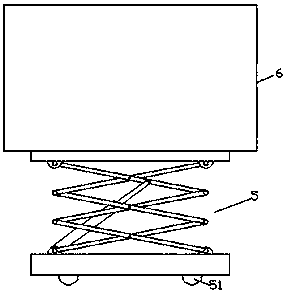

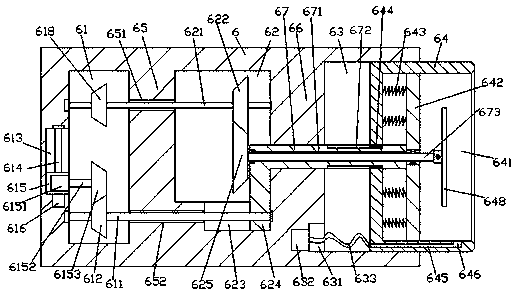

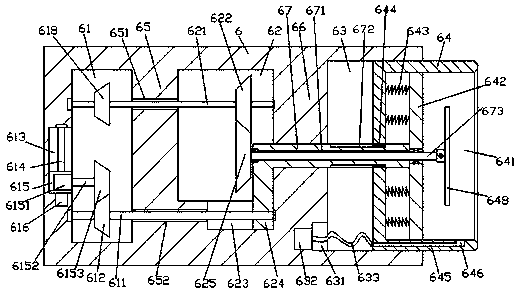

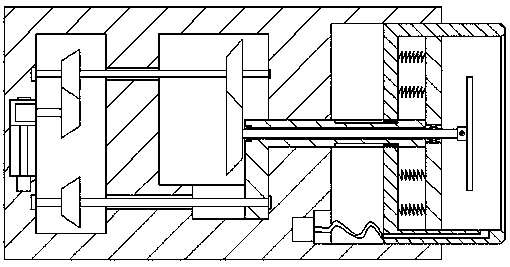

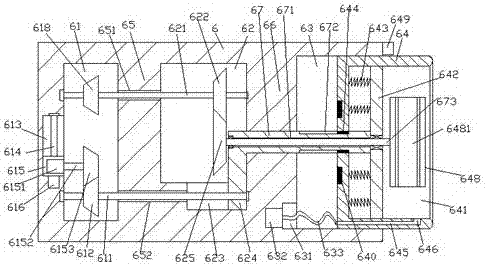

The invention discloses a wall face grinding device for architectural decoration and finishing. The wall face grinding device comprises a shear type lifting frame and a grinding mechanism mounted at the top of the shear type lifting frame. A storage groove is formed in the right end face of the grinding mechanism and connected with a closed sleeve in a sliding fit manner. A grinding cavity is formed in the closed sleeve. A transmission cavity is formed in the position, on the left side of the storage groove, in the grinding mechanism. A first partition plate is arranged between the transmission cavity and the storage groove. A drive cavity is formed in the position, on the left side of the transmission cavity, in the grinding mechanism. A second partition plate is arranged between the drive cavity and the transmission cavity. A first sliding groove is formed in the bottom wall in the transmission cavity. A connecting rod extending towards the left side and the right side is connected in the first partition plate in a sliding fit manner. The extending segment of the right side of the connecting rod stretches into the storage groove and penetrates the closed sleeve to extend into the grinding cavity. A supporting plate is fixedly arranged at the extending tail end of the right side of the connecting rod. A first through hole extending left and right is formed in the connecting rod. The wall face grinding device is simple in structure, reasonable in design and high in closing effect, dust flying is avoided, the occupied space can be reduced, and the manufacturing and maintaining cost is low.

Owner:广东中创建设有限公司

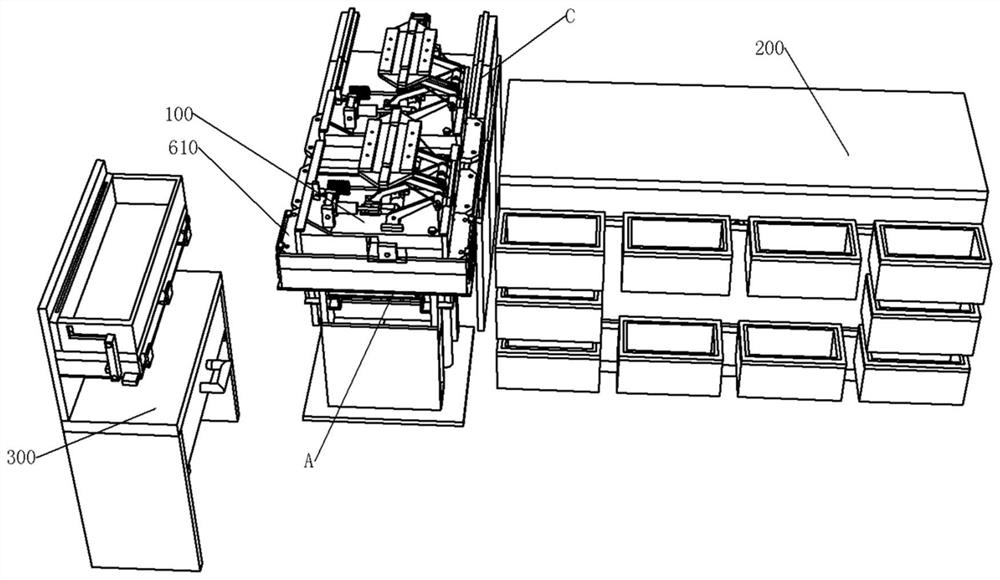

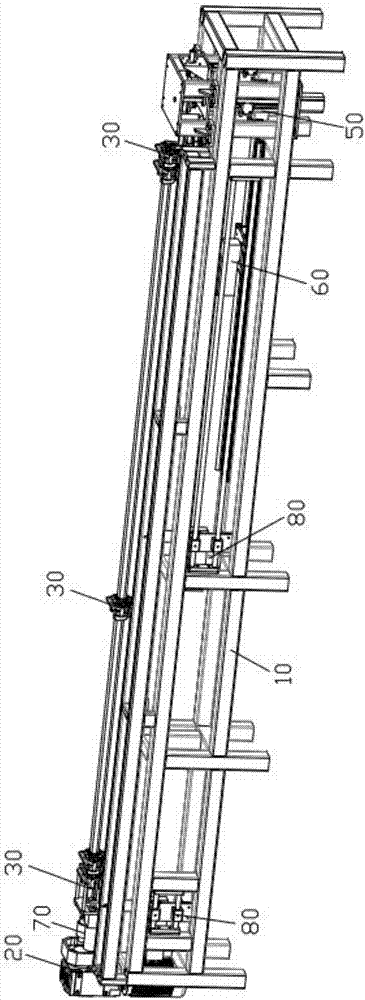

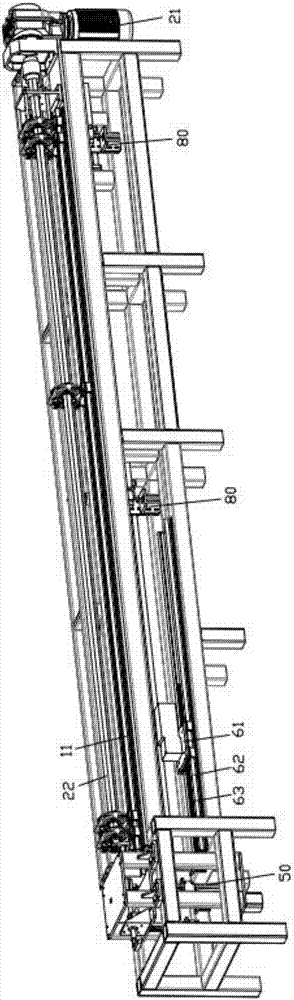

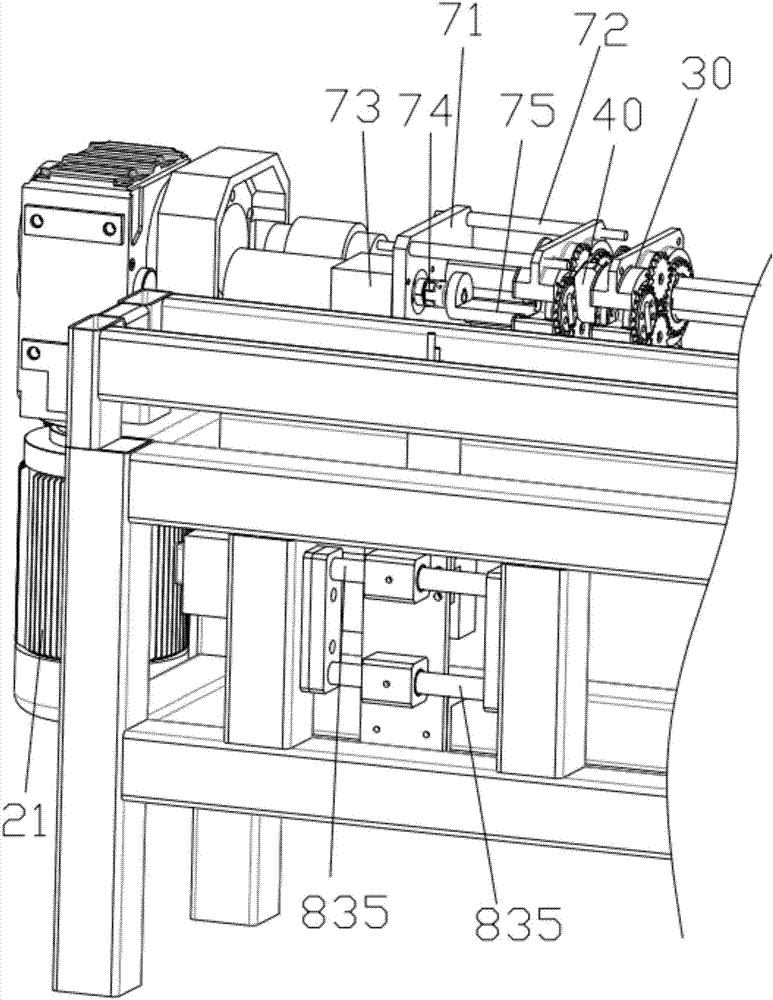

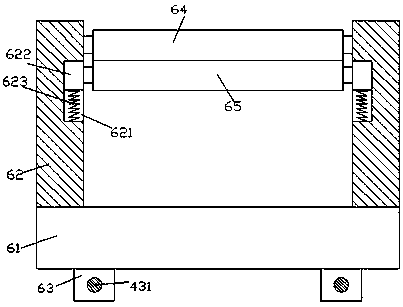

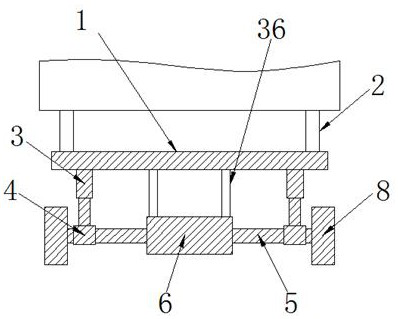

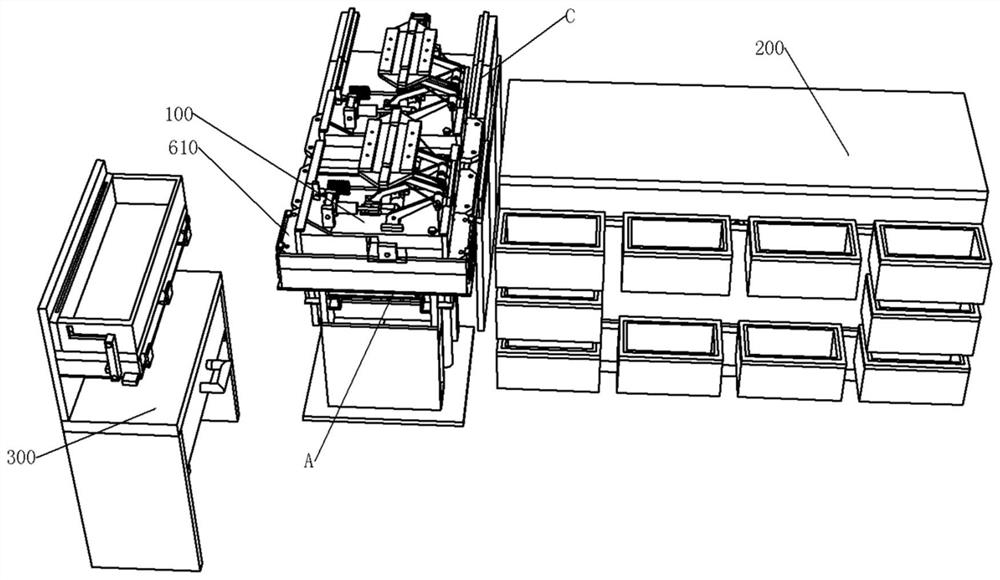

Book glue nail production line

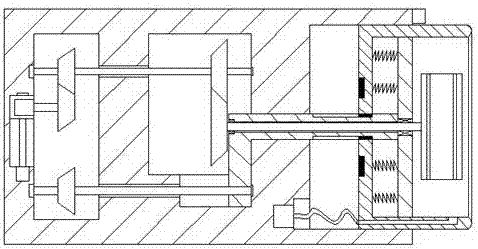

InactiveCN108944140ARealize automatic processingRealize automatic driveToysBook making processesProduction lineControl unit

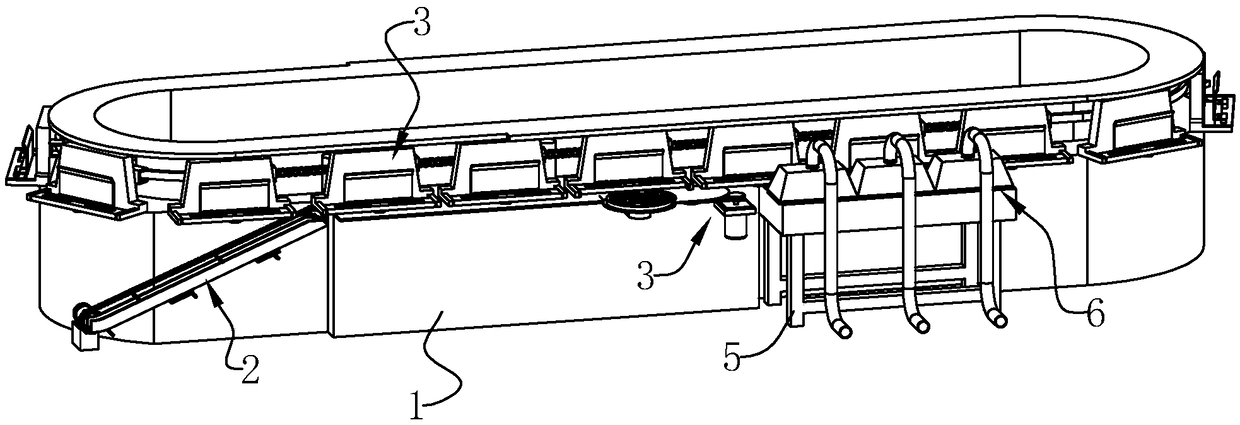

The invention discloses a book glue nail production line and relates to book gluing equipment. According to the key points of the technical scheme, the book glue nail production line comprises a rack,a feeding device arranged on one side of the rack, a conveying device arranged on the rack, a cutting device arranged on the rack and used for flat cutting spines, a worktable arranged behind the cutting device, a spine gluing device arranged on the worktable, a cover pasting device for pasting covers to books, and a discharging conveying device. The conveying device comprises a plurality of clamping assemblies which rotate annularly along the rack and clamp the books vertically, a control unit for controlling the clamping assemblies to conduct clamping or loosening, and a driving assembly for driving the clamping assemblies to rotate. The books can be automatically glued, and the book processing efficiency is improved.

Owner:北京昌联印刷有限公司

Cable winder

The invention discloses a cable winder. The cable winder comprises an oil pressure increasing device and a winding mechanism, wherein the winding mechanism is arranged at the top of the oil pressure increasing device; a storage groove is formed inside the right side surface of the winding mechanism; the storage groove is slidably connected with a closed sleeve in a matching manner; a winding chamber is arranged inside the closed sleeve; at the left side of the storage groove, the winding mechanism is internally provided with a conveying chamber; a first separating part is arranged between the conveying chamber and the storage groove; at the left side of the conveying chamber, the winding mechanism is internally provided with a driving chamber; a second separating part is arranged between the driving chamber and the conveying chamber; the inner bottom of the conveying chamber is provided with a first slidable connecting groove; the inside of the first separating part is slidably matched and connected with a connecting rod which is arranged in a manner of extending towards the left and right sides; the right side extending section of the connecting rod extends into the storage groove and extends into the winding chamber by penetrating through the closed sleeve; a push plate is fixedly arranged at the tail of the right side extending section of the connecting rod; a first duct arranged in a manner of extending towards the left direction and right direction is formed inside the connecting rod. The cable winder disclosed by the invention is simple in structure, reasonable in design, capable of reducing space occupation and low in manufacturing cost and maintenance cost.

Owner:华远高科电缆有限公司

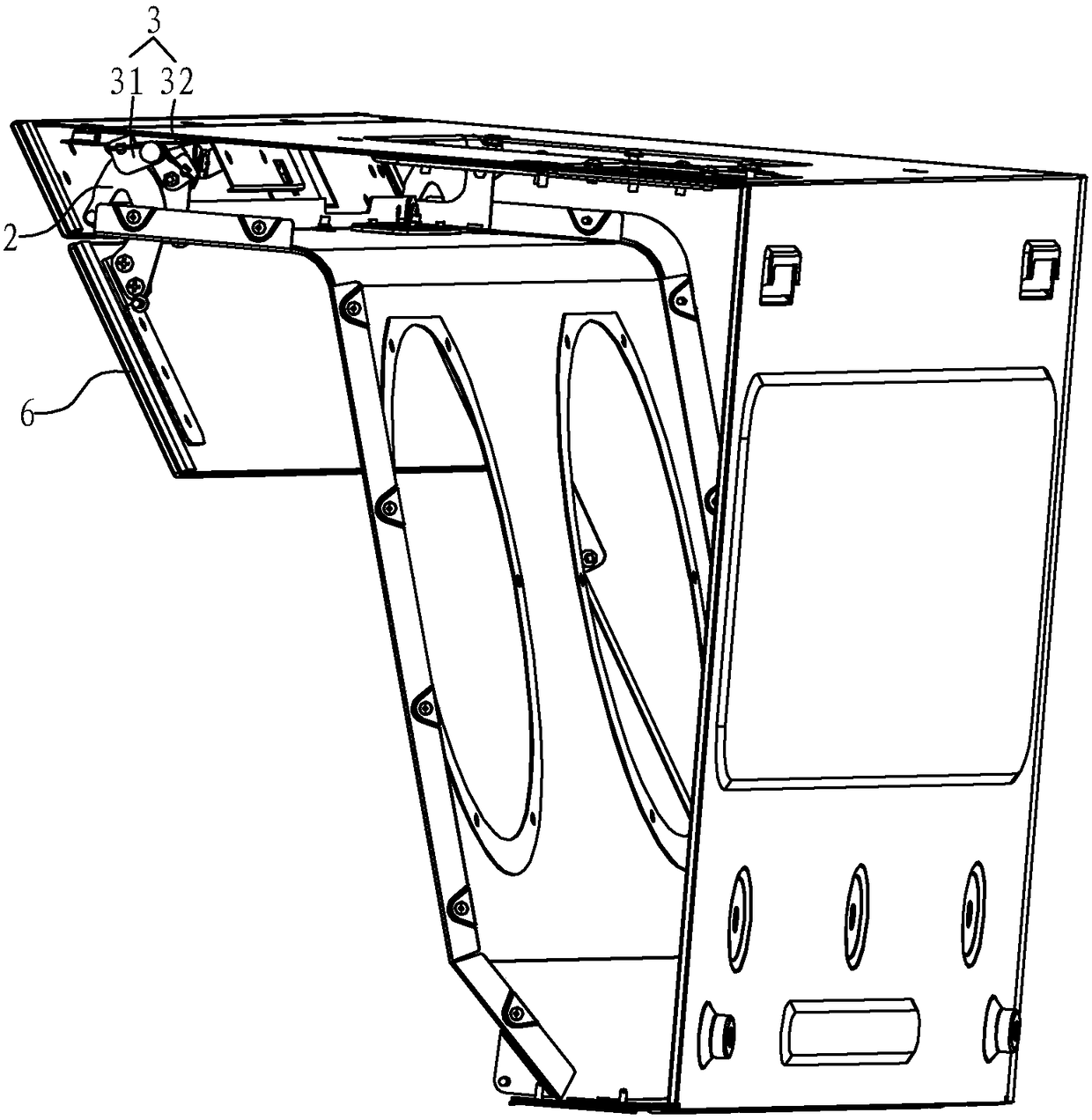

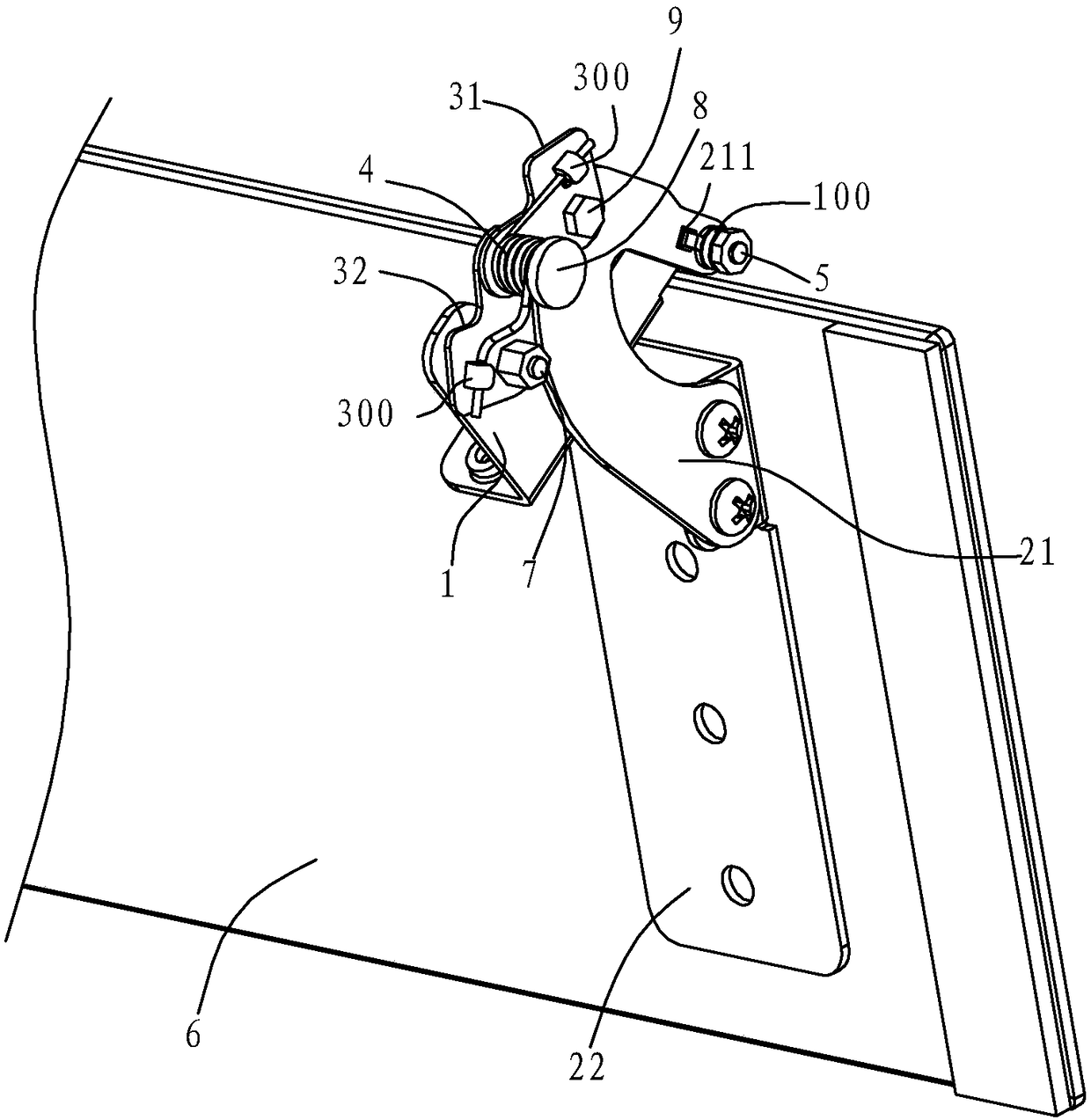

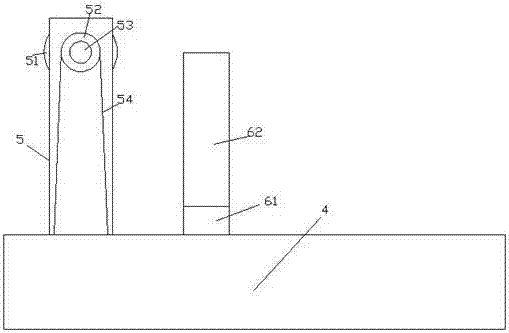

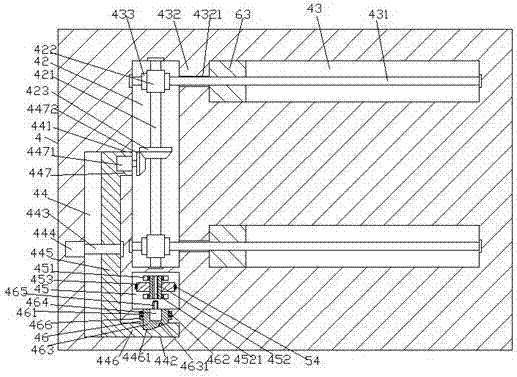

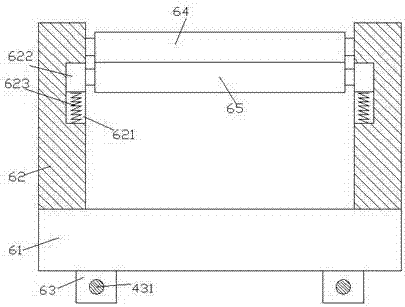

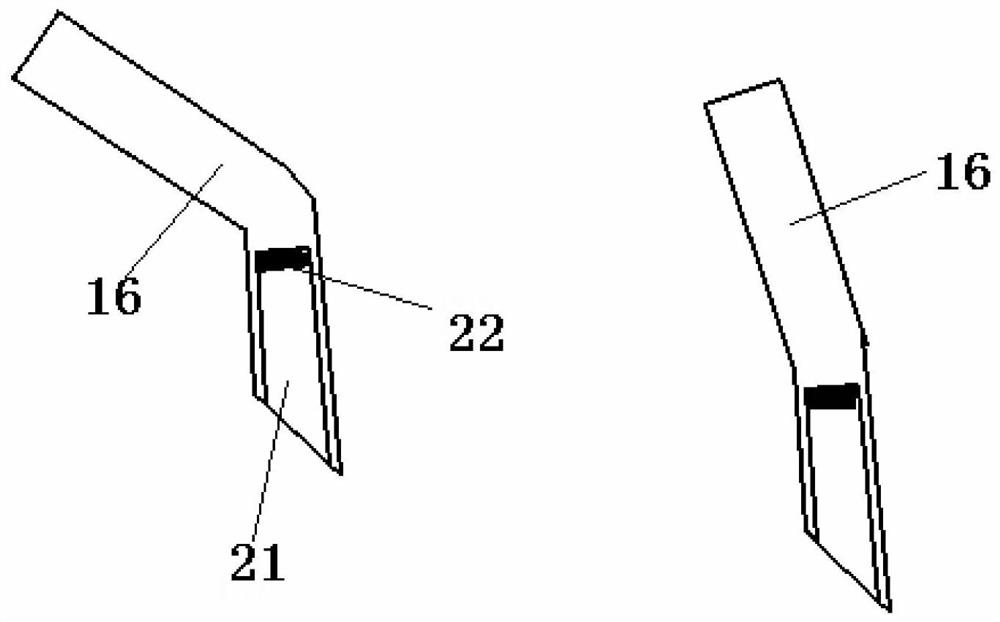

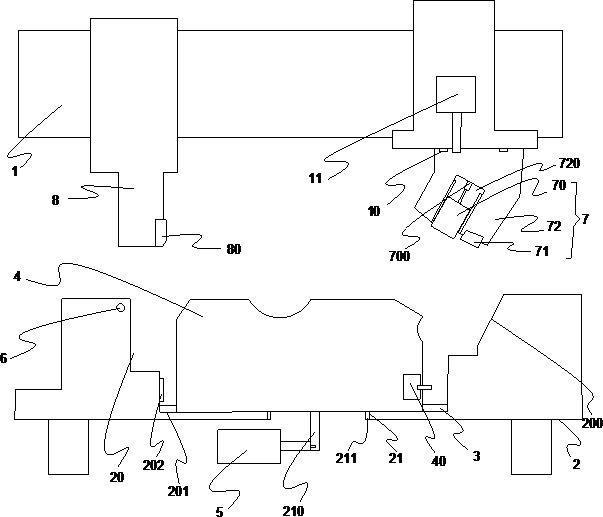

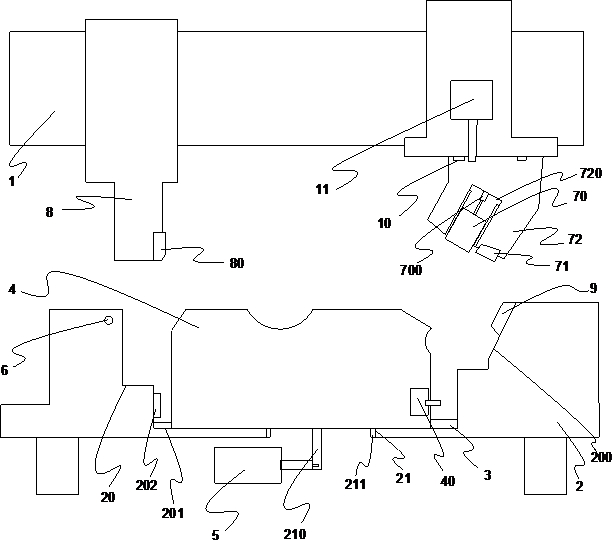

Rotating mechanism of range hood smoke baffle

PendingCN109425006ARealize automatic driveFit closelyDomestic stoves or rangesLighting and heating apparatusEngineeringMechanical engineering

The invention relates to a rotating mechanism of a range hood smoke baffle. The rotating mechanism comprises a base, a swinging component, a driving assembly and a torsional spring. The base is fixedly mounted on a shell of a range hood. The swinging component is fixedly connected with a smoke baffle, and is rotatably connected with the base by a first rotating shaft. The driving assembly comprises a first connecting arm and a second connecting arm which are rotatably connected. Two ends of the torsional spring are separately connected with the first connecting arm and the second connecting arm. The first connecting arm is connected with the swinging component. The second connecting arm is rotatably connected with the base by a second rotating shaft. When the smoke baffle opens or closes part of the angle, the swinging component drives the first connecting arm to move, and therefore the first connecting arm and the second connecting arm rotate relatively, the connecting inflection point between the first connecting arm and the second connecting arm is on the plane formed by axes of the first rotating shaft and the second rotating shaft. The rotating mechanism of the range hood smoke baffle enables the smoke baffle to continue to open or close after part of the angle is opened or closed by the smoke baffle and manually. Application is convenient and labor-saving.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

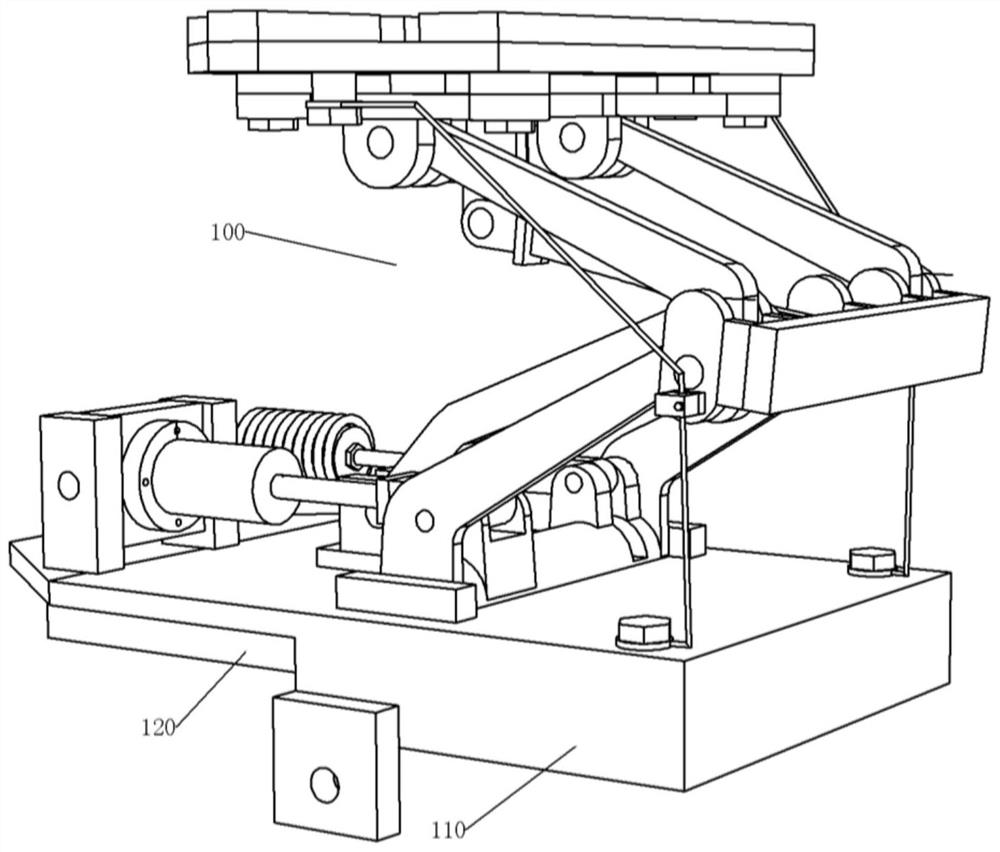

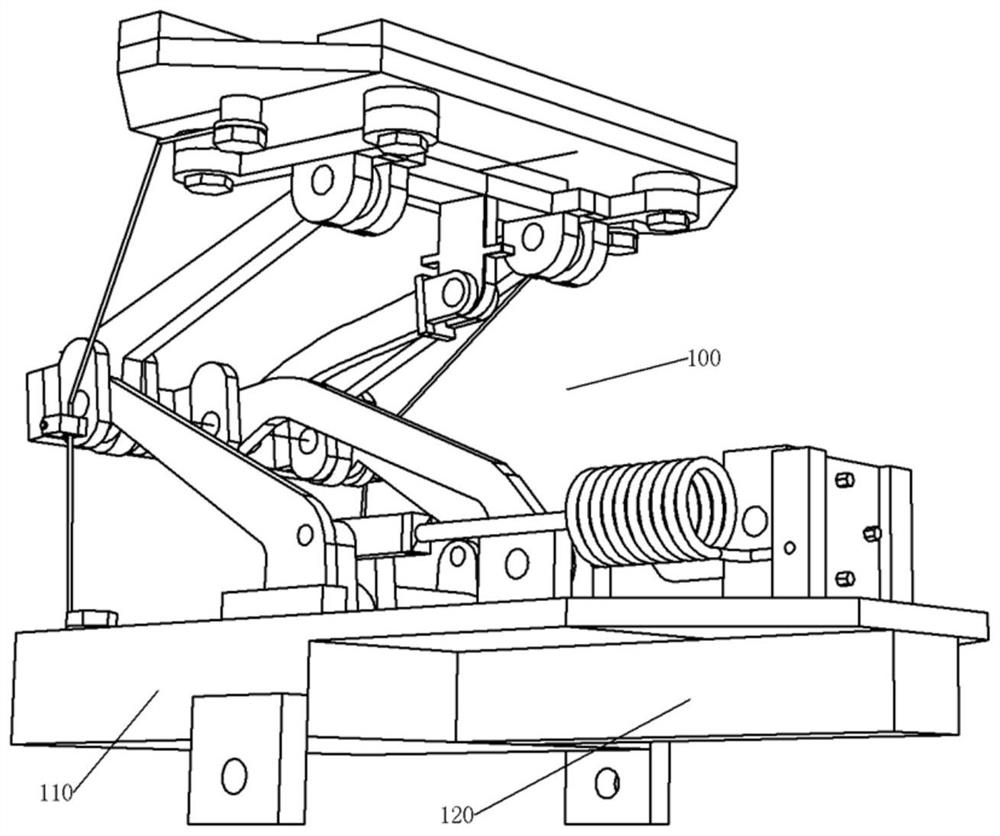

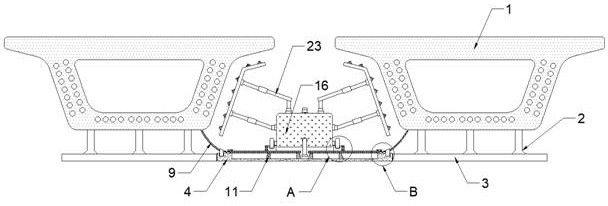

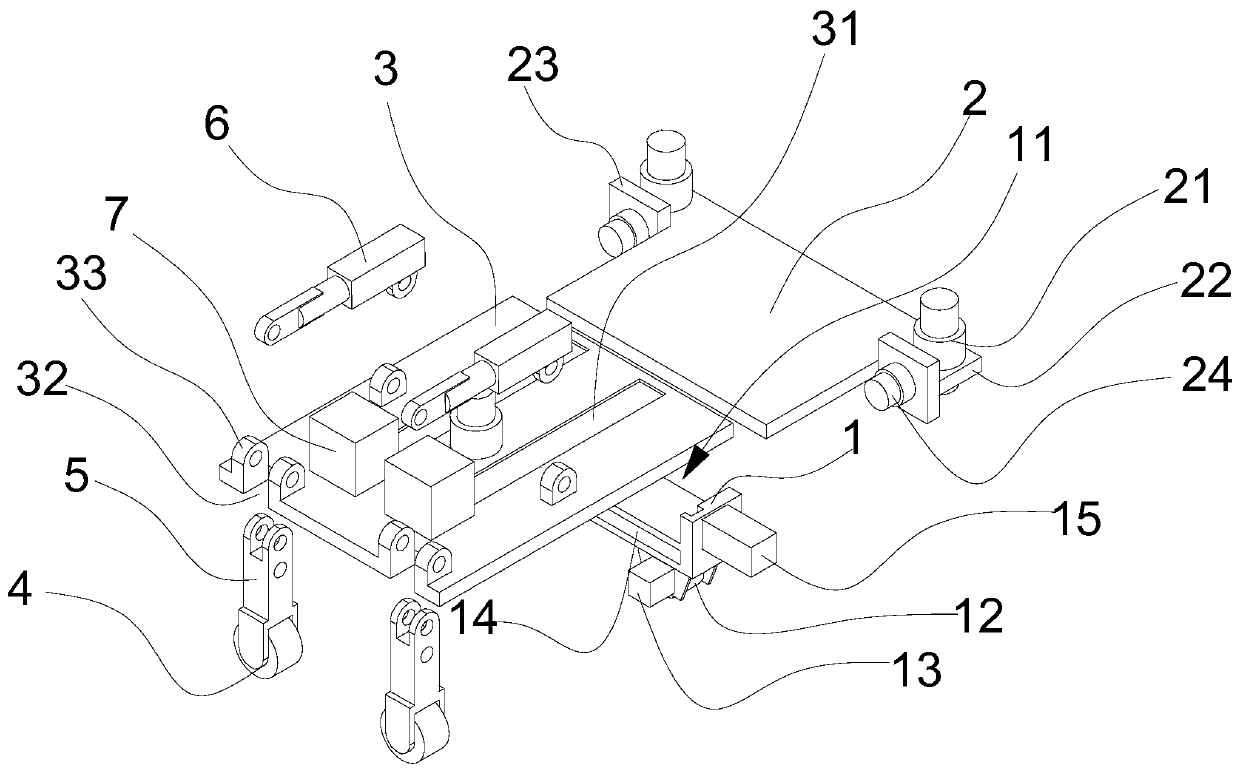

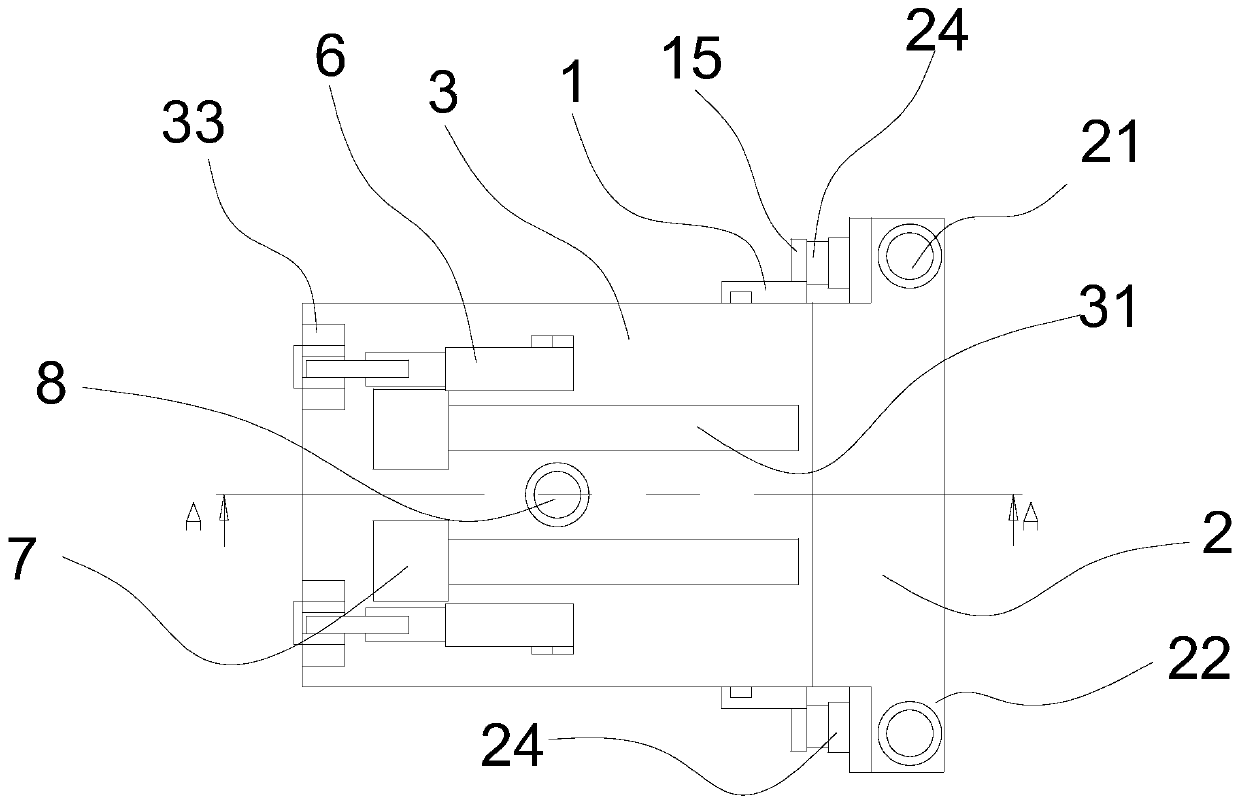

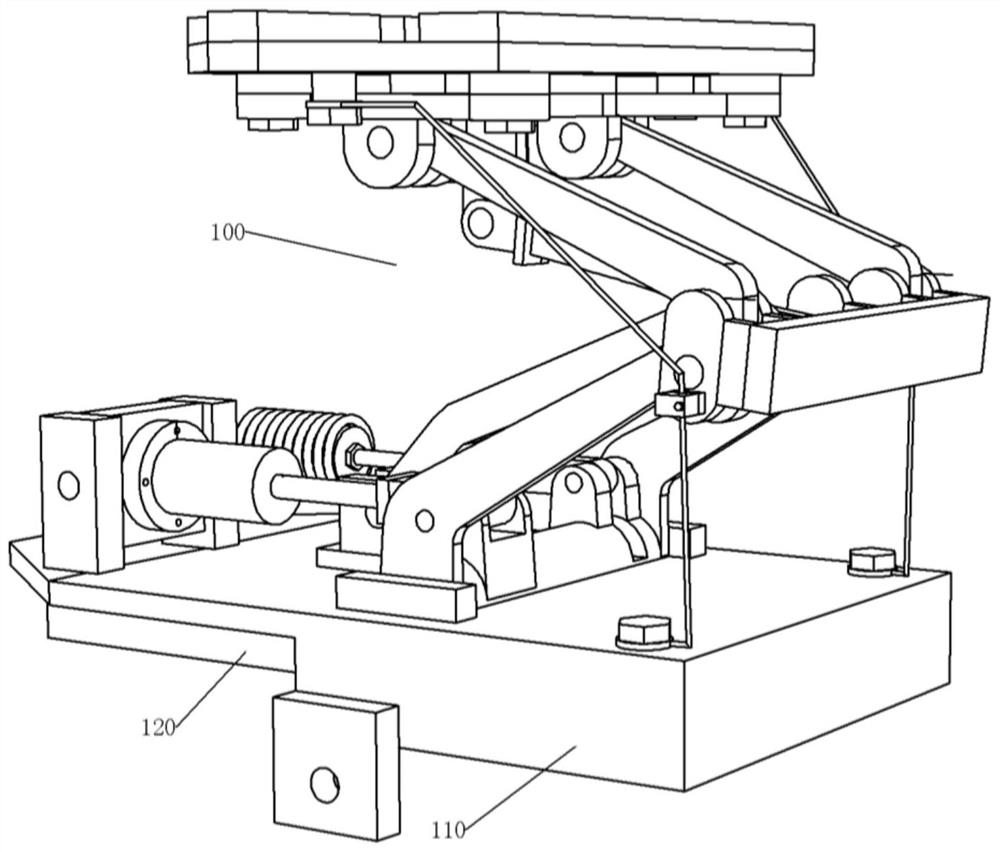

Disassembling and assembling module and subway pantograph overhauling platform thereof

ActiveCN114083283AConducive to centralized maintenanceReduce dependenceConveyorsAssembly machinesScrew threadIndustrial engineering

The invention discloses a disassembling and assembling module and a subway pantograph overhauling platform thereof. The disassembling and assembling module comprises a first disassembling and assembling plate, a second disassembling and assembling plate and a third disassembling and assembling plate, the second disassembling and assembling plate and the third disassembling and assembling plate are assembled through a disassembling and assembling rail frame, a disassembling and assembling rail is mounted on the disassembling and assembling rail frame, the first disassembling and assembling plate is mounted between the second disassembling and assembling plate and the third disassembling and assembling plate, and disassembling and assembling plate flanges are arranged at the two ends of the first disassembling and assembling plate correspondingly. The second disassembling and assembling plate and the third disassembling and assembling plate are assembled with the first disassembling and assembling guide shaft and the disassembling and assembling screw rod correspondingly, the first disassembling and assembling plate can axially and slidably sleeve the first disassembling and assembling guide shaft, and the first disassembling and assembling plate and the disassembling and assembling screw rod are assembled in a screwing mode through threads; and the second disassembling and assembling plate is further provided with a disassembling and assembling conveying plate, the disassembling and assembling conveying plate is assembled with the first disassembling and assembling belt shaft and the second disassembling and assembling belt shaft, the first disassembling and assembling belt shaft and the second disassembling and assembling belt shaft are connected through a disassembling and assembling belt to form a belt transmission mechanism, the disassembling and assembling belt is provided with disassembling and assembling belt protruding blocks, and the disassembling and assembling belt protruding blocks are used for being matched with the base conveying blocks to drive the conveying base.

Owner:CHONGQING VOCATIONAL INST OF ENG

Textile cloth winding device with automatic adjusting function

InactiveCN107324100AImprove mobile stabilityRealize automatic controlWebs handlingEngineeringConductor Coil

The invention discloses a textile cloth winding device with an automatic adjusting function. The textile cloth winding device comprises a base and a cloth winding frame fixed to the end face of the top of the left side of the base. A first cavity extending forward and backward is formed inside the left side of the base; guide grooves extending horizontally are formed in the part, on the right side of the first cavity, of the base in a longitudinal symmetry mode; a partition plate is arranged between the tail end of the left side of each guide groove and the right side end of the first cavity; a through hole is formed in each partition plate; a first thread rod extending towards the left side and the right side is arranged in each though hole in a transition fit mode; the extending tail ends of the left sides of the first thread rods extend into the first cavity and are connected with the inner wall of the left side of the first cavity in a rotating fit mode; and the extending tail ends of the right sides of the first thread rods extend into the guide grooves and are connected with the inner walls of the right sides of the guide grooves in a rotating fit mode. The textile cloth winding device is simple in structure, the winding quality of winding cloth and the cloth winding efficiency are improved, the regularity of cloth winding is achieved, the cloth surface of a wound cloth roll is smooth, and folds are avoided, so that the cloth winding quality is improved.

Owner:湖南华升洞庭麻业有限公司

Wall face grinding device for architectural decoration and finishing

InactiveCN107695815AImprove airtightnessImprove work efficiencyGrinding carriagesGrinding feed controlEngineeringSharpening

The invention discloses a wall face grinding device for architectural decoration and finishing. The wall face grinding device comprises a shear type lifting frame and a grinding mechanism mounted at the top of the shear type lifting frame. A storage groove is formed in the end face of the right side of the grinding mechanism. A closed sleeve is connected to the storage groove in a sliding fit manner. A grinding cavity is formed in the closed sleeve. A transmission cavity is formed in the position, on the left side of the storage groove, in the grinding mechanism. A first partition plate is arranged between the transmission cavity and the storage groove. A driving cavity is formed in the position, on the left side of the transmission cavity, in the grinding mechanism. A second partition plate is arranged between the driving cavity and the transmission cavity. A first sliding groove is formed in the bottom wall in the transmission cavity. A connecting rod arranged in a manner of extending towards the left side and the right side is connected in the first partition plate in a sliding fit manner. The extending segment on the right side of the connecting rod stretches into the storage groove and penetrates the closed sleeve to extend into the grinding cavity. A supporting plate is fixedly arranged at the extending tail end of the right side of the connecting rod. A first through hole arranged in a manner of extending left and right is formed in the connecting rod. The wall face grinding device is simple in structure, reasonable in design and high in closing effect, dust flying is avoided, the occupied space can be reduced, and the manufacturing and maintaining cost is low.

Owner:惠安县德虹数控设备有限公司

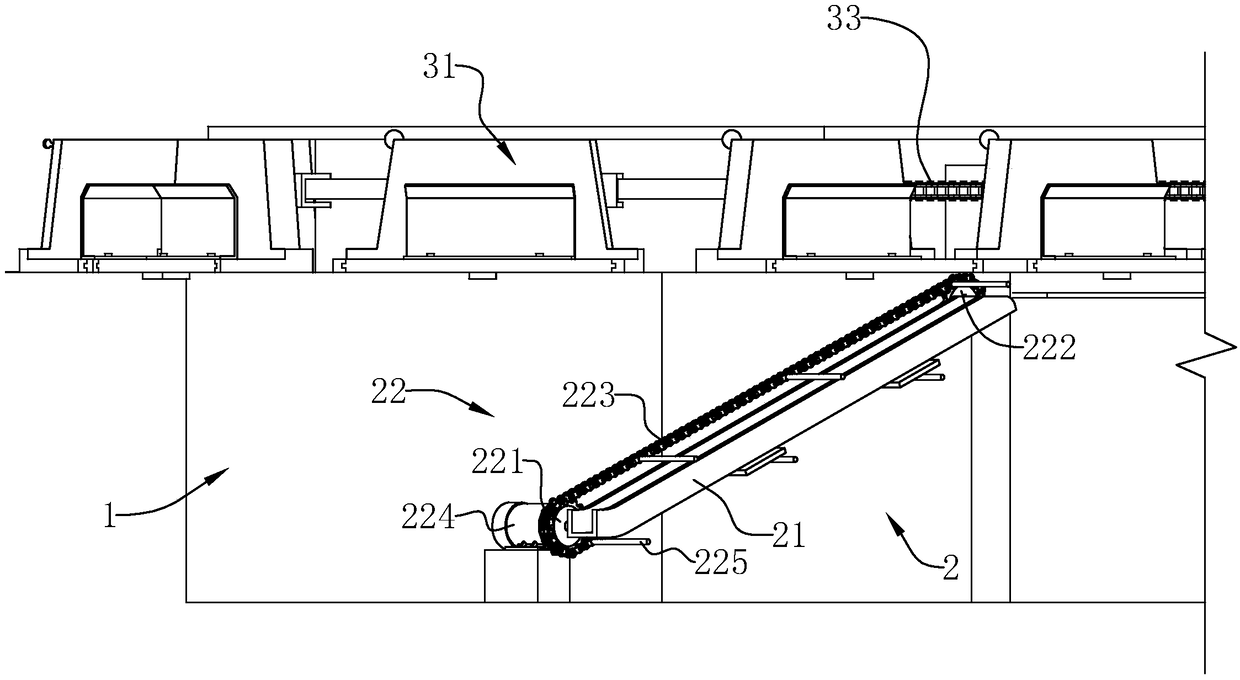

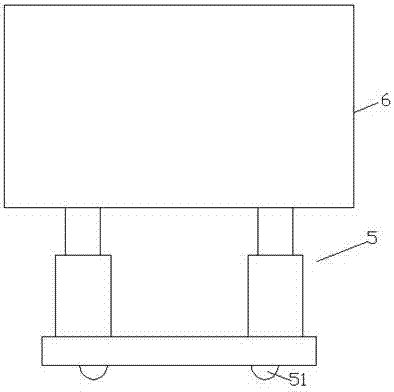

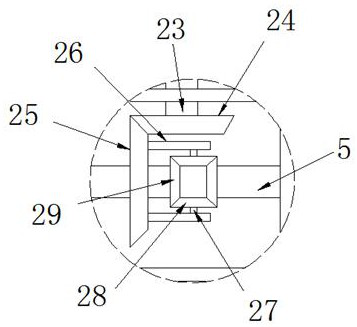

Energy-saving spraying system for precast beam maintenance

ActiveCN113211617AEfficient recyclingReduce wasteCeramic shaping apparatusDrive wheelWater resources

The invention discloses an energy-saving type spraying system for precast beam maintenance. The energy-saving type spraying system comprises precast beam bodies and water tanks; the lower ends of the precast beam bodies are placed on supporting plates through supporting legs, and the supporting plates are placed on the ground; a guide mechanism is arranged between every two supporting plates, and each guide mechanism is of an annular structure on the whole, wherein the two sides of each guide mechanism are parallel to the corresponding supporting plate, and the front end and the rear end of each guide mechanism are each of a semicircular structure; and each water tank is arranged at the position between every two precast beam bodies, and driving wheels used for walking are installed at the lower ends of the water tanks. According to the energy-saving type spraying system for precast beam maintenance, water resources can be effectively recycled and reused, waste of the water resources is reduced, spraying can be conducted on the side faces of two sets of precast beams at a time, and the spraying efficiency is improved; and the whole system is of a detachable structure, can be detached after being used, and is suitable for spraying of other precast beams.

Owner:黑龙江省铁投预制构件有限公司

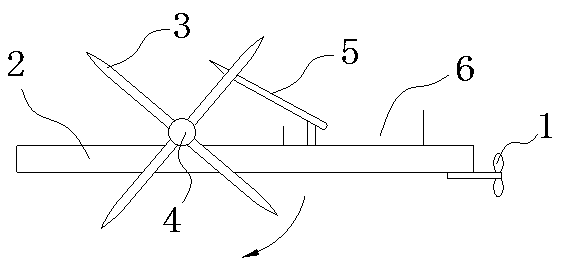

Automatic wall polishing device for architectural decoration

InactiveCN107695813AReduce investmentLow costGrinding carriagesGrinding drivesEngineeringBuilding renovation

The invention discloses an automatic wall grinding device for building decoration, which comprises a scissor-type lift frame and a grinding mechanism installed on the top of the scissor-type lift frame. A storage groove is arranged in the right end surface of the grinding mechanism, and the storage groove is slidably fitted. An airtight sleeve is connected, and a grinding chamber is provided in the airtight sleeve. A transmission chamber is provided in the grinding mechanism on the left side of the storage tank. A first partition is provided between the transmission chamber and the storage tank. The driving chamber is provided with a second partition between the driving chamber and the transmission chamber, the bottom wall of the transmission chamber is provided with a first sliding groove, and the connecting rods extending toward the left and right sides are slidably connected in the first partition, The extension section on the right side of the connecting rod extends into the storage tank and extends into the grinding chamber through the airtight sleeve. The right extension end of the connecting rod is fixed with a support plate, and the connecting rod is provided with a first through hole extending left and right; the structure of the present invention Simple, reasonable design, high airtight effect, prevents dust from flying, can reduce occupied space, and has low manufacturing and maintenance costs.

Owner:惠安县德虹数控设备有限公司

System and method for automatically driving function execution

PendingCN110187941ARealize automatic driveImprove acceleration performanceExecution paradigmsComputer scienceManagement functions

The invention discloses a system and method for automatically driving function execution, and belongs to the technical field of cluster management. The system for automatically driving function execution comprises an operation template table, an operation context table and an operation instance table, the operation template table is used for arranging various operation steps of different functions, the operation context table is used for parameter transmission among a plurality of steps, and the operation instance table is instantiation of the operation template table. The system for executingthe automatic driving function can easily meet the expansion requirement of a later cluster management function, maintenance personnel can conveniently and comprehensively track and monitor the cluster operation process of a whole management platform, convenience of later maintenance is guaranteed, and the system has very good application and popularization value.

Owner:SHANDONG LANGCHAO YUNTOU INFORMATION TECH CO LTD

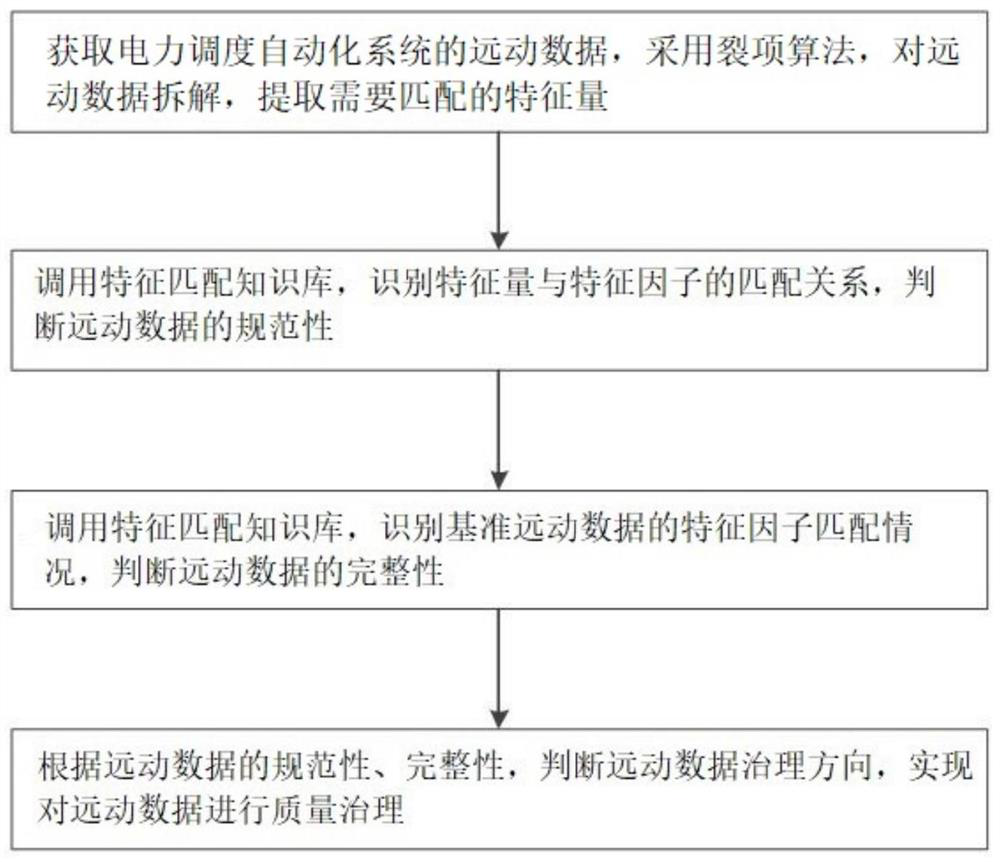

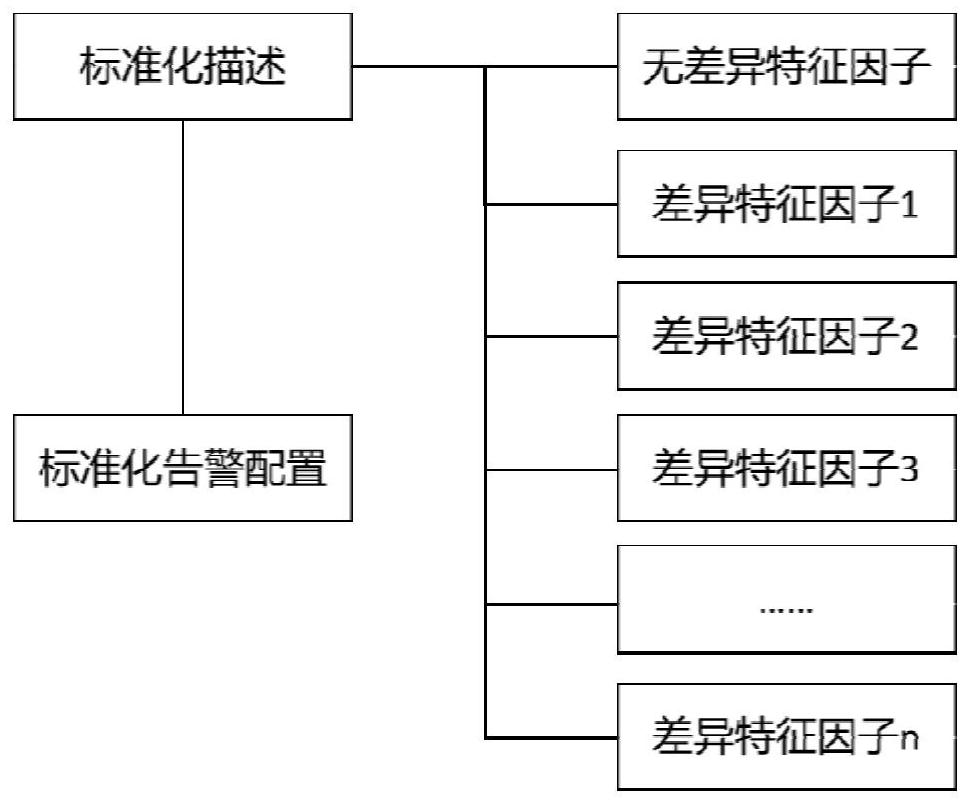

Electric power system telecontrol data quality management method and system based on feature matching knowledge base

ActiveCN112541833ARealize Quality GovernancePromote quality and efficiencyData processing applicationsSpecial data processing applicationsPower dispatchData quality

The invention discloses an electric power system telecontrol data quality management method and system based on a feature matching knowledge base, and the method comprises the following steps: S1, obtaining telecontrol data of an electric power dispatching automation system, employing a split item algorithm to disassemble the telecontrol data, and extracting a feature quantity needing to be matched; S2, calling a feature matching knowledge base, identifying a matching relationship between the feature quantity and the feature factor, and judging the normalization of the telecontrol data; S3, calling a feature matching knowledge base, identifying the feature factor matching condition of the reference telecontrol data, and judging the integrity of the telecontrol data; and S4, judging a telecontrol data management direction according to the standardization and integrity of the telecontrol data, thereby realizing quality management of the telecontrol data. Full-automatic auditing of telecontrol data quality of the power dispatching automation system is achieved, manual recognition is not needed, automatic operation, maintenance, quality improvement and efficiency improvement are achieved, meanwhile, an evaluation result is accurate, and the operation efficiency is high.

Owner:GUANGDONG POWER GRID CO LTD +1

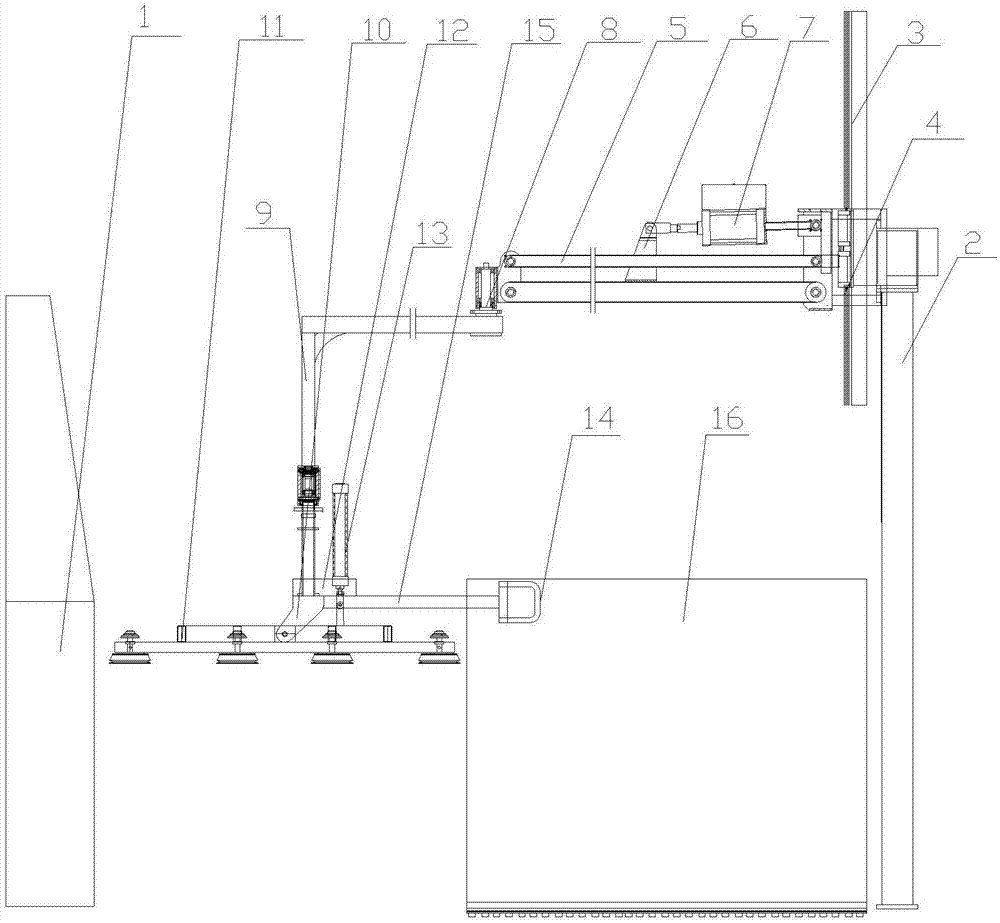

Glass feeding and discharging device for glass edge grinding machine

InactiveCN107283296AImplement step-by-step movementSimple structureEdge grinding machinesGrinding feedersArchitectural engineeringGlass sheet

A glass loading and unloading device for a glass edging machine. The main body is a gantry frame at the front end of the glass edging machine. It is arranged on the top of the gantry frame and can move horizontally. The vertical guide rail is installed on the vertical guide rail. There is a ferrule that can move up and down on the vertical guide rail, and a beam that is movably connected to the ferrule is installed on the ferrule. The top of the ferrule and the middle of the beam are provided with lugs, and there is a lift between the two lugs. Cylinder, a support shaft is installed at the end of the beam, an angle shaft that can rotate around the support shaft is set on the support shaft, an angle plate is connected to the bottom of the angle shaft, a glass suction cup is installed on the angle plate, and a positioning is arranged between the angle plate and the angle shaft The positioning plate is inverted and movably provided with a direction changing cylinder whose telescopic rod passes through the positioning plate and is connected to the glass suction cup. The present invention has a simple structure, and can realize the step-by-step movement of the glass panel through the mutual rotation and movement cooperation of a plurality of groups of movable shaft bodies, and the operation is convenient.

Owner:BENGBU GAODE MACHINERY AUTOMATION SCI & TECH

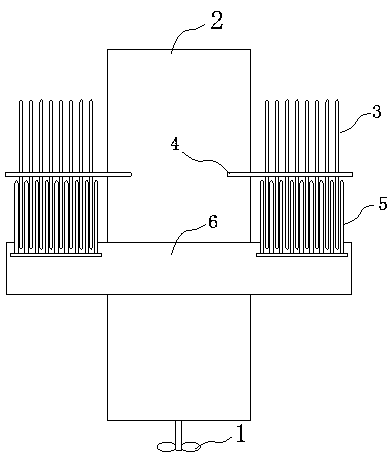

Water lettuce cleaning machine

InactiveCN109348837ARealize automatic driveHeight adjustableHarvestersEnvironmental engineeringUltimate tensile strength

The invention aims to provide a water lettuce cleaning machine which improves water lettuce cleaning efficiency. The water lettuce cleaning machine comprises a floating body and a plurality of water lettuce cleaning combs, the water lettuce cleaning combs comprise a plurality of parallel straight bar comb teeth and are radially fixed onto a rotating shaft, the rotating shaft is mounted on the floating body, connected with a rotating shaft driving mechanism and perpendicular to a walking direction of the floating body, the floating body is provided with a water lettuce removing comb positionedat the rear end of the rotating shaft, the distance between comb teeth of the water lettuce removing comb is as same as that of the water lettuce cleaning combs, the number of the teeth of the water lettuce removing comb is more than that of water lettuce cleaning combs, and the height of the water lettuce removing comb is gradually reduced from front to rear. The water lettuce cleaning machine issimple in structure and low in cost and has excellent practicability, water lettuces can be automatically and continually cleaned, and labor intensity is relieved.

Owner:黄格格

Railway maintenance vehicle

PendingCN109703579AOut of implementationSimple and fast operationRailway inspection trolleysRailway transportAutomotive engineering

Owner:ZHENGZHOU RAILWAY VOCATIONAL & TECH COLLEGE

Executing mechanism and hexagonal wire netting side locking device with executing mechanism

InactiveCN107127278ARealize automatic driveIncrease productivityMetal-working apparatusWire networkExecution unitEngineering

An executive mechanism, including two execution units and a seaming mold, the seaming mold is set between the two execution units, a twisted gear is arranged inside the execution unit, and a base circle facing the twisted gear is set on one side of the end face of the twisted gear The incision extending from the center of the shaft, the opening depth of the incision is greater than the radius of the base circle of the twisted gear, used to insert the hexagonal mesh and edge-receiving iron wire, and the edge-locking mold is connected with the twisted gear of the execution unit to make the edge-locking The mold rotates synchronously with the winch gear. The executive mechanism in the present invention includes two execution units and a seaming die. The seam lock die is arranged between the two execution units. The gear rotates, and then the hexagonal net is sewn up by the twisted gear. The present invention also proposes a hexagonal net selvage device provided with an actuator.

Owner:南京研华智能科技有限公司

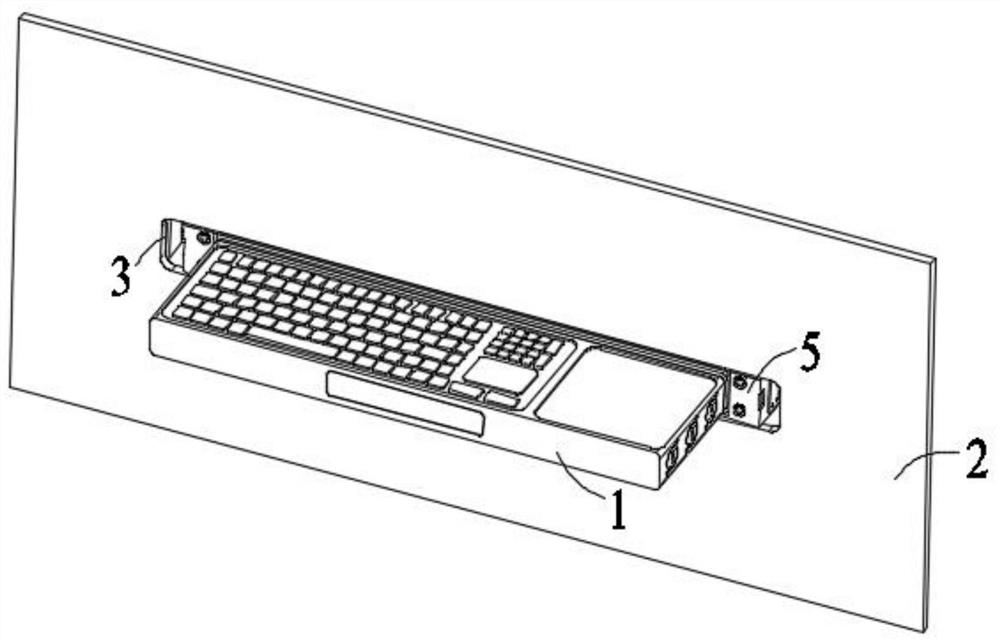

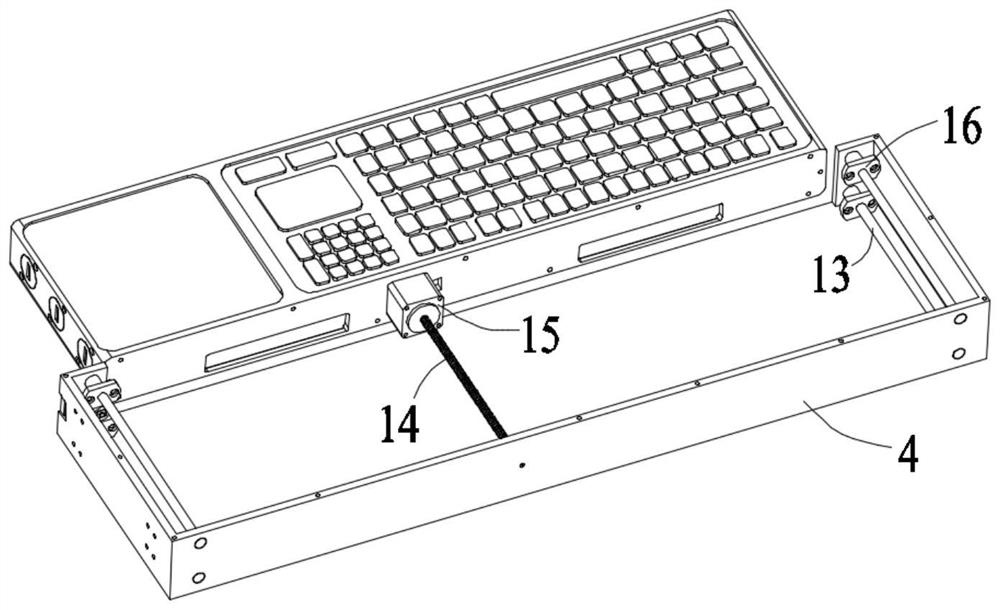

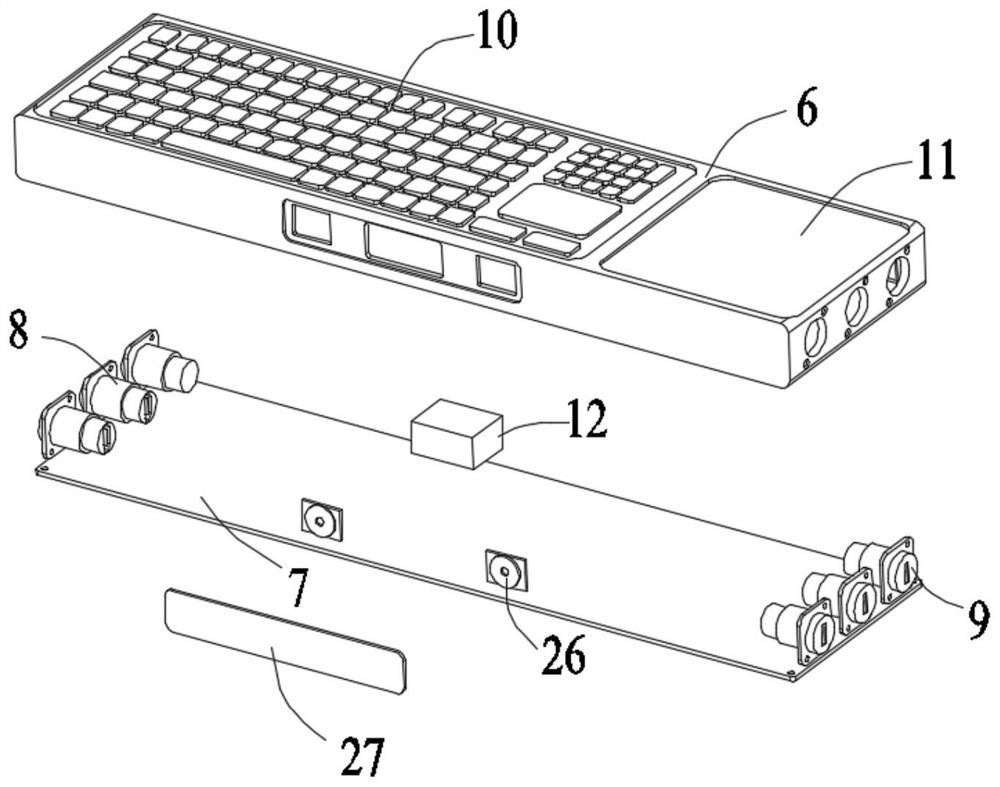

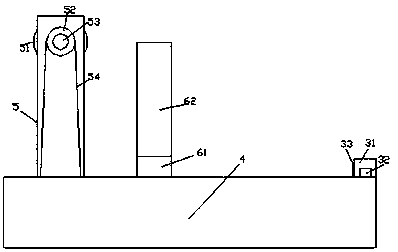

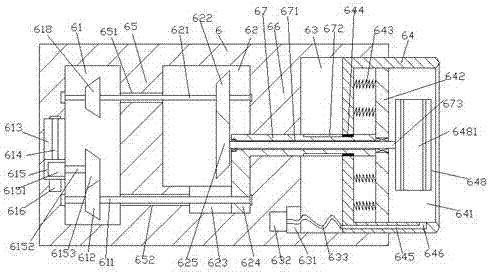

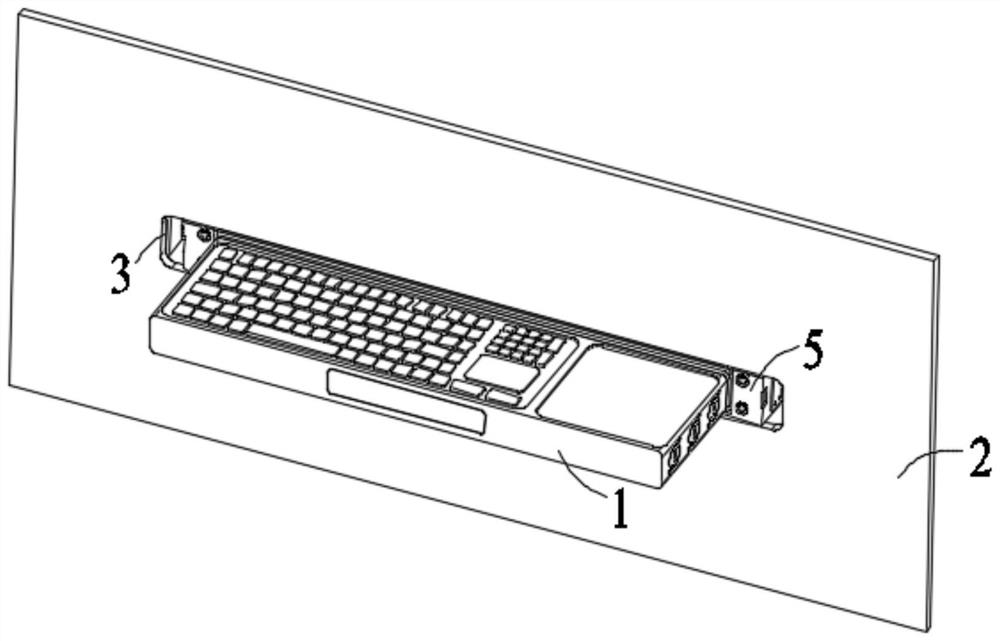

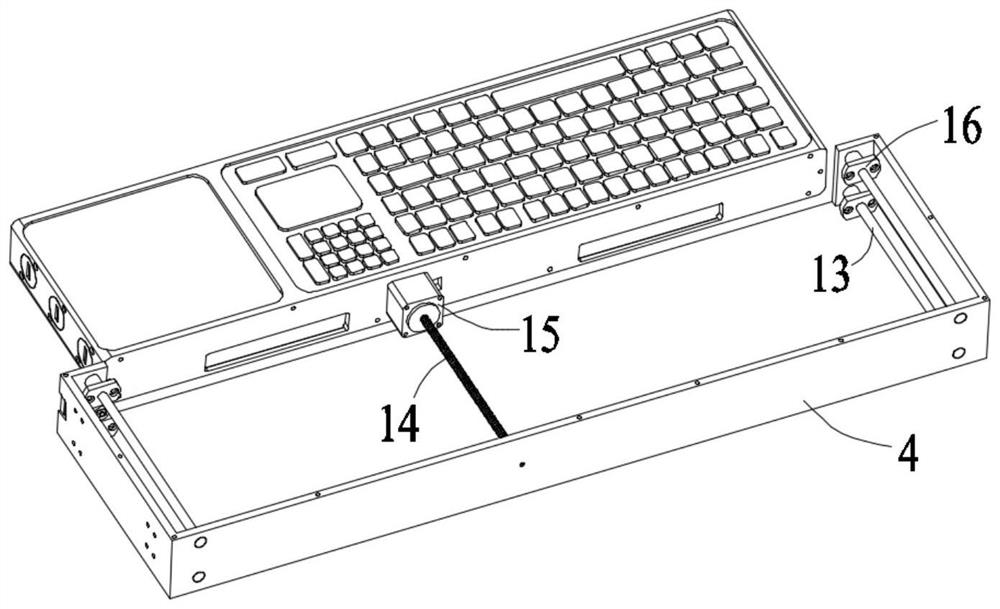

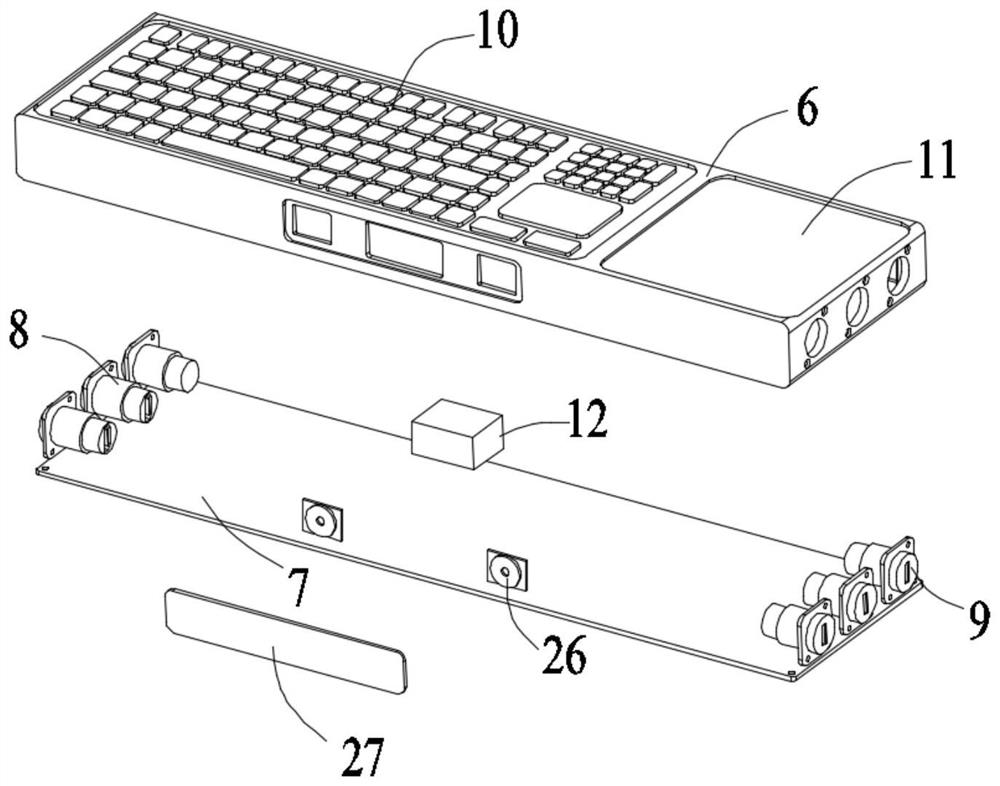

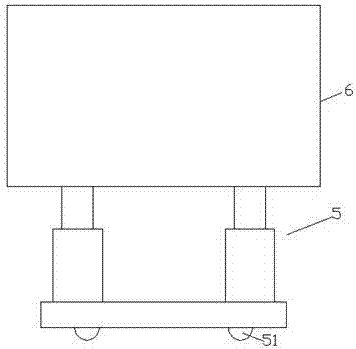

Multifunctional medical keyboard

PendingCN114564112ARealize automatic driveEasy to clean and disinfectInput/output for user-computer interactionElectric machineryUSB

The invention discloses a multifunctional medical keyboard which comprises a keyboard body installed on a wall, a strip-shaped through hole for the keyboard body to penetrate through is formed in a panel of the wall, and a storage box with one end communicated with the strip-shaped through hole is arranged on the inner side of the panel; the keyboard main body comprises an upper shell, a bottom plate mounted on the bottom surface of the upper shell, a plurality of video input interfaces and a plurality of USB (Universal Serial Bus) interfaces; at least two guide rails perpendicular to a wall panel are arranged in the storage box at intervals, the fixing plate is arranged on the guide rails in a sleeving mode and can move in a reciprocating mode along the guide rails, and a through type stepping motor is installed on the fixing plate in a penetrating mode. The multifunctional keyboard has a waterproof function and can be wiped and disinfected, the video input interface and the USB interface are integrated, multi-functionalization of the keyboard is achieved, the sterile condition of a medical environment is met, and the problem of dust accumulation is greatly solved.

Owner:SINODEU MEDICAL CO LTD

Cloth winding device with automatic adjusting function

InactiveCN107697693AImprove mobile stabilityRealize automatic controlWebs handlingEngineeringMechanical engineering

The invention discloses a cloth winding device with an automatic adjusting function. The cloth winding device comprises a base and a cloth winding frame fixed to the end face of the top of the left side of the base. A first cavity extending front and back is formed in the left side of the base, and the part, on the right side of the first cavity, of the base is internally provided with guiding grooves which are symmetric up and down and extend left and right. A partition plate is arranged between the tail end of the left side of each guiding groove and the right side end of the first cavity. Each partition plate is internally provided with a penetration hole. Each penetration hole is internally provided with a first threaded rod in a transition fit manner, wherein the first threaded rod extends towards the left side and the right side. The extending tail end of the left side of each first threaded rod stretches into the first cavity and is connected with the inner wall of the left sideof the first cavity in a rotation fit manner, and the extending tail ends of the right sides of the first threaded rods stretch into the guiding grooves and are connected with the inner walls of theright sides of the guiding grooves in a rotation fit manner. The cloth winding device is simple in structure, the winding quality of wound cloth is improved, the cloth winding efficiency is improved,the cloth winding tidiness is achieved, the surface of the cloth of the wound cloth roll is flat, and wrinkling is avoided.

Owner:吴康康

Convenient and fast cable winder

The invention discloses a convenient and fast cable winder. The convenient and fast cable winder comprises an oil pressure lifting device and a winding mechanism arranged at the top of the oil pressure lifting device. A storage groove is formed in the right side face of the winding mechanism and is connected with a closed sleeve in a sliding fit manner. A winding cavity is formed in the closed sleeve. A transmission cavity is formed in the position, on the left side of the storage groove, in the winding mechanism. A first division part is arranged between the transmission cavity and the storage groove. A driving cavity is formed in the position, on the left side of the transmission cavity, in the winding mechanism. A second division part is arranged between the driving cavity and the transmission cavity. A first sliding groove is formed in the inner bottom of the transmission cavity. A connecting rod extending towards the left side and the right side is connected in the first divisionpart in a sliding fit manner. The extending segment of the right side of the connecting rod stretches into the storage groove and penetrates the closed sleeve to extend into the winding cavity. A pushplate is fixedly arranged at the extending tail of the right side of the connecting rod. A first duct extending left and right is arranged in the connecting rod. The convenient and fast cable winderis simple in structure and reasonable in design, occupied space can be reduced, and the manufacturing and maintaining cost is low.

Owner:晋江市启清电子科技有限公司

A textile rolling device with automatic adjustment function

InactiveCN107324100BImprove mobile stabilityRealize automatic controlWebs handlingConductor CoilMechanical engineering

The invention discloses a textile cloth winding device with an automatic adjusting function. The textile cloth winding device comprises a base and a cloth winding frame fixed to the end face of the top of the left side of the base. A first cavity extending forward and backward is formed inside the left side of the base; guide grooves extending horizontally are formed in the part, on the right side of the first cavity, of the base in a longitudinal symmetry mode; a partition plate is arranged between the tail end of the left side of each guide groove and the right side end of the first cavity; a through hole is formed in each partition plate; a first thread rod extending towards the left side and the right side is arranged in each though hole in a transition fit mode; the extending tail ends of the left sides of the first thread rods extend into the first cavity and are connected with the inner wall of the left side of the first cavity in a rotating fit mode; and the extending tail ends of the right sides of the first thread rods extend into the guide grooves and are connected with the inner walls of the right sides of the guide grooves in a rotating fit mode. The textile cloth winding device is simple in structure, the winding quality of winding cloth and the cloth winding efficiency are improved, the regularity of cloth winding is achieved, the cloth surface of a wound cloth roll is smooth, and folds are avoided, so that the cloth winding quality is improved.

Owner:湖南华升洞庭麻业有限公司

Efficient wall face grinding device for architectural decoration and finishing

InactiveCN107695814AImprove airtightnessImprove work efficiencyGrinding carriagesGrinding drivesEngineeringStorage tank

The invention discloses an efficient wall face grinding device for architectural decoration and finishing. The efficient wall face grinding device comprises a shear type lifting frame and a grinding mechanism mounted at the top of the shear type lifting frame. A storage groove is formed in the end face of the right side of the grinding mechanism. A closed sleeve is connected to the storage groovein a sliding fit manner. A grinding cavity is formed in the closed sleeve. A transmission cavity is formed in the position, on the left side of the storage groove, in the grinding mechanism. A first partition plate is arranged between the transmission cavity and the storage groove. A driving cavity is formed in the position, on the left side of the transmission cavity, in the grinding mechanism. Asecond partition plate is arranged between the driving cavity and the transmission cavity. A first sliding groove is formed in the bottom wall in the transmission cavity. A connecting rod arranged ina manner of extending towards the left side and the right side is connected in the first partition plate in a sliding fit manner. The extending segment on the right side of the connecting rod stretches into the storage groove and penetrates the closed sleeve to extend into the grinding cavity. A supporting plate is fixedly arranged at the extending tail end of the right side of the connecting rod. A first through hole arranged in a manner of extending left and right is formed in the connecting rod. The efficient wall face grinding device is simple in structure, reasonable in design and high in closing effect, dust flying is avoided, the occupied space can be reduced, and the manufacturing and maintaining cost is low.

Owner:惠安县德虹数控设备有限公司

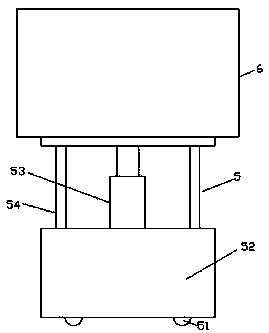

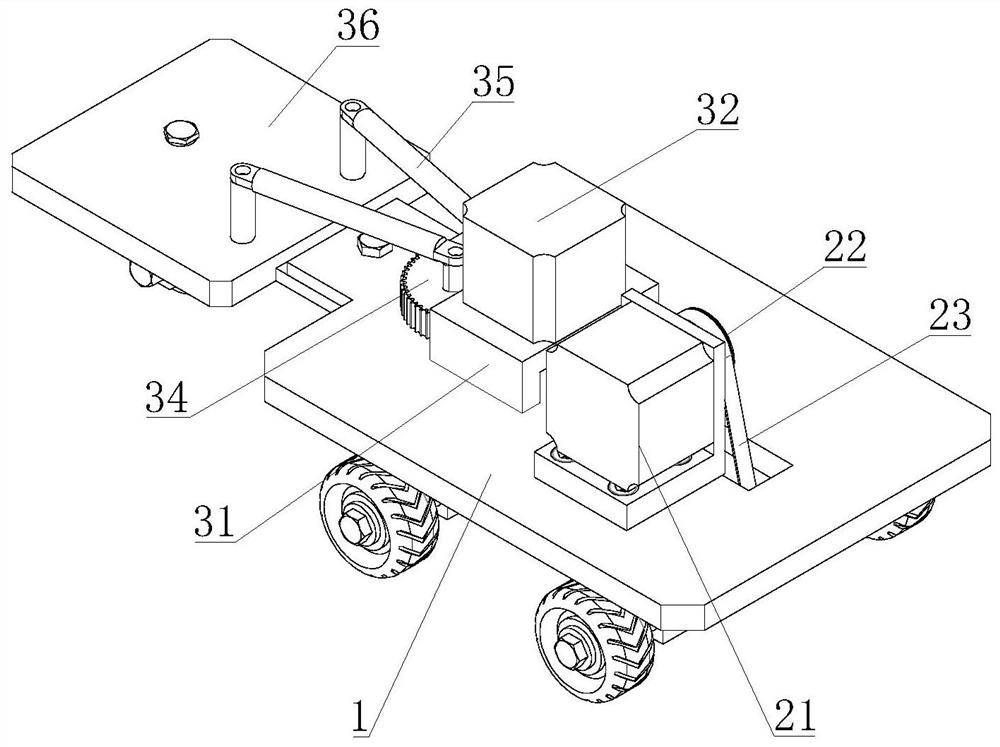

Automatic transplanting machine for vegetable pot seedlings

ActiveCN109362296BPlanting depth changeImprove practicalityTransplantingAgricultural engineeringStructural engineering

The invention discloses an automatic transplanting machine for vegetable pot seedlings, which comprises a bottom plate, a plurality of support rods are arranged on both sides of the top of the bottom plate, adjustment devices are arranged on both sides of the bottom of the bottom plate, and the adjustment device The bottoms are provided with bearings 1, and the interior of the bearings 1 is provided with a rotating shaft matched therewith, a driving device is arranged between the rotating shafts, and one side of the rotating shaft is far away from the driving device. Both sides are provided with hubs, and rollers matched with them are provided on the hubs. Beneficial effects: reasonable design, easy to use, compared with the traditional vegetable pot seedling automatic transplanting machine, the present invention can adjust the height of the transplanting machine chassis according to the use requirements, so that it can change the pot seedling planting depth , so that it can be suitable for planting vegetable pot seedlings of different depths, thereby effectively improving its practicability.

Owner:新疆科创天达农业工程有限公司

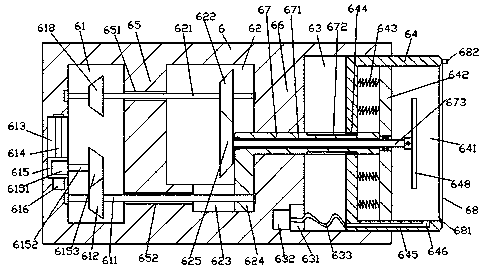

A waste gas treatment machine

ActiveCN107052016BRealize automatic driveEfficient conversion coordinationCombination devicesDirt cleaningWaste management

The invention discloses a waste gas treatment machine. The waste gas treatment machine comprises a hydraulic jacking device and a sucking and purifying structure arranged at the top of the hydraulic jacking device. An accommodating trough is formed inside the right side surface of the sucking and purifying structure and connected with a gas collecting hood in a sliding fit mode; a gas collecting cavity is arranged inside the gas collecting hood; a conversion cavity is arranged at the position, on the left side of the accommodating trough, in the sucking and purifying structure; a first isolation board is arranged between the conversion cavity and the accommodating trough; a driving cavity is arranged at the position, on the left side of the conversion cavity, in the sucking and purifying structure; a second isolation board is arranged between the driving cavity and the conversion cavity; a first sliding groove is formed in the bottom surface of the interior of the conversion cavity; and a connecting rotating rod which extends towards the left side and the right side is connected to the inside of the first isolation board in a sliding fit mode, the right-side extending section of the connecting rotating rod extends into the accommodating trough and penetrates through the gas collecting hood to extend into the gas collecting cavity, the right-side extending tail of the connecting rotating rod is fixedly provided with a supporting board, and a first through groove extending in the left-right direction is formed inside the connecting rotating rod. The waste gas treatment machine is simple in structure and reasonable in design, the occupied space can be reduced, and the manufacturing cost and the maintaining cost are low.

Owner:深圳科莱环保科技有限公司

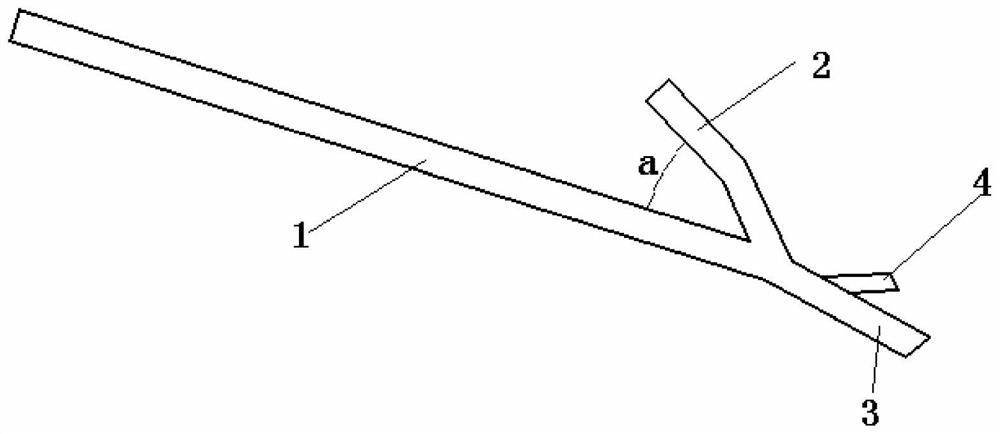

An auxiliary device for removing bent rods

ActiveCN108581410BAchieve demolitionEasy to take outMetal working apparatusStructural engineeringMechanical engineering

The invention discloses a bent rod dismantling auxiliary device. When a bent rod is dismantled, a first fulcrum bar and a second fulcrum bar limit a steel plate arranged on a pipe sheet turnover framethrough the included angle formed between the first fulcrum bar and the second fulcrum bar; and a clamping bar hooks and clamps a bent rod connecting steel ring arranged at the outer end of the bentrod, and when the bent rod is dismantled, the bent rod is dismantled by applying lever force on a force applying bar through a fulcrum formed by the first fulcrum bar and the second fulcrum bar. According to the bent rod dismantling auxiliary device, the steel ring arranged at the tail of the bent rod is hooked through the clamping bar, the bent rod can be easily taken out through the lever principle, convenience and fastness are achieved, labor and time are saved, and the bent rod can be quickly dismantled; in addition, automatic driving can be achieved, the bent rod can be automatically dismantled, not only can automatic driving on the force applying bar be achieved, but also the fulcrum can be positioned through hydraulic driving, and dismantling is very convenient.

Owner:洛阳城投工程建设有限公司

A wall grinding device for building decoration

InactiveCN107160249BImprove airtightnessImprove work efficiencyPlane surface grinding machinesGrinding/polishing safety devicesEngineeringBuilding renovation

Owner:广东中创建设有限公司

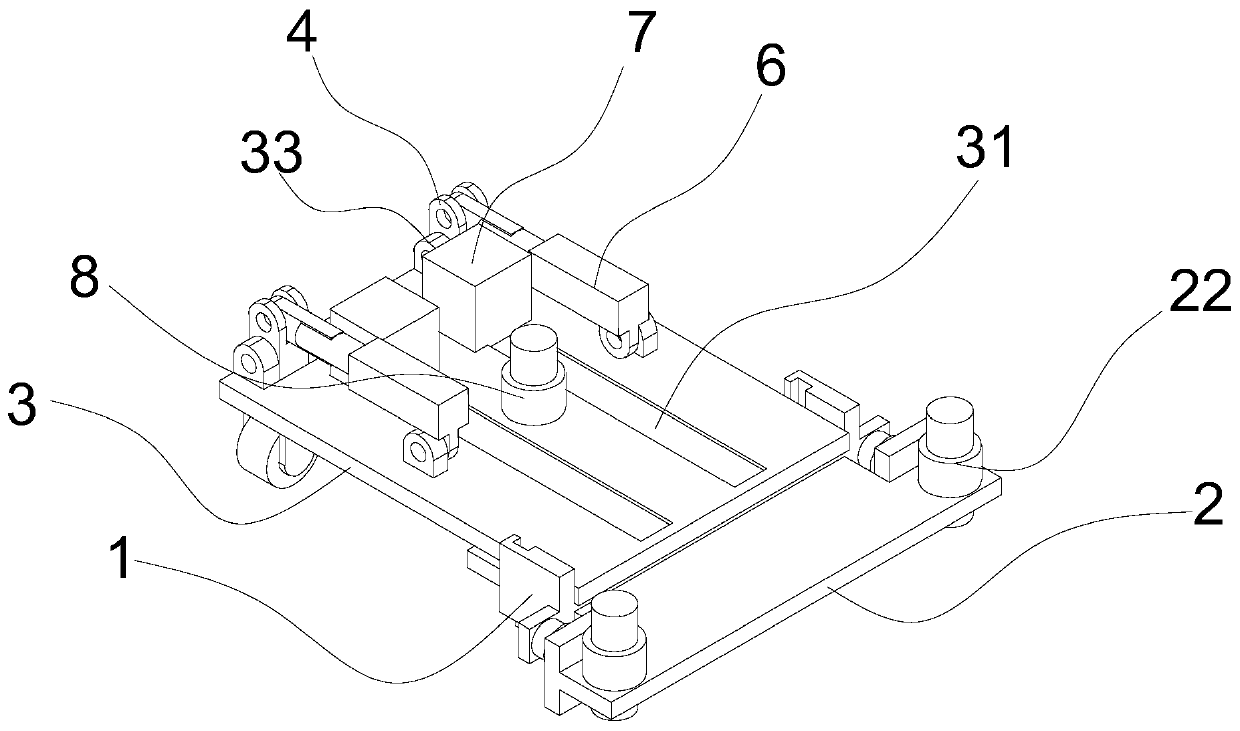

Transfer module and subway pantograph maintenance platform thereof

ActiveCN113927532AConducive to centralized maintenanceReduce dependenceWork holdersWork tools storageGear wheelClassical mechanics

The invention provides a transfer module and a subway pantograph maintenance platform thereof. The transfer module comprises a transfer bottom plate, a transfer track plate is mounted on the transfer bottom plate, and a transfer track is mounted on the transfer track plate; a transfer belt plate is further mounted on the transfer bottom plate, two transfer belt shafts are mounted on the transfer belt plate in a circumferential rotation mode, the two transfer belt shafts are connected through a transfer belt to form a belt transmission mechanism, and a transfer belt protruding block is arranged on the transfer belt and used for being matched with a base conveying block of a conveying base to drive the conveying base to move. One ends of two transfer belt shafts penetrate out of the corresponding transfer belt plates and then are assembled with third transfer gears correspondingly, the transfer belt shafts are further assembled with a linkage frame, a first transfer shaft and a second transfer shaft are mounted on the linkage frame correspondingly, a first transfer gear and a second transfer gear correspondingly sleeve the first transfer shaft and the second transfer shaft, the first transfer gear, the second transfer gear and the third transfer gear are sequentially in meshing transmission, and the second transfer shaft is hinged to one end of a first transfer supporting rod.

Owner:CHONGQING VOCATIONAL INST OF ENG

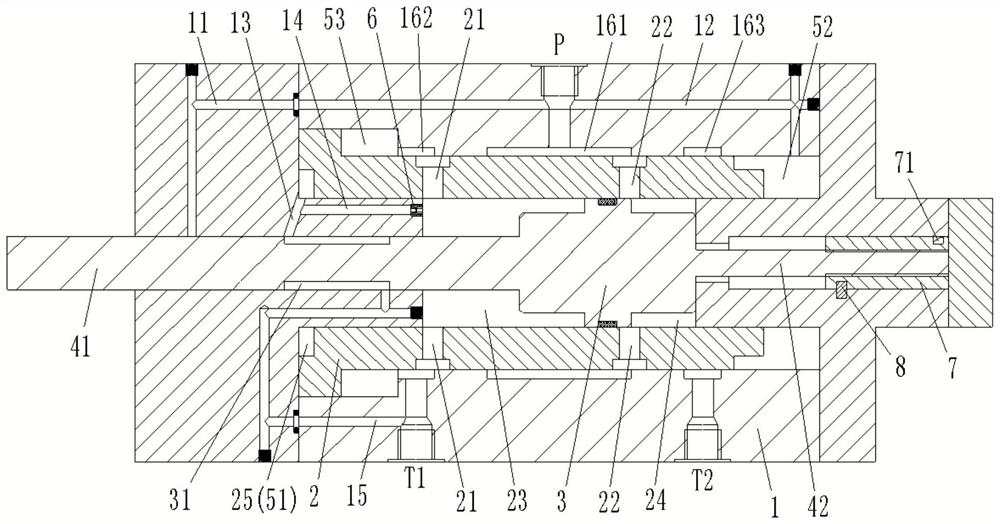

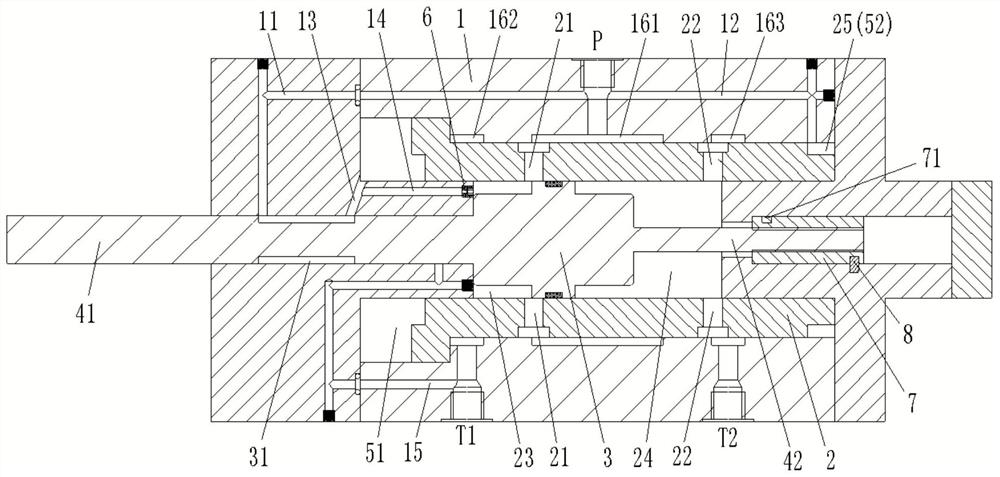

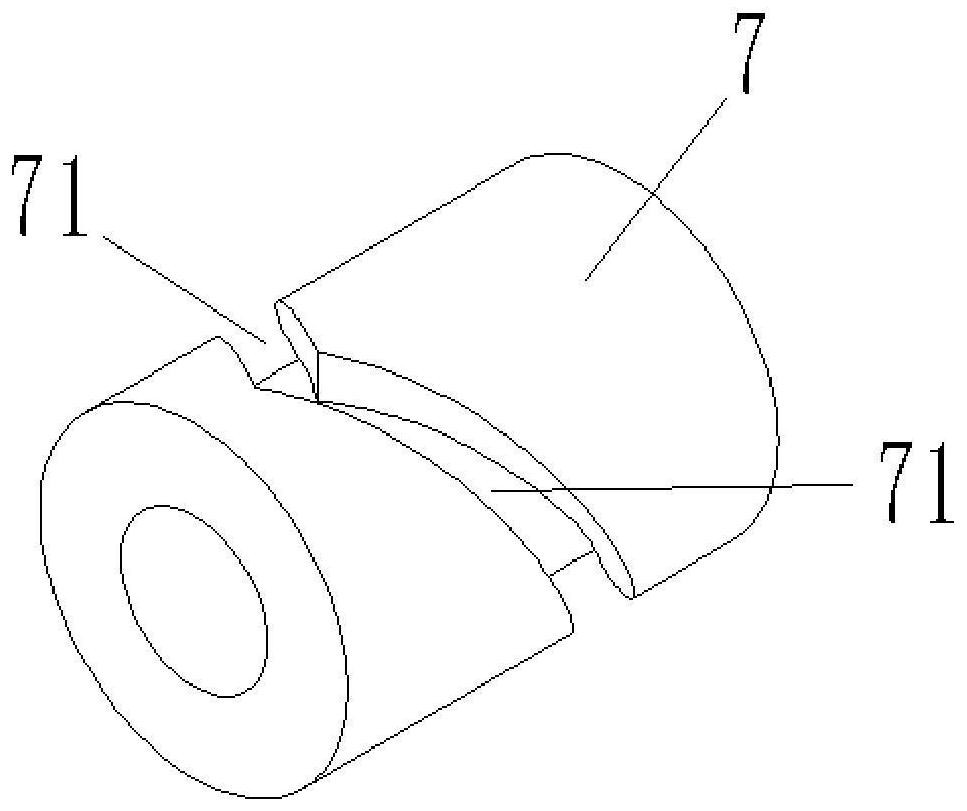

A multi-directional side shaping mold for automobile door lock parts

ActiveCN111760979BKeep returningSecure return tripShaping toolsEjection devicesSolenoid valveNitrogen gas

The invention relates to a multi-directional side shaping mold for automobile door lock parts, which includes an upper and lower mold base, a shaping punch and a guiding slope are arranged on the lower mold base; the shaping punch is fixedly connected with a first nitrogen spring, and the first nitrogen spring is on The sliding of the shaping punch is against the side wall of the groove; the bottom of the lower mold base is provided with a driving cylinder controlled by a solenoid valve that drives the sliding of the shaping punch, and a pressure sensor electrically connected to the solenoid valve of the driving cylinder; The seat is equipped with a side shaping module corresponding to the limit slide of the guide slope, and a driving block is arranged corresponding to the tail of the shaping punch; the side shaping module includes a pressing block, a shaping knife block, a wedge slider, and the wedge slider limit Slidingly arranged on the upper mold base and can form a wedge sliding connection with the guide slope, the binder block is slidably arranged on the wedge slider, and the shaping knife block is fixedly connected to the wedge slider. The invention can automatically drive and align, and realize automatic multi-directional side shaping.

Owner:SHENZHEN EVA PRECISION TECH GRP CO LTD

Medical multifunctional integrated keyboard

PendingCN114489349ARealize automatic driveEasy to clean and disinfectInput/output for user-computer interactionStands/trestlesElectric machineryUSB

The invention discloses a medical multifunctional integrated keyboard which comprises a keyboard body installed on a wall, a strip-shaped through hole for the keyboard body to penetrate through is formed in a panel of the wall, and a storage box with one end communicated with the strip-shaped through hole is arranged on the inner side of the panel; the keyboard main body comprises an upper shell, a bottom plate mounted on the bottom surface of the upper shell, a plurality of video input interfaces and a plurality of USB (Universal Serial Bus) interfaces; at least two guide rails perpendicular to a wall panel are arranged in the storage box at intervals, the fixing plate is arranged on the guide rails in a sleeving mode and can move in a reciprocating mode along the guide rails, a through type stepping motor is installed on the fixing plate in a penetrating mode, and one end of a lead screw on the through type stepping motor is connected with the storage box. The keyboard has a waterproof function and can be wiped and disinfected, automatic driving of contraction movement of the keyboard body is achieved, the keyboard body can be stored on the inner side of a wall panel when not used, and the situation that the keyboard body is subjected to dust collection and dust deposition and becomes a pollution source is avoided.

Owner:SINODEU MEDICAL CO LTD

Novel cable winder

The invention discloses a novel cable winder which comprises an oil pressure lifting device and a winding mechanism arranged at the top of the oil pressure lifting device; a storage groove is formed in the right side surface of the winding mechanism; the storage groove is connected with a closing sleeve in a sliding connection fit manner; a winding cavity is formed in the closing sleeve; a transfer cavity is formed in the part, on the left side of the storage groove, of the winding mechanism; a first separator is arranged between the transfer cavity and the storage groove; a driving cavity isformed in the part, on the left side of the transfer cavity, of the winding mechanism; a second separator is arranged between the driving cavity and the transfer cavity; a first sliding connection groove is formed in the bottom in the transfer cavity; the interior of the first separator is connected with a connecting rod extending towards the left side and the right side in a sliding connection fit manner; the right side extension section of the connecting rod stretches into the storage groove, penetrates through the closing sleeve and extends into the winding cavity; a push board is fixedly arranged at the right side extension end of the connecting rod of the connecting rod; and a first hole way extending leftwards and rightwards is formed in the connecting rod. The novel cable winder issimple in structure and reasonable in design, an occupied space can be reduced, and the manufacturing and maintenance cost is low.

Owner:晋江市启清电子科技有限公司

Transfer equipment for glass plate processing and working method thereof

InactiveCN111960108AImprove transport efficiencyPlay the role of steeringCharge manipulationConveyor partsDrive wheelEngineering

The invention discloses transfer equipment for glass plate processing. A drive wheel assembly and a steering assembly are installed on a transfer equipment base. The drive wheel assembly is used to drive the transfer equipment base to move. The steering assembly is used to steer the movement of the transfer equipment base. A drive case is fixedly installed on the transfer equipment base. The drivecase covers above the drive wheel assembly and the steering assembly. The equipment is driven to move by the drive wheel assembly, the drive wheel assembly plays a driving role in movement of the equipment, and automatic driving without manual push can be realized. During the movement of the equipment, the steering assembly of the equipment is used to automatically control the steering of the equipment to improve the transfer efficiency of a glass plate. An electric telescopic rod is arranged to drive a pressure plate to move up and down to effectively and stably store the glass plate, and itis ensured that the glass plate cannot be damaged due to shaking during storage and transfer.

Owner:安徽艺云玻璃有限公司

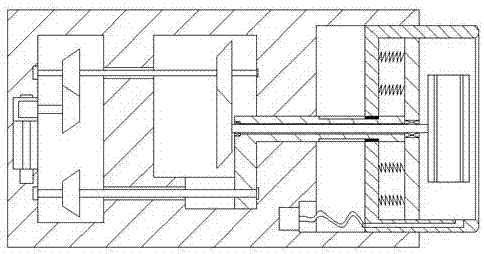

A hydraulic impact drill power device

ActiveCN110984843BRealize shock movementRealize automatic driveReciprocating drilling machinesConstructionsGear wheelCylinder head

Owner:东台市高科技术创业园有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com