Textile cloth winding device with automatic adjusting function

An automatic adjustment and functional technology, applied in the direction of winding strips, transportation and packaging, thin material handling, etc., can solve the problems of affecting the efficiency of rolling cloth, affecting work efficiency, power consumption, etc., to improve the stability of rolling cloth, improve Work efficiency, improve the effect of mobile stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

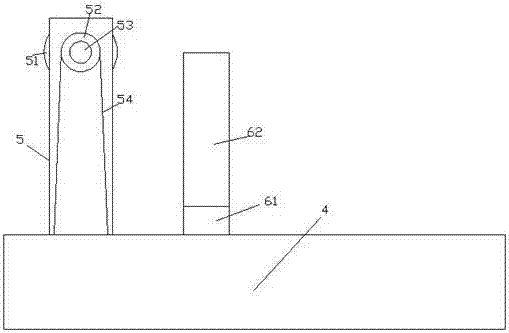

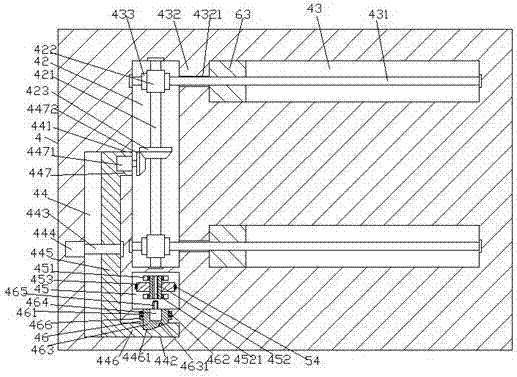

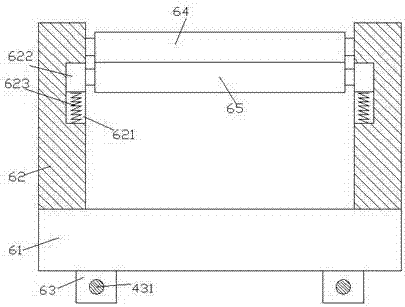

[0022] like Figure 1-Figure 5 As shown, a textile rolling device with automatic adjustment function of the present invention includes a base 4 and a cloth rolling frame 5 fixed on the top end surface of the left side of the base 4, and the left side of the base 4 is provided with front and rear extensions The first cavity 42, the base 4 on the right side of the first cavity 42 is provided with guide grooves 43 that are vertically symmetrical and extend left and right, and the left end of each guide groove 43 is connected to the first A partition 432 is provided between the right ends of the cavity 42, each of the partitions 432 is provided with a through hole 4321, and each of the through holes 4321 is provided with transition fittings extending to the left and right sides. The first threaded rod 431, the left end of the first threaded rod 431 protrudes into the first cavity 42 and is connected with the left inner wall of the first cavity 42 in rotation, the first threaded ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com