Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

95results about How to "Packing speed is fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

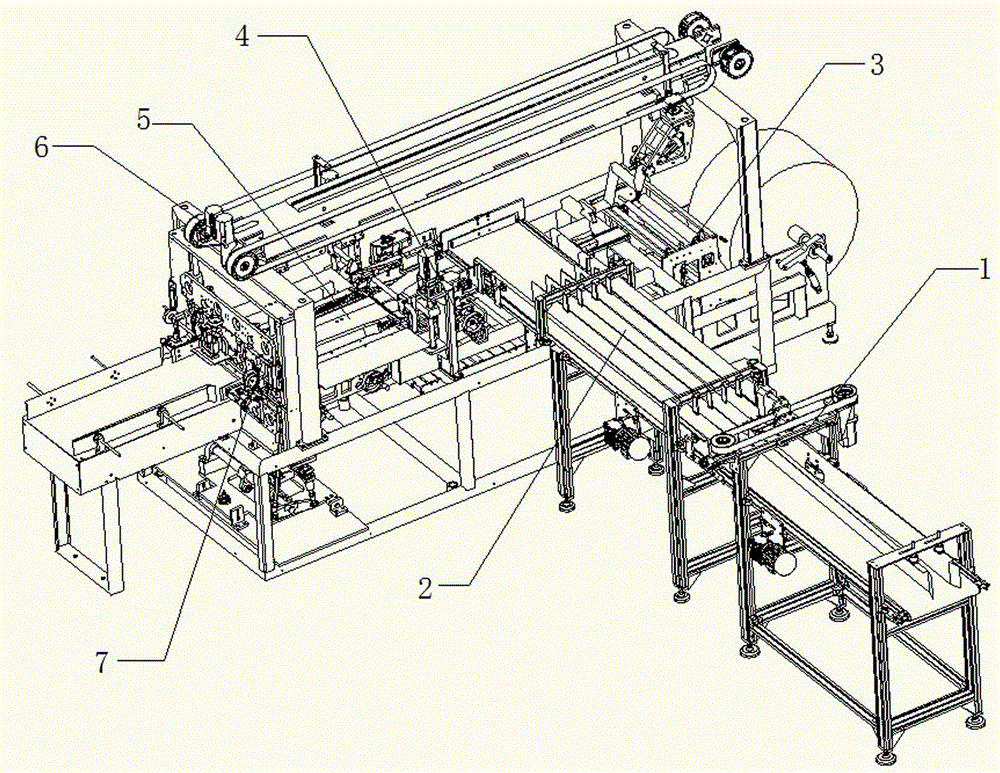

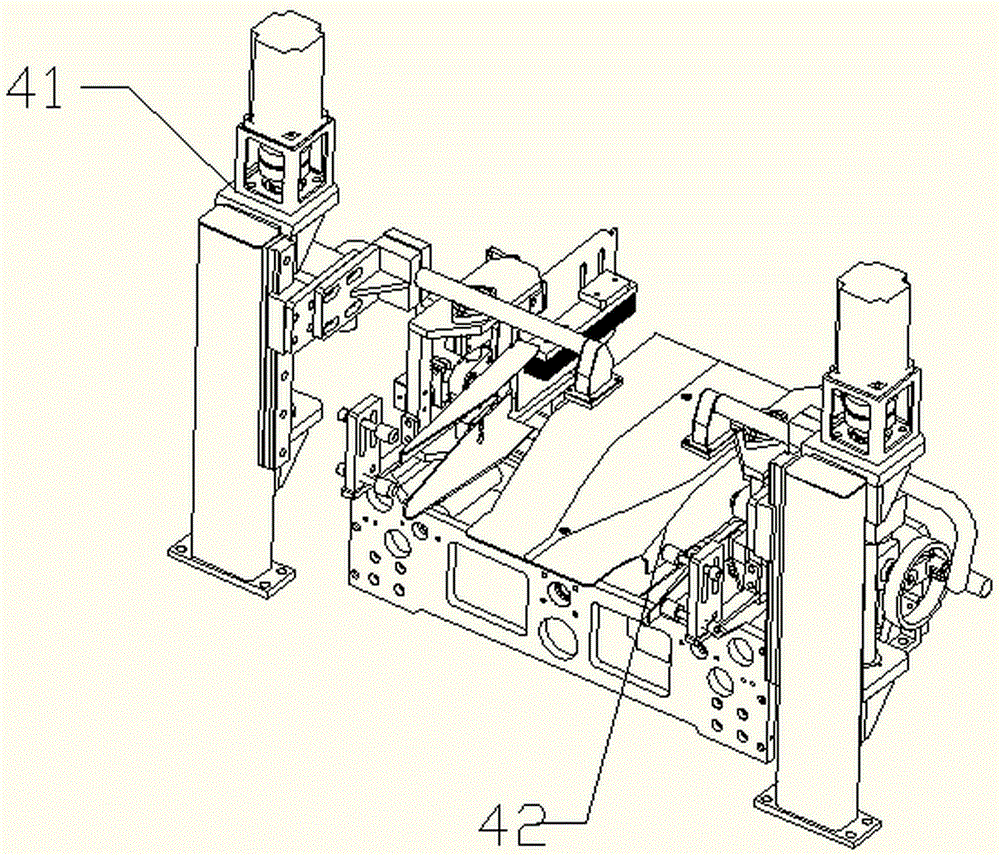

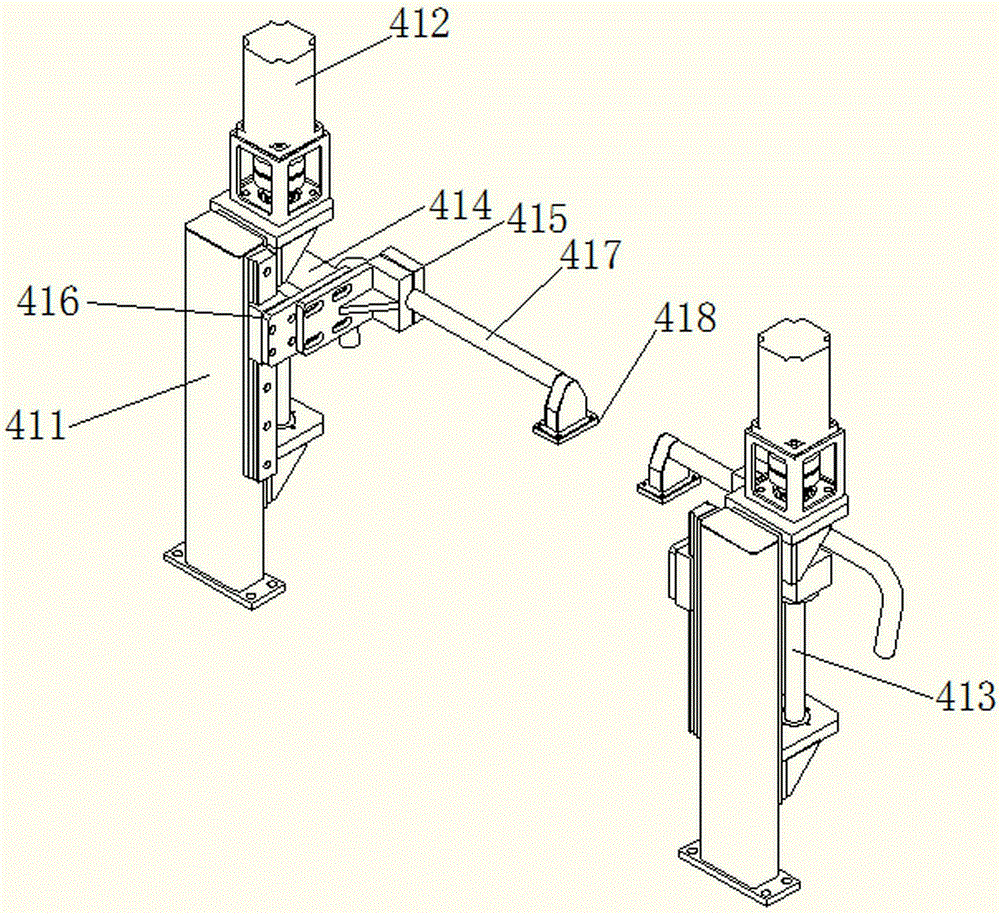

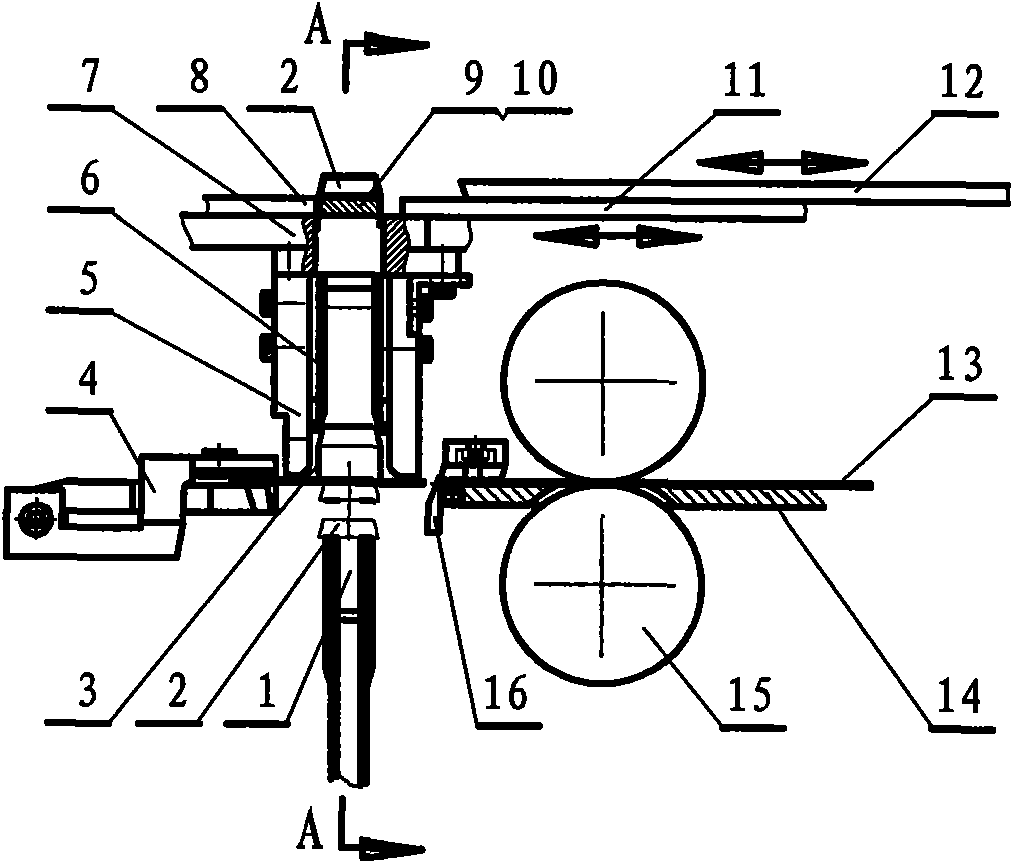

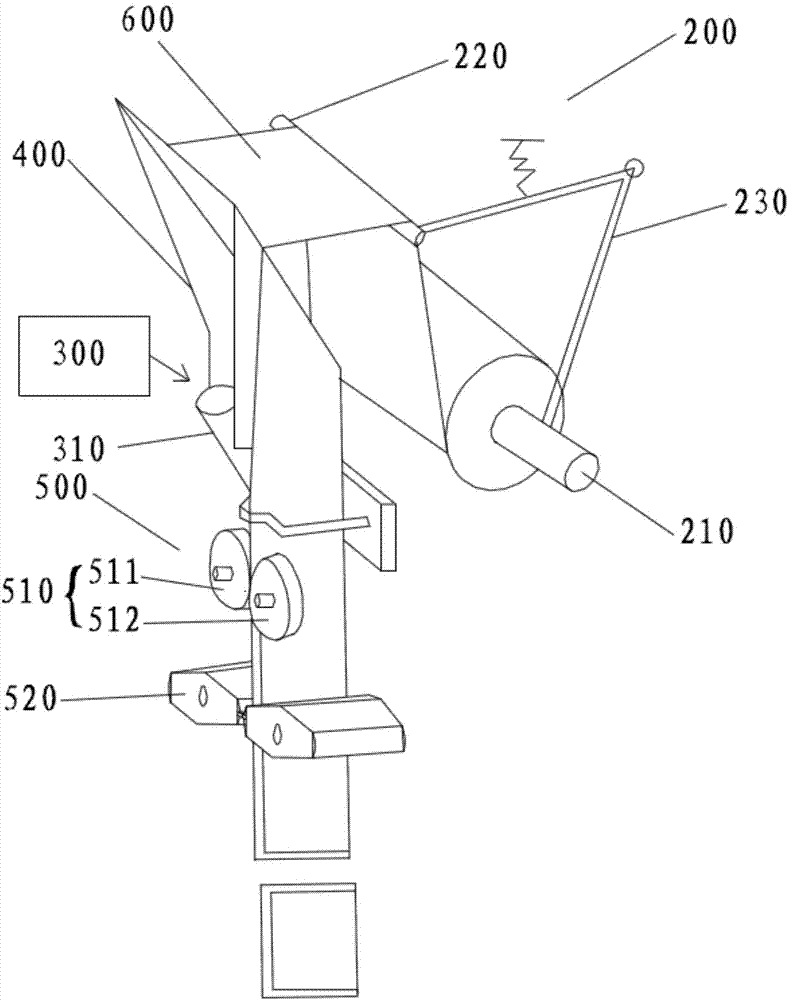

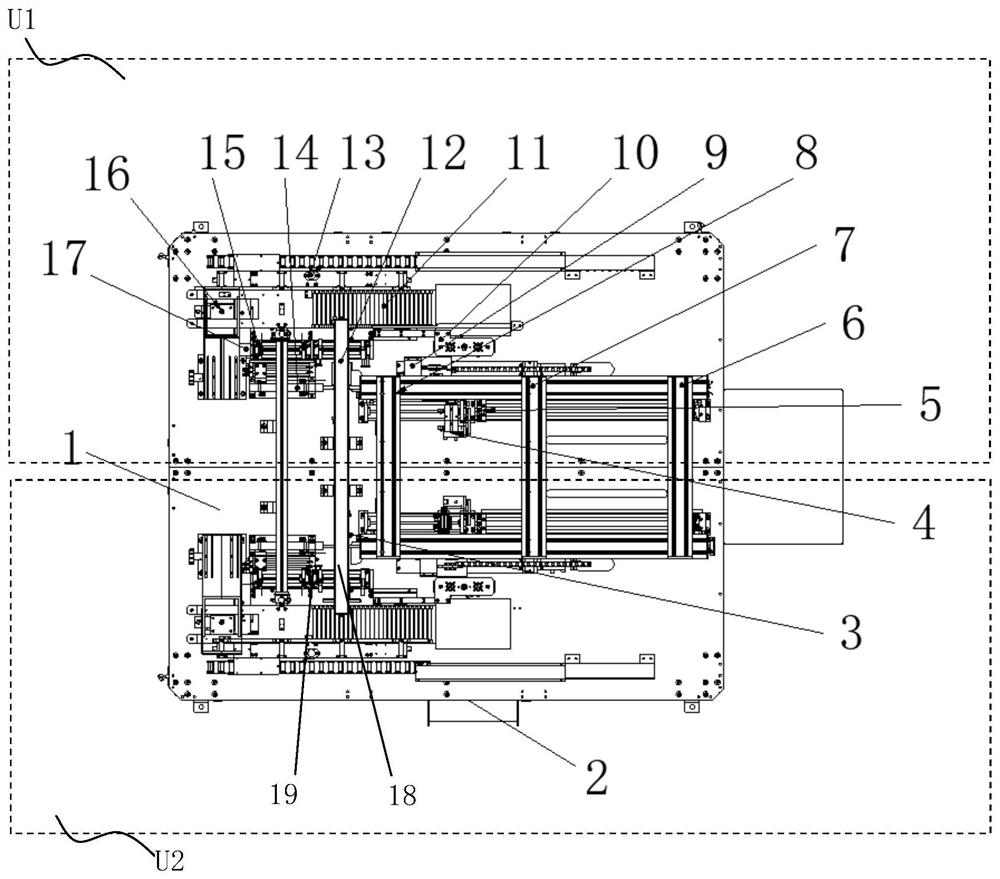

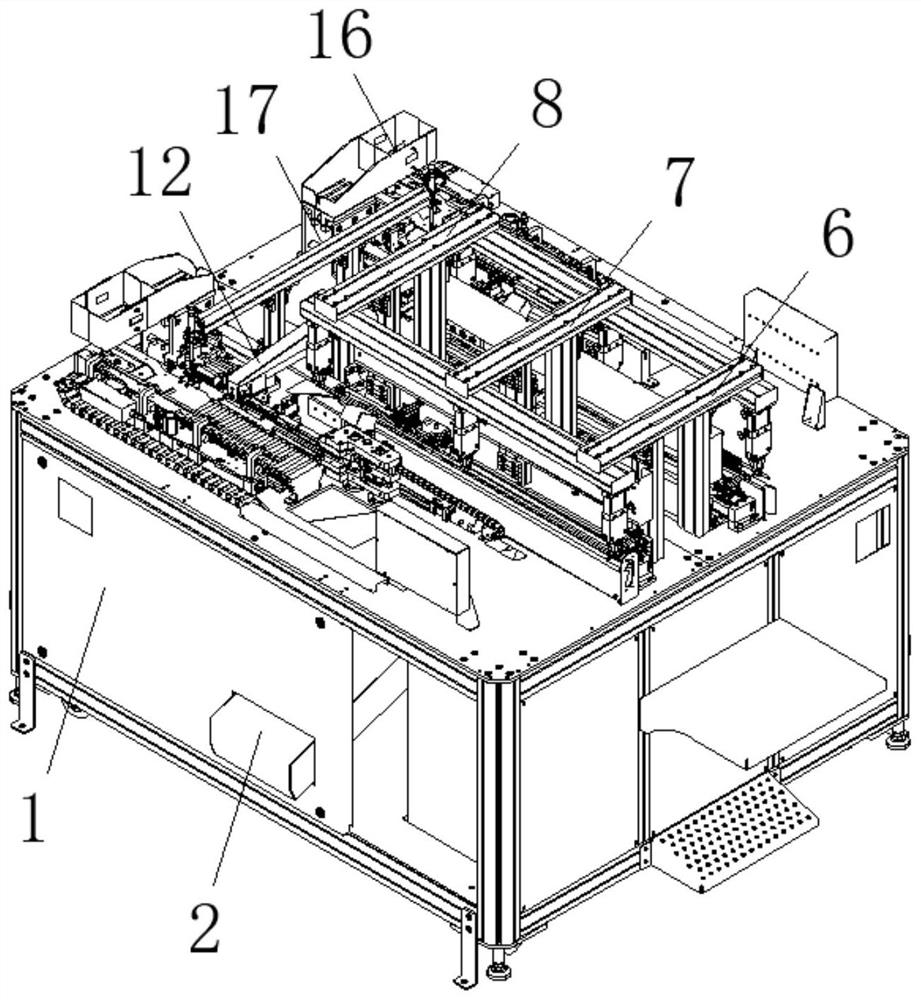

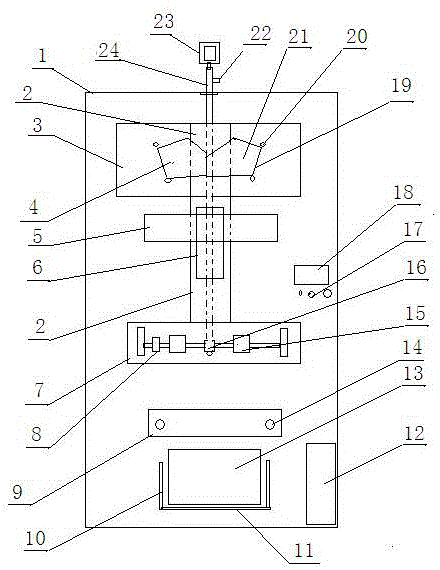

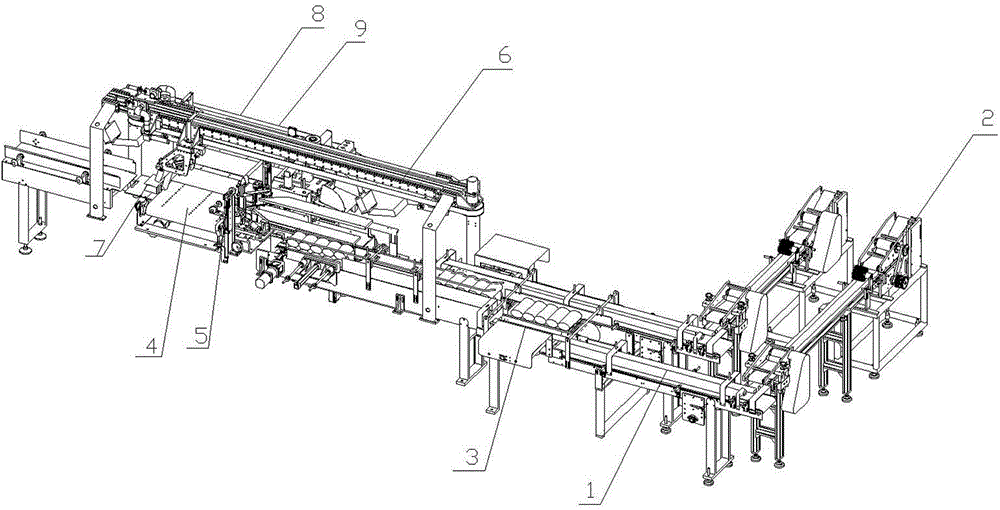

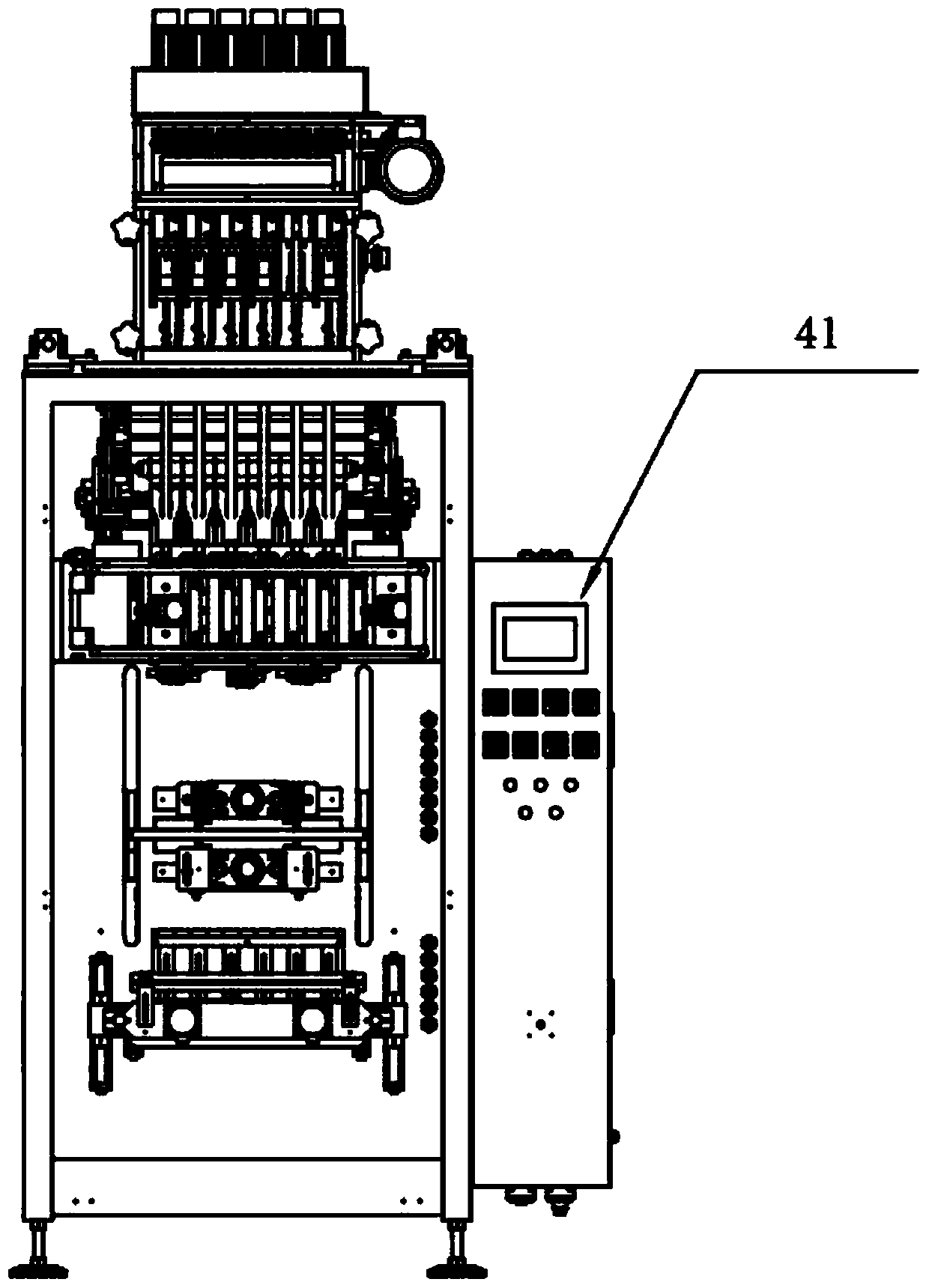

Soft tissue packing machine

ActiveCN103950590AGuaranteed uniformityReduce labor costsPaper article packagingWrapping material feeding apparatusEngineeringSoft tissue

The invention discloses a soft tissue packing machine, and relates to the technical field of tissue packing machinery. The soft tissue packing machine comprises a path division conveying component, a material sorting conveying component, a membrane supporting and conveying component, a bag opening and strutting component, a negative pressure conveying component, a bag pushing component and a cutter seal component. The soft tissue packing machine disclosed by the invention has the advantages that the bag opening and strutting component, a membrane conveying mechanism and a membrane conveying mechanism are improved, according to the soft tissue packing machine, the bag opening size of packing bags can be regulated, the soft tissue packing machine is suitable for the package of products in any specifications, the soft tissue packing machine adopts integral operation, the efficiency is improved, the cost is reduced, and the packing quality can also be unified.

Owner:上海松川峰冠包装自动化有限公司

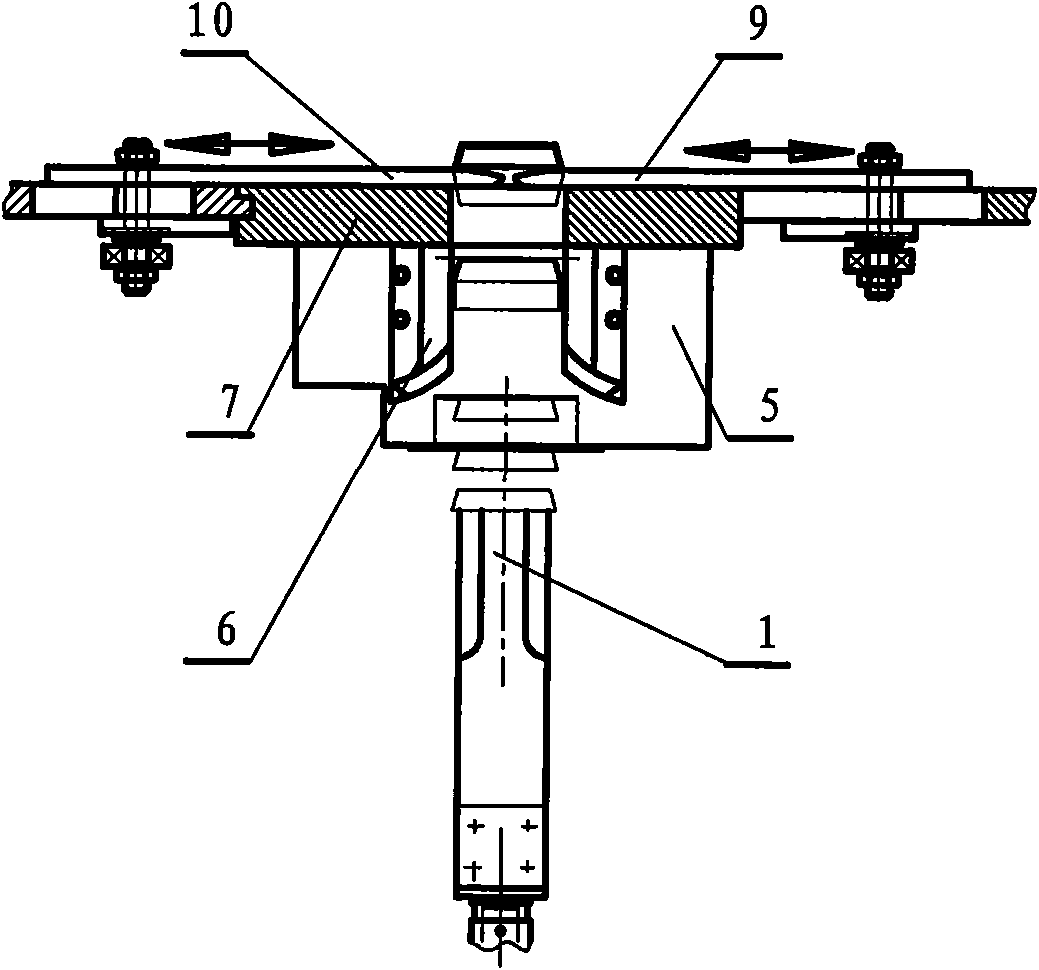

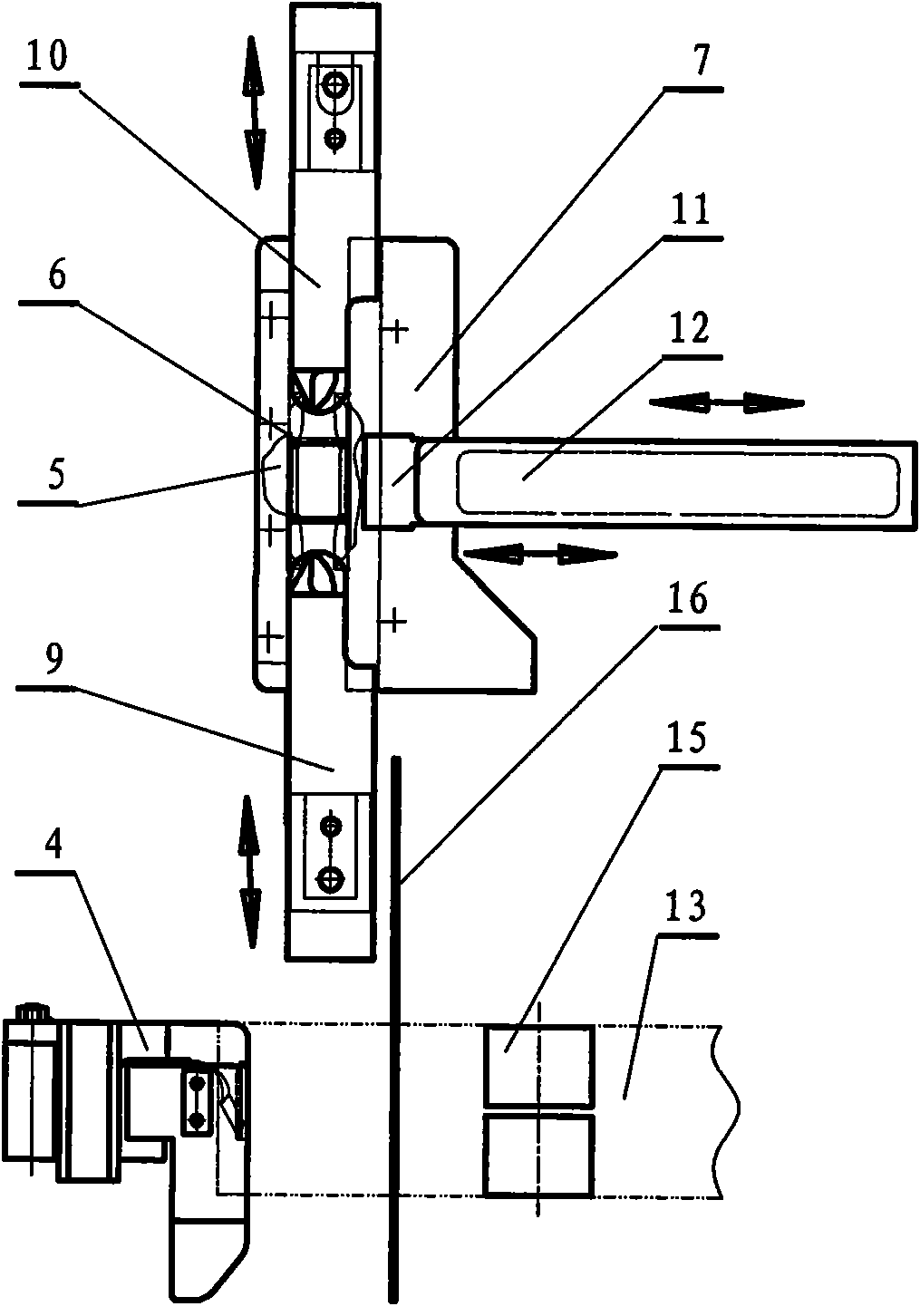

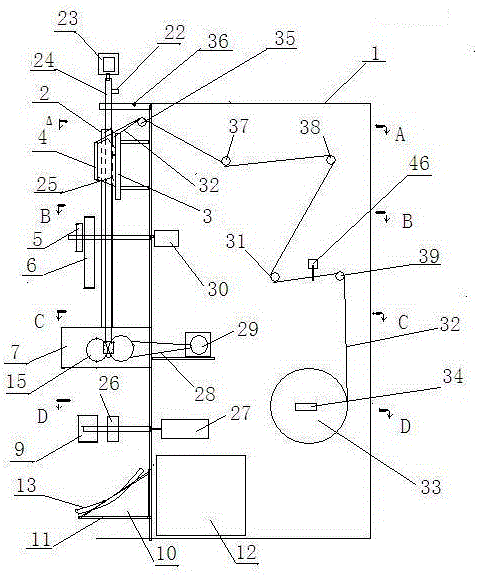

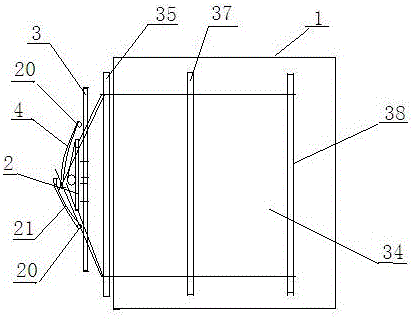

Candy bar folding packing machine

InactiveCN101559842APacking speed is fastIncrease productivityWrapping material feeding apparatusConveyor wrappingFuselage

The invention discloses a candy bar folding packing machine which comprises a machine body, a paper-feeding roller and a paper-clamping clip. The paper-feeding roller and the paper-clamping clip are arranged on the machine body and correspond to each other; the machine body is also provided with a pair of folding box side plates arranged in parallel, the top surfaces of the two folding box side plates are fixedly connected with a folding box top plate, and two packing paper edge folding guide strips are fixedly mounted on the inner side surface of either folding box side plate; a left folding edge rod and a right folding edge rod with left-and-right reciprocating sliding capabilities are arranged on the top of the folding box top plate in opposite directions; the top of the folding box top plate is also provided with a fixedly mounted discharge baffle and a front folding edge rod with the fore-and-aft reciprocating sliding capability, and a rear folding edge rod with the fore-and-aft reciprocating sliding capability is stacked on the front folding edge rod; and feeding claws with the up-and-down reciprocating sliding capability are respectively arranged at the lower parts of the folding box side plates. The packing machine not only realizes the regular hexahedral package of candies, but also has reasonable structure and high production efficiency.

Owner:江苏海特尔机械有限公司

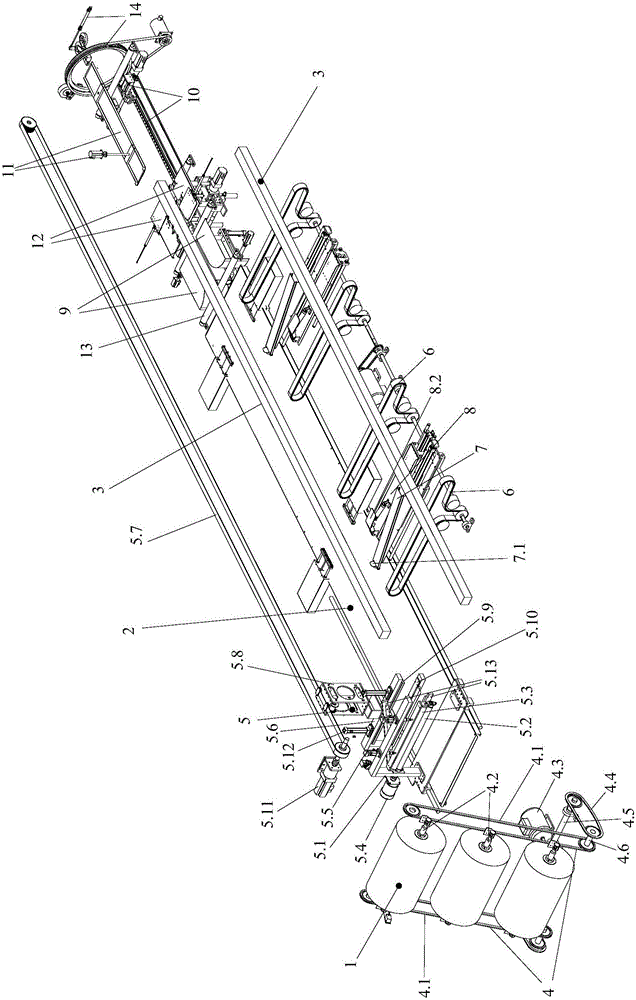

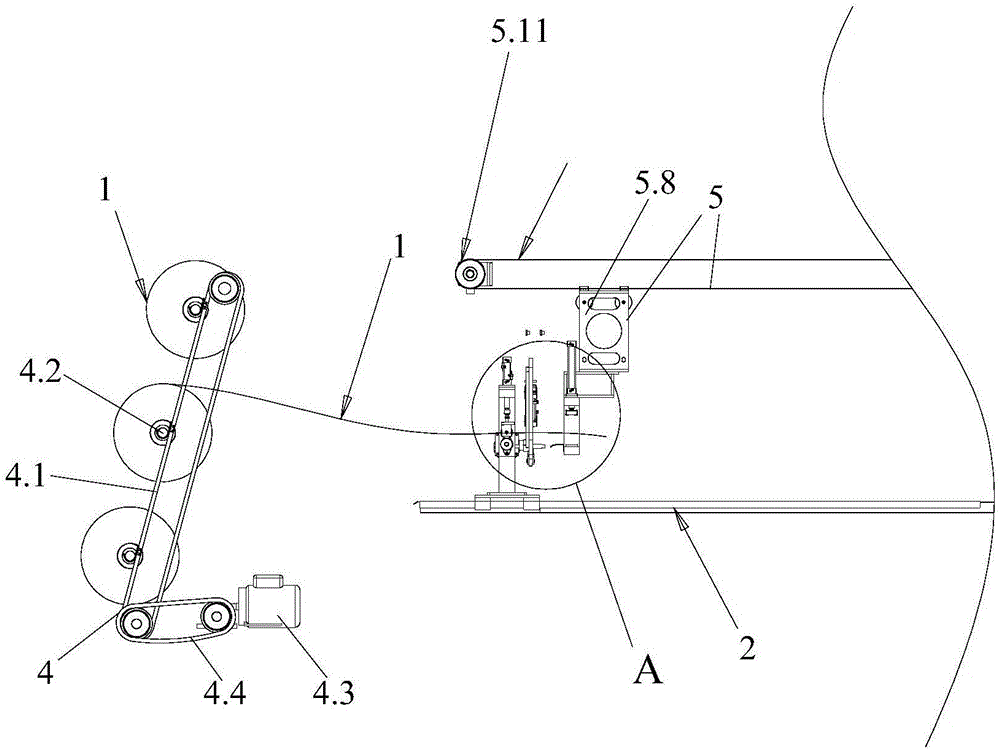

Section bar automatic packaging equipment

ActiveCN106218968AIncrease productivitySolve the low degree of automationWrapper folding/bending apparatusWrappingReciprocating motionUltimate tensile strength

The invention provides section bar automatic packaging equipment. The section bar automatic packaging equipment comprises a packaging paper feeding mechanism, a section feeding mechanism, a vertical folding mechanism, horizontal folding mechanisms, a packaging mechanism, a clamping and feeding mechanism, a pushing mechanism and a control mechanism, wherein the packaging paper feeding mechanism is used for lifting, pulling out and shearing and paving packaging paper on a platform; the section feeding mechanism is used for transferring and locating a section bar in the middle part of the platform where the packaging paper is paved; the vertical folding mechanism is used for adjusting the side edge separation distance of the packaging paper and bending the side edge of the packaging paper paved on the platform; the horizontal folding mechanisms are used for adjusting the side edge separation distance of the packaging paper and bending the side edge of the packaging paper paved on the platform and then horizontally folding the upper part of the side edge of the packaging paper, so that the packaging paper wrap the end surface of the section bar; the packaging mechanism is used for winding and sealing the packaging paper which wraps the section bar; the clamping and feeding mechanism is used for a reciprocating motion to transfer the section bar wrapped by the packaging paper to the packaging mechanism; and the pushing mechanism is used for compacting the opening of the packaging paper which wraps the end surface of the section bar. The section bar automatic packaging equipment provided by the invention can solve the problems that the efficiency is low and the labor intensity is great due to a manual operation, so that the packaging efficiency and quality of the section bar are improved.

Owner:佛山市嘉荣智能机械有限公司

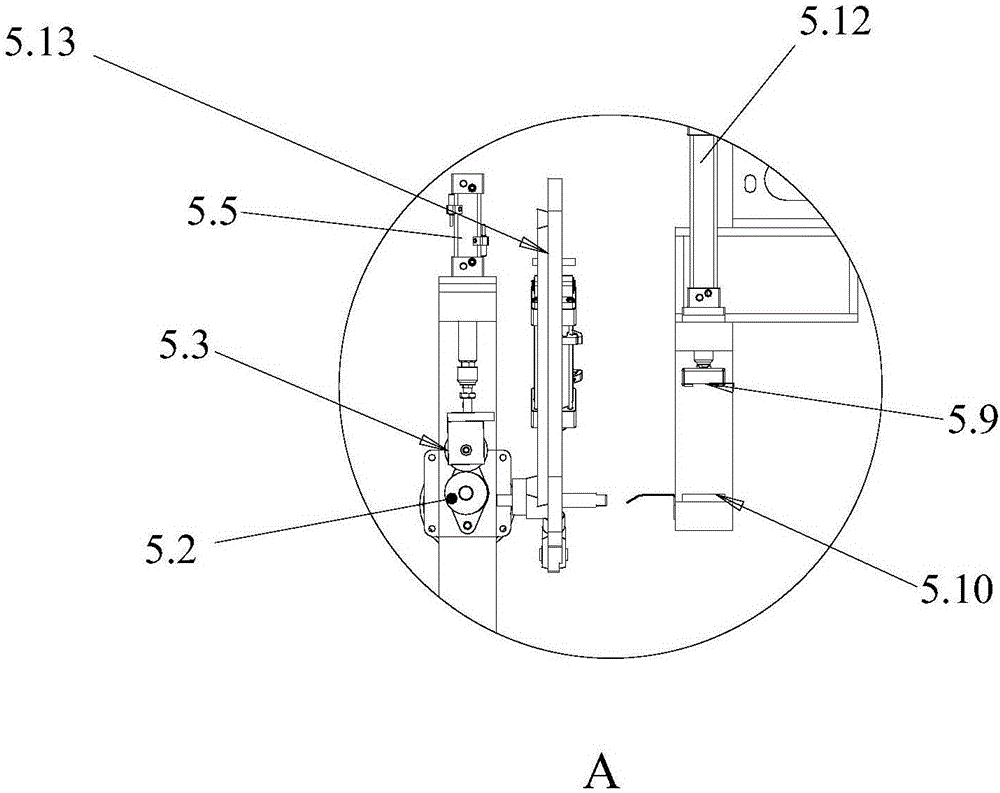

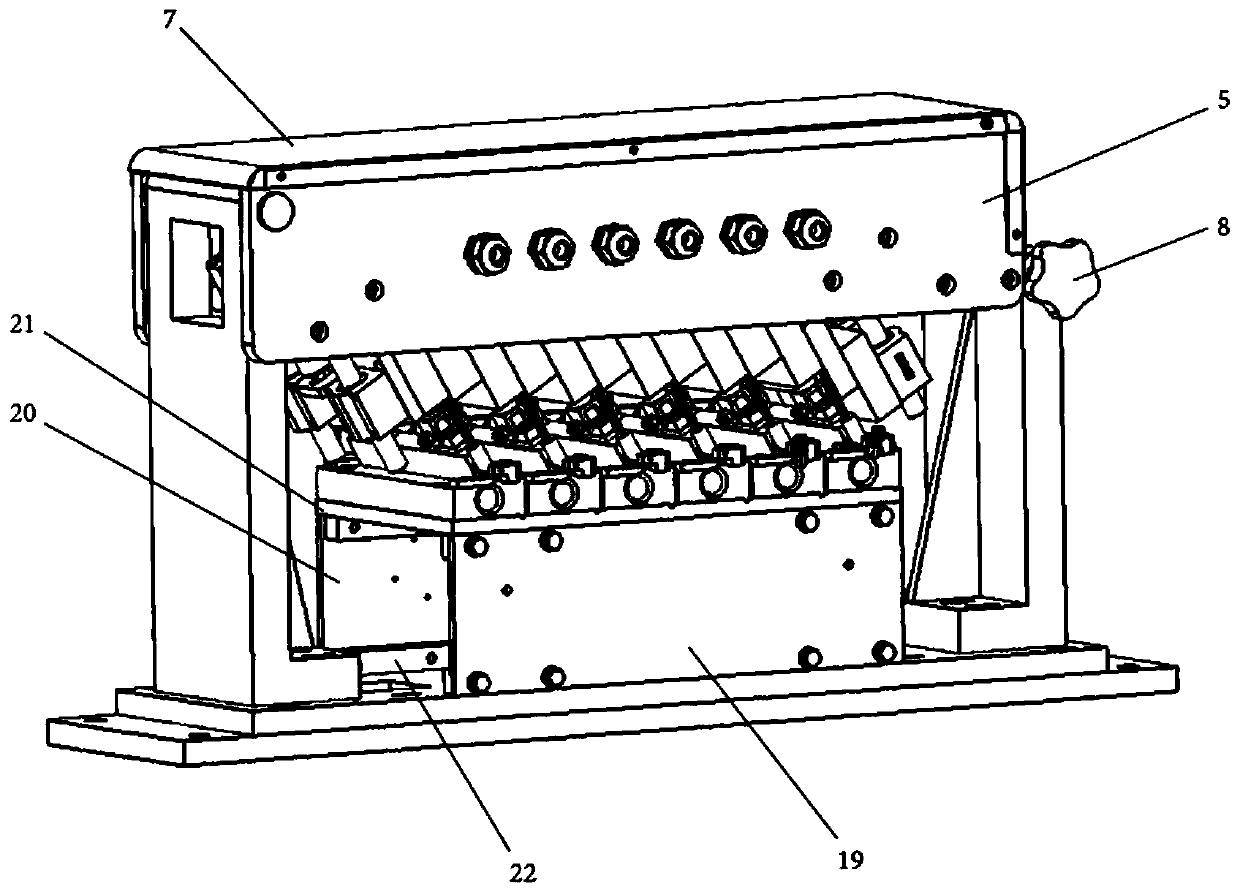

Apparatus for detecting of dropping tablets in automatic medicine packaging machine

ActiveUS7438201B2Packing speed is fastSimple structureRacksDispensing apparatusWindow shutterEngineering

An apparatus for precisely, detecting a tablet dropped in a last hopper so that packaging speed of tablets is increased and operation of a shutter and a sealer is precisely performed, is disclosed. The automatic medicine packaging machine includes a last hopper provided at the lower end of a hopper installed in a main frame, a shutter installed in the last hopper, and a shutter driving part for driving the shutter to open and close the last hopper, and the apparatus includes a dropping tablet detector installed in the last hopper to detect when the tablet is dropped into the last hopper and to input the detected information about the dropping tablet to the controller such that the moment when the shutter is opened is optimized.

Owner:JVM CO LTD

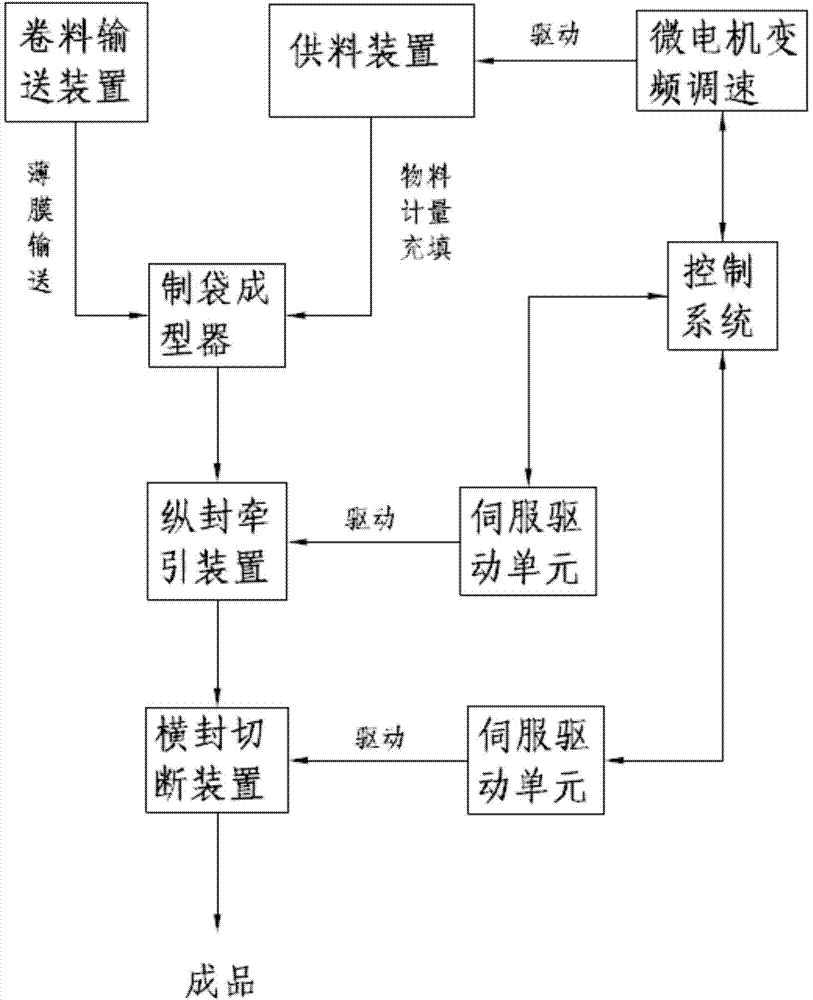

Particle material packaging machine

ActiveCN104760717AOvercome defectsImprove reliabilityWrapper twisting/gatheringPackaging automatic controlLap jointEngineering

The invention discloses a particle material packaging machine which comprises a vertical machine frame, a rolled material conveying device, a material supply device, a bag-making forming device and an opening sealing device. The opening sealing device comprises a longitudinal traction device and a transverse-sealing cutting-off device. The longitudinal traction device is arranged above the transverse-sealing cutting-off device. The particle material packaging machine is of a vertical structure, all parts are ingenuously arranged, specific part improvement is performed, and the structure is greatly simplified, required occupied area is decreased. In addition, the reliability, packaging speed and finished product rate of the machine can be further effectively improved, operation is also simple and convenient, particle materials can be effectively, quickly and accurately packaged into pillow-shaped longitudinally-sealed lap joint bag products. A traction device is not needed to be independently arranged, the sealing demand is met through the original transverse-sealing cutting-off device, and meanwhile the demand that packaging films are sheared and cut off from the sealing positions and accordingly a shearing device is omitted is further met.

Owner:悦熙堂(山东)生物科技有限公司

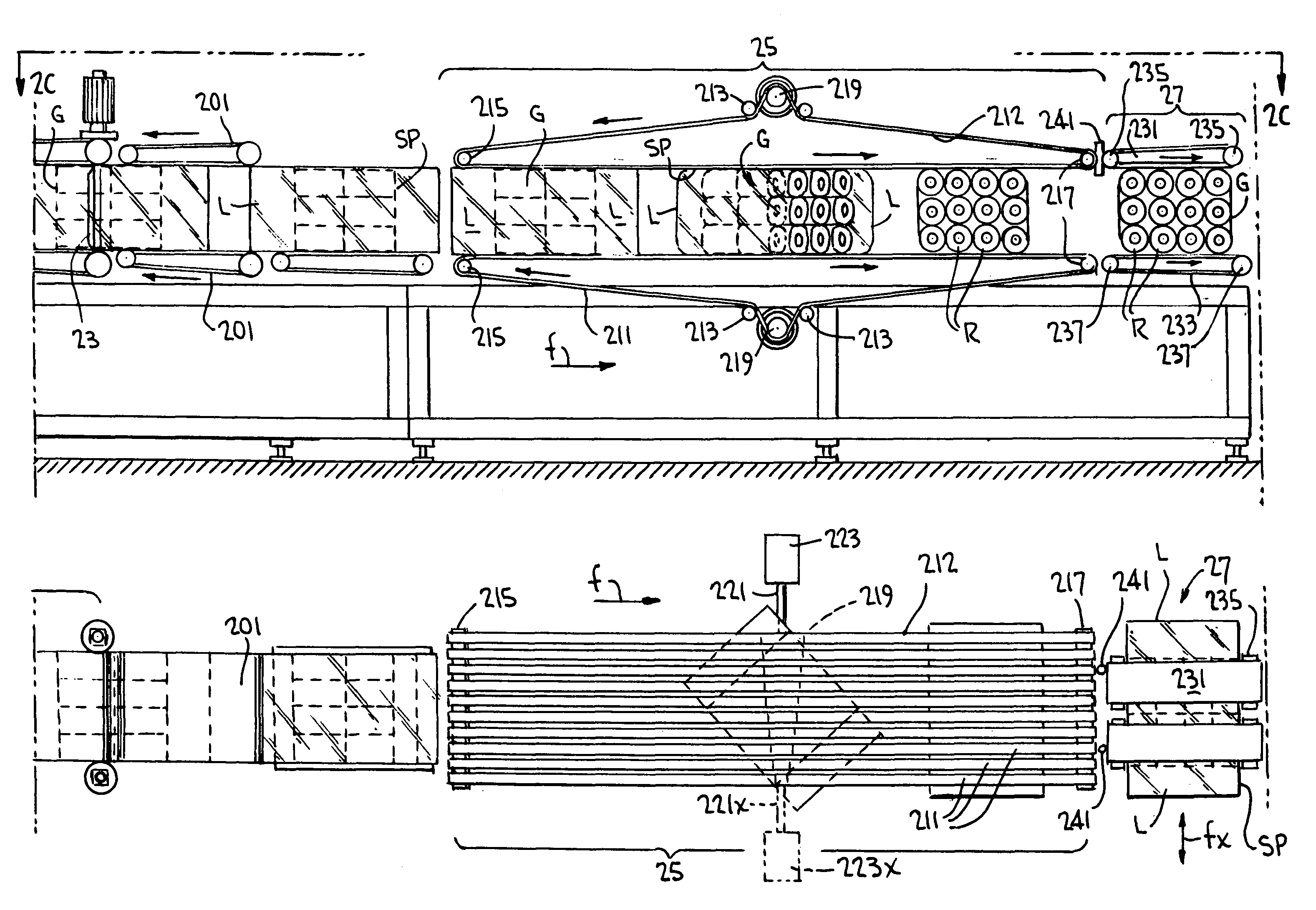

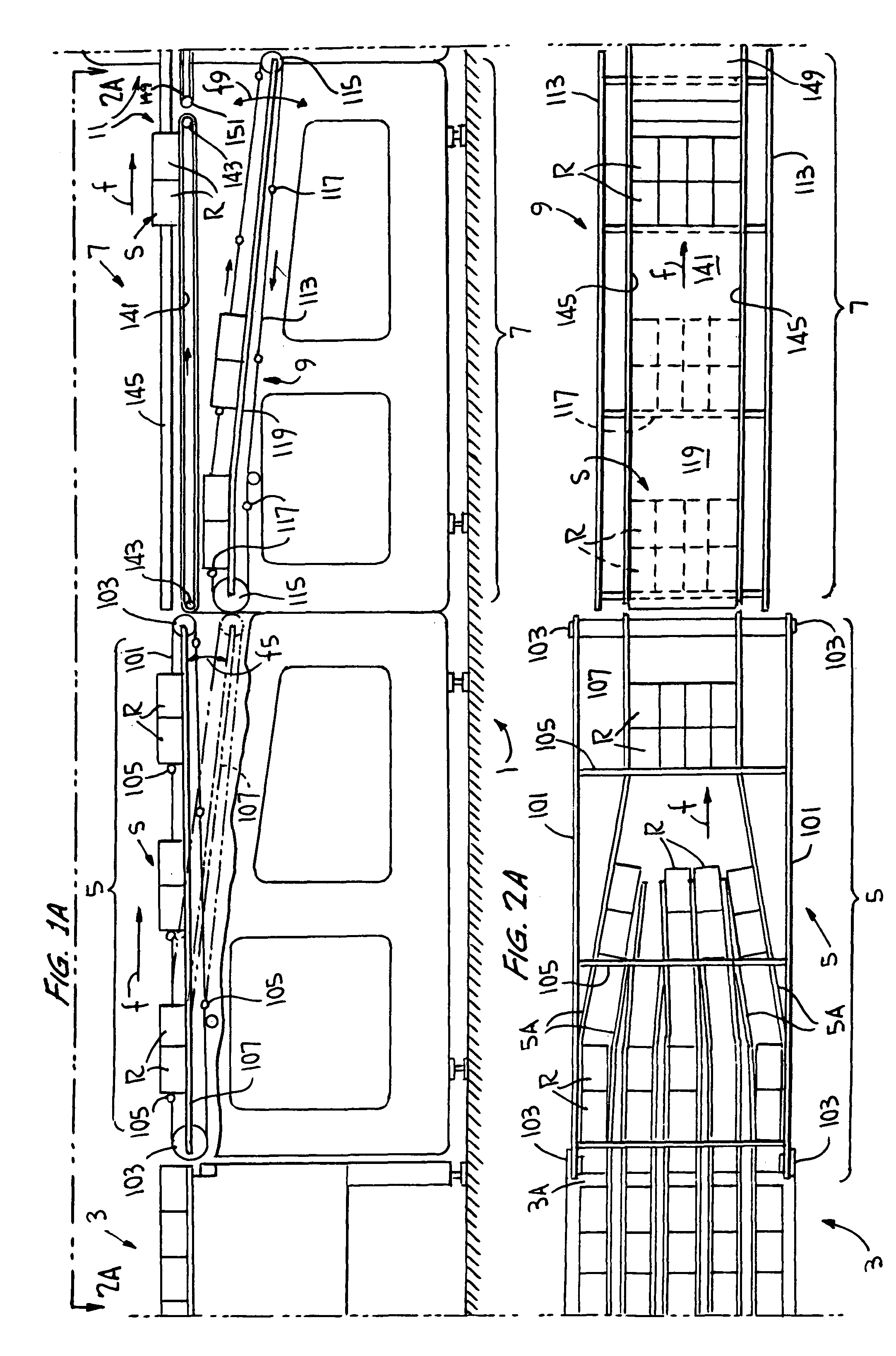

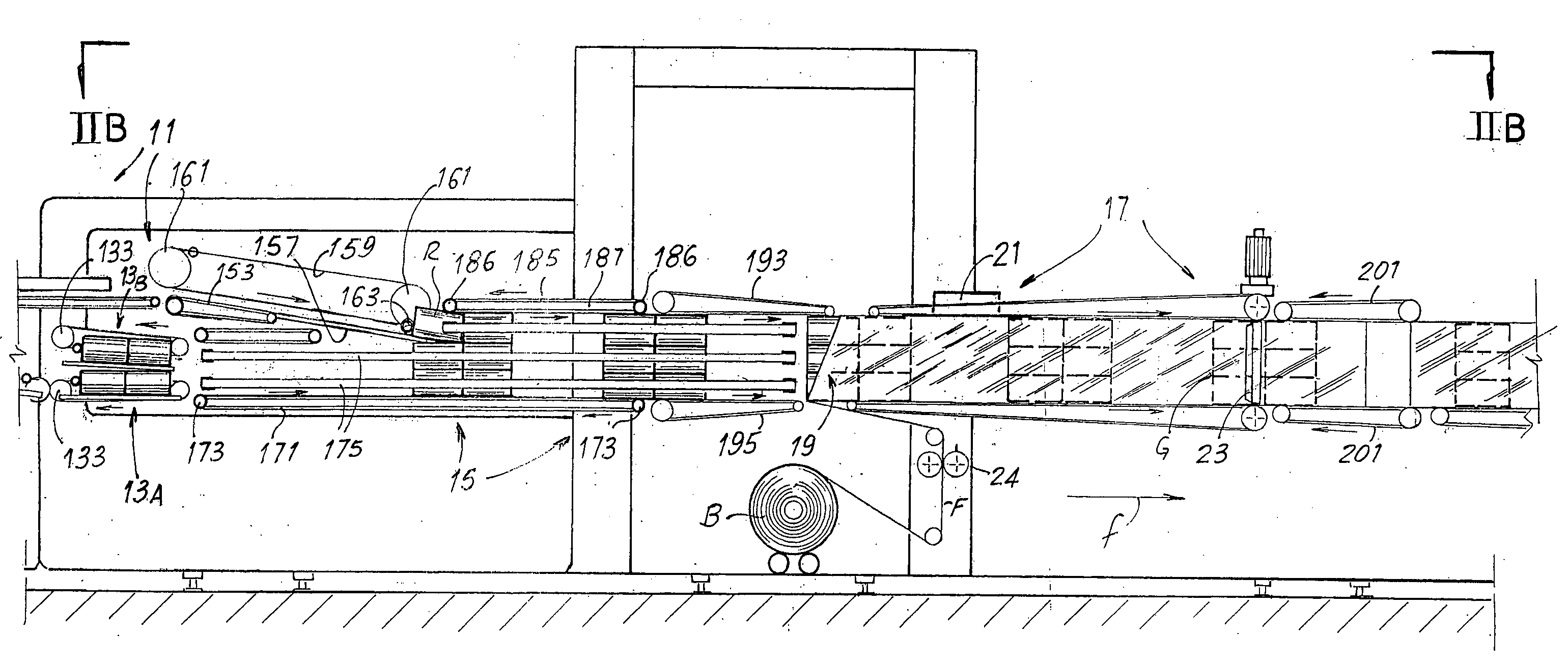

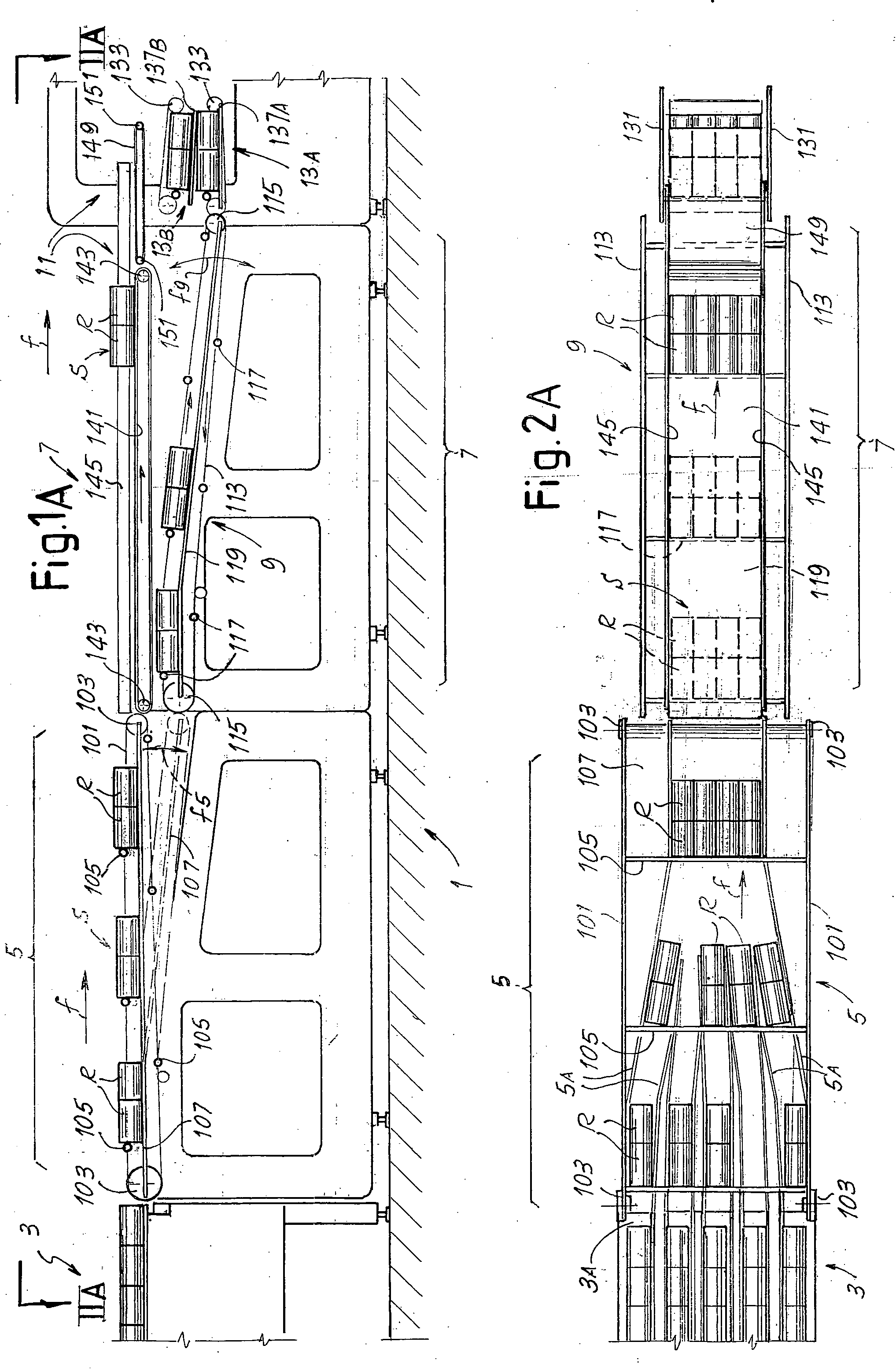

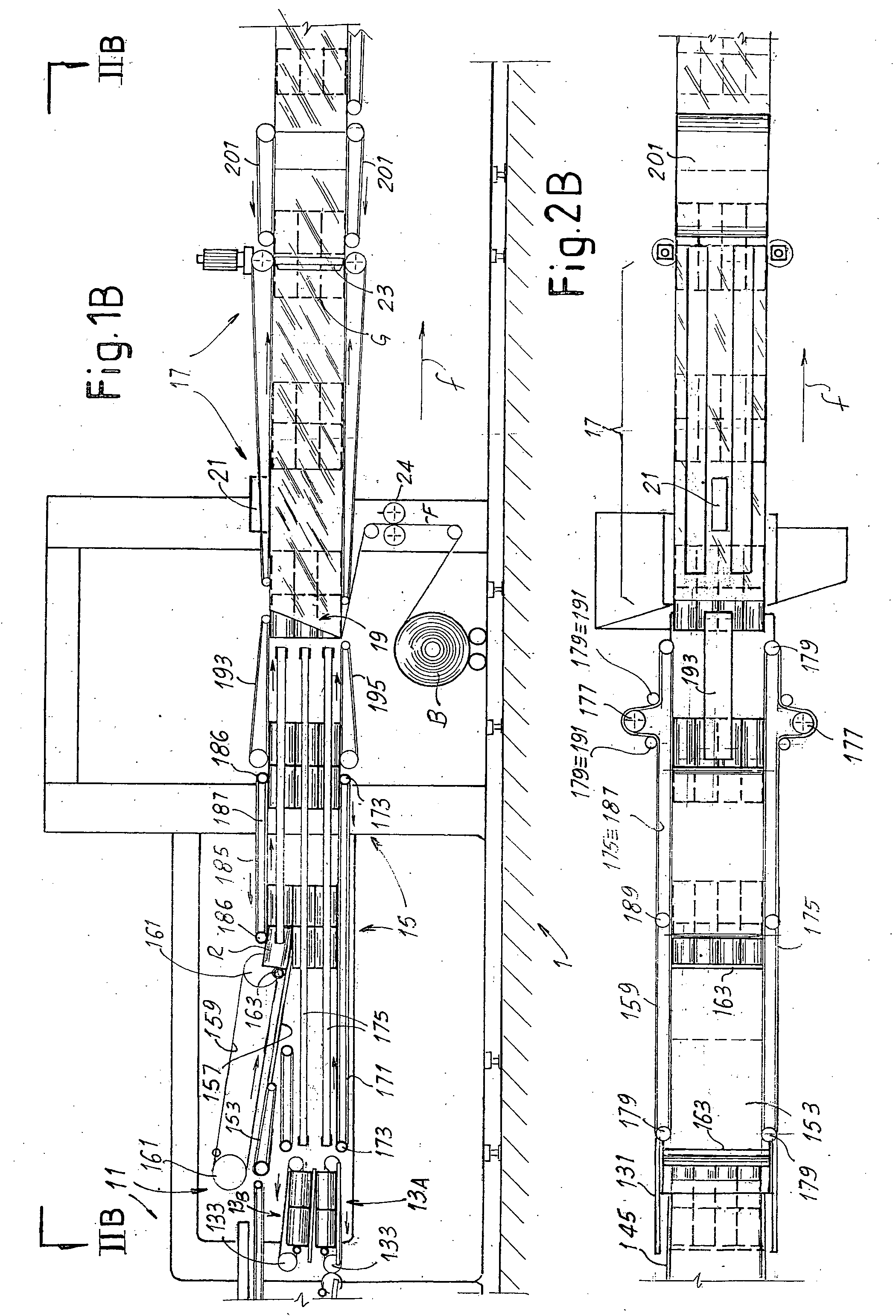

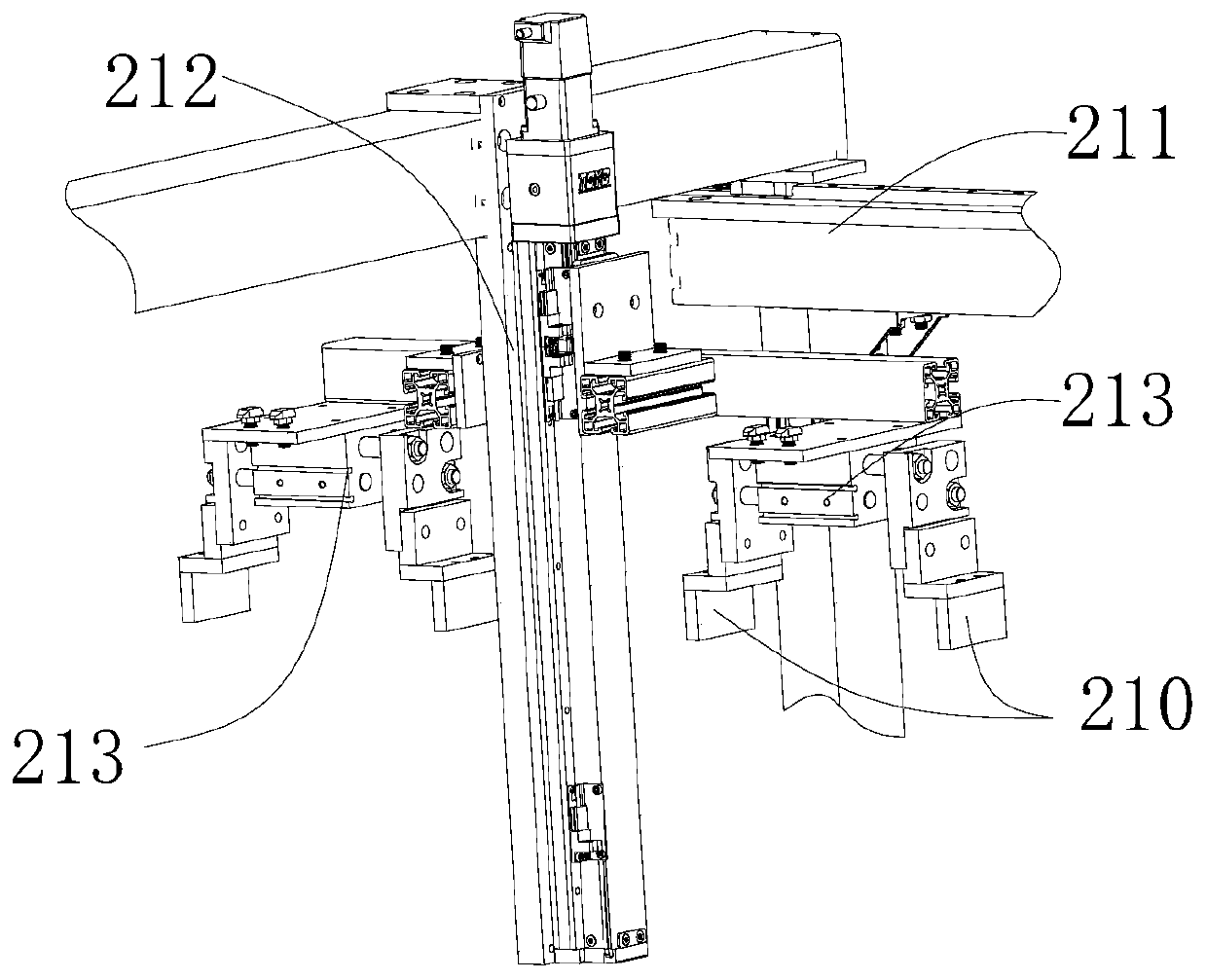

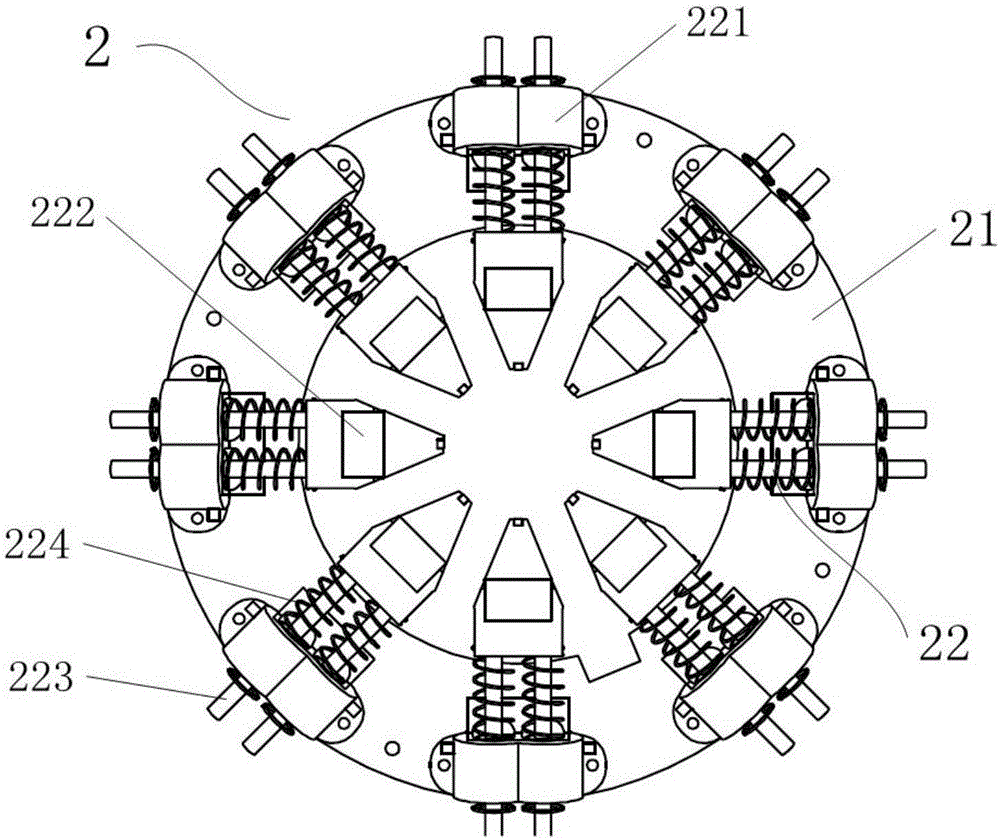

Machine and method for packaging groups of products

InactiveUS7703264B2Improve efficiencyPacking speed is fastWrapper twisting/gatheringStacking articlesEngineeringPlastic film

To orient groups of products to be packaged in a plastic film the groups (G) are wrapped in lengths of film and fed between two series of opposite conveyor belts (211, 212). Each series of belts comprises several parallel belts controlled at proportionally variable speeds to cause the group (G) to rotate through approximately 90° about an axis orthogonal to the direction of feed.

Owner:KPL PACKAGING

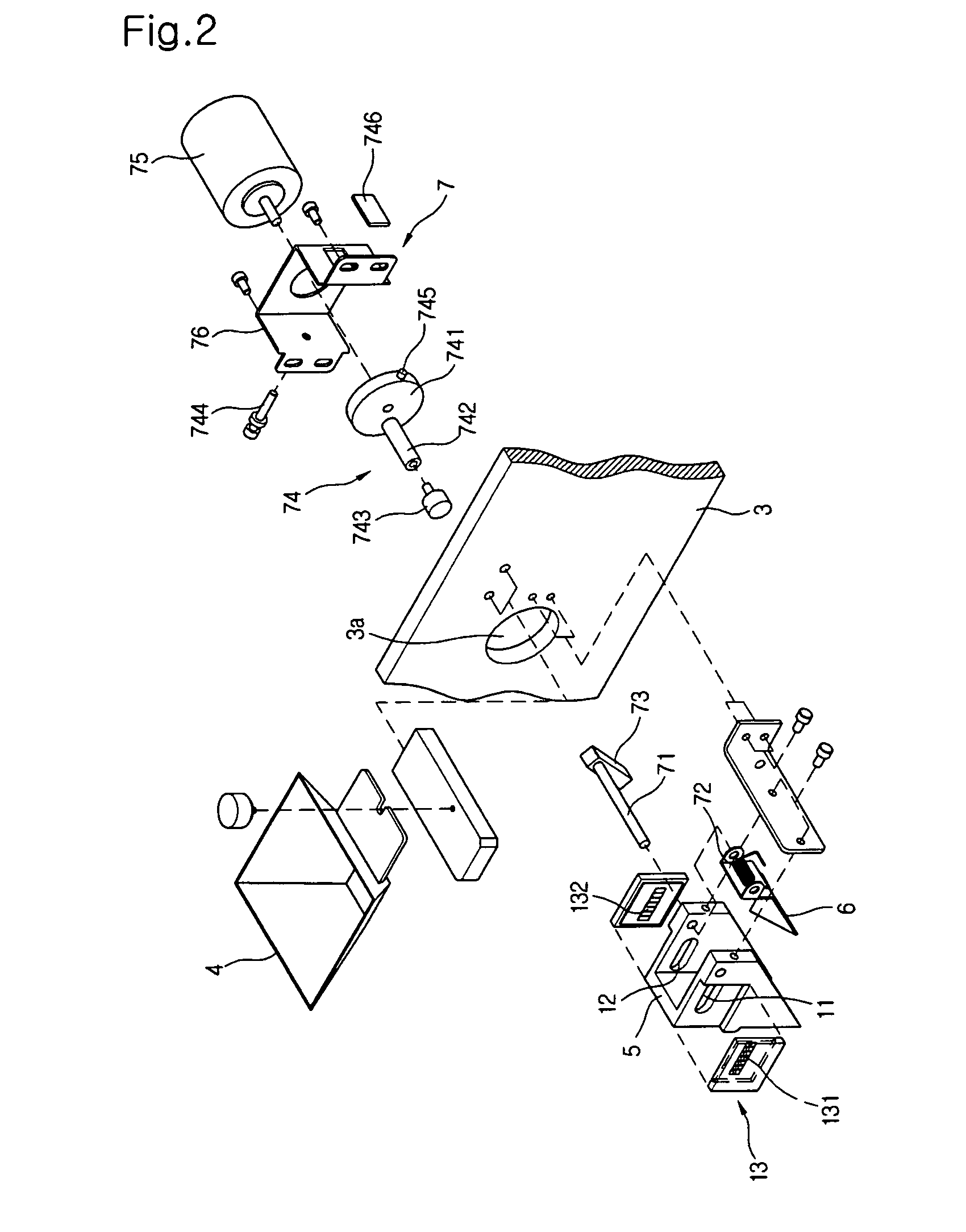

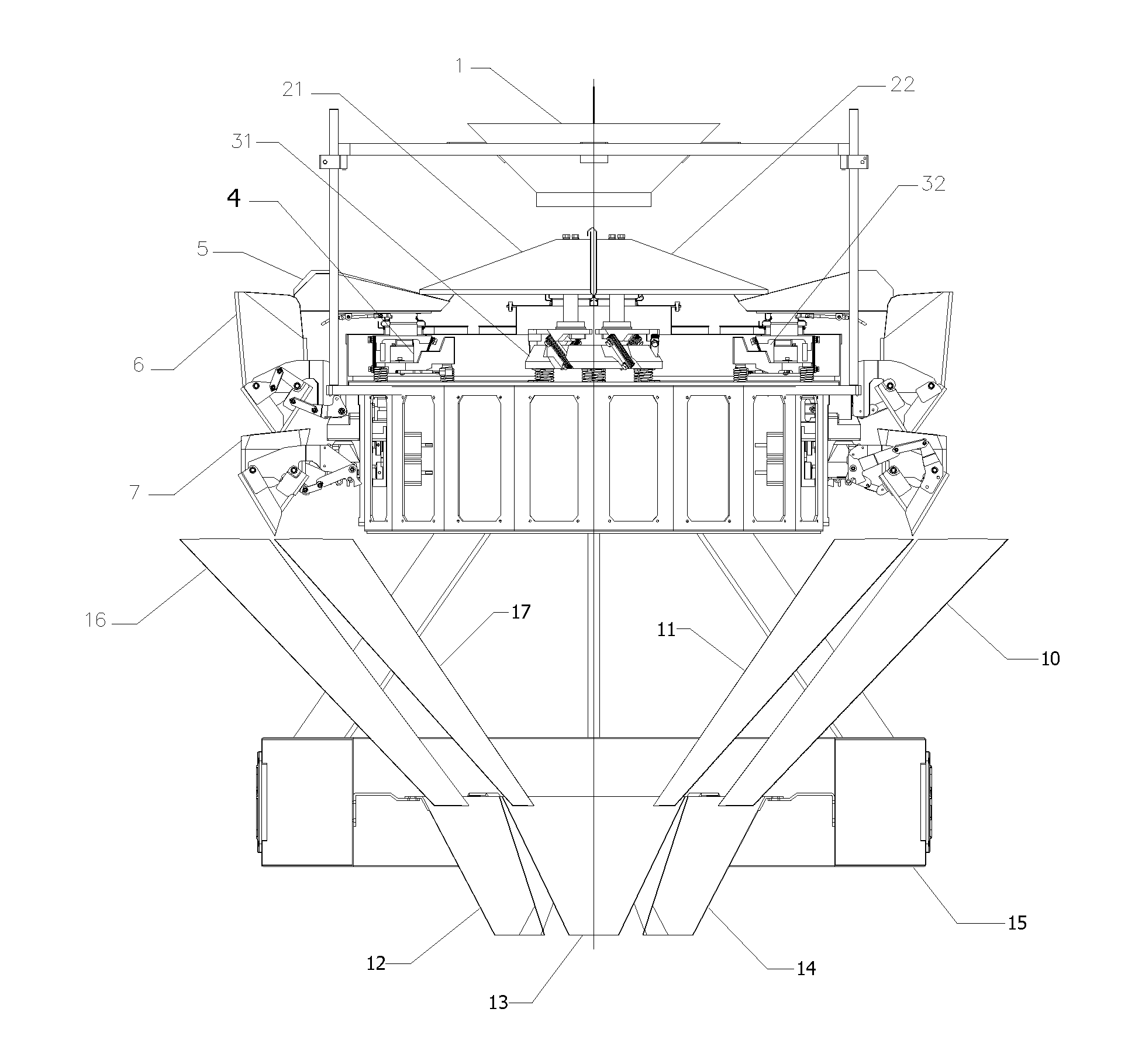

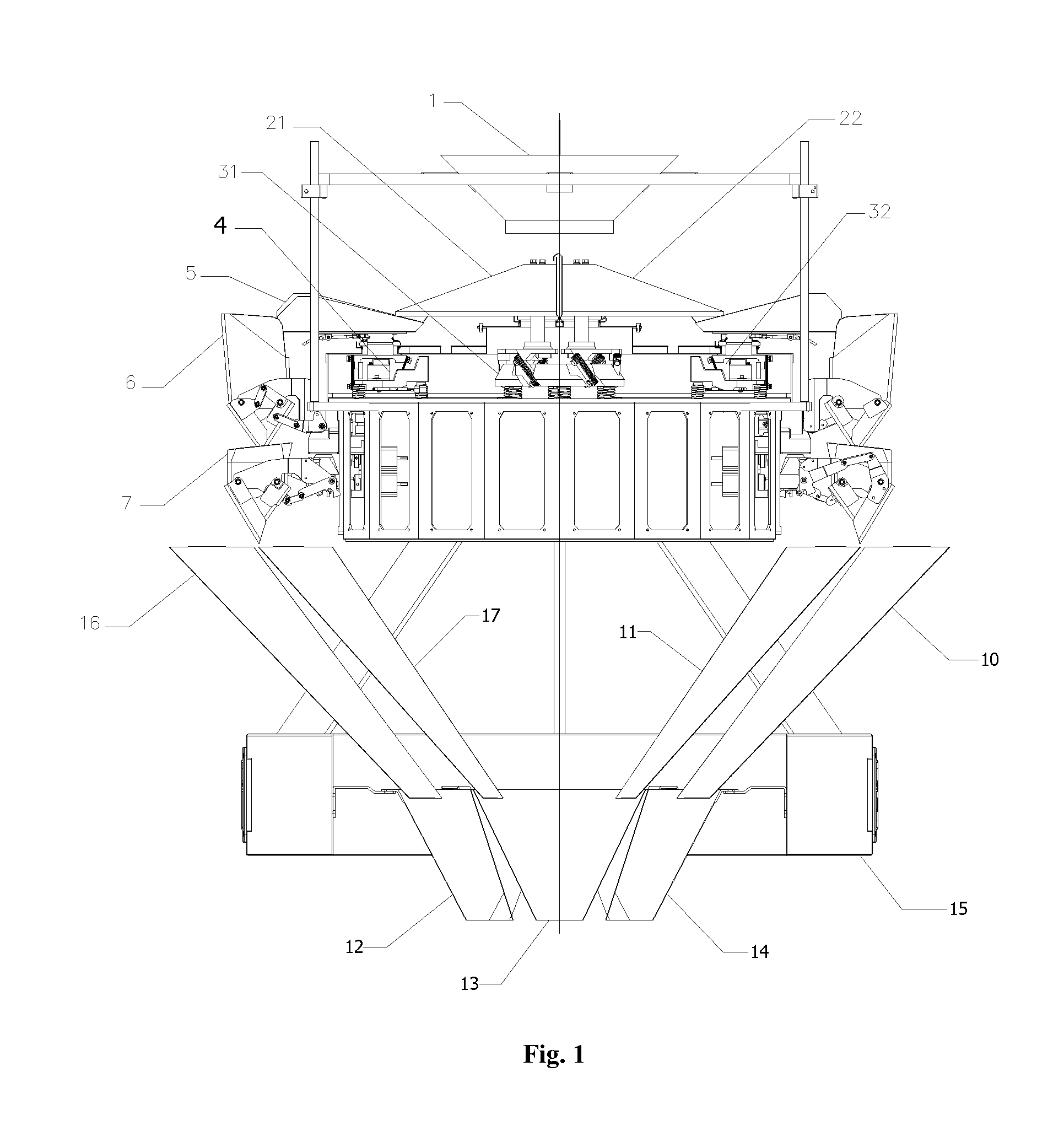

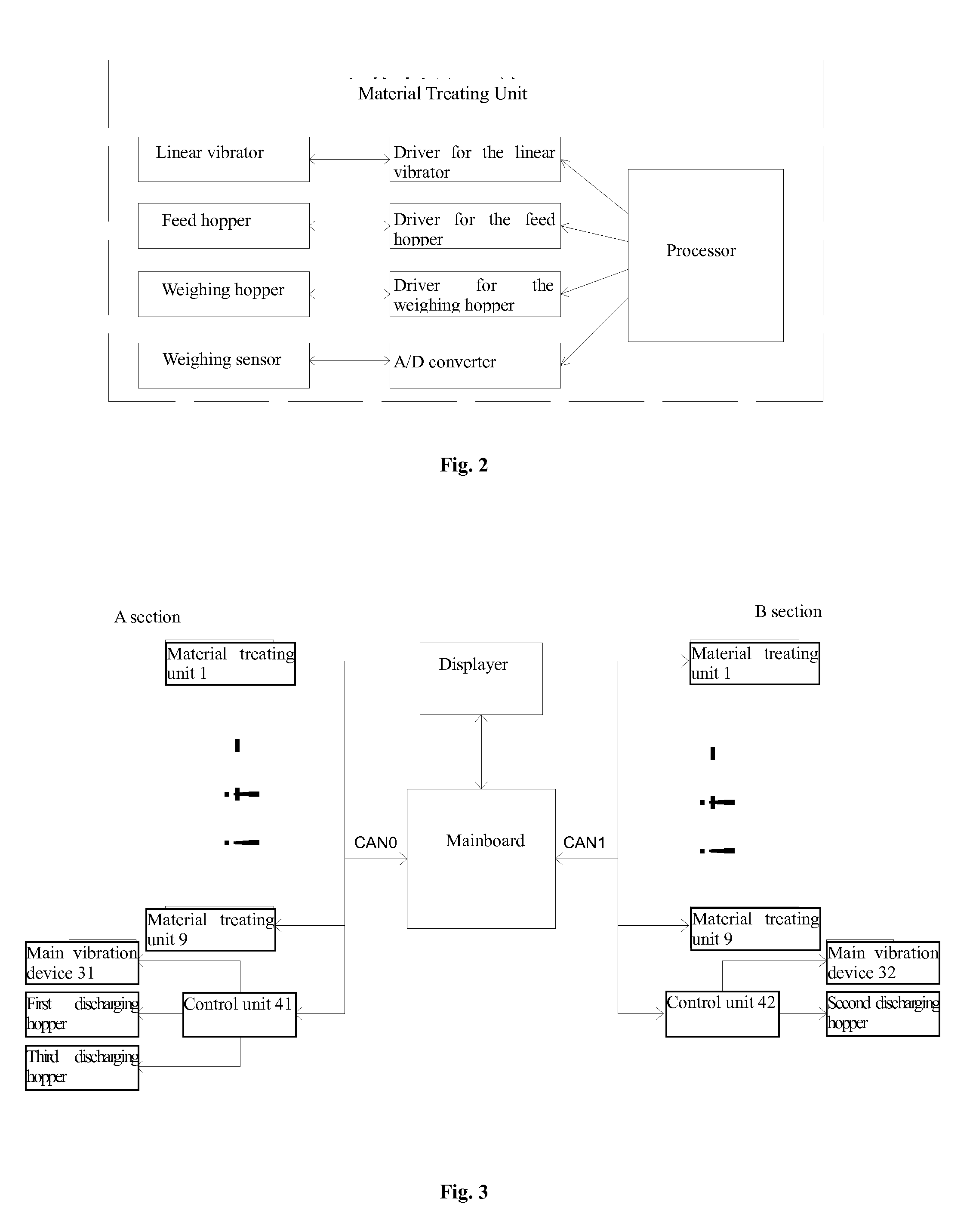

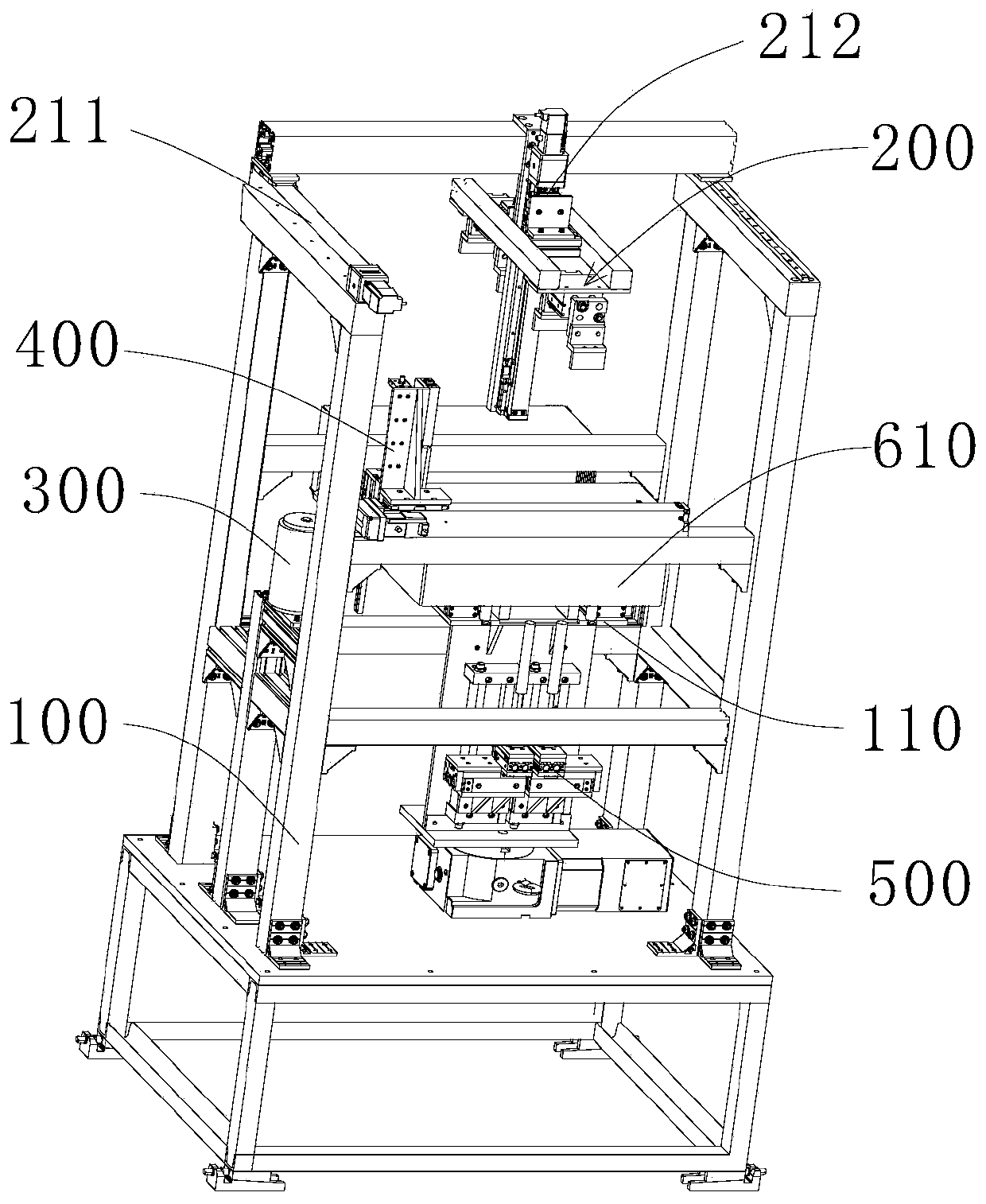

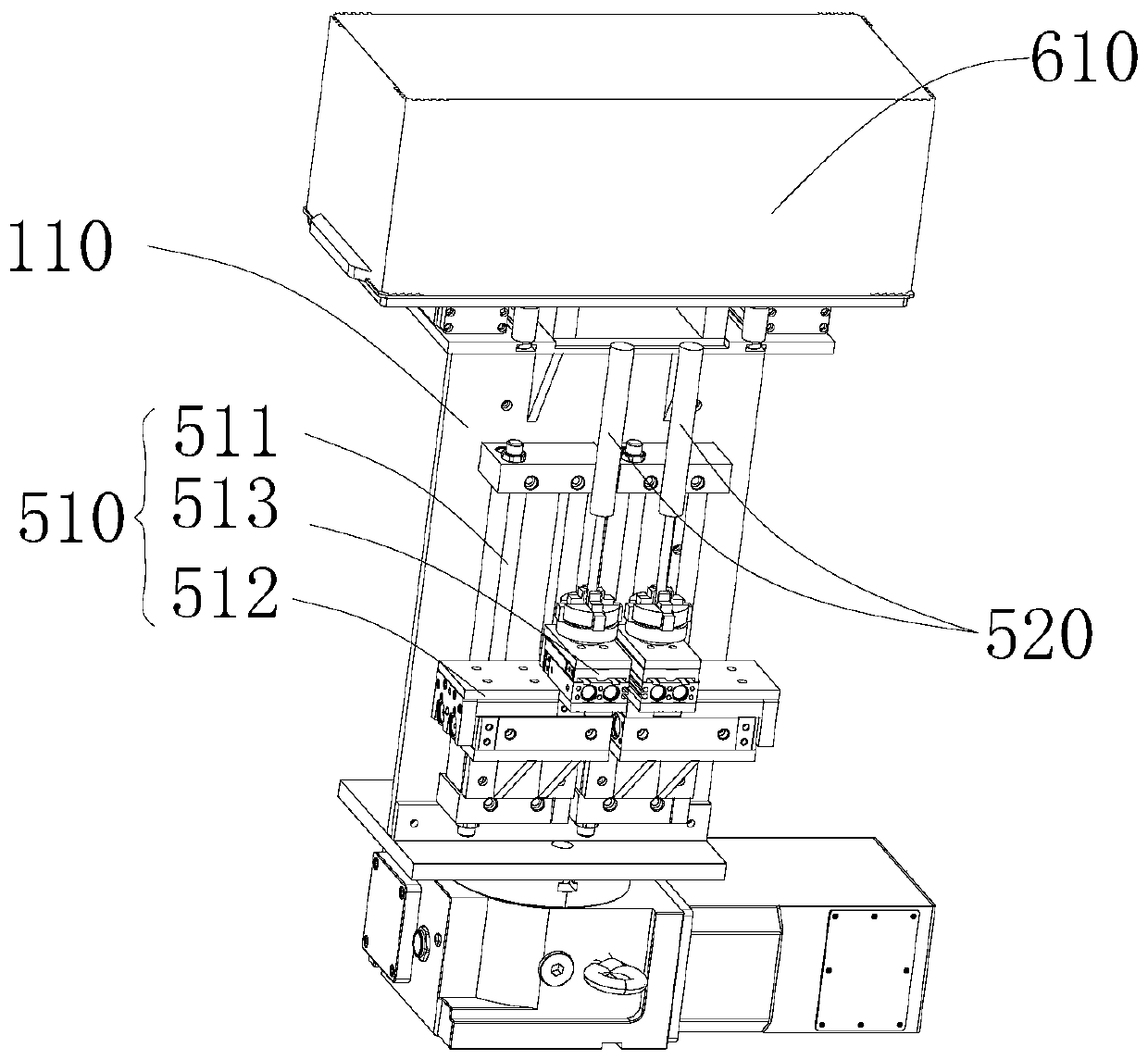

Combination weighing device and operating method thereof

ActiveUS20120103703A1Improve efficiencyData transfer speed is fastSolid materialWeighing apparatus for materials with special property/formControl signalEngineering

A combination weighing device and an operating method thereof are disclosed. The device comprises N material treating units, a mainboard, chutes (10, 11, 16, 17) and discharging hoppers (12, 13, 14), wherein the material treating units are used for receiving materials, outputting the weight value of materials and discharging materials according to the discharging control signal from the mainboard; the mainboard is used for selecting materials by combinatorial calculation based on the present-period weight value during every period and outputting the discharging control signal to weighing hoppers (7); the chutes (10, 11, 16, 17) are used for collecting the materials through a discharging route, discharging the materials to the discharging hoppers (12, 13, 14), after a discharging route is determined; the discharging hoppers (12, 13, 14) are used to separately collect materials discharged from the chutes (10, 11, 16, 17) during the same weighing period and send the materials to a packing machine; each material treating unit comprises a linear vibrator (5), a feed hopper (6), a weighing hoper (7), a weighing sensor used to weigh the materials in the weighing hoper (7), a processor and a A / D converter which is connected with the weighing sensor and the processor, N material treating units are connected with the mainboard signal together by two data receiving and delivering communication converters of the mainboard.

Owner:GUANGODNG HIGH DREAM INTELLECTUALIZED MACHINERY

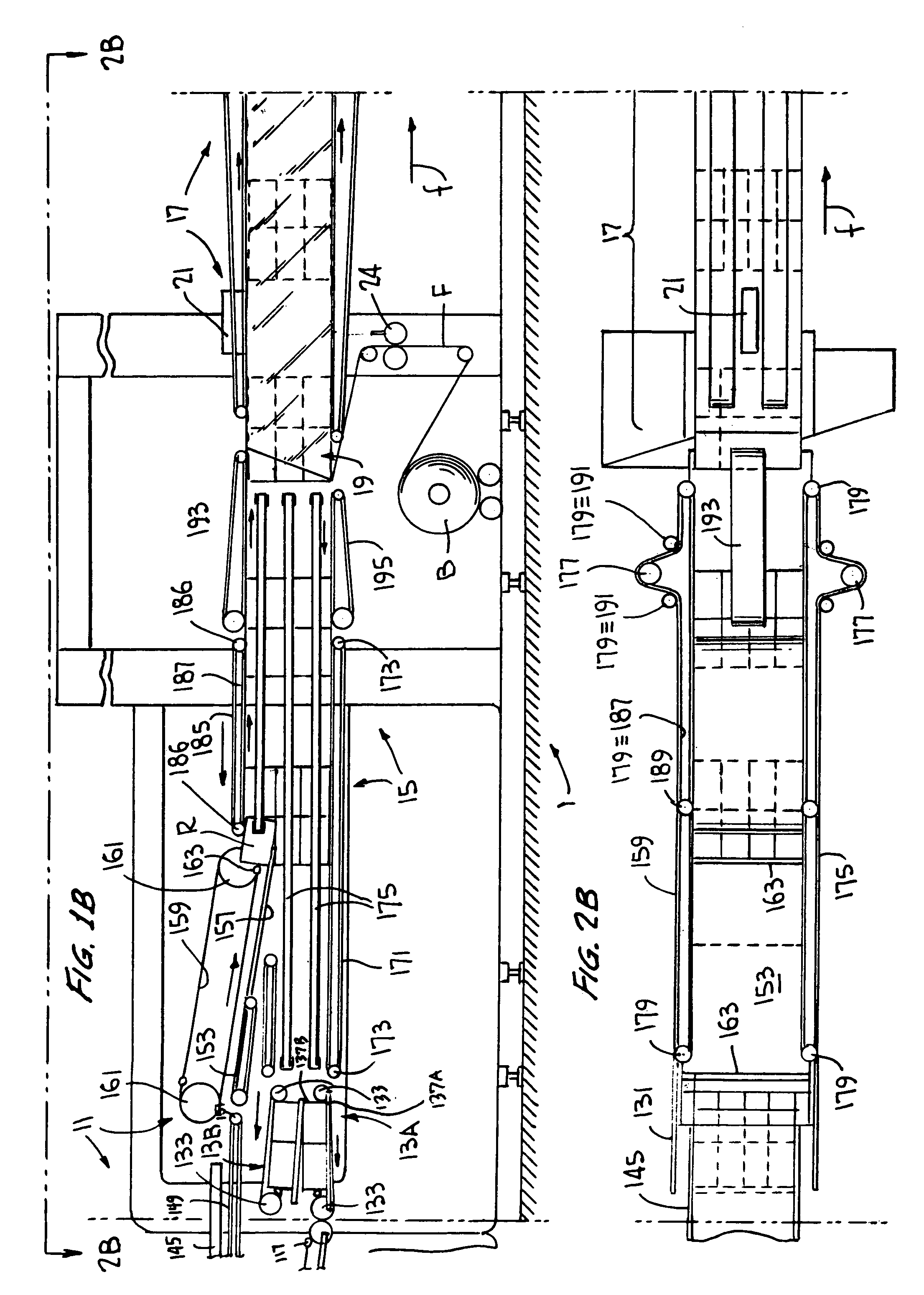

Machine and Method for Packaging Groups of Products

InactiveUS20090113849A1Low costIncrease control flexibilityWrapper twisting/gatheringSolid materialEngineeringPlastic film

To orient groups of products to be packaged in a plastic film the groups (G) are wrapped in lengths of film and fed between two series of opposite conveyor belts (211, 212). Each series of belts comprises several parallel belts controlled at proportionally variable speeds to cause the group (G) to rotate through approximately 90° about an axis orthogonal to the direction of feed.

Owner:KPL PACKAGING

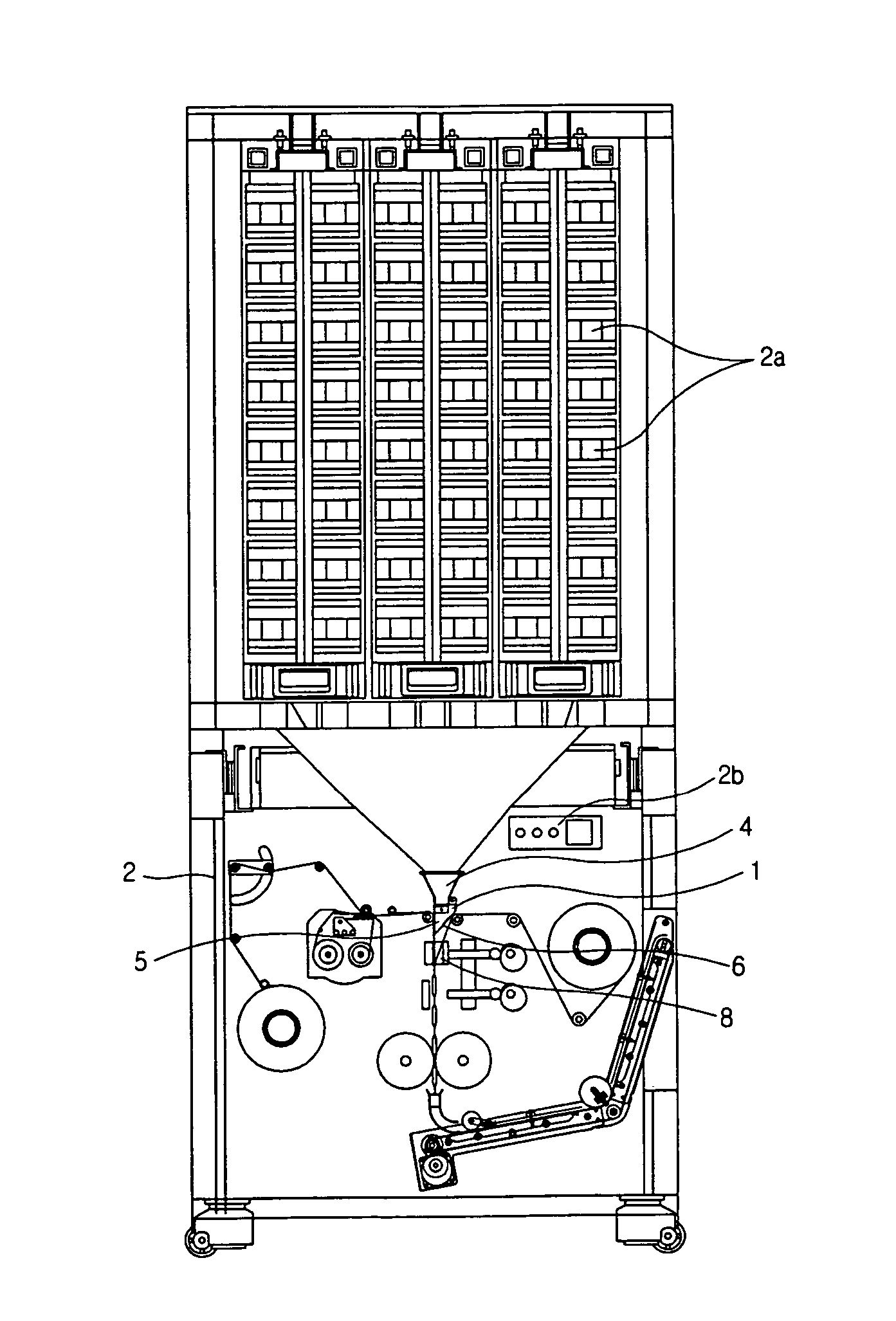

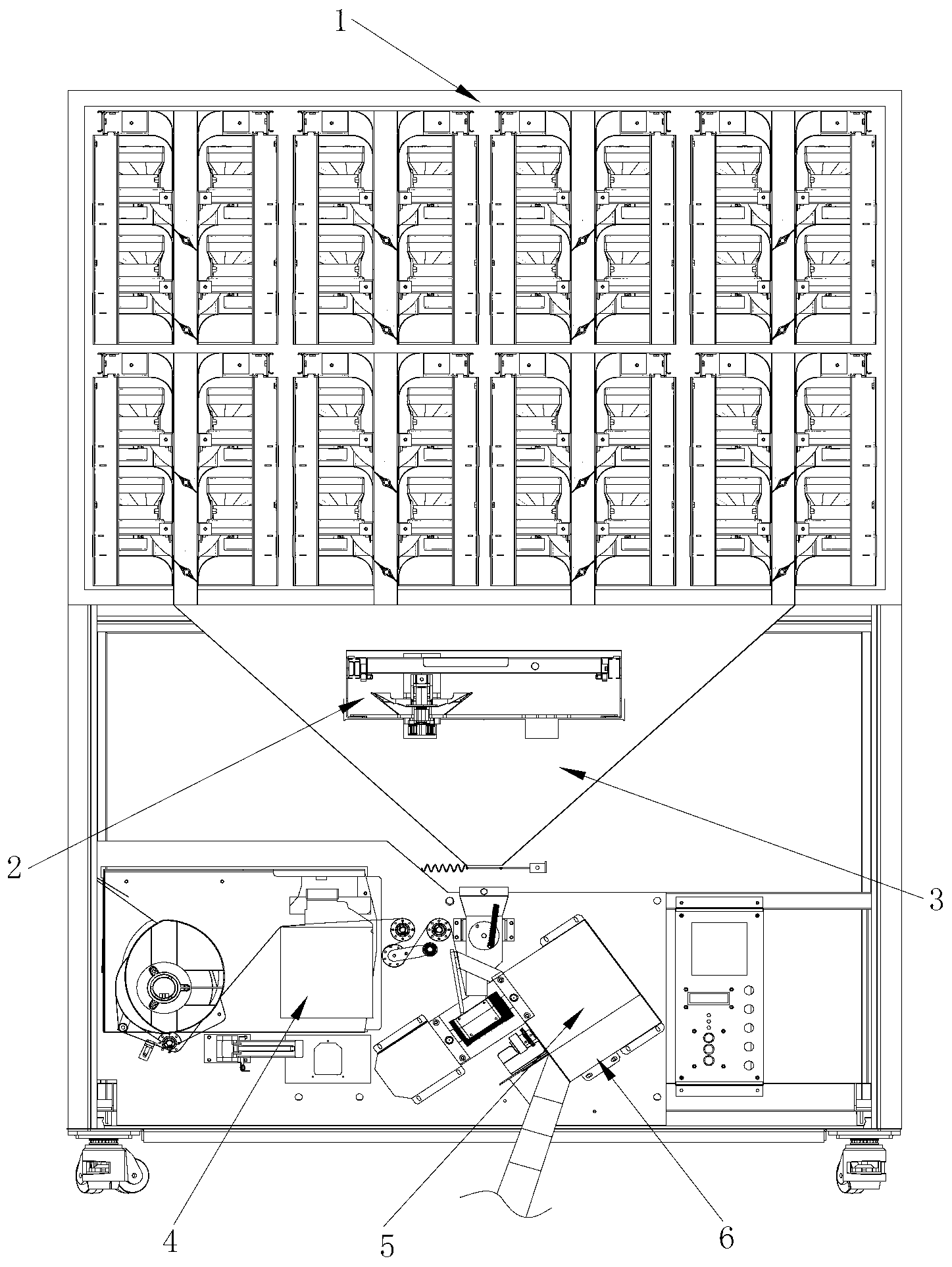

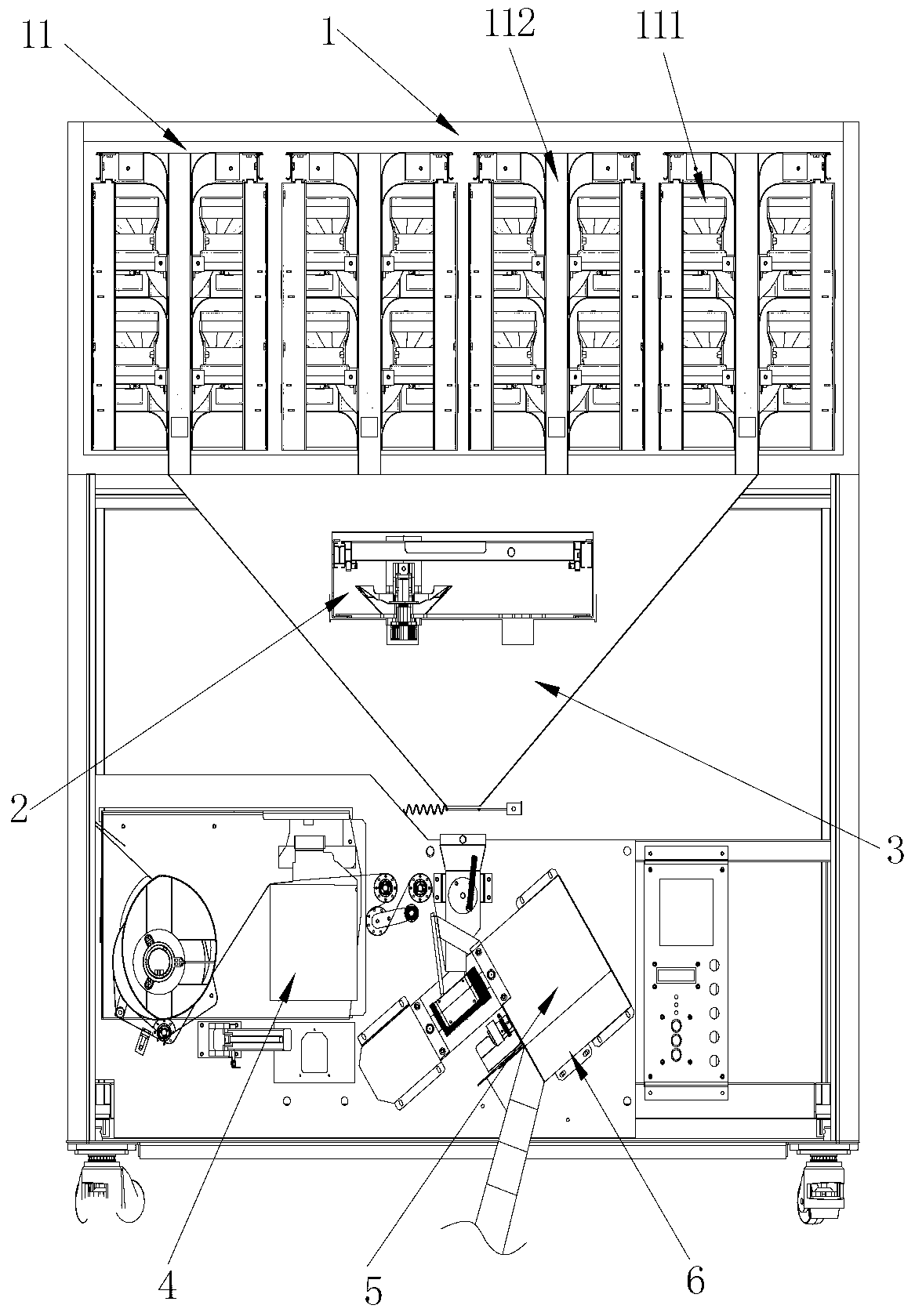

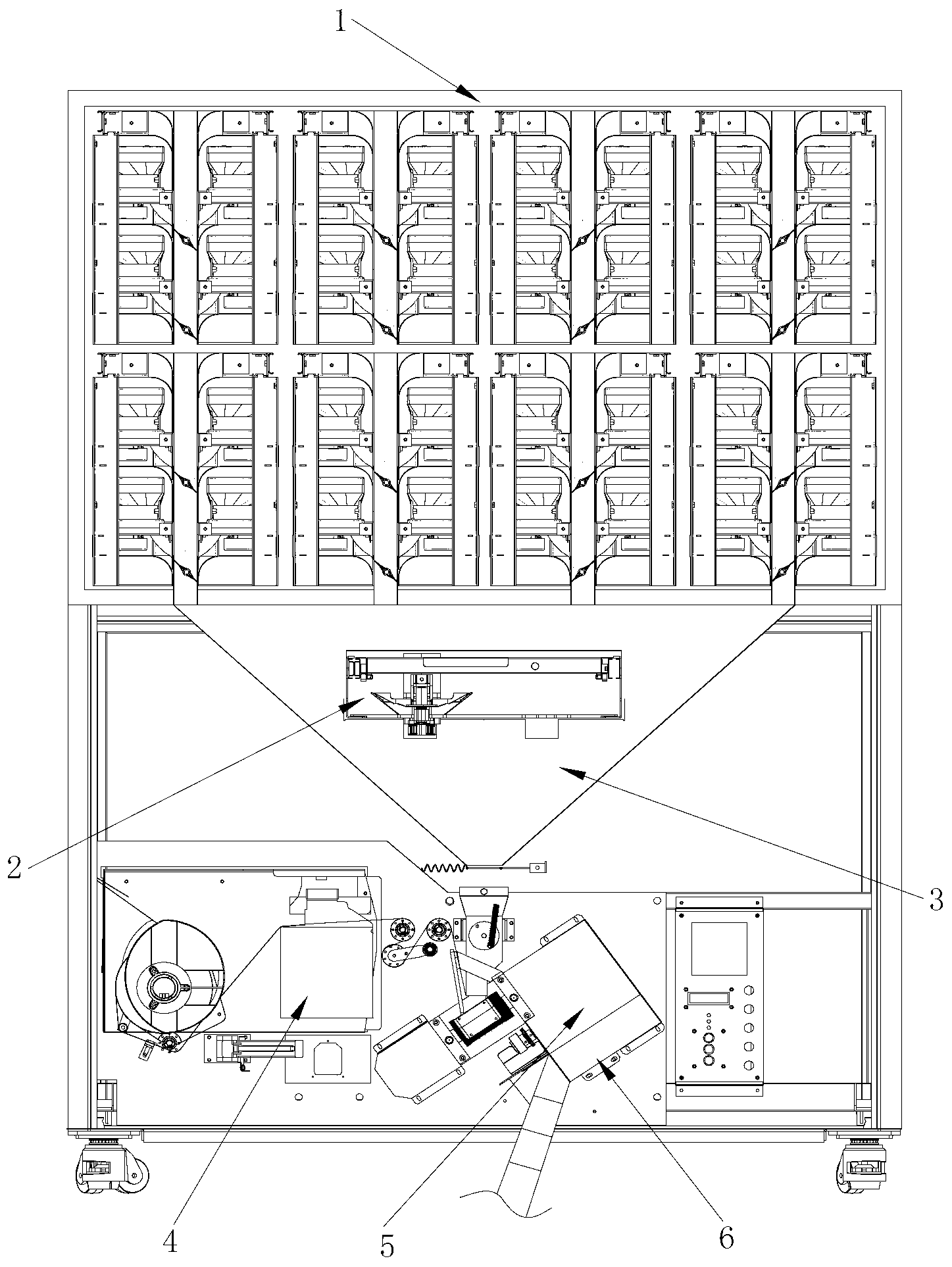

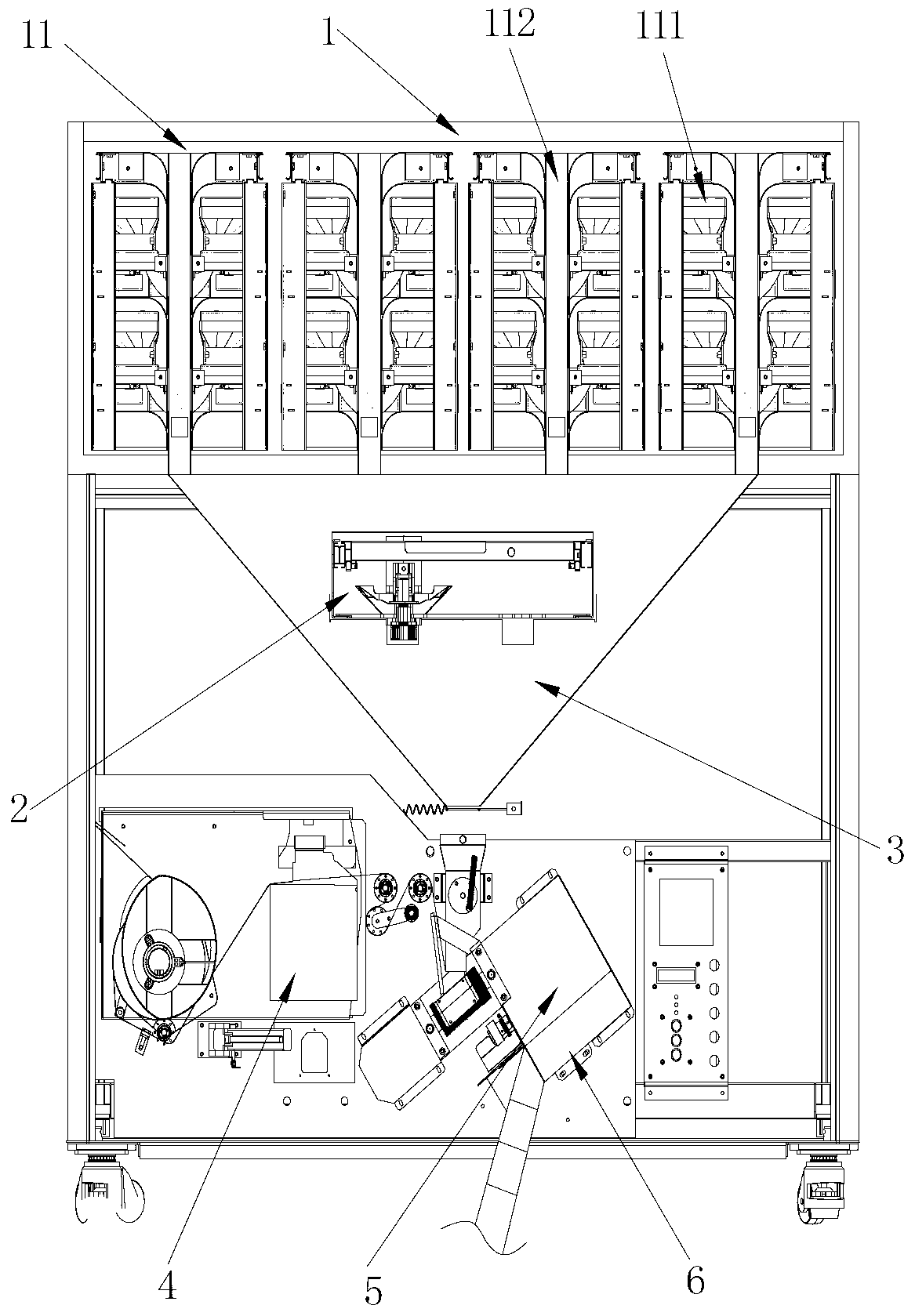

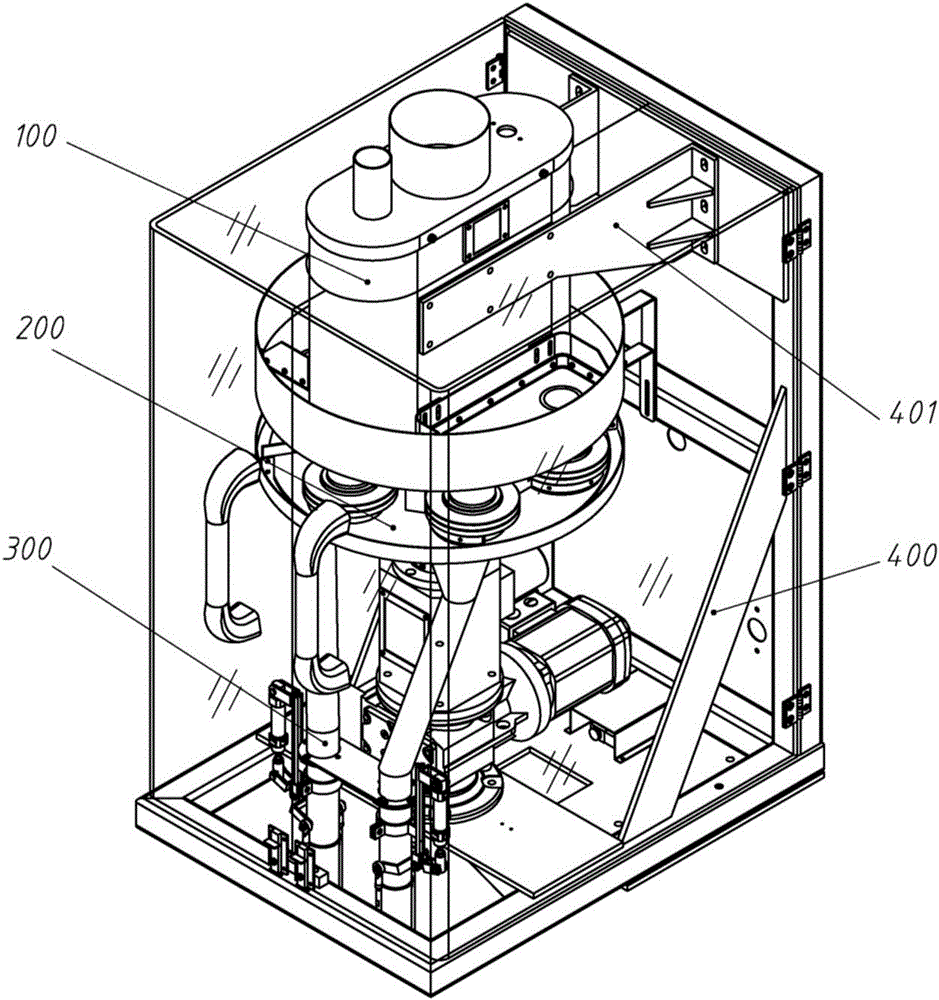

Fast full-automatic medicine packaging device

ActiveCN103318591AReduce travel timeReduce kinetic energySolid materialStorage devicesBiomedical engineeringComputer case

The invention discloses a fast full-automatic medicine packaging device which comprises a medicine storage cabinet and a case. A collection mechanism 3 is arranged in the case, a printing mechanism 4 is arranged on the lower surface of the collection mechanism 3 and is connected with a packaging mechanism 5, and the packaging mechanism 5 is communicated with a bag discharge mechanism 6. At least one medicine supply combination unit 11 is arrayed in the medicine storage cabinet 1. The fast full-automatic medicine packaging device disrupts the intrinsic flow process of medicine packaging in the prior art, many medicine bags can discharge medicines simultaneously without affecting each other through the at least one medicine supply combination unit, a medicine collection channel sharing structure, an interception device multi-collection structure and the like, and the medicine packaging speed of the whole packaging device is manifold improved.

Owner:TIANJIN SENYA MEDICAL EQUIP TECH CO LTD

Semi-automatic carton packing machine

The invention relates to the technical field of packing equipment, in particular to a semi-automatic carton packing machine. The machine comprises a carton unfolding mechanism, a sealing wing closing mechanism, a glue beating mechanism and a glue sealing mechanism; the carton unfolding mechanism includes a support part for placing a carton and an unfolding baffle plate, and opens the carton in a board state; sealing wings of the carton are closed through the sealing wing closing mechanism; and an adhesive tape is bonded on the carton through the glue beating mechanism and the glue sealing mechanism to finish automatic packing of the carton. The carton packing machine solves the problems of low efficiency and high labor intensity in pure manual packing in the prior art, saves the packing time, accelerates the delivery speed, reduces the production cost, and meanwhile, is simple in structure, convenient to operate and more suitable for individuals and Taobao sellers.

Owner:CHENGDU TECH UNIV

Bag feeding type dental floss packaging machine

PendingCN113135307AOrganize efficientlyQuick tidy upPackaging automatic controlIndividual articlesDental flossingDentistry

The invention discloses a bag feeding type dental floss packaging machine. The bag feeding type dental floss packaging machine comprises a feeding module, an arrangement module, a conveying module, a receiving module and a pushing module. The feeding module is used for inputting to-be-packaged dental floss and transferring the to-be-packaged dental floss to the arrangement module. The arrangement module is used for arranging the input dental floss and forming a dental floss pile. The conveying module is used for receiving one dental floss pile from the arrangement module and conveying the dental floss pile to the subsequent receiving module, and the conveying module is provided with a conveying rod used for hanging the dental floss pile. The receiving module is used for receiving the dental floss pile from the conveying module and transferring the dental floss pile to the pushing module. The pushing module is used for receiving the dental floss pile from the receiving module and pushing the dental floss pile into a packaging container. The dental floss packaging machine is unique in structure, automation can be achieved, packaging and labor cost is reduced, efficiency is improved, and dental floss is clean and sanitary.

Owner:SHANGHAI COLOSHORE AUTOMATION TECH CO LTD

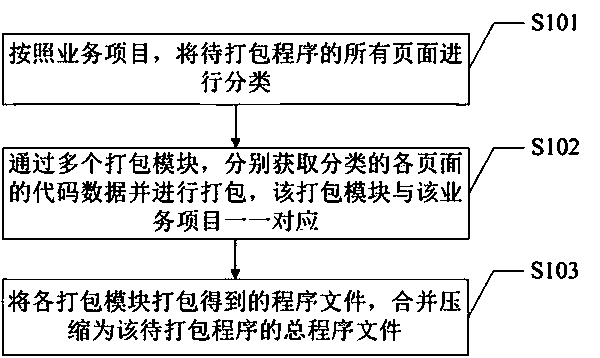

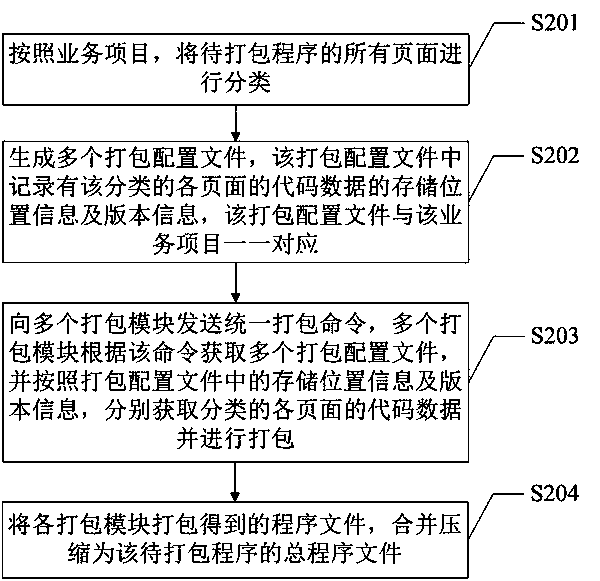

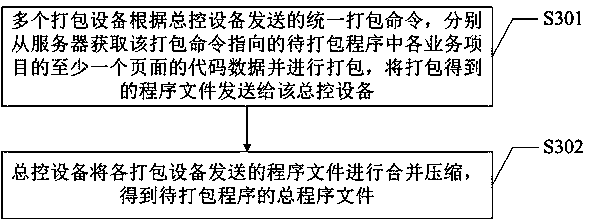

Program packaging method and system and terminal device

InactiveCN107908404AImprove packaging efficiencyPacking speed is fastVersion controlProgram documentationTerminal equipmentSoftware engineering

The embodiment of the invention discloses a program packaging method and system and a terminal device. The program packaging method comprises the steps of classifying all pages of a to-be-packaged program according to business items; acquiring code data of the classified pages and carrying out packaging through a plurality of packaging modules, wherein the packaging modules and the business itemsare in one-to-one correspondence; packaging the packaging modules to obtain program files; and combining and compressing the program files into a total program file of the to-be-packaged program. According to the program packaging method and system and the terminal device, the joint packaging operation can be automatically carried out on a plurality of business items, the plurality of business items can be packaged in parallel, and the packaging efficiency and speed can be improved.

Owner:深圳市泉眼网络科技有限公司

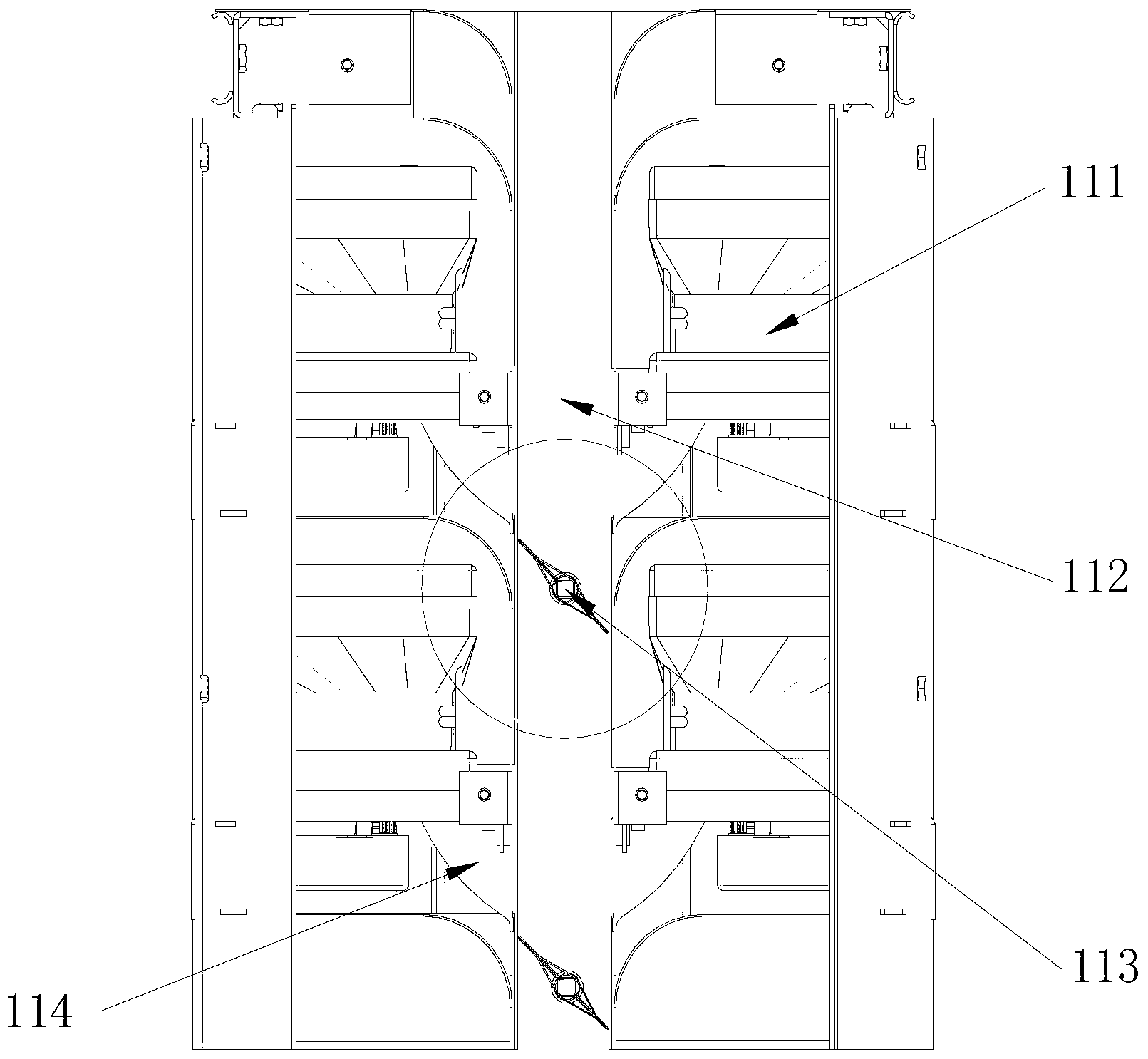

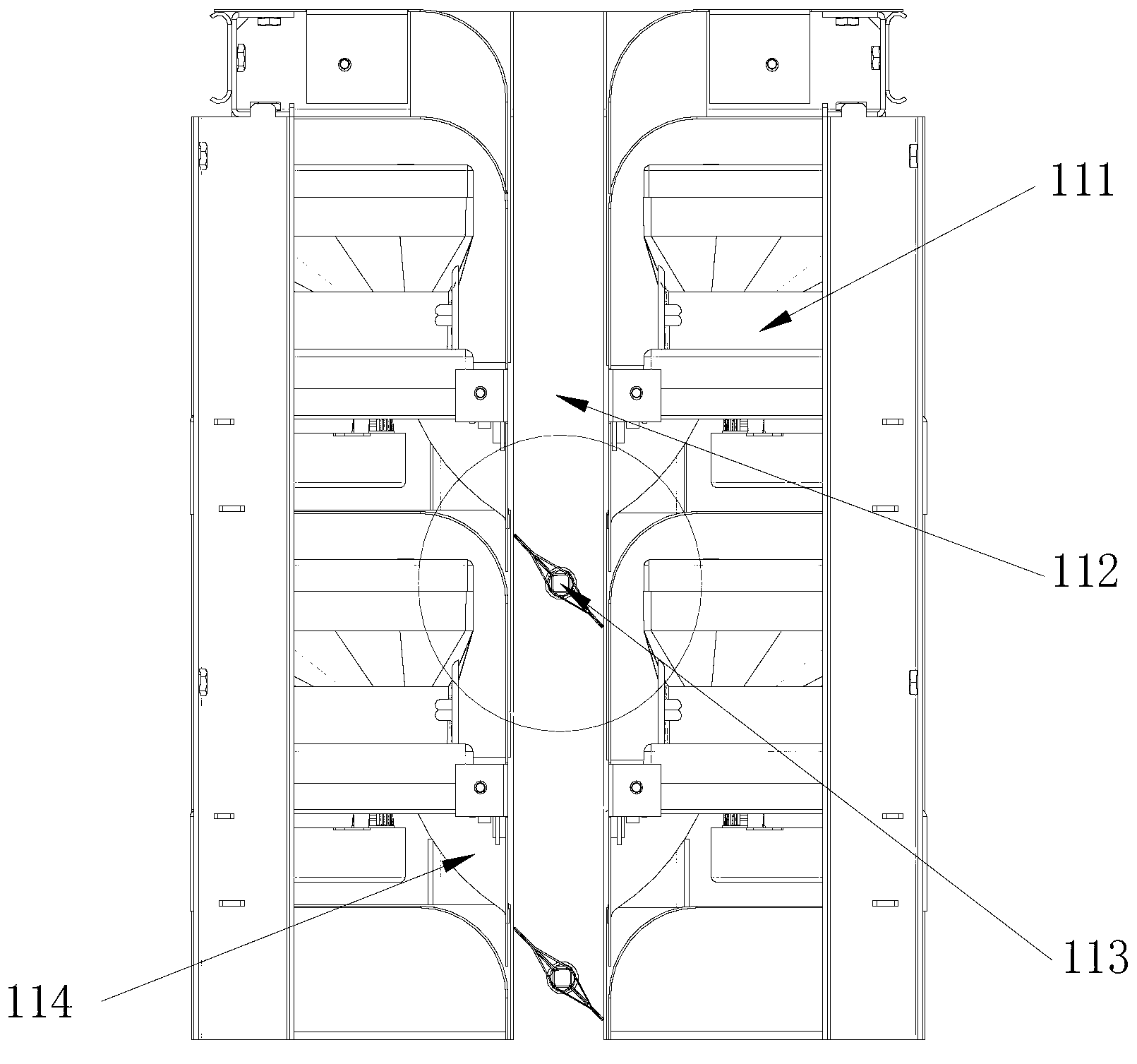

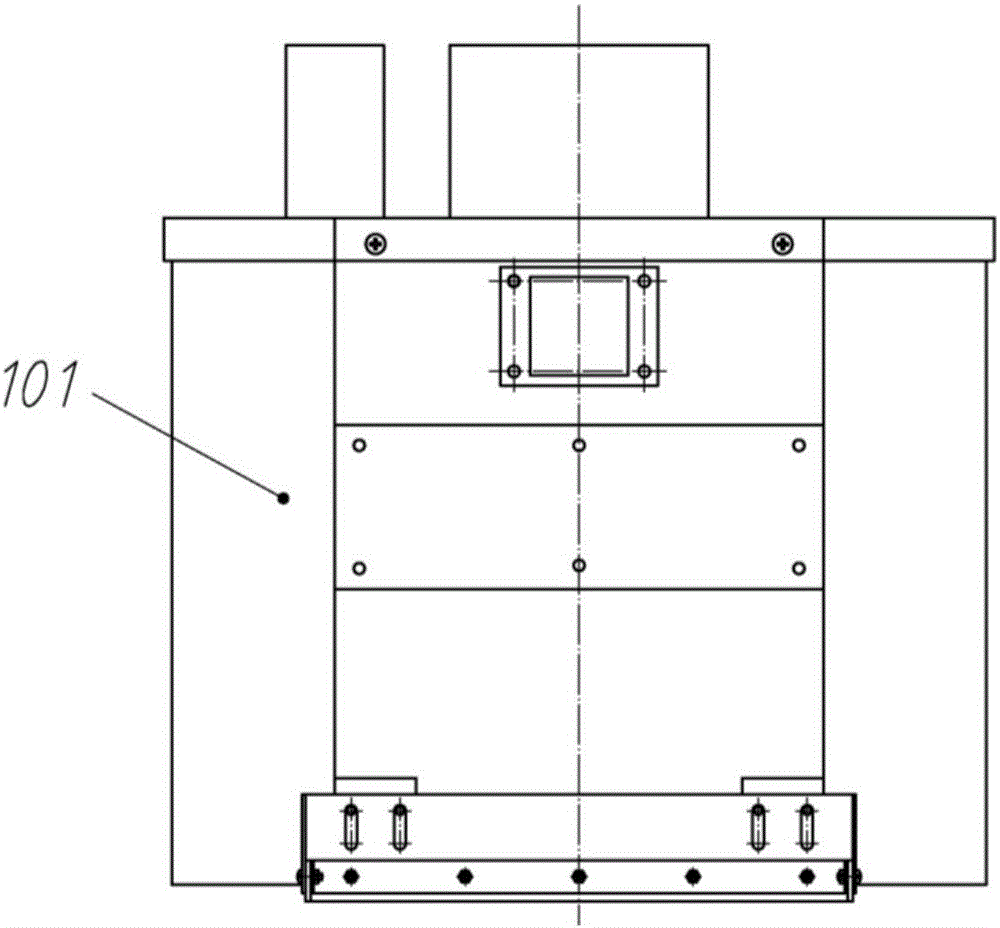

Drug supply combined unit of drug packaging device

ActiveCN103318590AGuaranteed retentionReduce travel timeSolid materialStorage devicesDrug productDrug supply

The invention discloses a drug supply combined unit of a drug packaging device. The drug supply combined unit comprises at least one drug supply device (111), wherein drug guiding channels (114) through which drugs slide out are arranged under the at least one drug supply device (111), vertical drug collecting channels (112) are arranged on sides of the at least one drug supply device (111), the drug guiding channels (114) are communicated with the drug collecting channels (112), and retaining devices (113) which are used for retaining and temporarily storing the drugs are installed inside the bottom ends of the drug collecting channels (112). The drug supply combined unit can help the drug packaging device to conduct collection repeatedly, so that a plurality of drug bags can dispense drugs simultaneously without being interfered, that is, the drug packaging speed of the whole device is multiplied.

Owner:TIANJIN SENYA MEDICAL EQUIP TECH CO LTD

Box self-winding packing machine

ActiveCN110481837APacking speed is fastReduce cumbersome manual operationsWrapping material feeding apparatusWrapping with article rotationEngineeringMechanical engineering

The invention provides a box self-winding packing machine and relates to the technical field of film wrapping packing. The box self-winding packing machine comprises a rack, a feeding assembly, a filmsupply roller, a film supply assembly and pressing assemblies. The feeding assembly is connected to the rack in a sliding mode and located above a rotary frame. A clamping component is arranged at the lower end of the feeding assembly. The film supply assembly is connected with the rack and provided with two film clamping bars which extend downwards and is used for clamping a packing film. The pressing assemblies are arranged on the side portion of the rotary frame and used for moving upwards and pressing the packing film to the side wall of a box. According to the box self-winding packing machine provided by the invention, the box is arranged on the rotary frame through the feeding assembly, the packing film on the film supply roller is pulled to the outer side of the box by means of thefilm clamping bars of the film supply assembly, the packing film is pressed to the outer side surface of the box through the pressing assemblies, the rotary frame drives the box and the pressing assemblies to rotate so as to wrap the outer side of the box with the packing film, tedious manual operation is omitted in the process, and the packing film wrapping speed is greatly increased.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Convenient type thin film winding mechanism

InactiveCN105501495APacking speed is fastImprove work efficiencyWrapping material feeding apparatusWeb rotation wrappingConductor CoilLarge size

The invention discloses a convenient type thin film winding mechanism. The convenient type thin film winding mechanism comprises a rack (1) and an unwinding device (2), wherein the unwinding device (2) is arranged on the rack through a hoisting and conveying device (3); the hoisting and conveying device is connected with a reversing transmission device (4); the rack is provided with a hoisting guide rail (6) and is connected with a hoisting seat (7) of the unwinding device. Reversing power output of forward rotation or reversed rotation is realized through the reversing transmission device; the unwinding device is used for hoisting or descending the unwinding device and a thin film on the unwinding device is repeatedly wound on large-size equipment for a plurality of times through all-directional changes of up and down directions, left and right directions, front and back directions and the like along the pushing of the whole rack, so that effective bundling and packaging are realized. The convenient type thin film winding mechanism is simple in structure, convenient to operate and easy to package, and has the advantages of rapid winding speed, stability in working, firmness in bundling and low packaging cost; the speed and working efficiency of external packaging of objects are improved.

Owner:全越

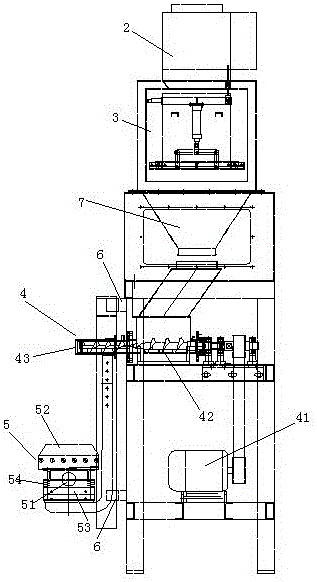

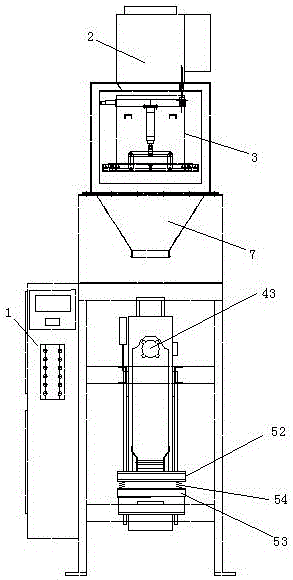

Quantitative liquid automatic bagging and sealing integrated machine

ActiveCN106477085AIncreased metering and packaging speedLabor savingWrapping material feeding apparatusLiquid materialAutomatic controlPlastic bag

The invention discloses a quantitative liquid plastic bag packaging integrated machine, relates to a quantitative liquid plastic bag packaging technology, and particularly relates to a quantitative liquid plastic bag packaging integrated machine. The provided machine is a high-speed integrated machine device for plastic bag packaging and automatic sealing, which is high in metering accuracy. The integrated machine comprises a support frame, a filling metering mechanism, a plastic film conveying mechanism, a plastic bag vertical sealing mechanism, a plastic film driving mechanism, a plastic bag transverse sealing mechanism and a bag material leading-out mechanism, wherein the filling metering mechanism, the plastic film conveying mechanism, the plastic bag vertical sealing mechanism, the plastic film driving mechanism, the plastic bag transverse sealing mechanism and the bag material leading-out mechanism are arranged on a front end face of a rack sequentially from top to bottom. Metering and conveying are controlled by adopting a cylinder, and the time for waiting is not needed, so that the metering and packaging speeds are increased; and by adopting automatic control, the integral automation of plastic film bag making and metering filling is realized, the manpower is saved, the cost is reduced, and the integrated machine has the characteristics of compact structure, small floor area and high efficiency.

Owner:江西森达自动化设备有限公司

Flat roll packaging machine

ActiveCN104129529AGuarantee the quality of materialsIncrease productivityPackagingEngineeringPackaging machine

The invention discloses a flat roll packaging machine, and relates to the field of tissue packaging machines. The flat roll packaging machine comprises conveying devices, a film conveying device, a bag opening and supporting device, a package pushing device and a negative pressure forming device and further comprises flattening devices and a laminating device. The conveying devices comprise the first conveying device, the second conveying device and the third conveying device. The laminating device comprises a first pushing platform and a second pushing platform, the first pushing platform and the second pushing platform are provided with pushing air cylinders respectively, and the first pushing platform and the second pushing platform are arranged on the two sides of the first conveying device respectively. According to the flat roll packaging machine, flattening is conducted on a paper roll twice, the paper roll is flattened and formedcompletely, the situations of jumping and warping can be avoided, automatic laminating processing can be achieved, laminating packaging is completed automatically, and packaging operation is completed efficiently.

Owner:SHANGHAI SOONTRUE MACHINERY EQUIP

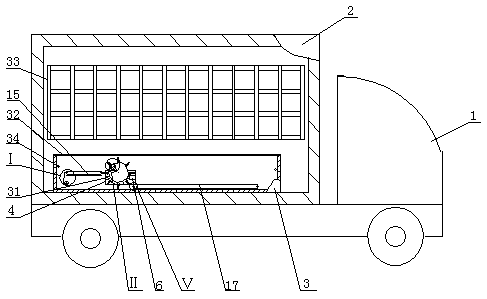

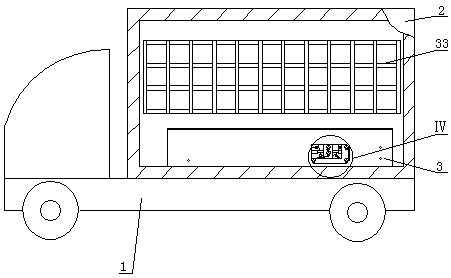

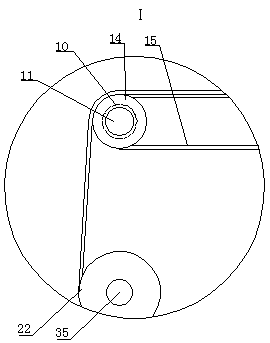

Meat food preservation device during cold-chain logistics

InactiveCN108177894APacking speed is fastFunction increaseLarge containersTank wagonsCold chainLogistics management

The invention relates to a meat food preservation device during cold-chain logistics. The meat food preservation device during cold-chain logistics comprises a vehicle body and a refrigeration container. The refrigeration container is fixedly installed on the vehicle body; a tank is fixedly installed in the middle of the bottom part in the refrigeration container; the top part of the tank is opened; rectangular holes are symmetrically formed in the front side face and the back side face of the tank; rectangular plates are arranged in the rectangular holes; the upper ends of the rectangular plates are matched with the top parts in the corresponding rectangular holes in a contacting way; the lower ends of the rectangular plates are matched with the bottom parts in the corresponding rectangular holes in a contacting way; the right end of each rectangular plate is fixedly connected with the right side in the corresponding rectangular hole through a first electric telescopic rod; and each rectangular plate can move back and forth along a length direction of the corresponding rectangular hole. Through a simple mechanical design, the meat food preservation device during cold-chain logistics provided by the invention can be used for automatically simply packing preservative films on meat food, and workers only need to simply treat two non-tightly packed end parts of the simply packed meat food, so that being assisted by the meat food preservation device provided by the invention, the workers can effectively improve preservative film packing speed for the meat food, and a preservative film packing part can move along with the vehicle body.

Owner:CHONGQING IND POLYTECHNIC COLLEGE

Dual measuring hopper type automatic valve port packaging machine

PendingCN106143963AHigh automation and packaging precisionWide range of adaptationSolid materialEngineeringFilling rate

The invention relates to a dual measuring hopper type automatic valve port packaging machine. The dual measuring hopper type automatic valve port packaging machine comprises a controller, a feeder, a measuring hopper, a discharging conical hopper and a discharge device, wherein the feeder, the measuring hopper, the discharging conical hopper and the discharge device are sequentially arranged from top to bottom. A vibration device is arranged below the discharge device. A weight sensor is connected to the measuring hopper. The discharge device is connected with a discharging weight sensor. Metering of fed materials and discharged materials is achieved through the weight sensor at the measuring hopper and the discharging weight sensor at the discharge device; meanwhile, when materials are metered in the measuring hopper, the set weight is slightly larger than the required final packaging weight, when the materials enter a packaging bag through a discharge opening to be fed and metered, the set weight is consistent with the required final packaging weight, and by means of the setting, the overall packaging stability and the packaging speed can be increased; and by means of the vibration device, air between the materials is reduced, material accumulation is avoided, the compactness of the materials is increased, and the filling rate is increased.

Owner:JIANGSU INNOVATIVE PACKAGING TECH CO LTD

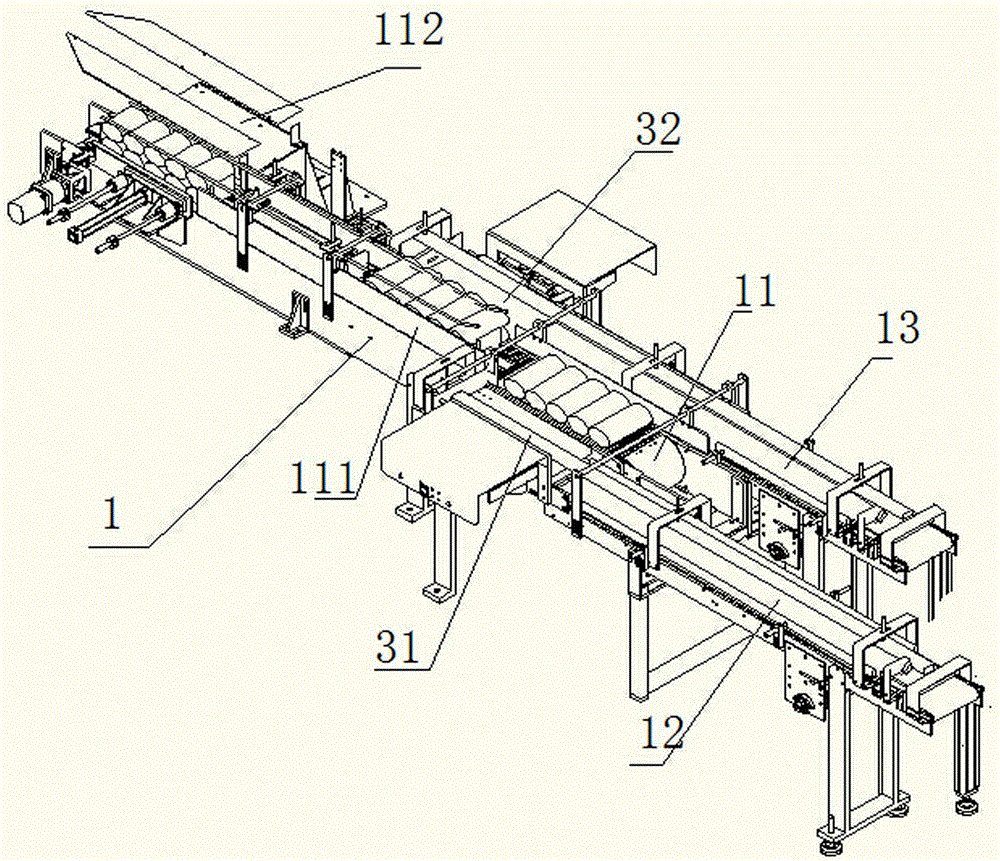

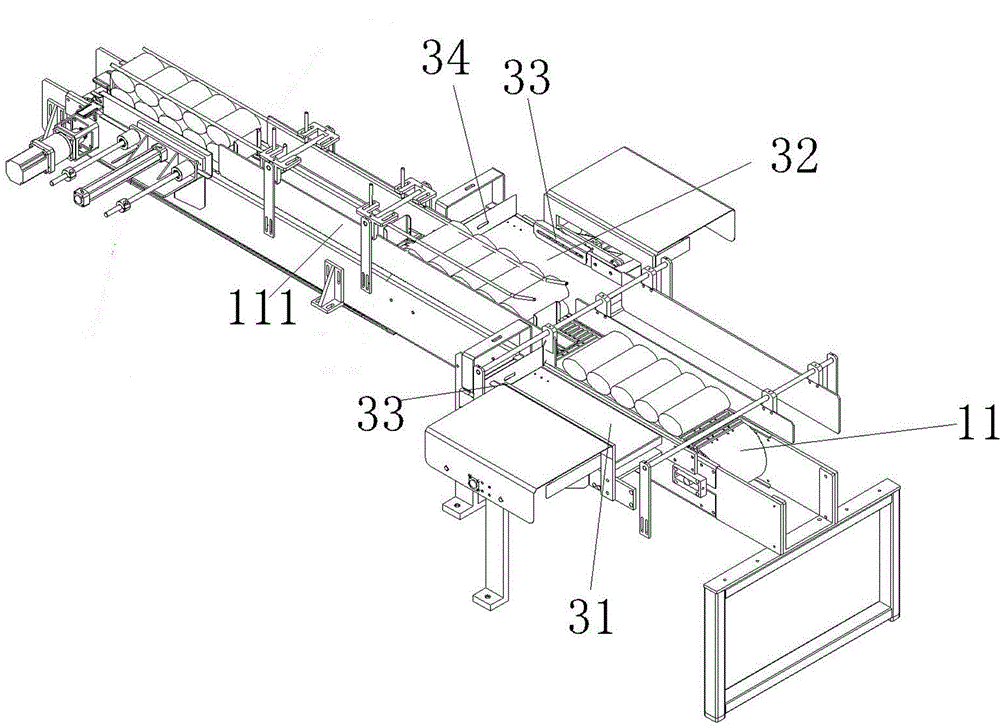

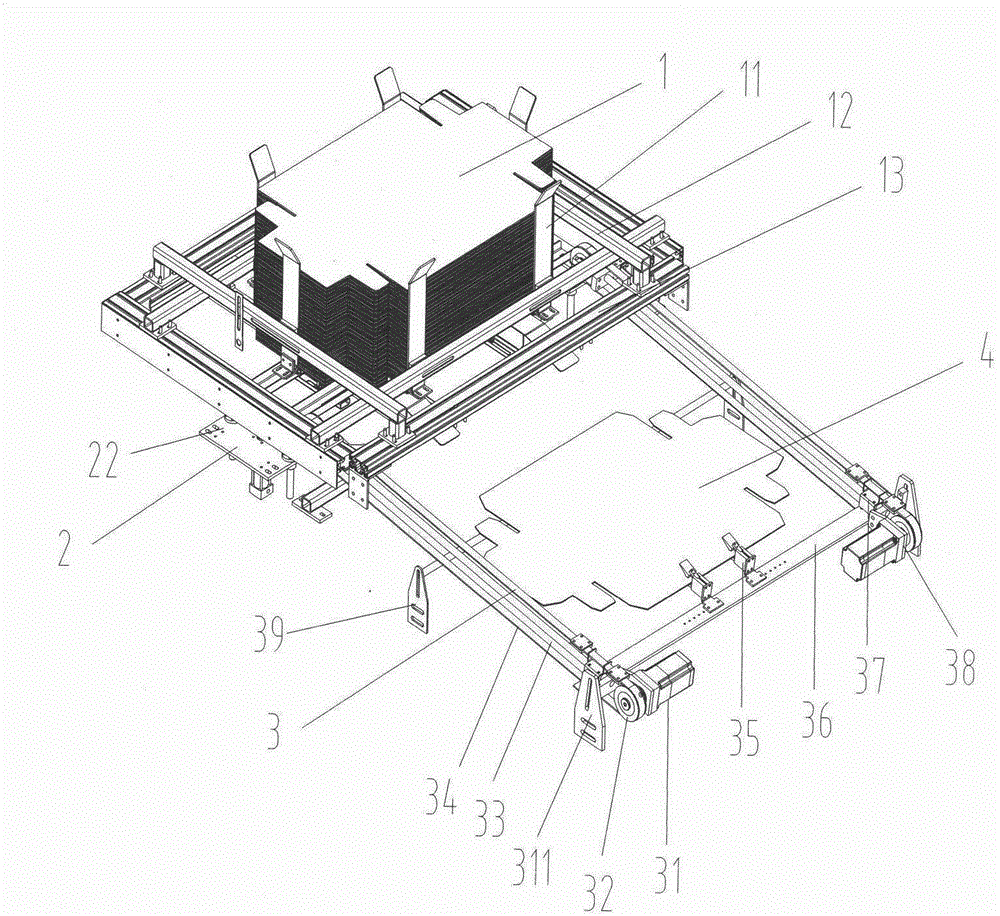

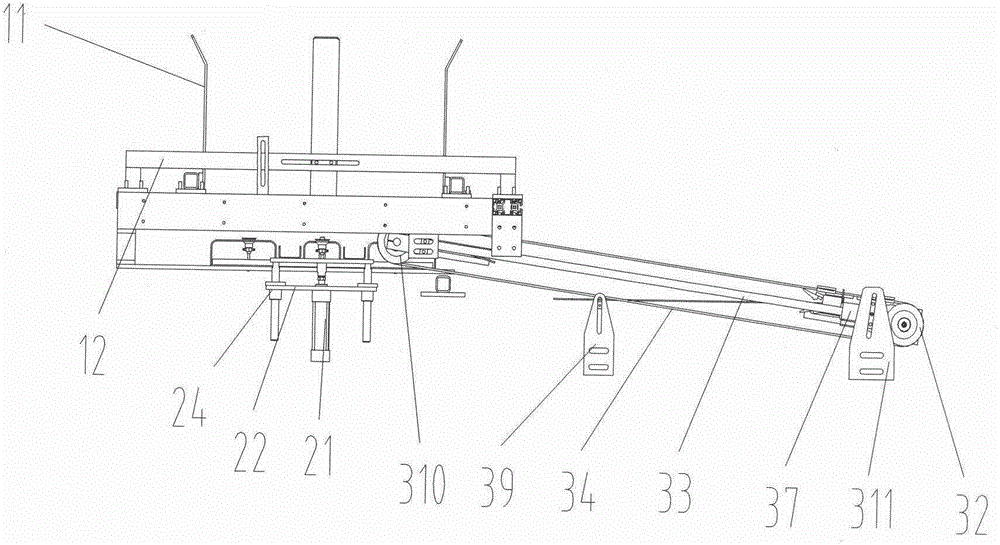

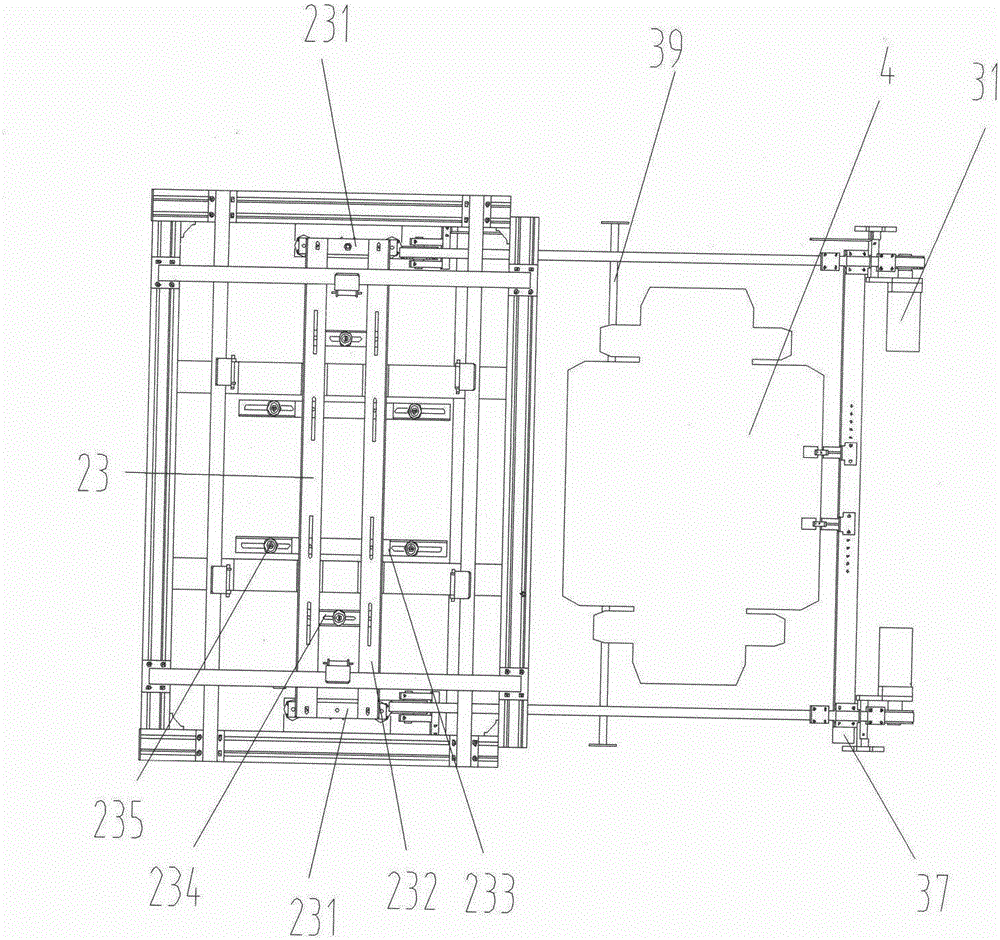

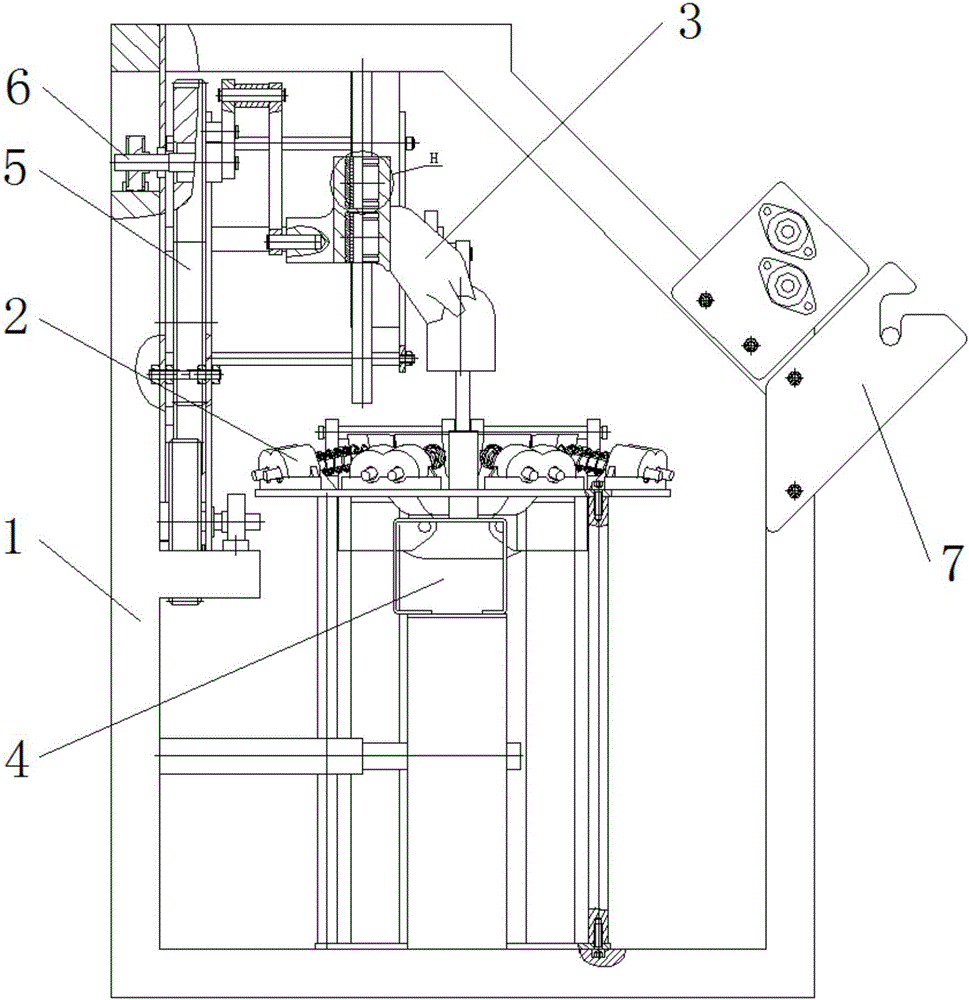

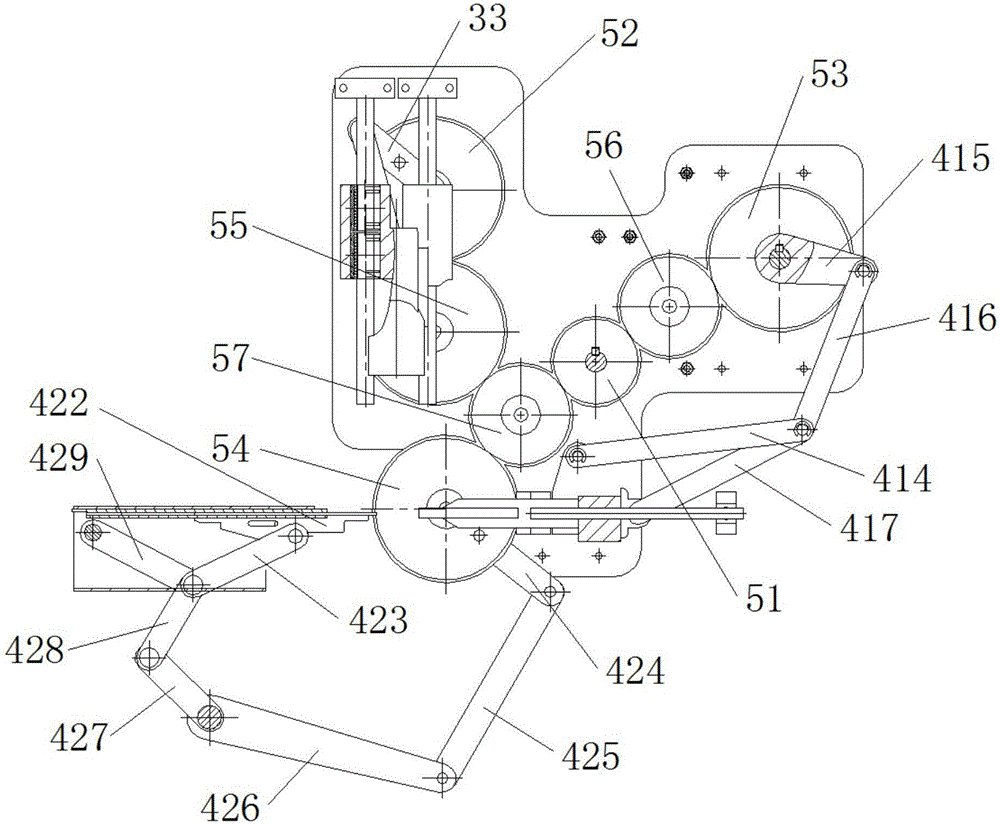

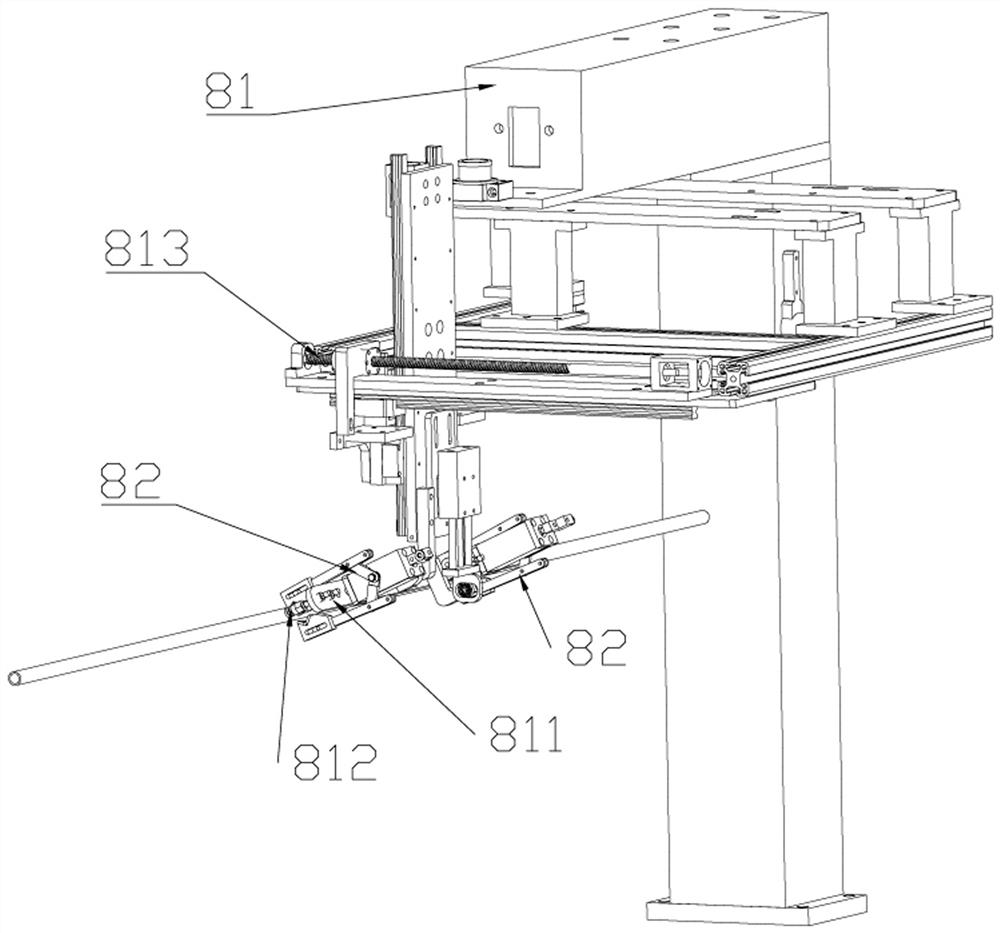

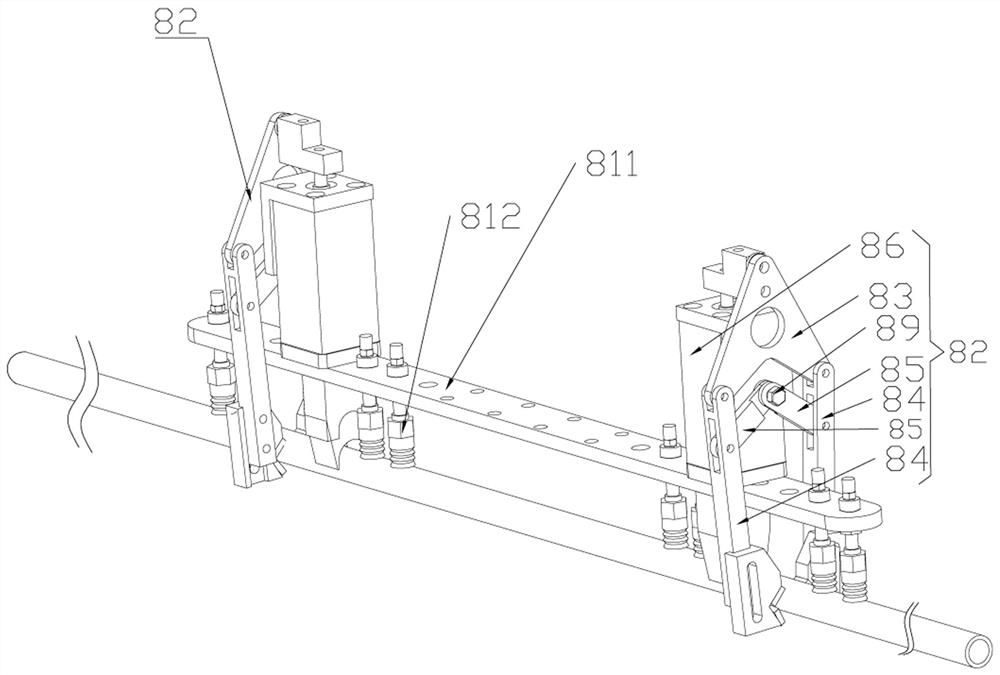

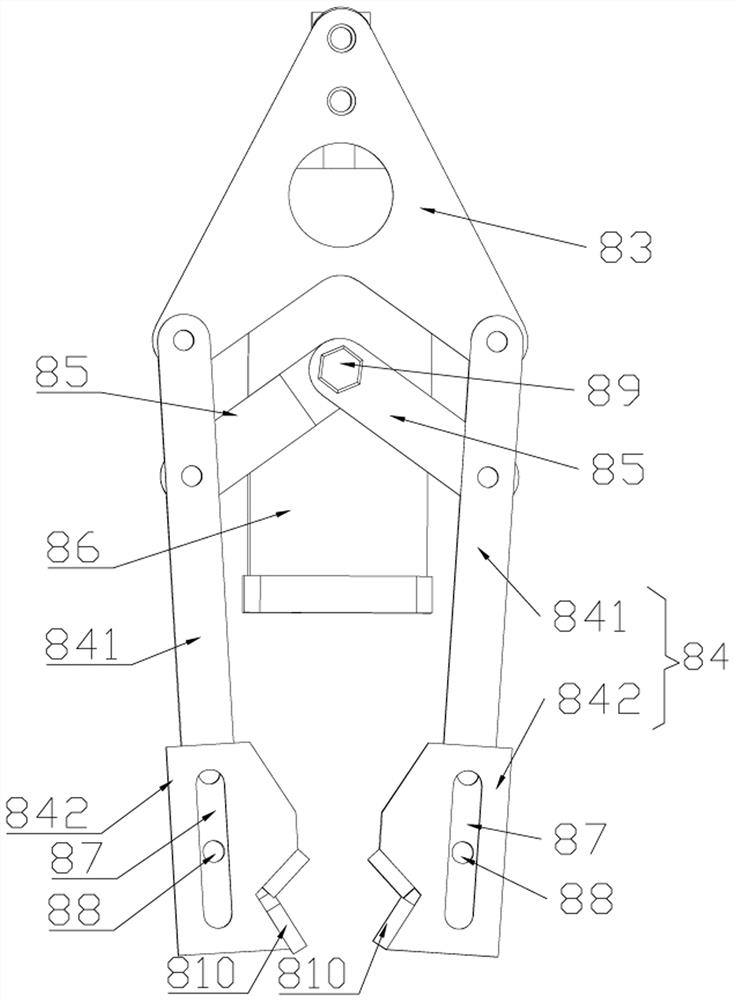

Fast paper box fetching mechanism for ceramic tile packaging line

The invention provides a fast paper box fetching mechanism for a ceramic tile packaging line. The fast paper box fetching mechanism comprises a paper box bin assembly (1), a paper box suction assembly (2) and a paper clamping and pulling assembly (3), wherein the paper box bin assembly (1) is installed at the upper part of a rack and arranged just above a transportation line; the paper box suction assembly (2) is arranged at the middle part between the paper box bin assembly (1) and the transportation line and is connected with the rack; the paper clamping and pulling assembly (3) is arranged just above the transportation line and behind the paper box bin assembly (1), is inclined downwards in an inclining manner and is connected with the rack. The invention provides a mechanism with capabilities of online storing a cardboard box, automatically sucking the cardboard box, and rapidly and accurately clamping and transferring the cardboard box to a packaging waiting position for the ceramic tile packaging line, thus the packaging speed of the ceramic tile packaging production line is increased, and the packaging effect is improved.

Owner:GUANGDONG SINID TECH

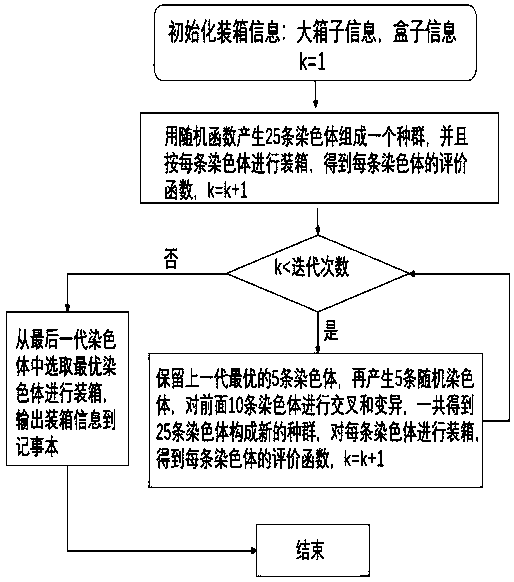

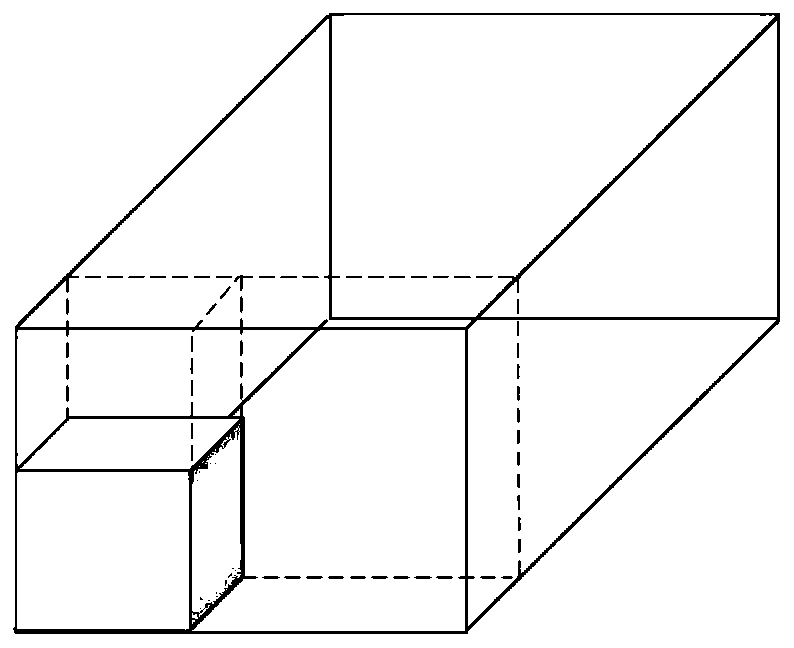

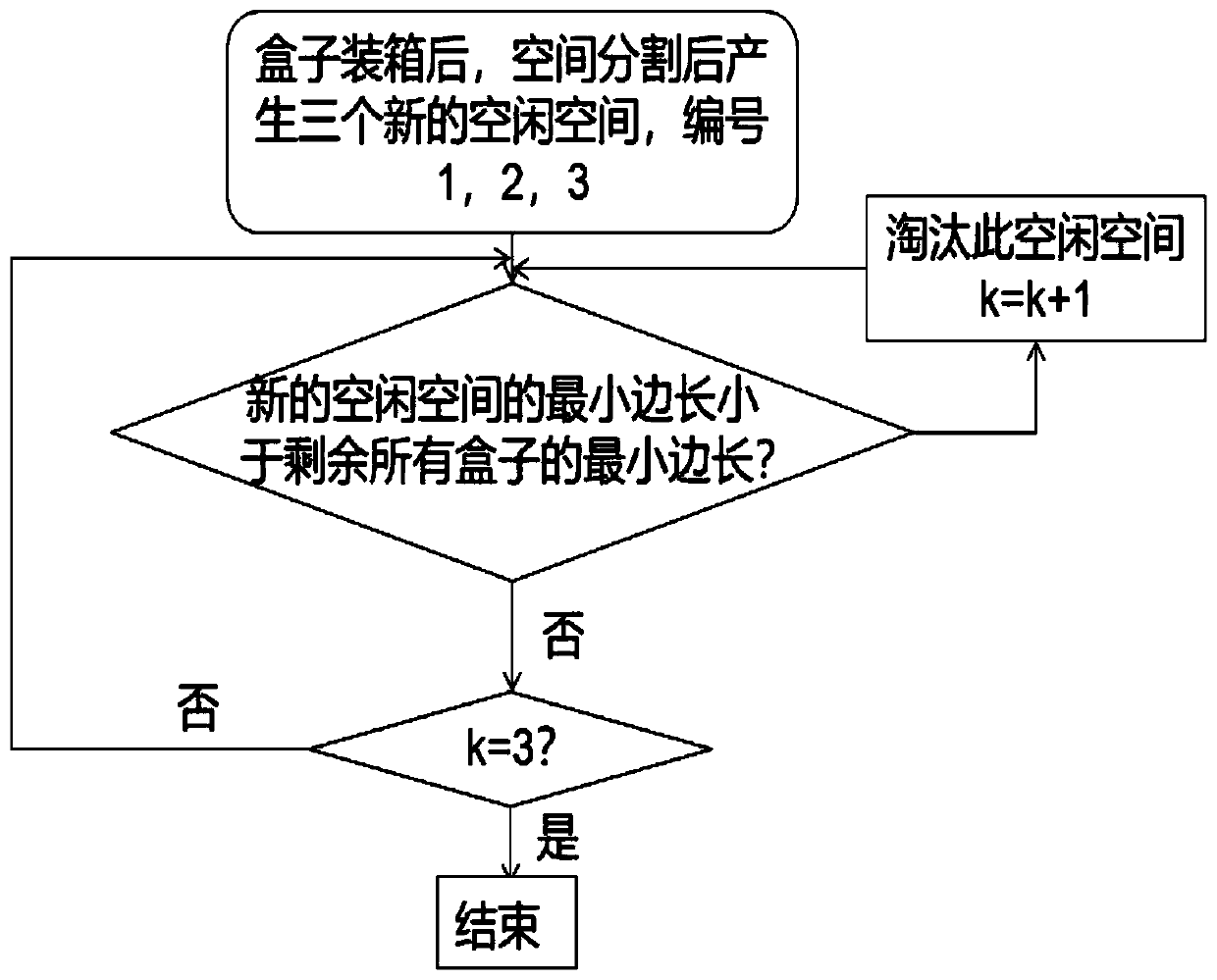

Boxing method based on genetic algorithm

InactiveCN110490371AImprove computing efficiencyPacking speed is fastForecastingLogisticsData informationGenetic algorithm

Owner:XIAN UNIV OF TECH

Double-station measuring cup metering device

The invention discloses a double-station measuring cup metering device. The double-station measuring cup metering device comprises a bin assembly, a measuring cup assembly, a discharge tube assembly and a supporting frame assembly, wherein the bin assembly, the measuring cup assembly and the discharge tube assembly are sequentially arranged on the supporting frame assembly from top to bottom; the output end of the storage bin assembly is in butt-jointed with the input end of the measuring cup assembly; the output end of the measuring cup assembly is connected with the input end of the discharge tube assembly; two discharge openings are formed in the measuring cup assembly; the discharge tube assembly comprises two discharge tubes; upper ends of the two discharge tubes are respectively butt-jointed with the two discharge openings of the measuring cup assembly in the; and a pneumatic gate valve is arranged at the lower end of each of the discharge tubes. Through the adoption of the double-station measuring cup metering device, the packaging speed is increased by one time, and accurate control of the discharge time is effectively improved, so that the packaging efficiency is improved by adopting the same manufacture cost.

Owner:WUHAN RENTIAN PACKAGING TECH

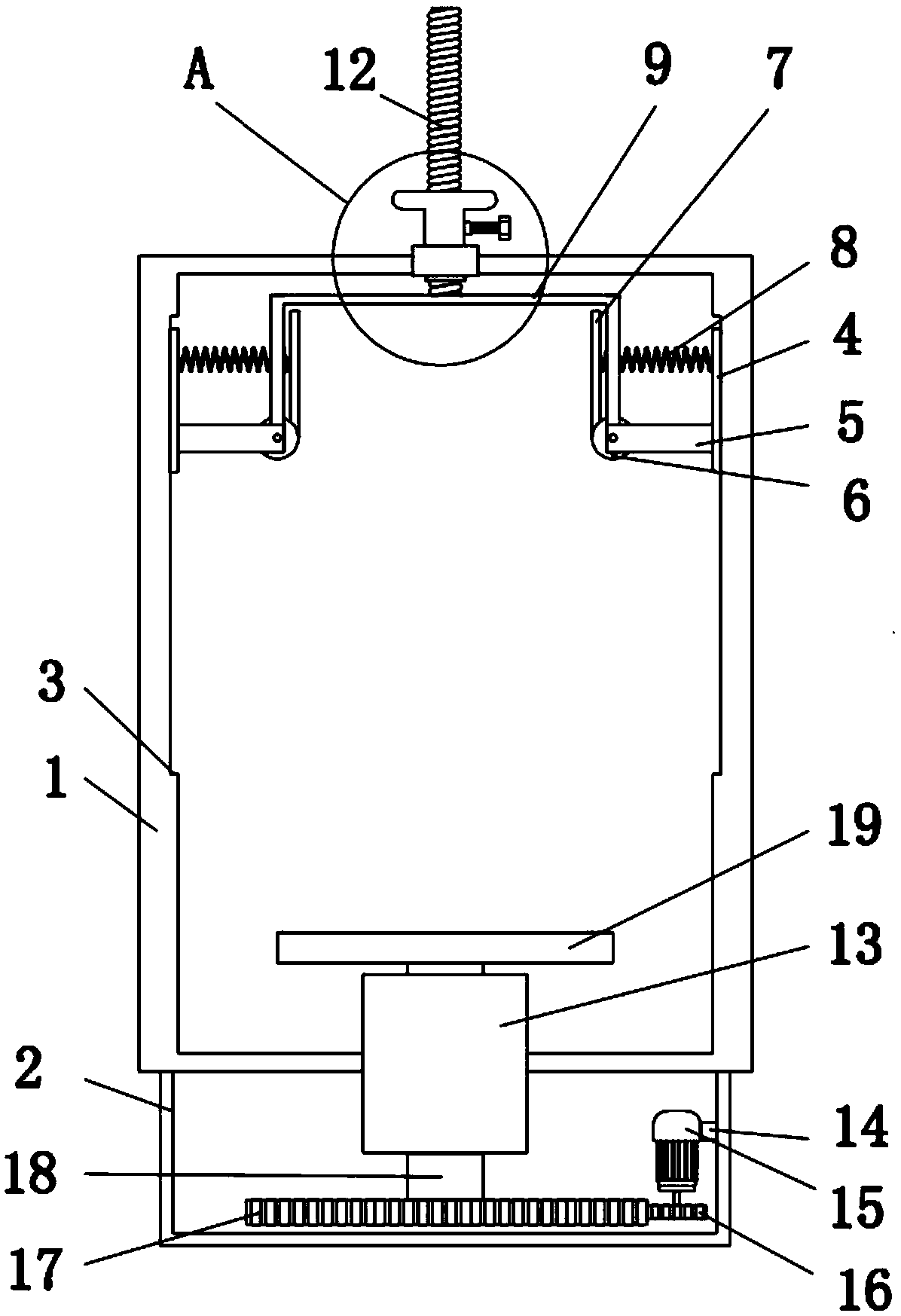

Robot for packaging production

The invention provides a robot for packaging production and relates to the technical field of machines. The robot for packaging production comprises a main box body and an auxiliary box body; slidinggrooves are formed in the two sides of the inner wall of the main box body; a sliding block is arranged in the sliding grooves; the bottom end of the sliding block is fixedly provided with a connection block and a spring; the connection block is movably connected with a roller shaft and fixedly provided with a U-shaped connection rod; a pressing plate is fixedly installed on the roller shaft; a screw rod is fixedly installed at the top end of the U-shaped connection rod; a rotary screw sleeve is arranged at the top end of the main box body, and a second bearing is fixedly installed at the bottom end of the main box body; the top end of a rotary shaft is fixedly provided with a rotary table; a motor support is fixedly installed on the inner wall of the auxiliary box body; and a rotary tablemotor is fixedly installed on the motor support. The robot for packaging production has high controllability and a high degree of automation, the number of packaging varieties is high, the robot canbe operated automatically, and the packaging speed and working benefits are improved.

Owner:杨程

Fruit packing machine

InactiveCN106347743ASimple structureEasy to useWrappingWrapper twisting/gatheringSelf adaptivePlastic packaging

The invention discloses a fruit packing machine. The fruit packing machine mainly consists of a push-pressing mechanism, a carrier table, an opening sealing mechanism and a driving mechanism, wherein plastic packaging paper is delivered to the carrier table, and then fruits and the plastic packaging paper are pressed into the self-adaptive carrier table by utilizing the push-pressing mechanism. When fruit package is completed, then the push-pressing mechanism rises, meanwhile opening sealing work is executed by utilizing the opening sealing mechanism to complete package, and the power of the whole machine is transmitted through a one-end-input and multi-end-output parallel connection shunting drive mechanism. The fruit packing machine is simple in whole structure and high in automation degree, the fruit packaging efficiency and packaging quality are greatly improved, and the labor costs are reduced.

Owner:CHONGQING UNIV

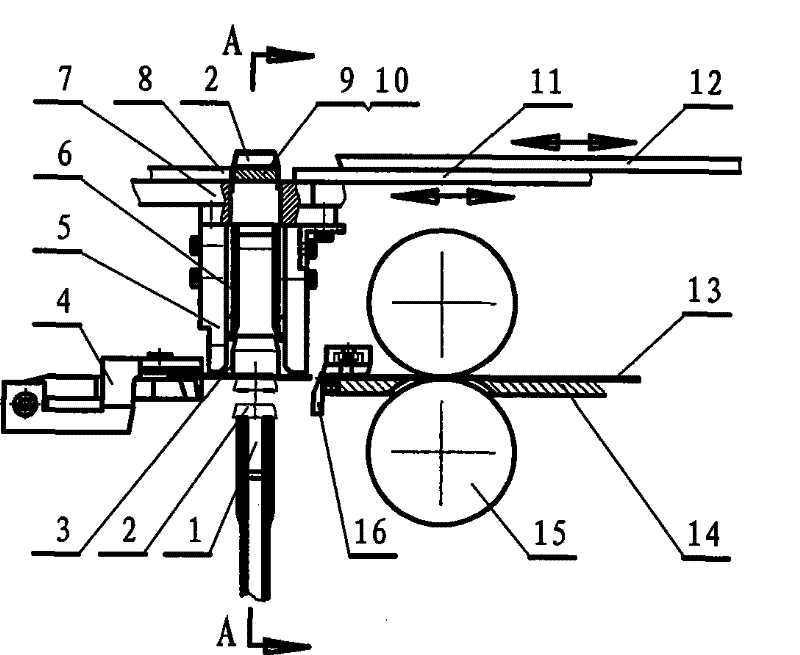

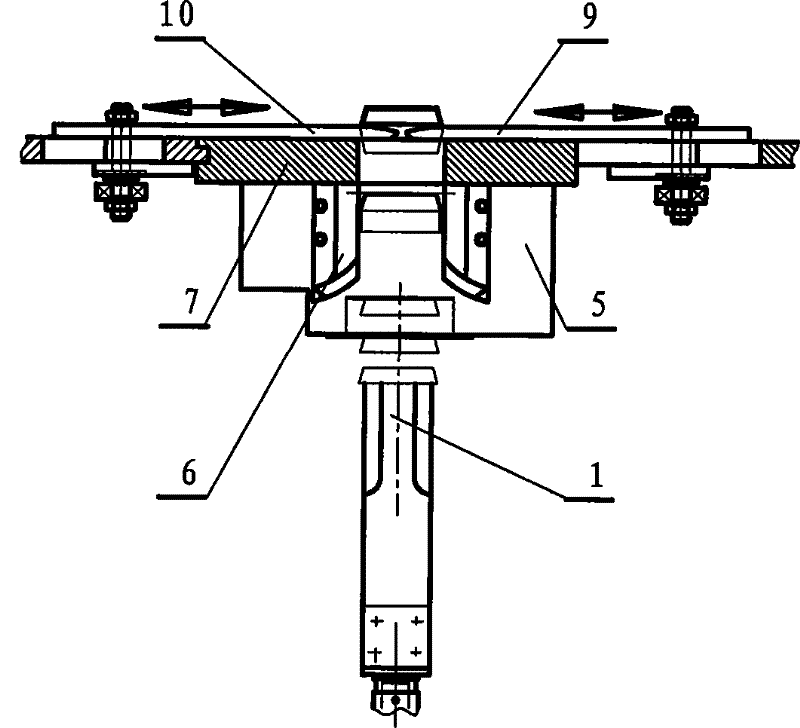

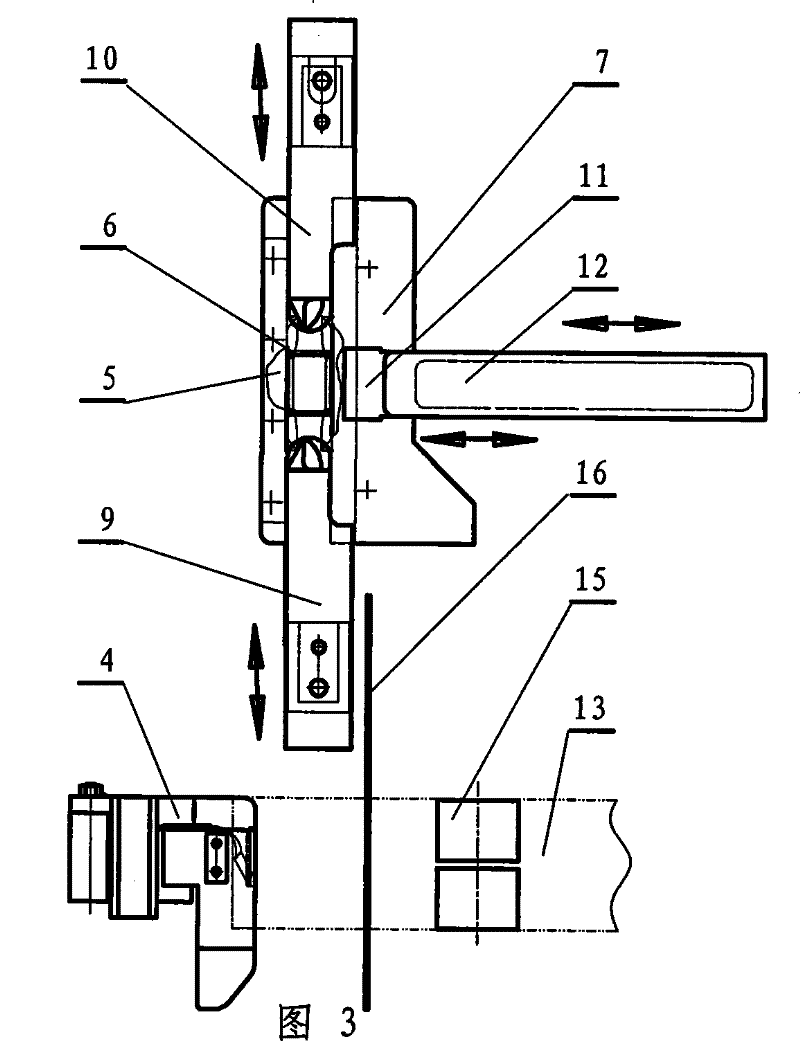

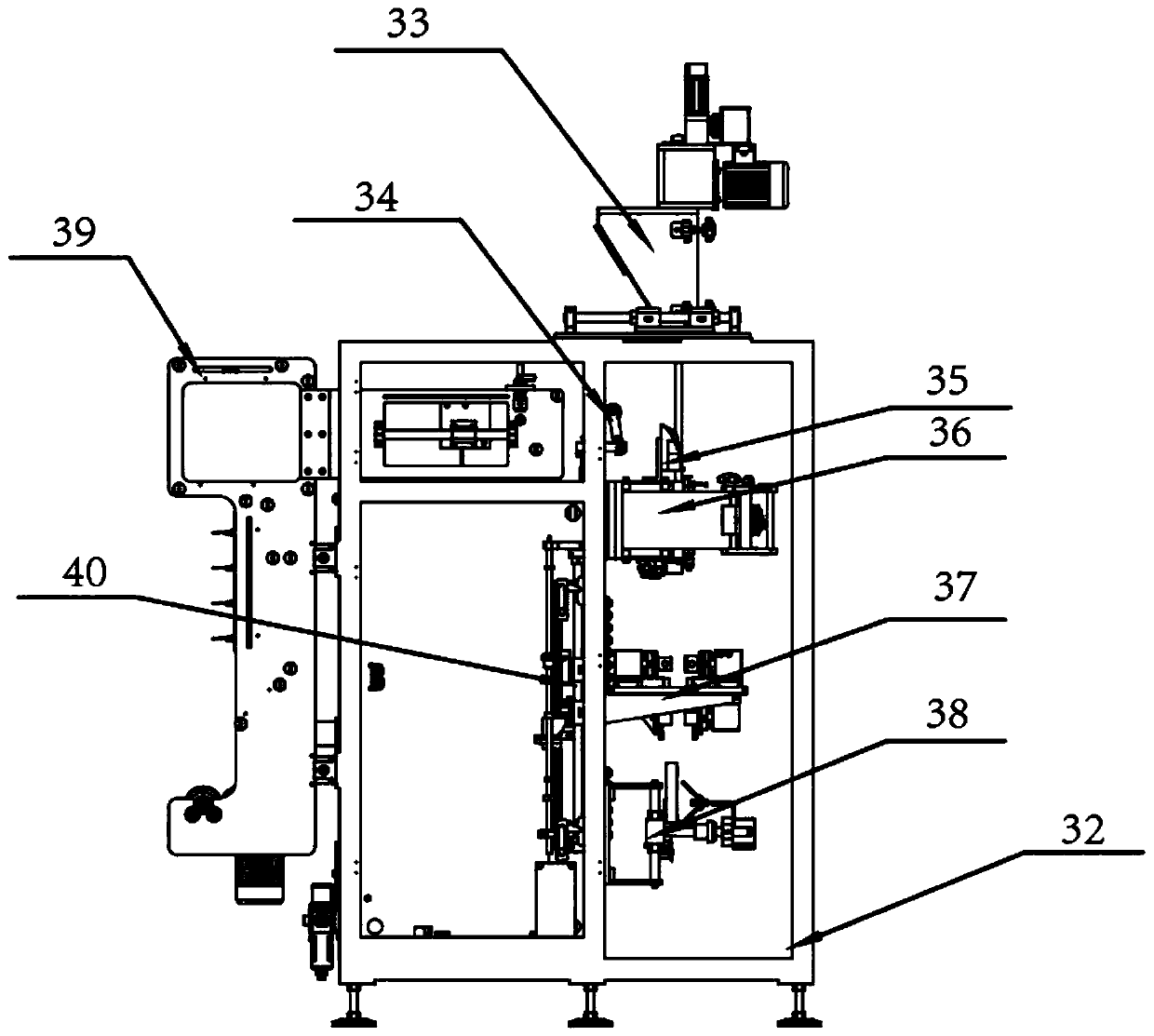

Candy bar folding packing machine

InactiveCN101559842BPacking speed is fastIncrease productivityWrapping material feeding apparatusConveyor wrappingEngineeringMechanical engineering

The invention discloses a candy bar folding packing machine which comprises a machine body, a paper-feeding roller and a paper-clamping clip. The paper-feeding roller and the paper-clamping clip are arranged on the machine body and correspond to each other; the machine body is also provided with a pair of folding box side plates arranged in parallel, the top surfaces of the two folding box side plates are fixedly connected with a folding box top plate, and two packing paper edge folding guide strips are fixedly mounted on the inner side surface of either folding box side plate; a left foldingedge rod and a right folding edge rod with left-and-right reciprocating sliding capabilities are arranged on the top of the folding box top plate in opposite directions; the top of the folding box topplate is also provided with a fixedly mounted discharge baffle and a front folding edge rod with the fore-and-aft reciprocating sliding capability, and a rear folding edge rod with the fore-and-aft reciprocating sliding capability is stacked on the front folding edge rod; and feeding claws with the up-and-down reciprocating sliding capability are respectively arranged at the lower parts of the folding box side plates. The packing machine not only realizes the regular hexahedral package of candies, but also has reasonable structure and high production efficiency.

Owner:江苏海特尔机械有限公司

Multi-row packaging machine

PendingCN110451034AReduce manufacturing costReasonable structural designWrapper twisting/gatheringEngineeringPackaging machine

The invention discloses a multi-row packaging machine. The multi-row packaging machine is characterized by comprising a frame, a feeding mechanism, a paper holding mechanism, a longitudinal sealing mechanism, a transverse sealing mechanism, a film pulling mechanism, a transverse cutting mechanism and a control mechanism, wherein the feeding mechanism is arranged at the top of the frame, the paperholding mechanism is arranged on one side of the frame, the longitudinal sealing mechanism is arranged inside the frame and on the lower portion of the feeding mechanism, and the control mechanism iselectrically connected with the feeding mechanism, the paper holding mechanism, the longitudinal sealing mechanism, the transverse sealing mechanism, the film pulling mechanism and the transverse cutting mechanism. The multi-row packaging machine can automatically and continuously complete multi-row automatic packaging, is reasonable in structural design and wide in adaptability, and improves production efficiency and packaging speed.

Owner:天津市永创伟业包装机械有限公司

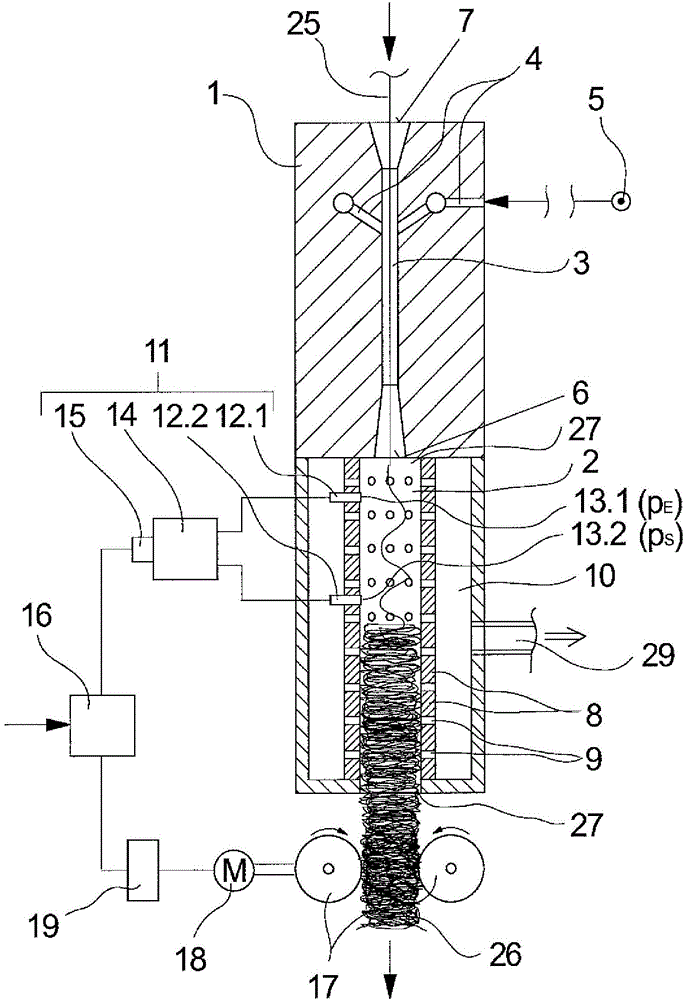

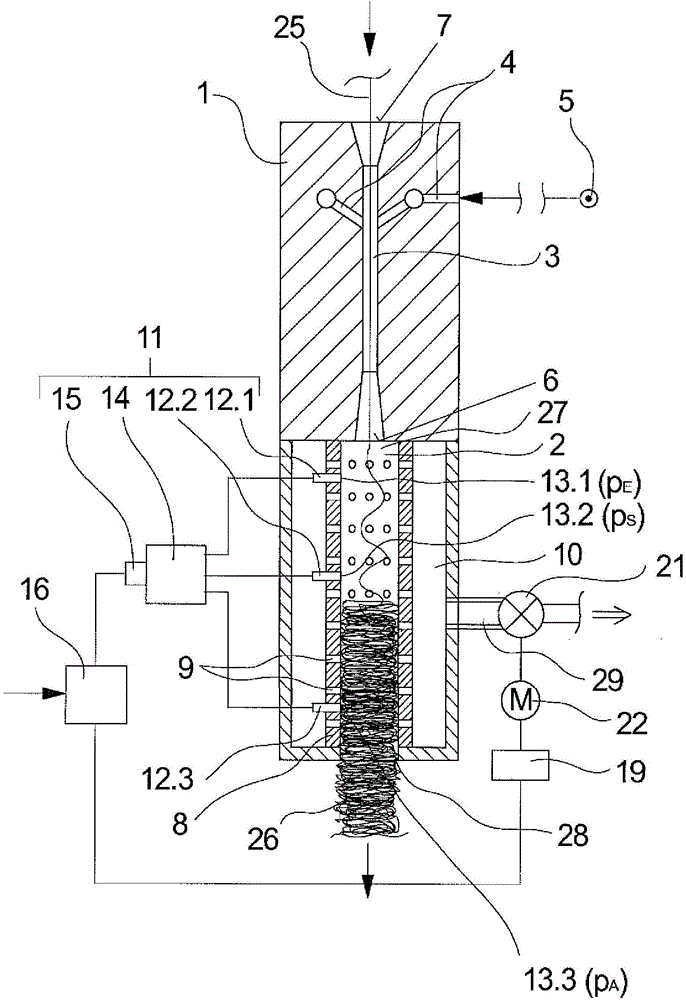

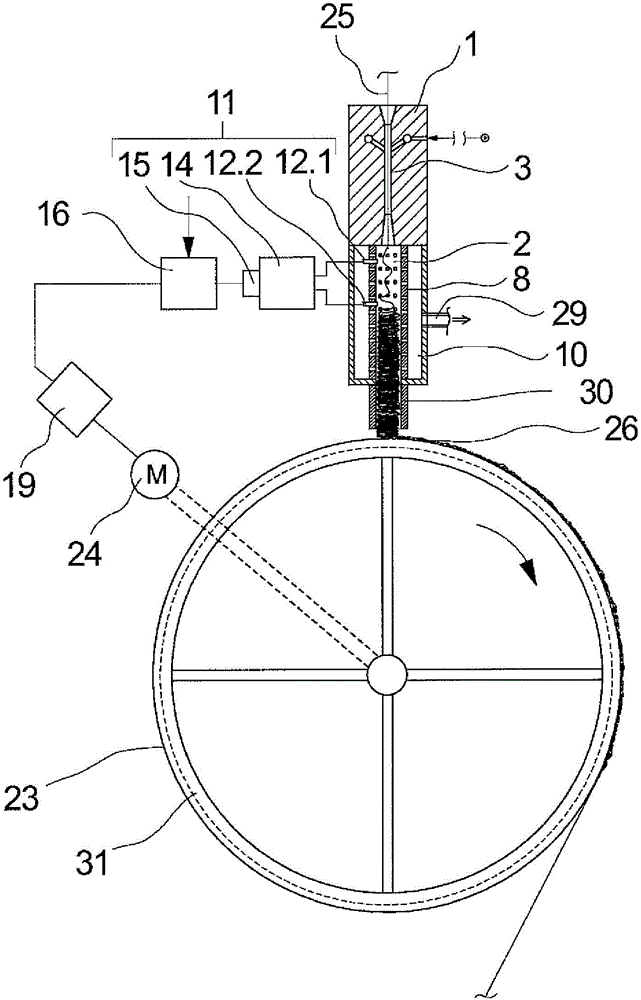

Method and device for crimping a multifilament thread

InactiveCN104040053AOptimal Process AdjustmentDetermine the degree of fillingTextiles and paperFiberMeasurement point

A method and a device for crimping a multifilament thread are described. The thread is blown by means of a transport nozzle through a compressed air stream guided in a thread channel into a gas-permeable compression chamber. Inside the compression chamber, the thread is compressed to form a thread plug, which is then continuously removed through an outlet of the compression chamber. The compression and the removal of the thread plug are monitored by measuring the pressure of the compressed air stream. According to the invention, a plurality of pressures of the compressed air stream in the compression chamber are measured at a plurality of measurement points distributed over the length of the compression chamber for monitoring the thread plug formation in order to perform the compressing and cooling of the thread plug with a uniform filling of the compression chamber.

Owner:OERLIKON TEXTILE GMBH & CO KG

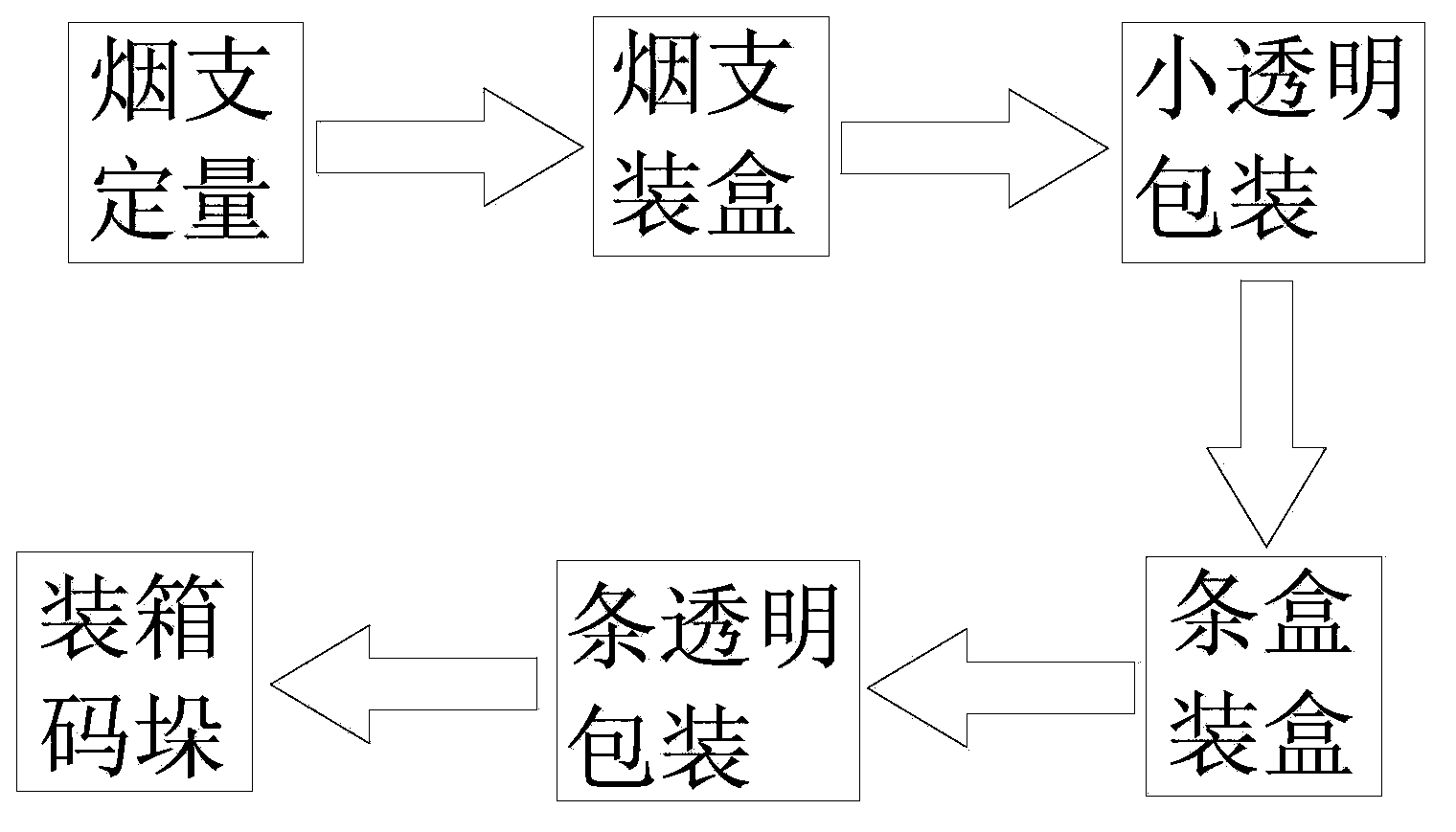

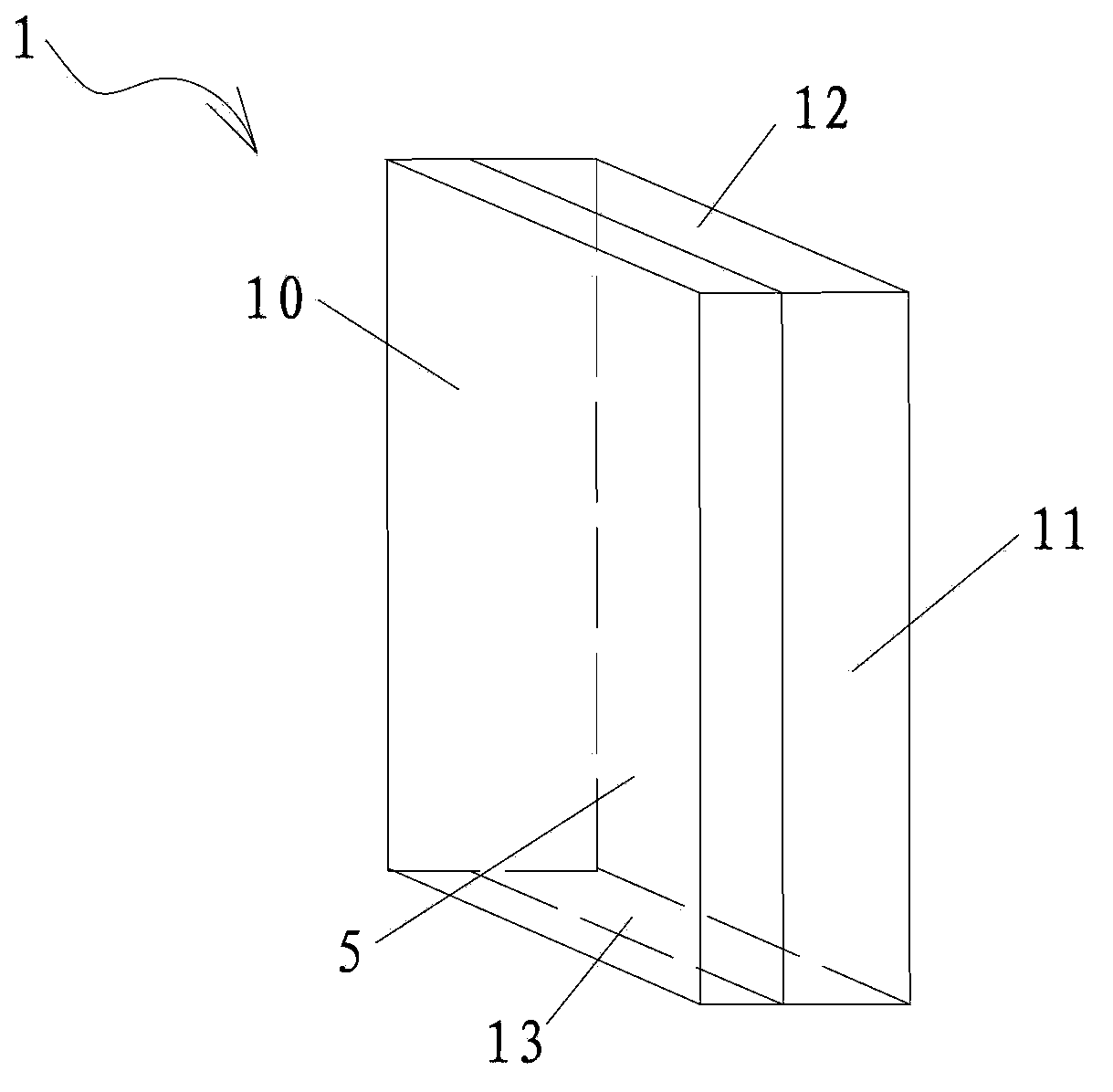

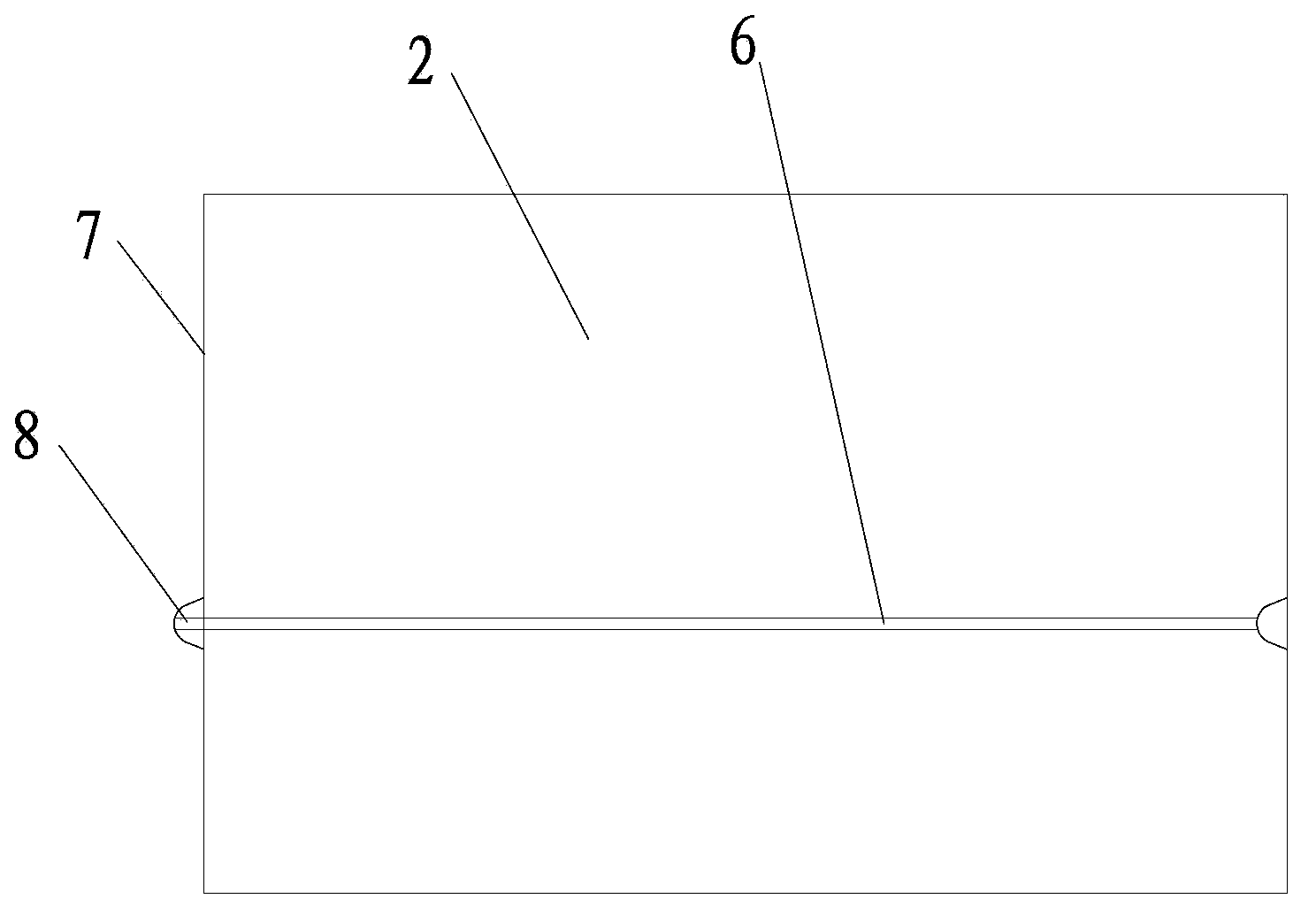

Method for packing cigarettes in side-open cases

ActiveCN103895893AQuality assurancePacking speed is fastContainers for flexible articlesPackaging cigaretteCartonEngineering

The invention discloses a method for packing cigarettes in side-open cases. The method includes: 1) separating the cigarettes into groups of 20 and checking appearance quality of the cigarettes; 2) preparing cigarette cases, cutting small transparent paper for covering the outer surfaces of the cigarette cases according to the size of the cigarette cases; 3) placing the cigarette cases with openings facing upwards, loading 20 cigarettes in each cigarette case and closing cigarette case covers; 4) wrapping the cigarette cases by the small transparent paper and heat-sealing with an soldering iron; 5) preparing a carton and cutting large transparent paper for covering the outer surface of the carton according to the size of the carton; 6) loading the 10 cigarette cases finished in fabrication in the step 3) into the carton; 7) wrapping the carton by the large transparent paper and heat-sealing with the soldering iron. By the aid of the method, a norm and uniform packing standard is provided, so that quality of packed products is guaranteed, and a packing speed and a packing ratio are increased.

Owner:CHINA TOBACCO SHANDONG IND

Full-automatic ampoule bottle production system and method

PendingCN113415460AMeet the needs of automatic productionVarious methodsCharge manipulationPackaging automatic controlProcess engineeringAmpoule

The invention discloses a full-automatic ampoule bottle production system and method. The full-automatic ampoule bottle production system comprises a controller and ampoule bottle body production and detection equipment which is controlled by the controller to work, and further comprises an automatic pipe feeding machine and boxing equipment which are controlled by the controller to work; and a material pipe output port of the automatic pipe feeding machine corresponds to a material pipe input port of the ampoule bottle body production and detection equipment, and the discharging position of the ampoule bottle body production and detection equipment corresponds to the feeding position of the boxing equipment. The full-automatic ampoule bottle production method comprises the following steps of S1, feeding pipes, S2, making a bottle, and S3, boxing. A full-automatic ampoule bottle production line is formed. The Full-automatic ampoule bottle production system and method are suitable for producing ampoule bottles.

Owner:SHIJIAZHUANG LOYAL MACHINERY MFG

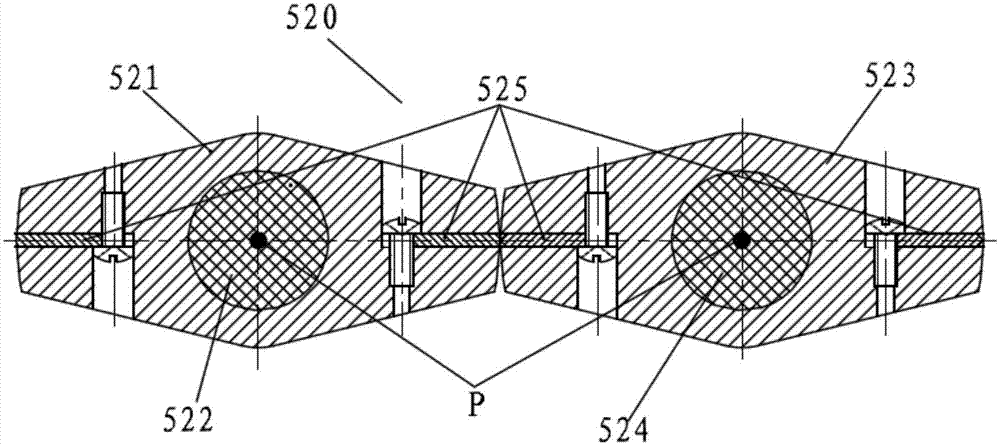

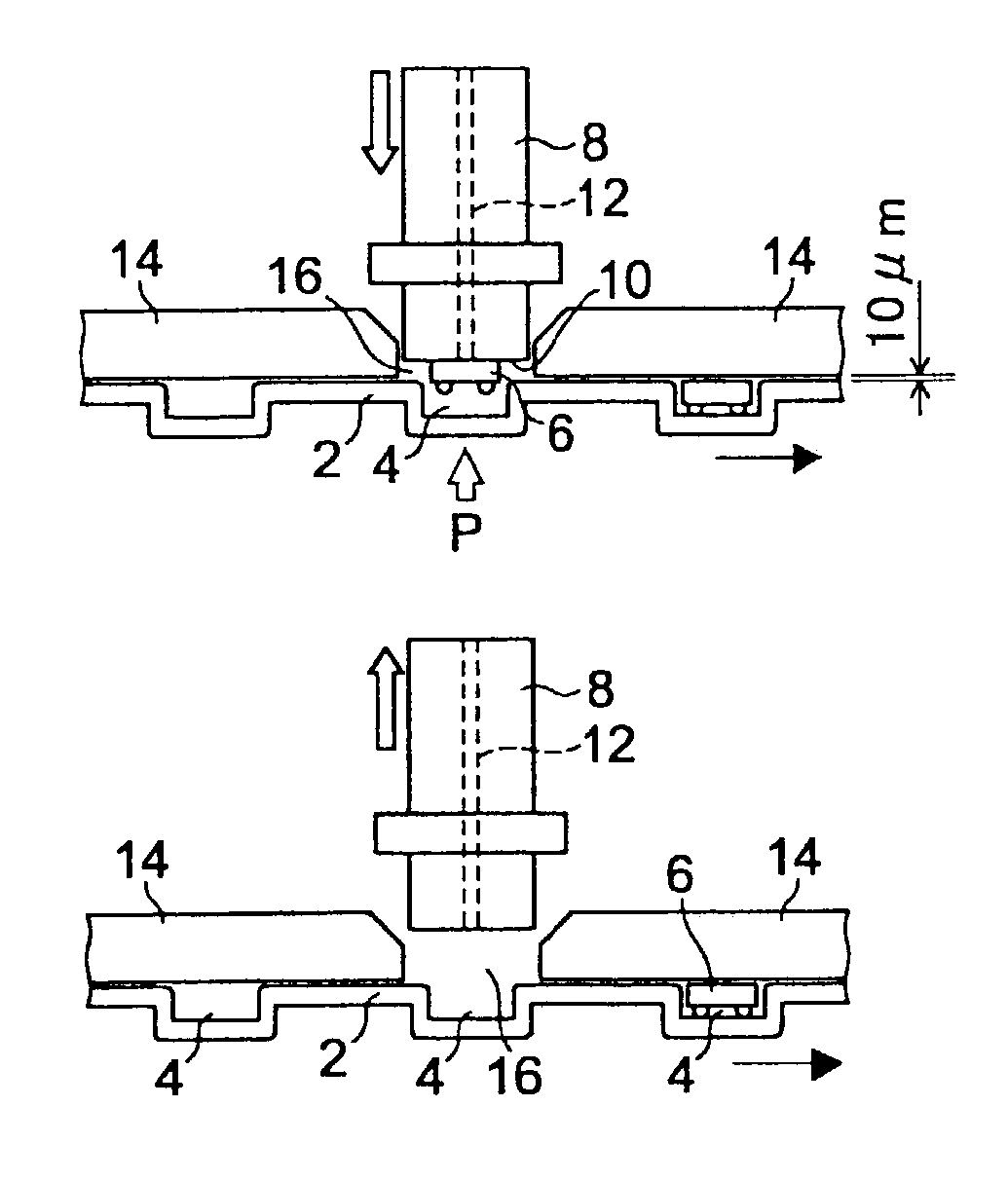

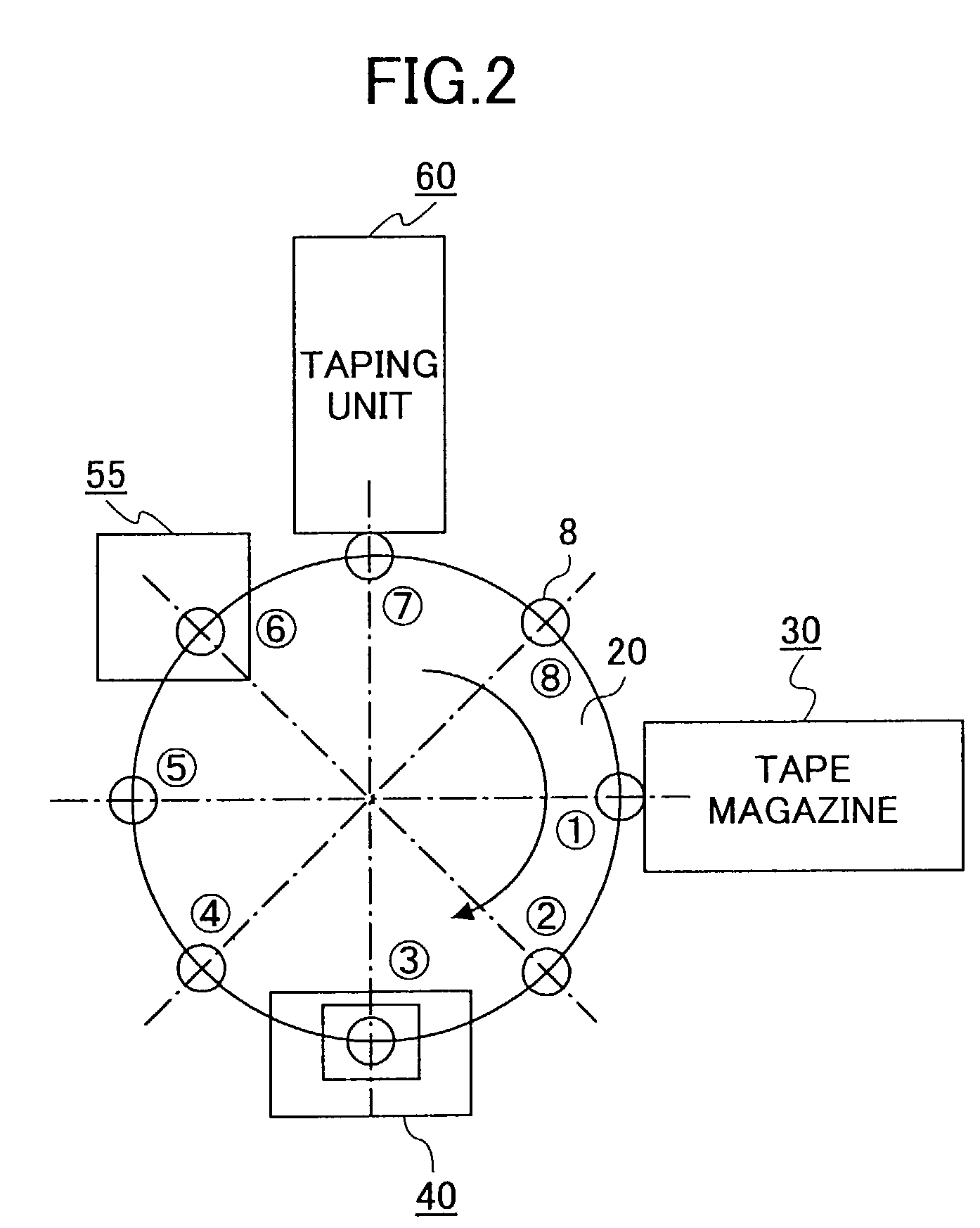

Chip-component accommodating device and examining apparatus having the same

InactiveUS7103967B2Packing speed is fastIncrease equipment costSemiconductor/solid-state device detailsSolid-state devicesEngineeringNozzle

According to the present invention, in the field of packaging the chip component, increase in speed and stability in packaging the chip component is achieved without significantly increasing the cost of the device. The size of the suction face of the suction nozzle is set so as to be larger than the relevant chip component. Near the inserting position P of the chip component, a push cover is provided in close proximity to the upper surface of the carrier tape. A hole is provided in the push cover at the inserting position P, and the size of the hole is slightly larger than the size of the tip face of the suction nozzle. After the chip component held to the suction nozzle enters the component-accommodating recess of the carrier tape, the suction of the suction nozzle is released and the carrier tape starts to move in the direction shown with an arrow, orthogonal to the suction nozzle. The suction nozzle is raised after the opening of the component-accommodating recess is completely under the push cover.

Owner:RICOH ELECTRONIC DEVICES CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com