Bag feeding type dental floss packaging machine

A packaging machine and dental floss technology, applied in the field of packaging, can solve the problems of low packaging efficiency, unhygienic human contact, unstable manual counting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

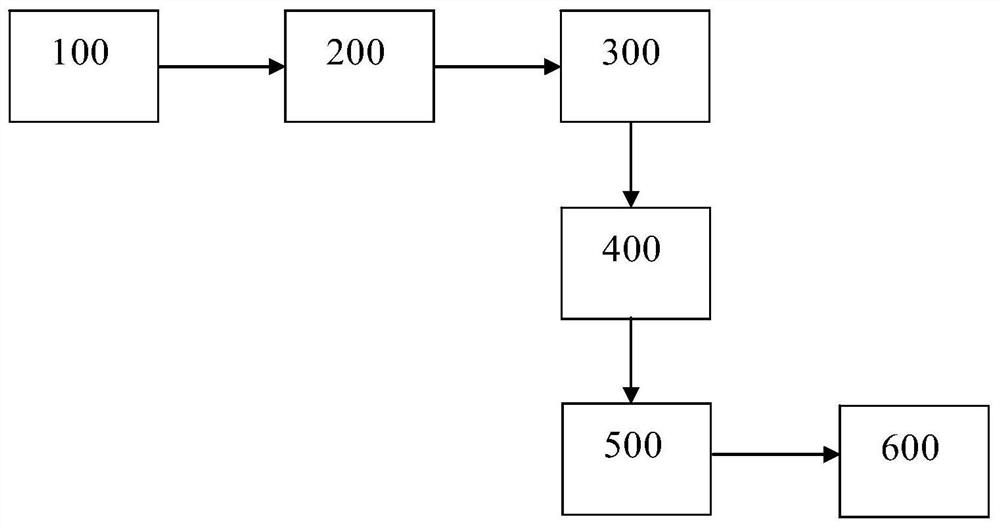

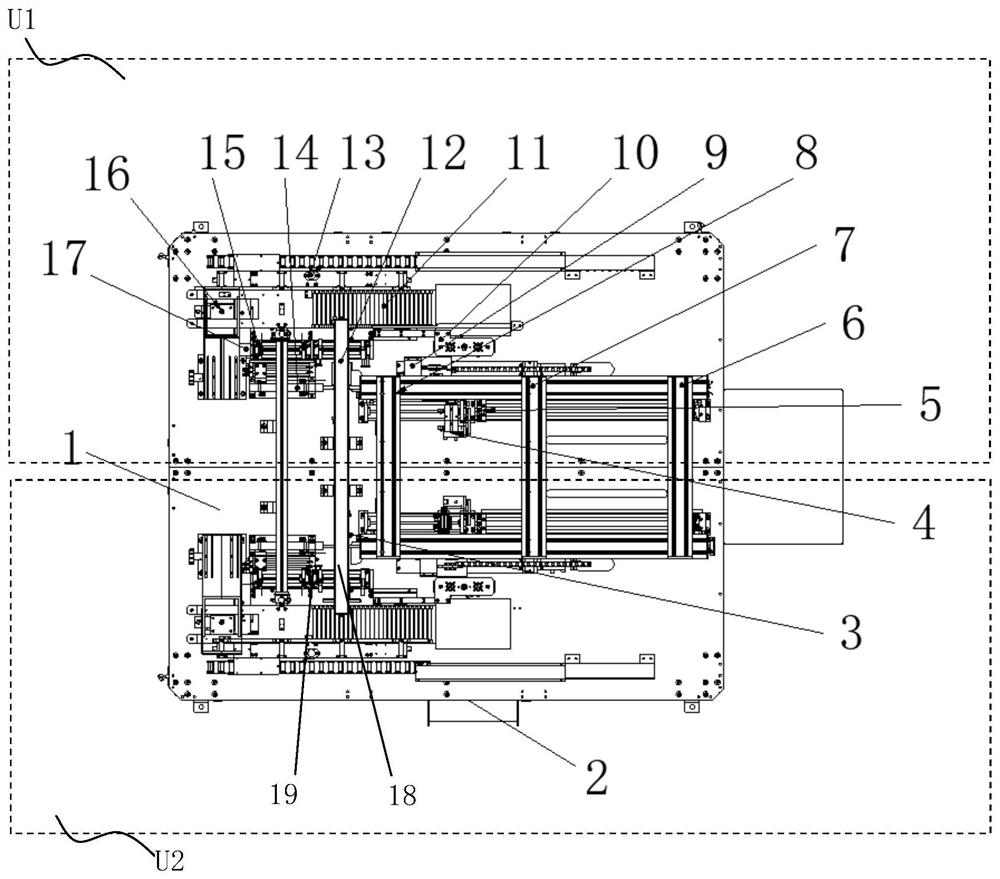

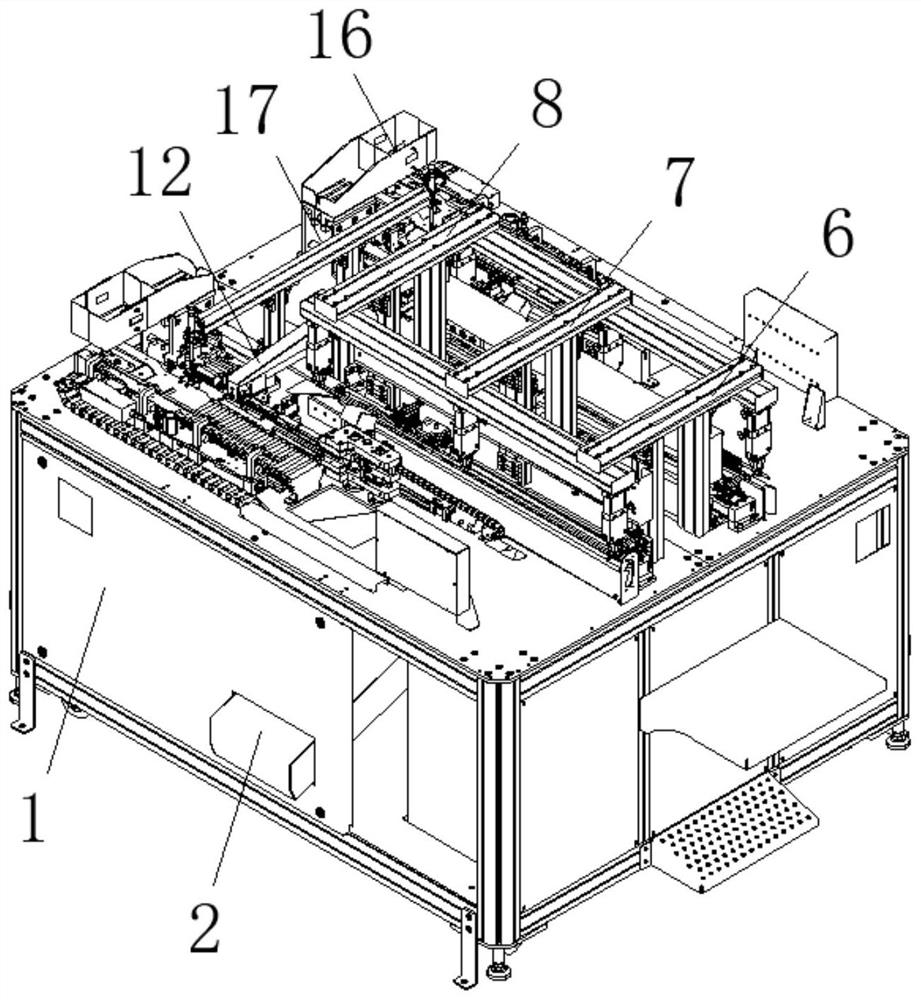

[0126] refer to figure 1 , figure 2 with image 3 , the present invention provides a bag-type dental floss packaging machine, which includes two groups of mechanisms U1 and U2 arranged symmetrically or stacked up and down, and the two groups of mechanisms U1 and U2 are used to pack a plurality of dental floss The line is sorted to contain a predetermined number of stacks of dental floss and packaged, wherein the two sets of mechanisms U1 and U2 can operate independently, including simultaneously or sequentially.

[0127] Each group of mechanisms (U1 or U2) independently includes modules such as a loading module, a sorting module, a feeding module, a receiving module, and a pushing module.

[0128] see figure 2 with 3 , the bag-feeding dental floss packaging machine of the present invention includes a packaging body 1, and the upper surface of the packaging body 1 is equipped with a clamp one 6, a clamp two 7 and a clamp three 8, and a clamp one 6, a clamp two 7 and Clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com