Cable winder

A wire winding device and cable technology, applied in the field of electric power, can solve the problems of not being suitable for small-sized cable winding, unfavorable to the health of workers, and the volume of the wire winding device is large, and achieves the effects of simple structure, reduced equipment investment, and reduced cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

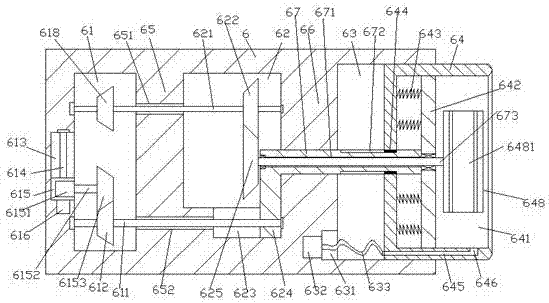

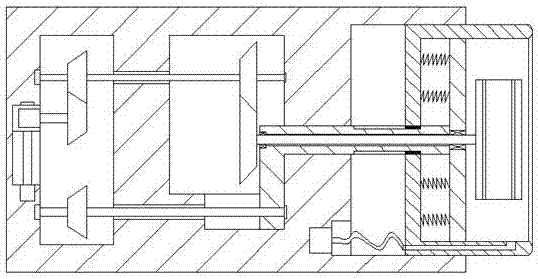

[0021] Such as Figure 1-Figure 5 As shown, a cable winder of the present invention includes a hydraulic lifting device 5 and a winding mechanism 6 arranged on the top of the hydraulic lifting device 5, and a storage tank is provided inside the right side of the winding mechanism 6 63, the storage tank 63 is slidably connected with a closing sleeve 64, the inside of the closing sleeve 64 is provided with a winding cavity 641, and the inside of the winding mechanism 6 on the left side of the storage tank 63 is provided with a transfer cavity 62, A first partition 66 is provided between the transfer cavity 62 and the storage tank 63, and a drive cavity 61 is provided inside the winding mechanism 6 on the left side of the transfer cavity 62, and the drive cavity 61 is connected to the storage tank 63. A second partition 65 is provided between the transfer chambers 62, and the inner bottom of the transfer chamber 62 is provided with a first sliding groove 623, and the first partit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com