Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Convenient marking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

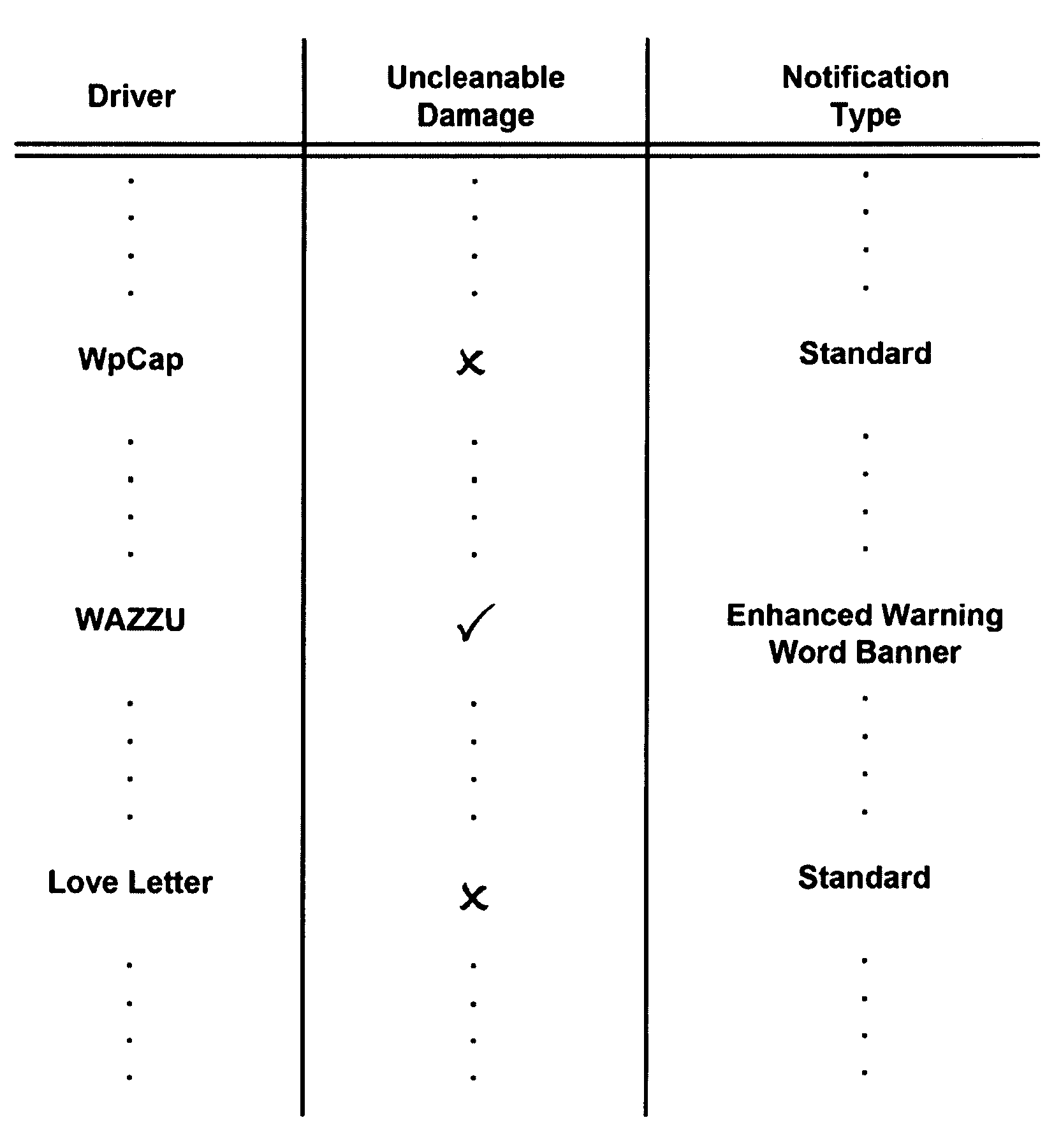

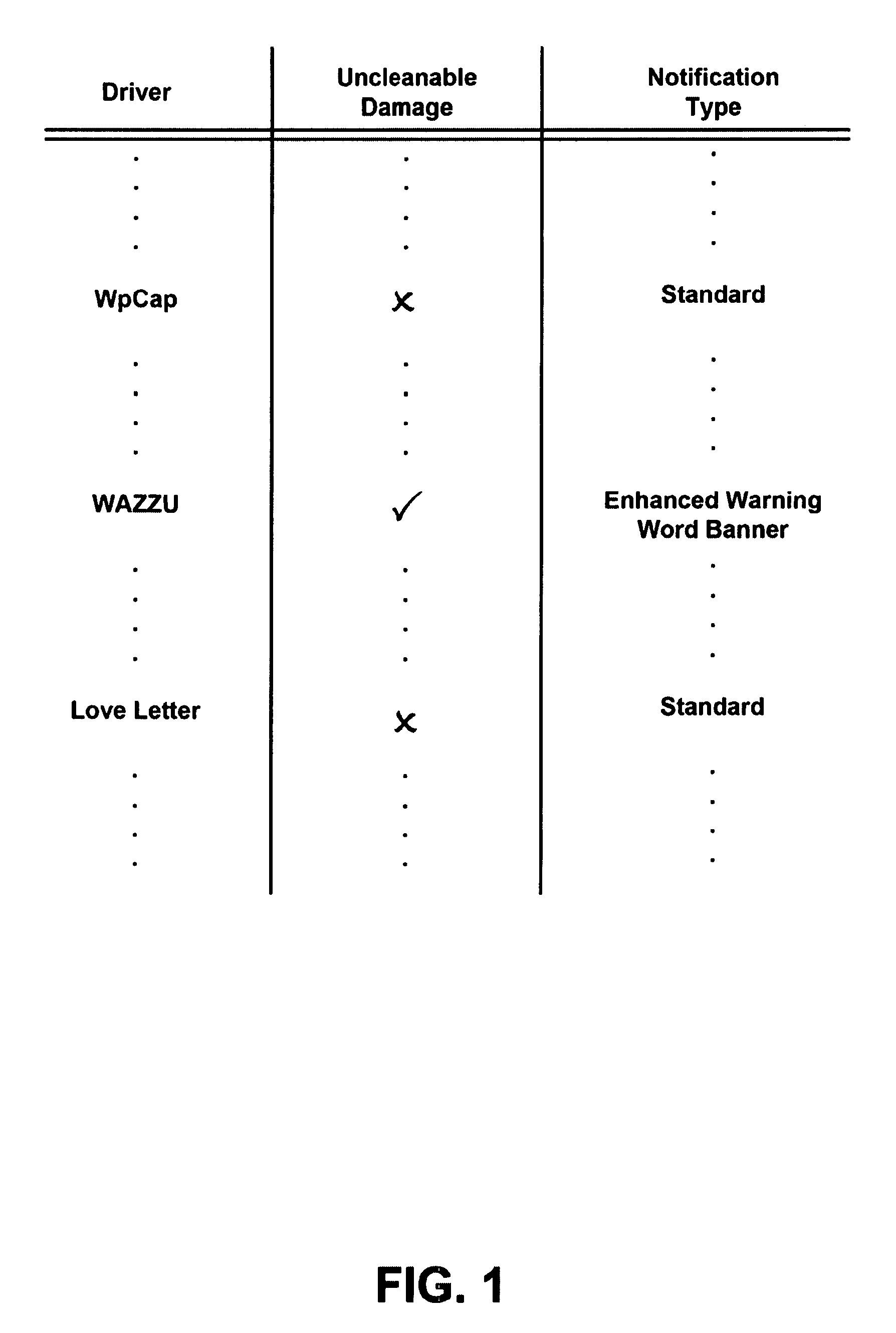

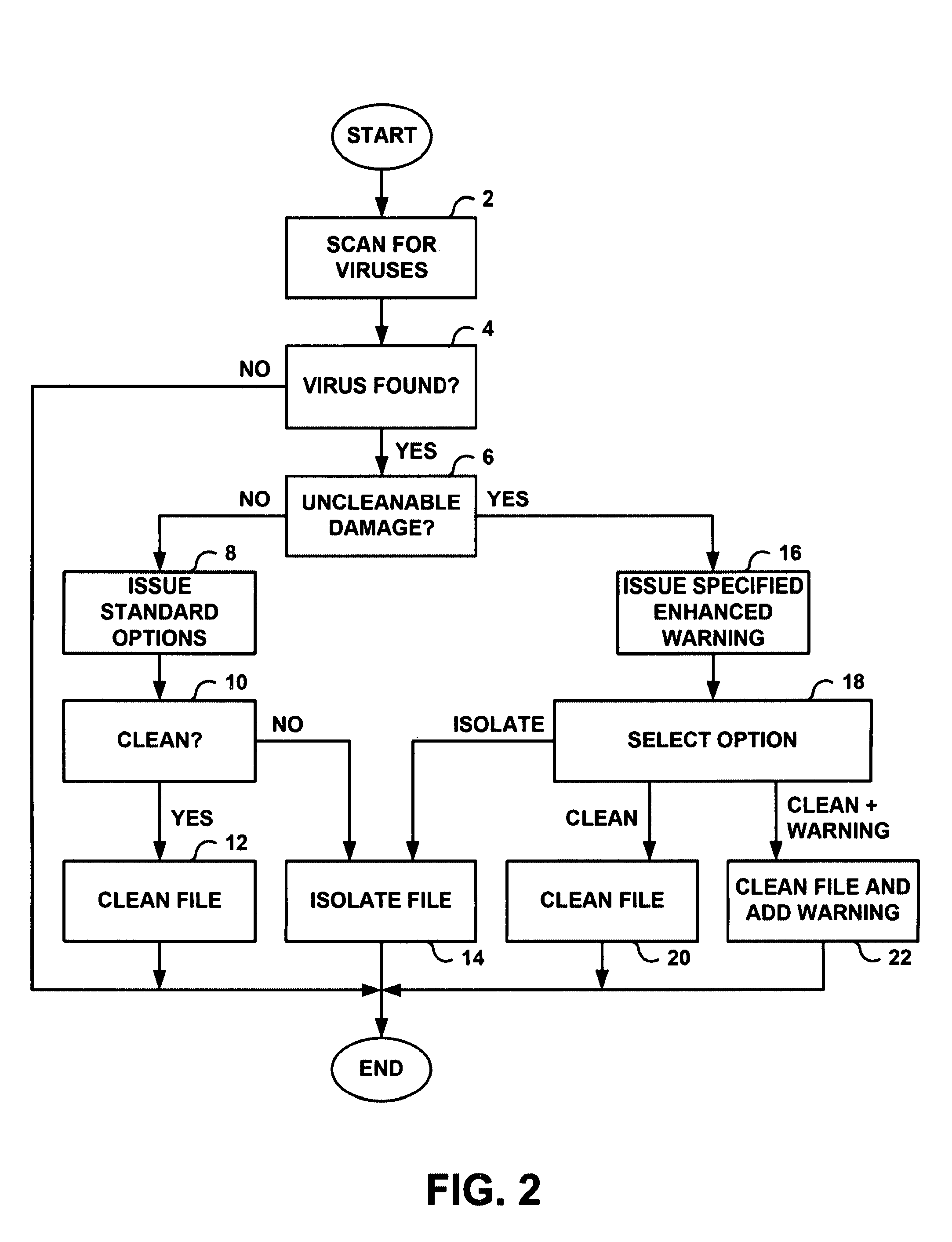

User alerts in an anti computer virus system

InactiveUS7272724B2Maintains impactStay flexibleReliability increasing modificationsError preventionComputer scienceVirus

An anti computer virus program uses a library of virus drivers that includes an indication of whether a particular virus can cause irreparable damage and data indicating enhanced user warnings and actions that might be associated with such viruses. If a detected computer virus is one that can cause irreparable damage, then an enhanced user warning (16) is issued indicating this to the user and a notification (28) of the possibility of such corruption is added into the repaired computer file. The notification may take the form of an electronically signed (30) banner message or the like.

Owner:MCAFEE LLC

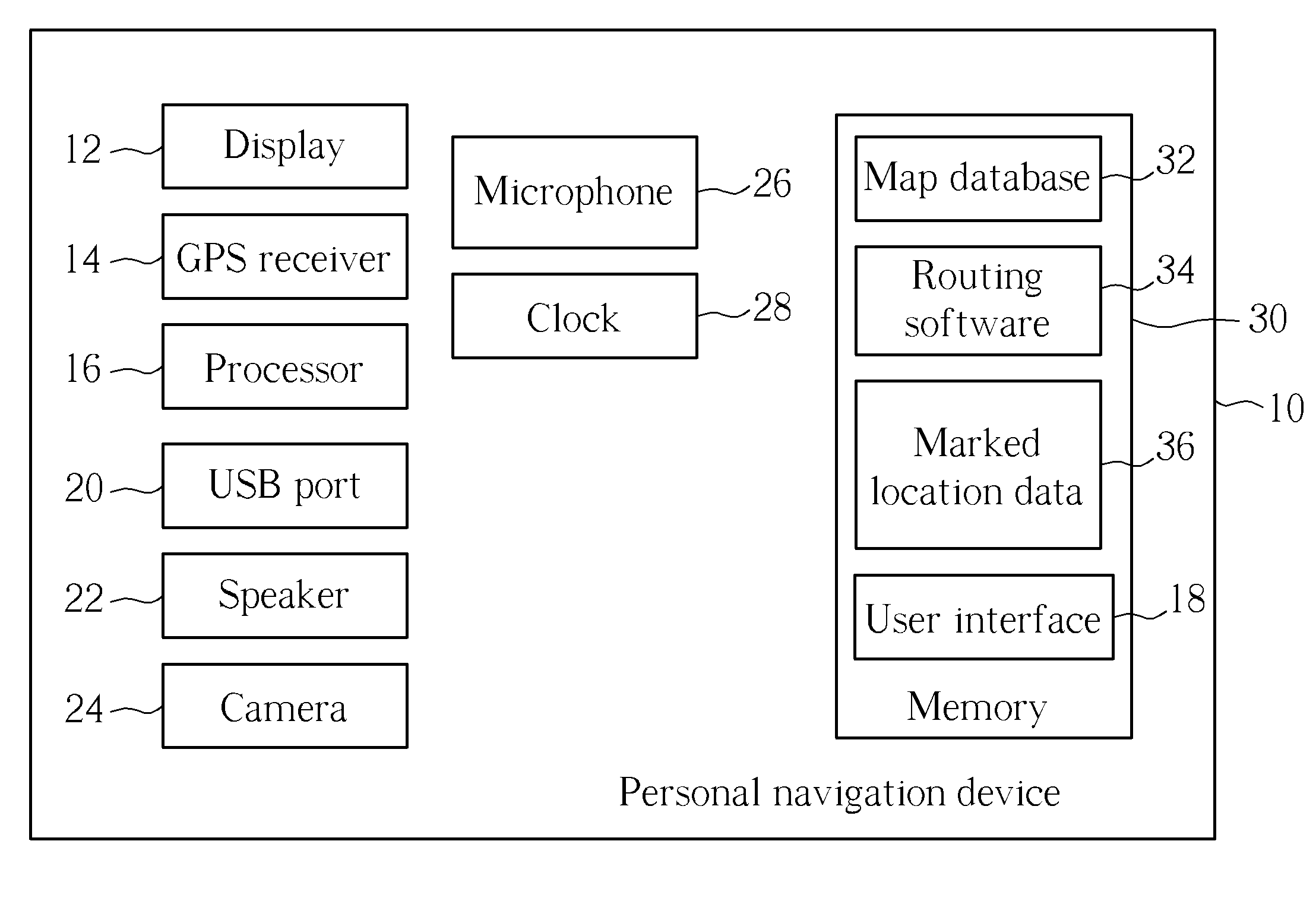

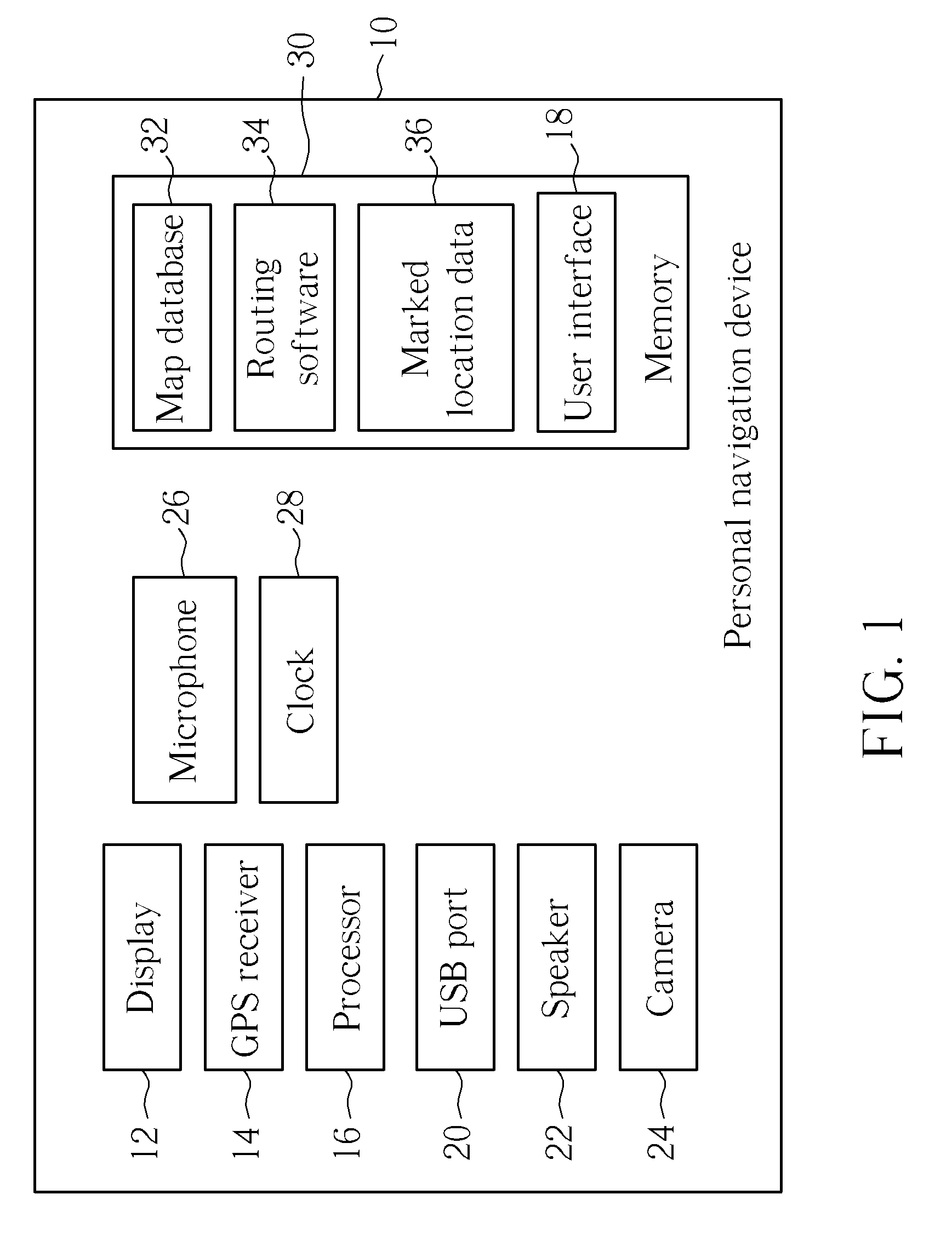

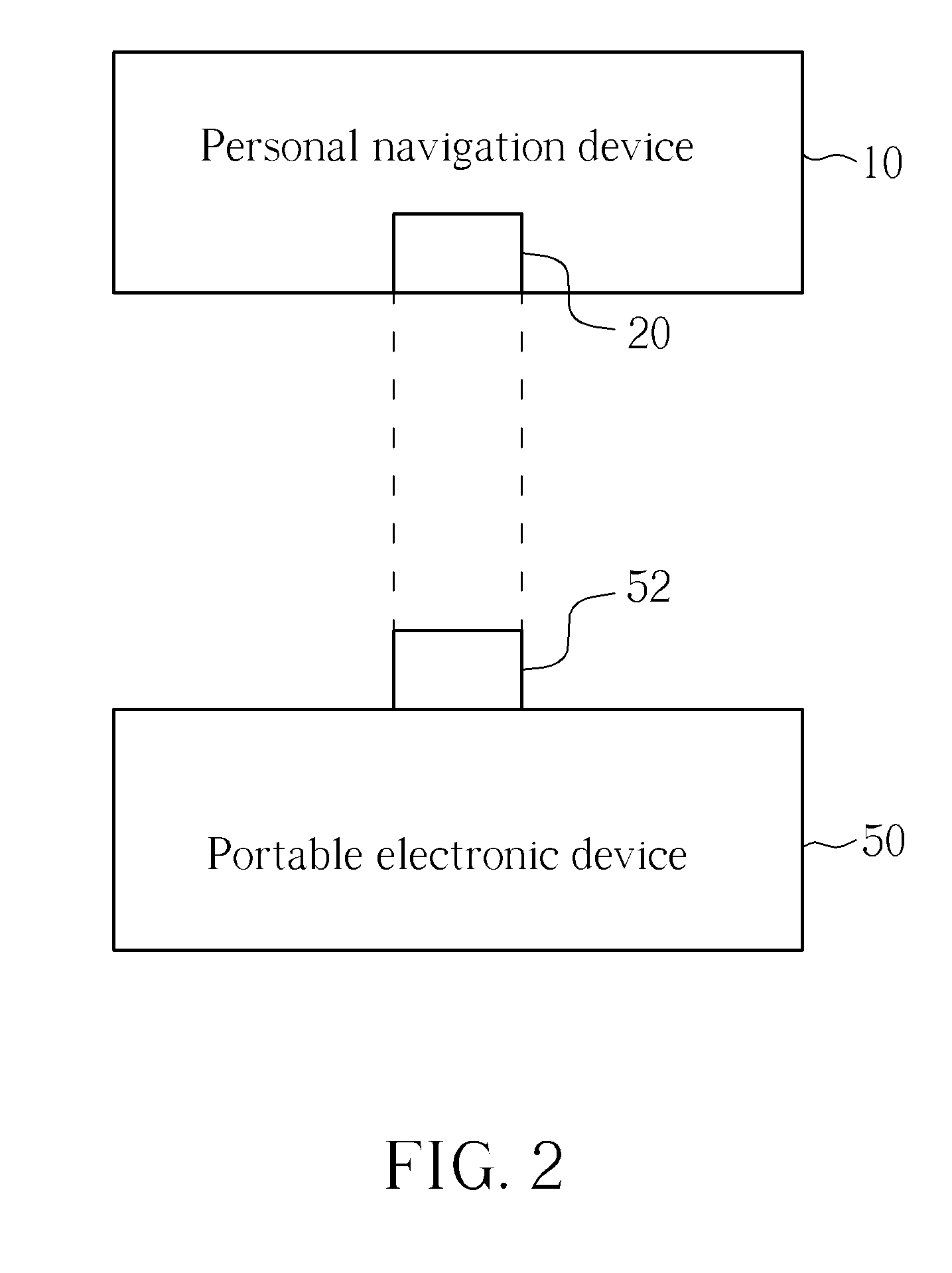

User-defined marked locations for use in conjunction with a personal navigation device

InactiveUS20110077852A1Quickly and conveniently markMark accuratelyInstruments for road network navigationRoad vehicles traffic controlComputer hardwarePersonal navigation device

Owner:MITAC INT CORP

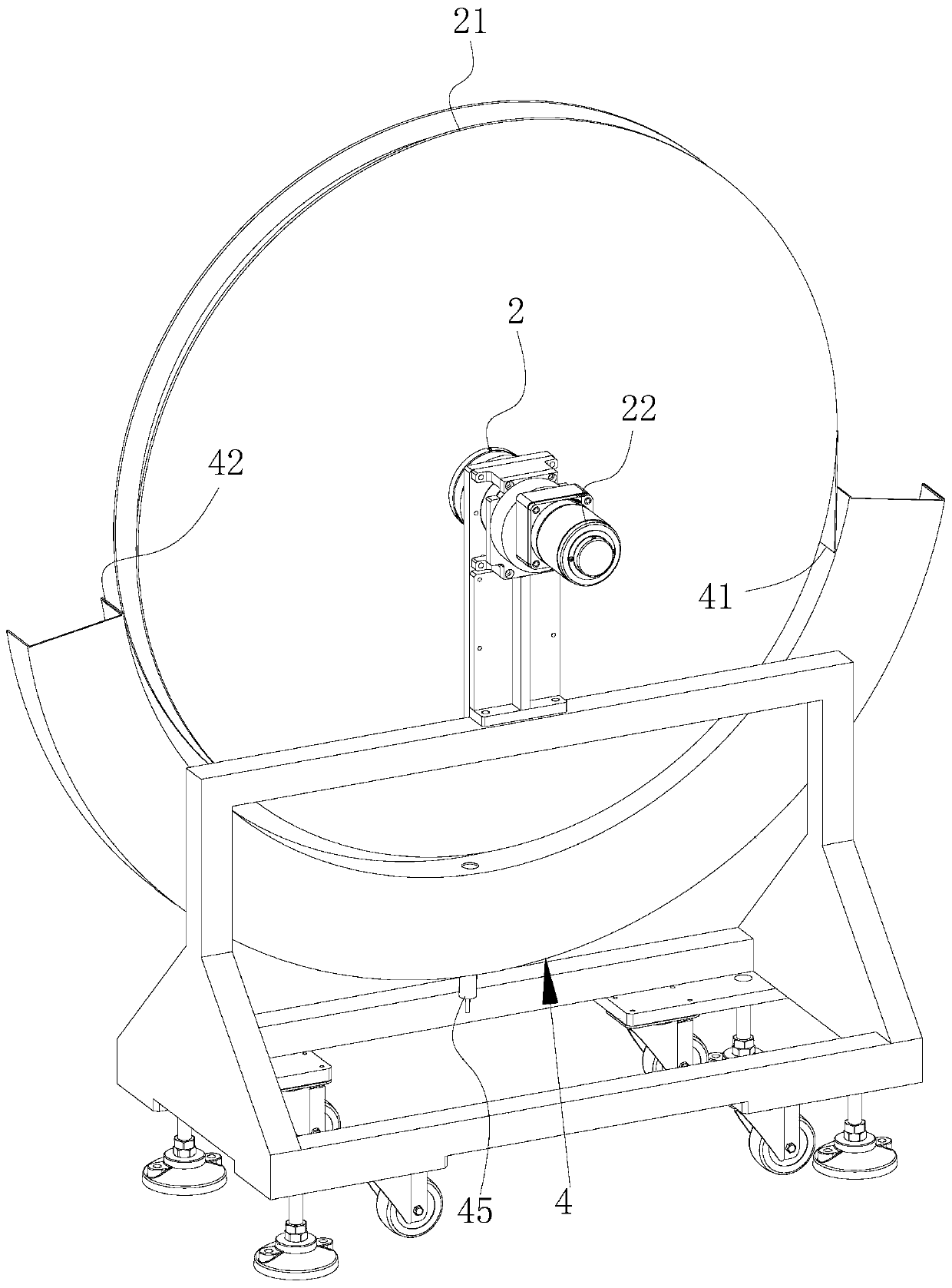

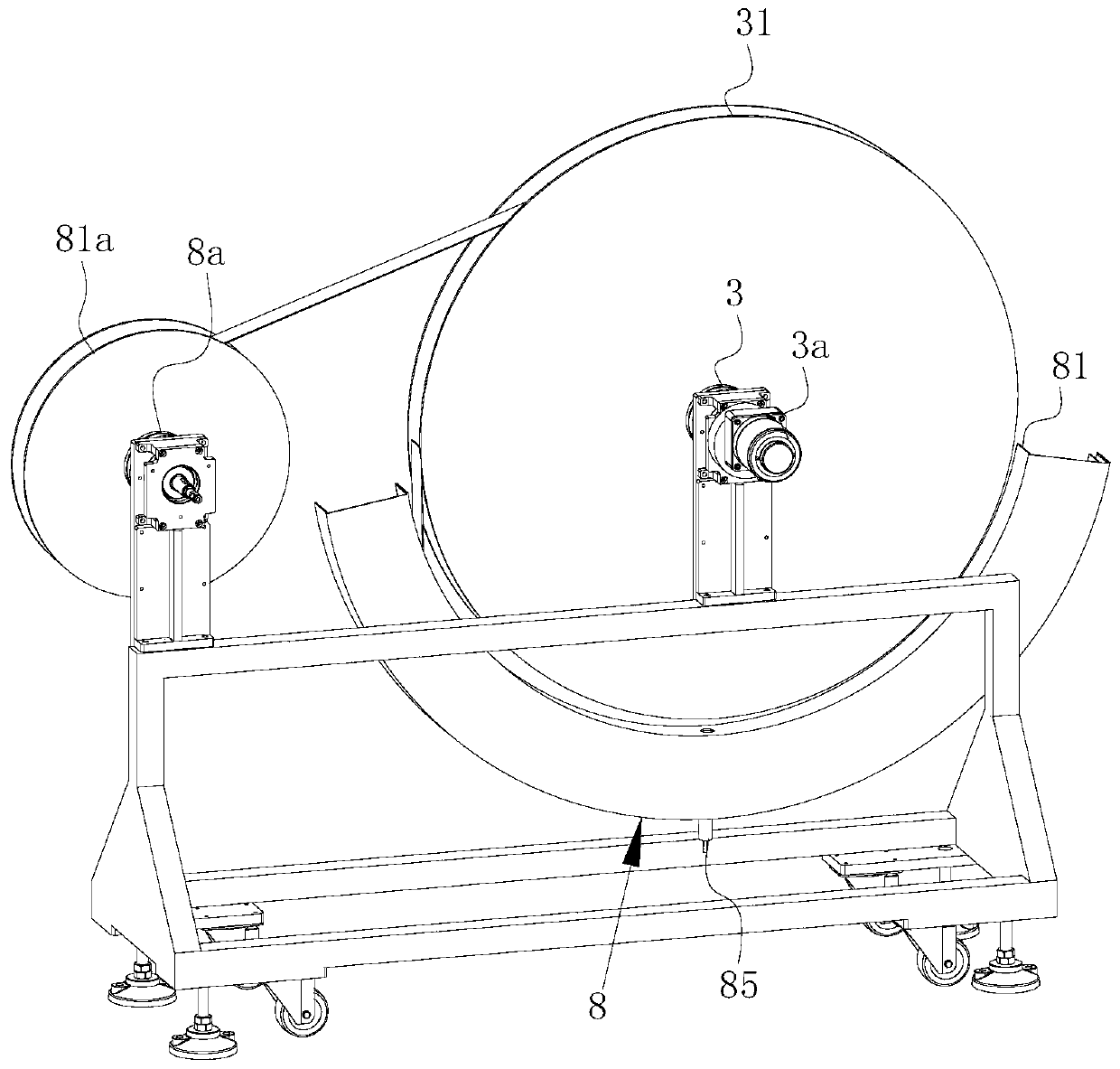

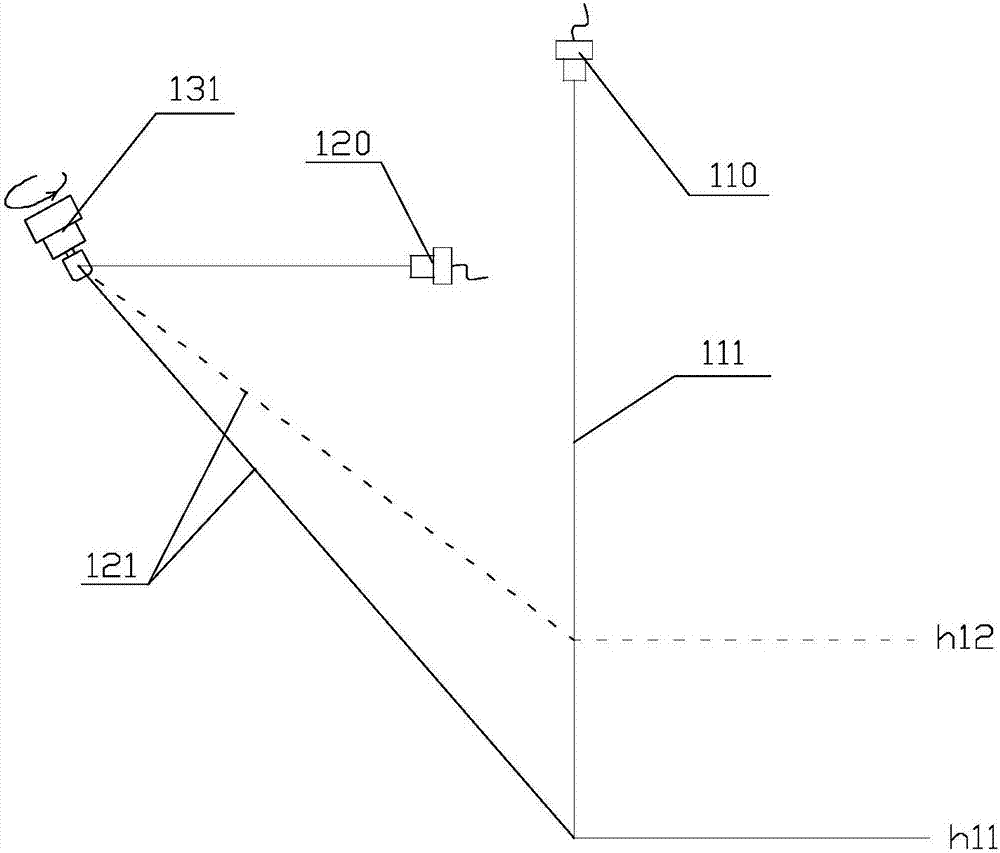

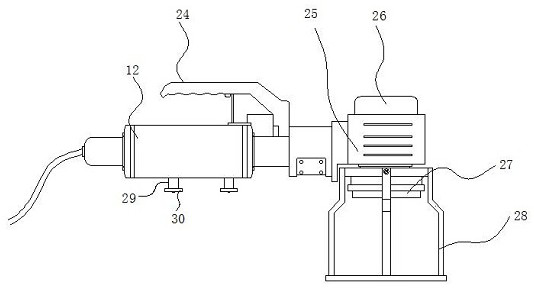

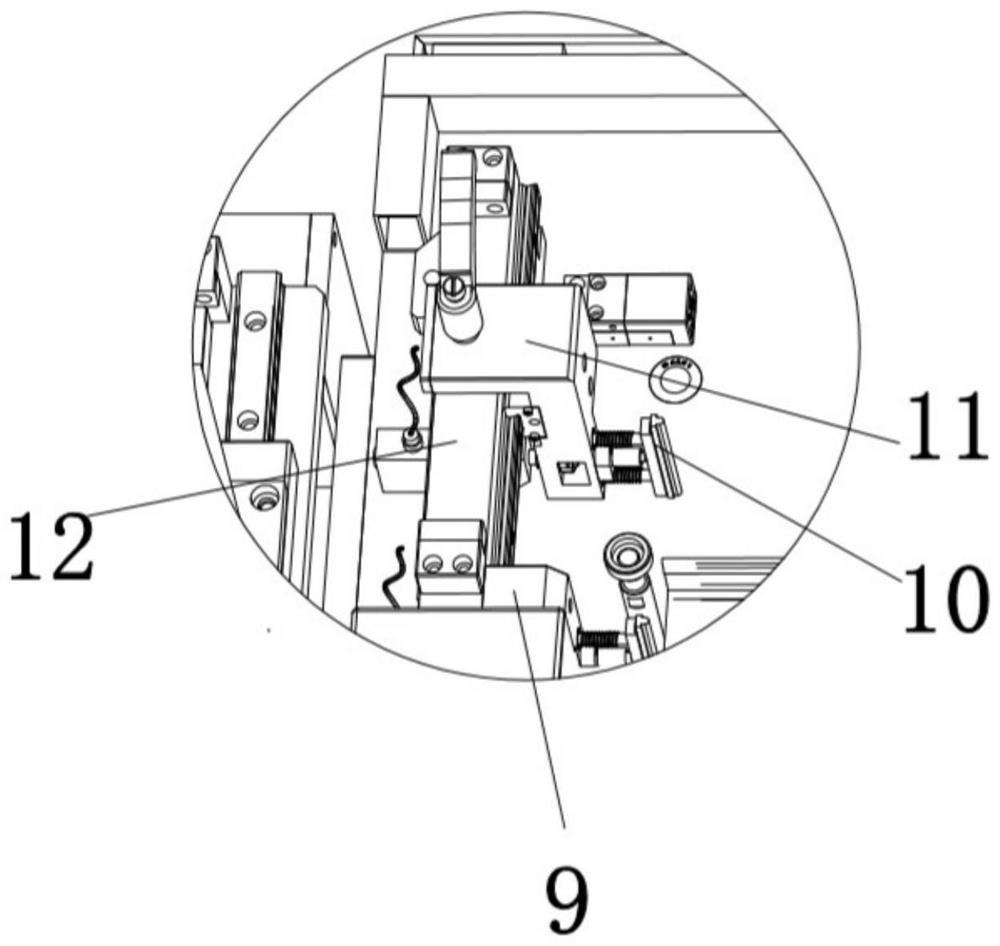

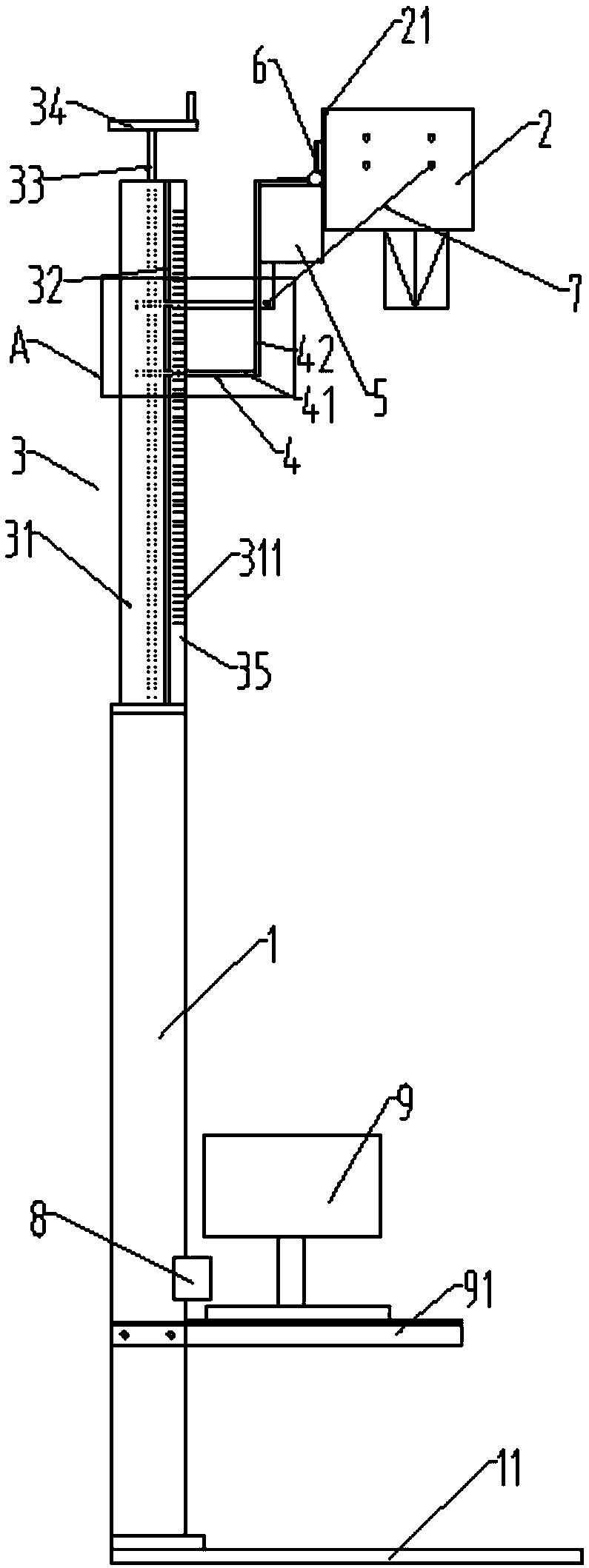

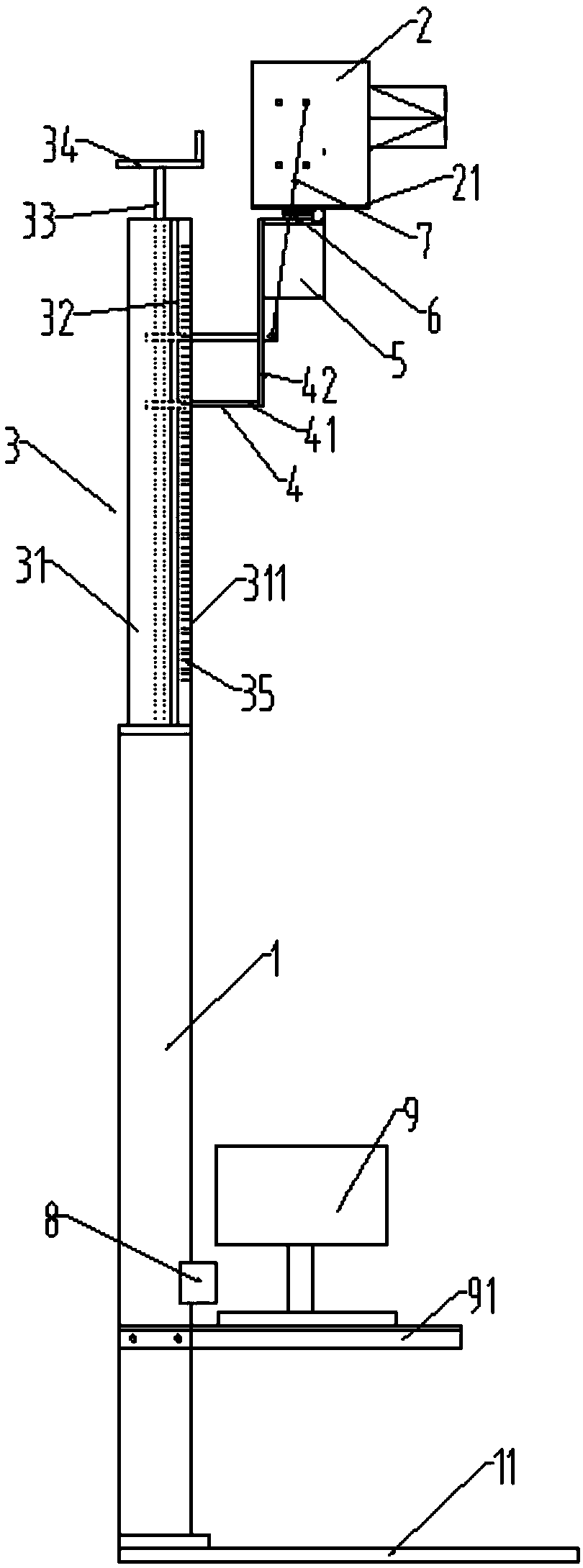

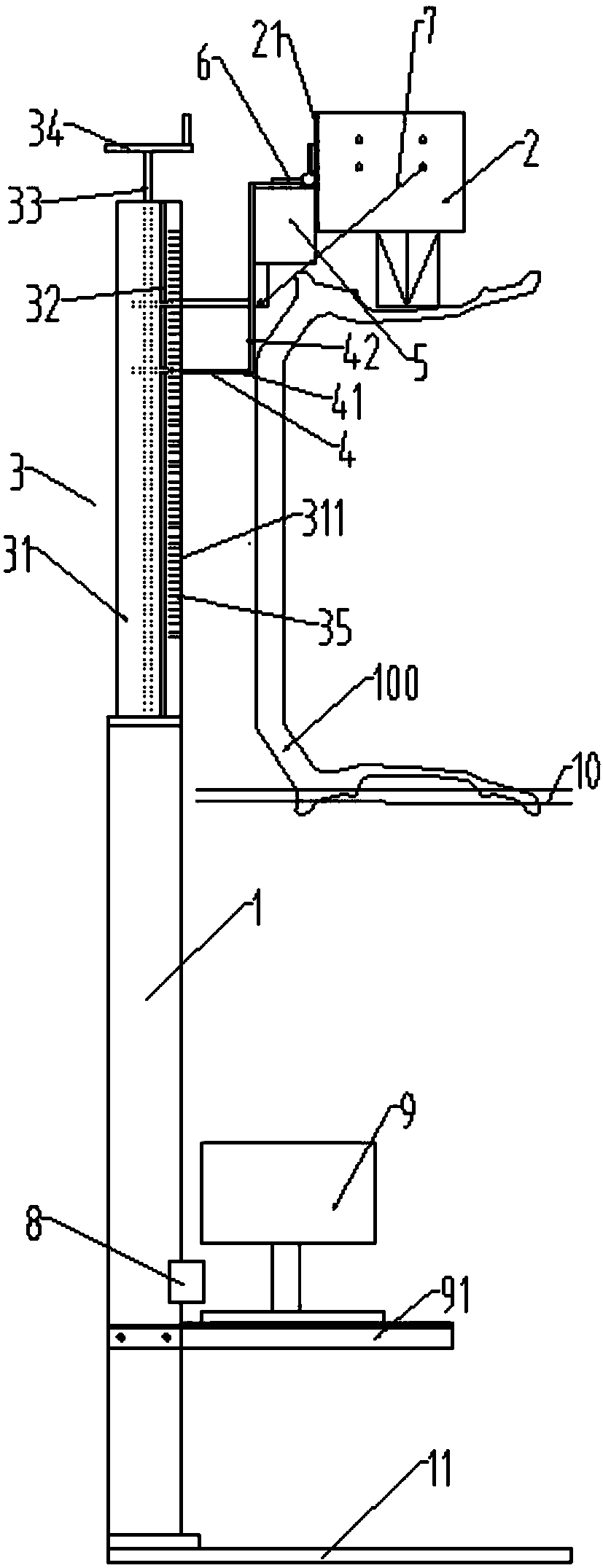

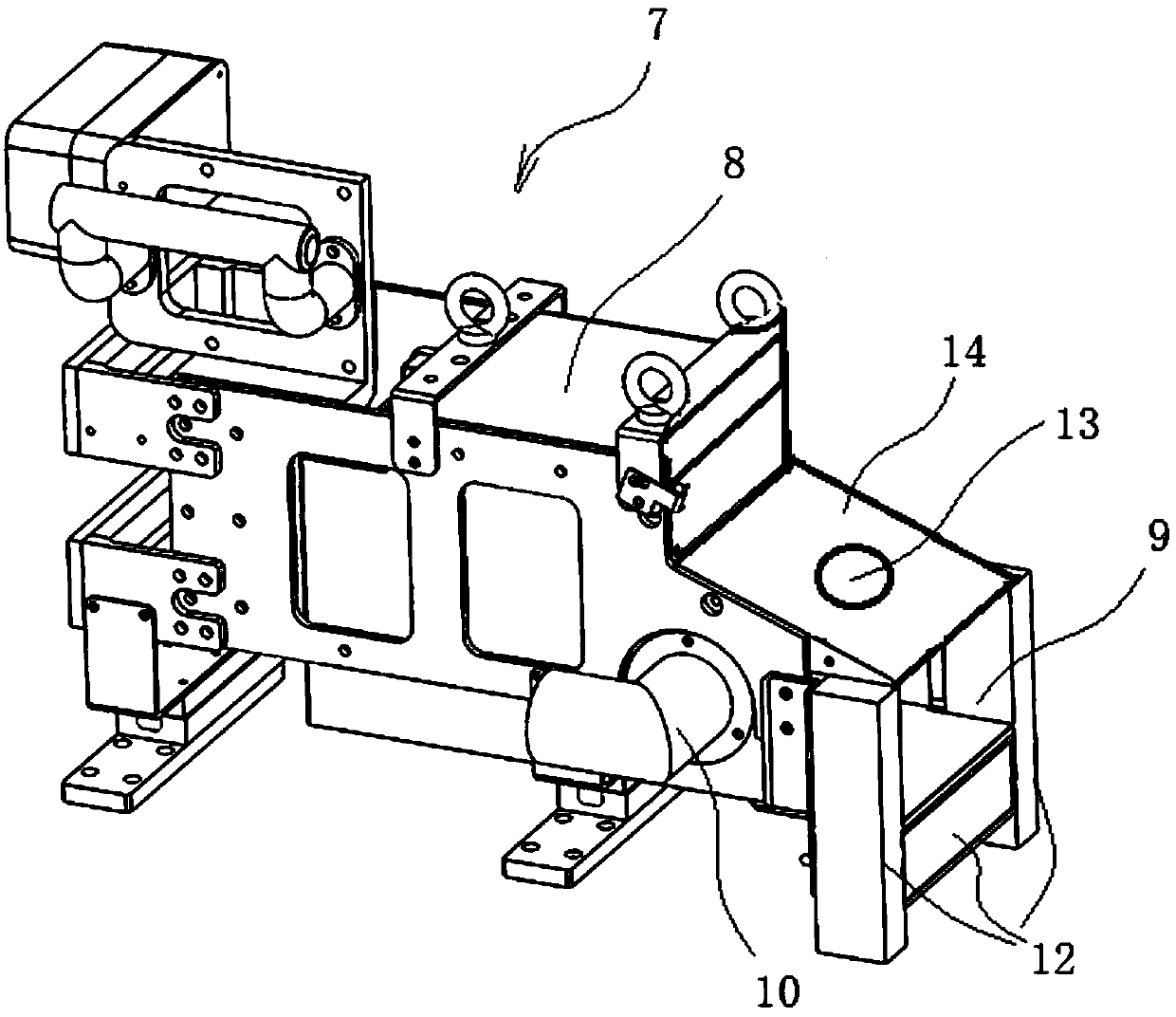

Marking method based on controllable distance indication and 3D (three-dimensional) laser marking machine

ActiveCN104551409AConvenient markingImprove convenienceTypewritersLaser beam welding apparatusLight beamControl cell

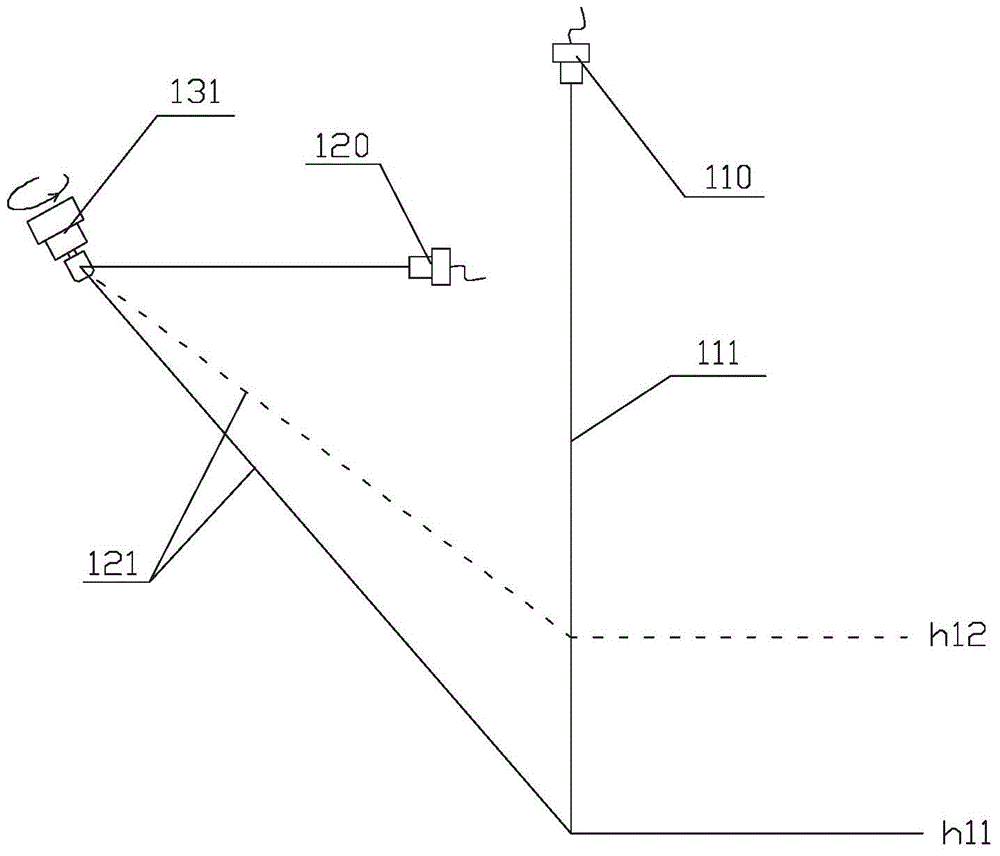

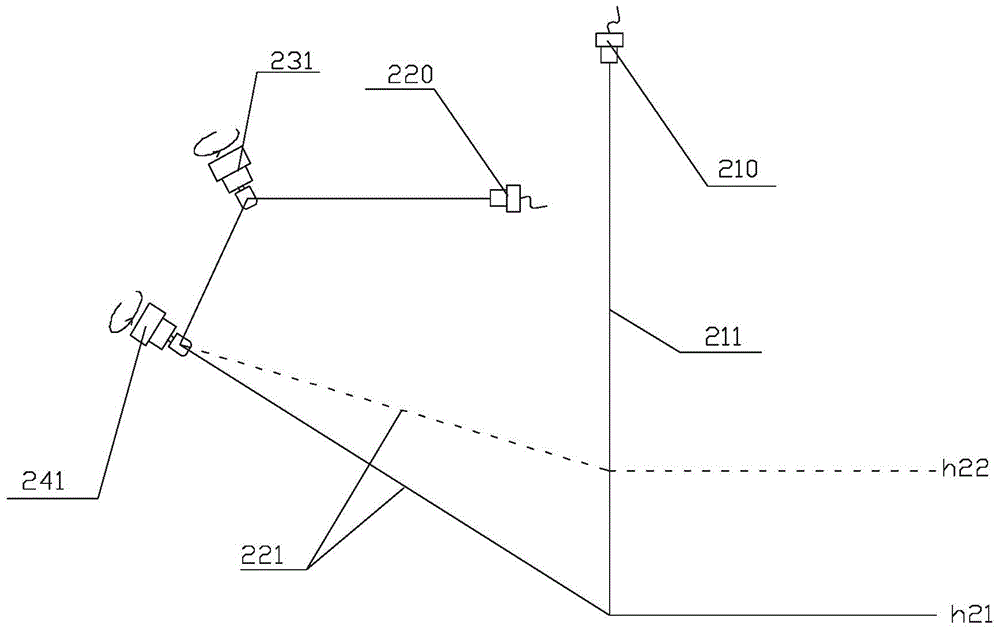

The invention discloses a marking method based on controllable distance indication and a 3D (three-dimensional) laser marking machine using the method. The 3D laser marking machine comprises a first visible light indicator, a second visible light indicator and a control unit, wherein the first visible light indicator can emit a first visible light beam to a marking area, a reflecting device is arranged on a light path of the second visible light indicator, and is used for reflecting a second visible light beam, the second visible light beam is reflected and is crossed with the first visible light beam in the marking area, the controlling unit is used for controlling the deflecting angle of the reflecting device, and the crossing point of the first light beam and the second light beam corresponds to an initial focus point of the 3D laser marking machine. The 3D laser marking machine has the advantage that the initial focus distance of the laser marking can be displayed through controlling the crossing of the visible light beams, and the 3D laser marking machine can automatically focus, so the indication of the initial focus distance can be accurately and quickly completed.

Owner:GUANGZHOU NEW CKLASER CO LTD

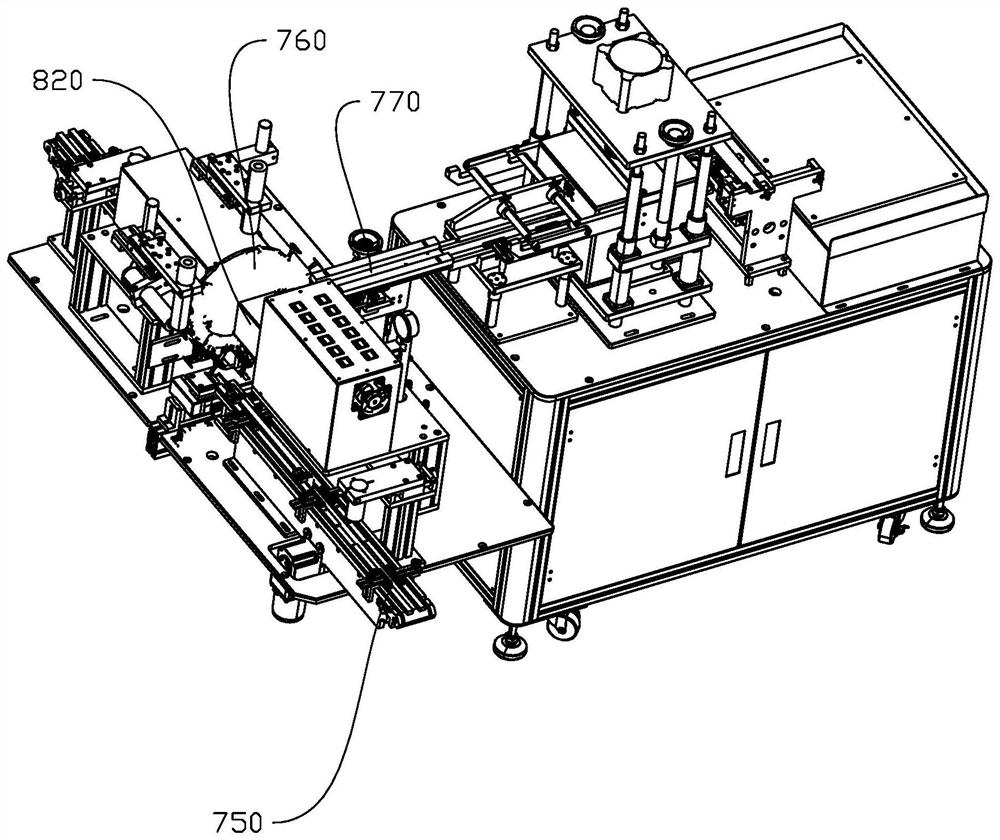

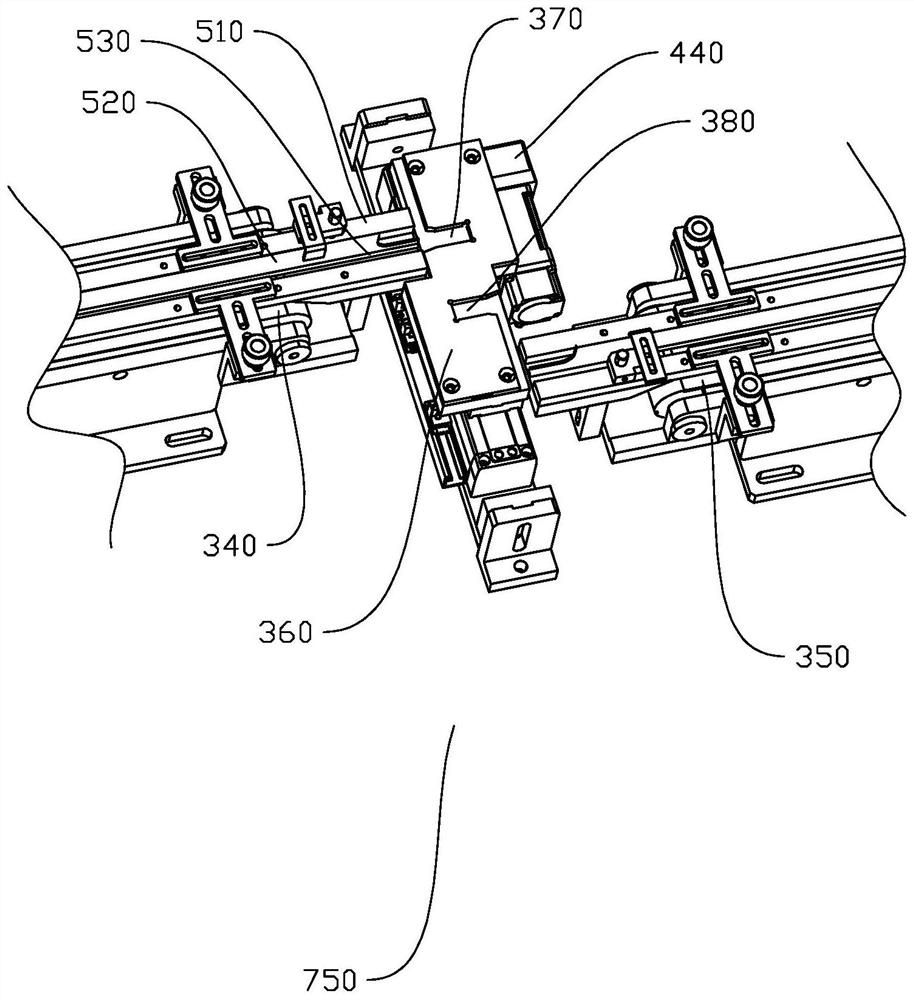

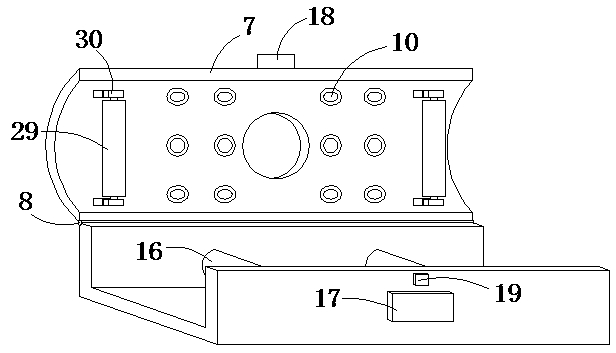

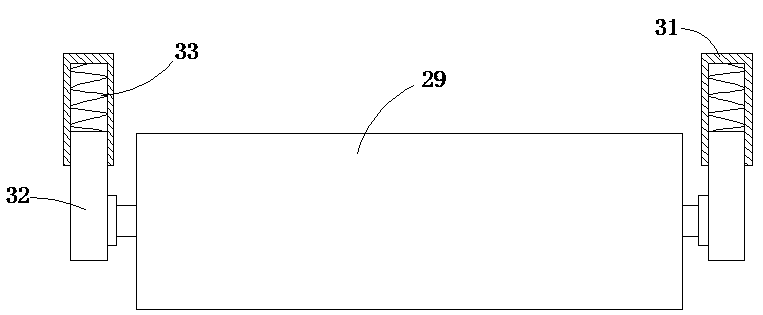

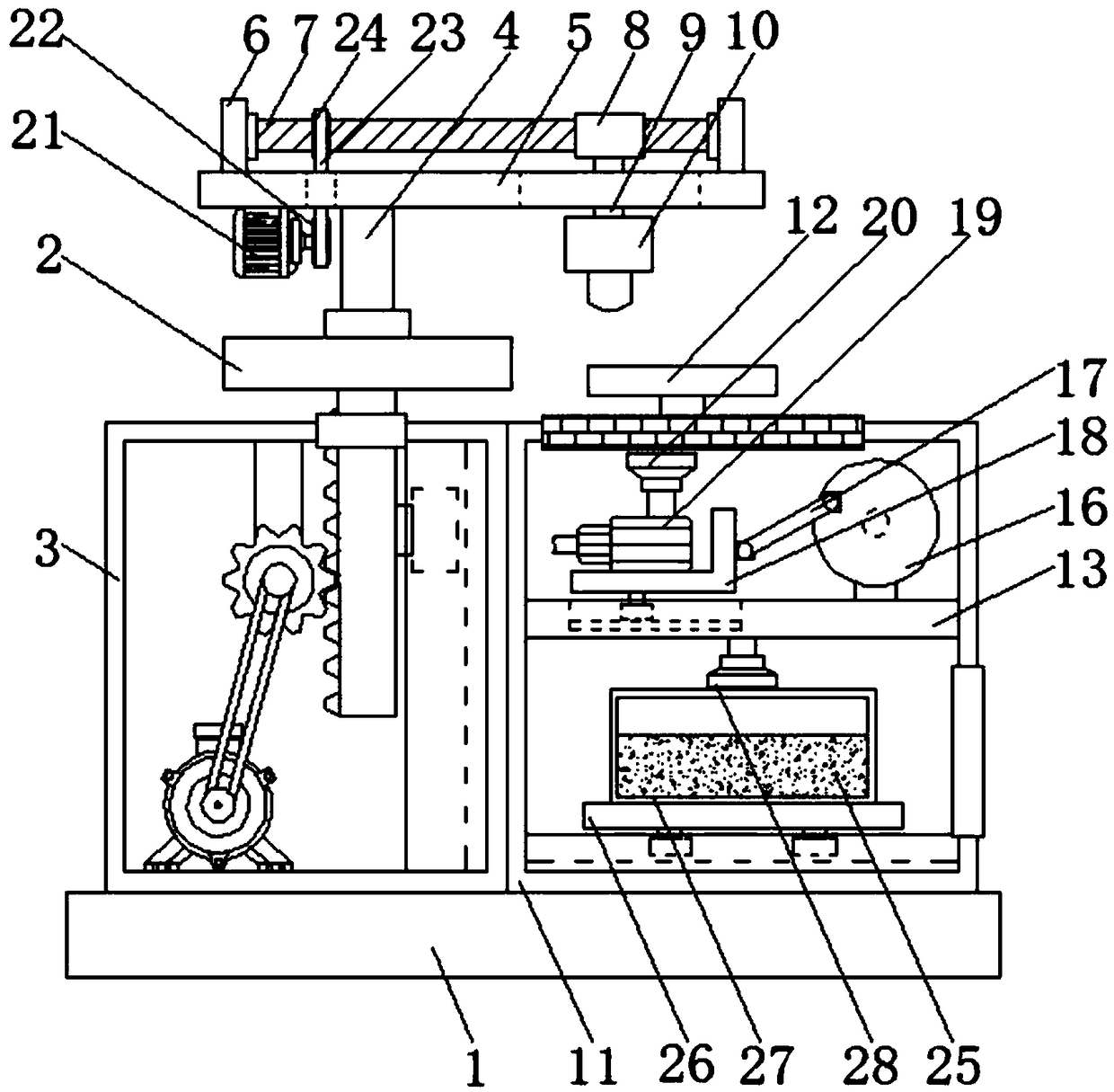

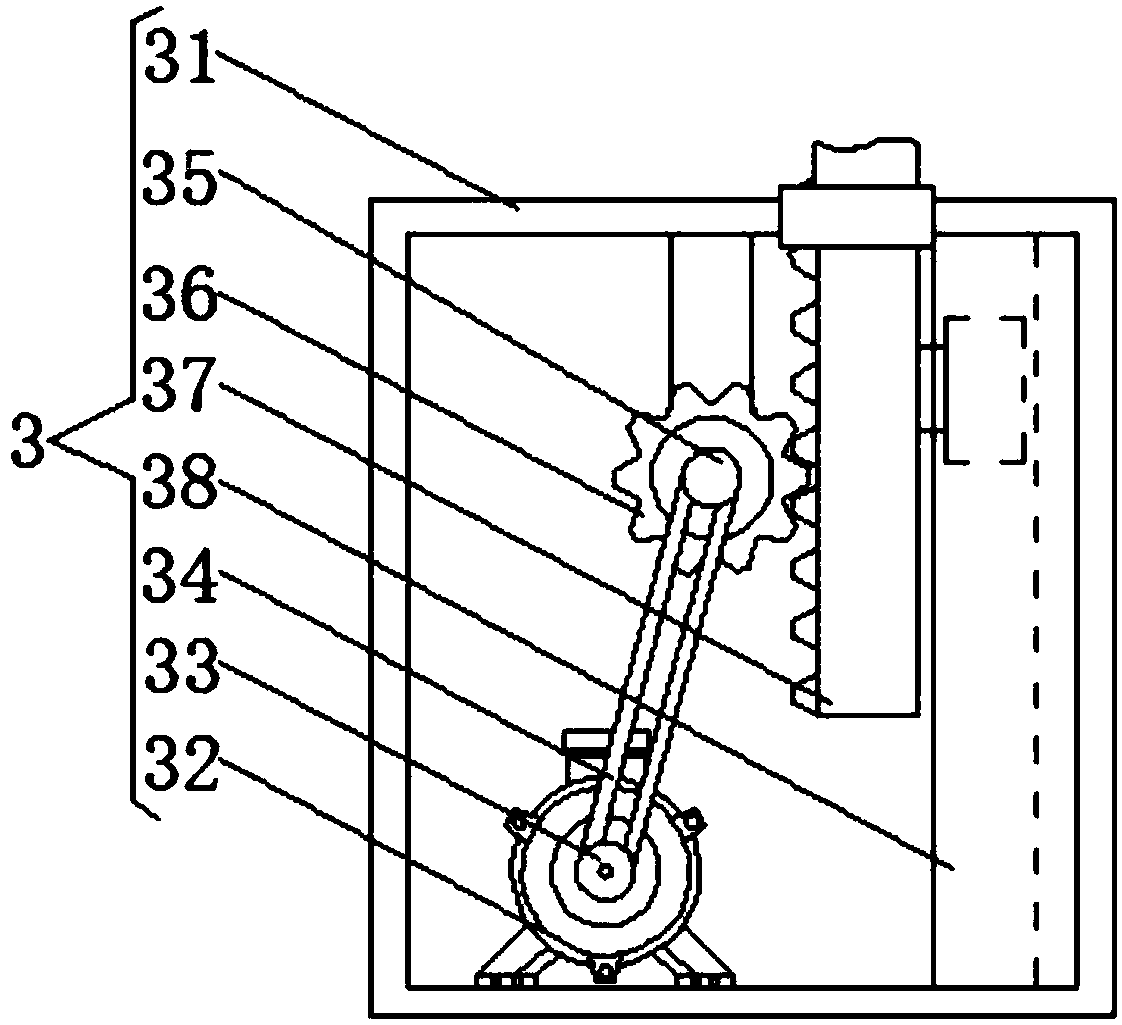

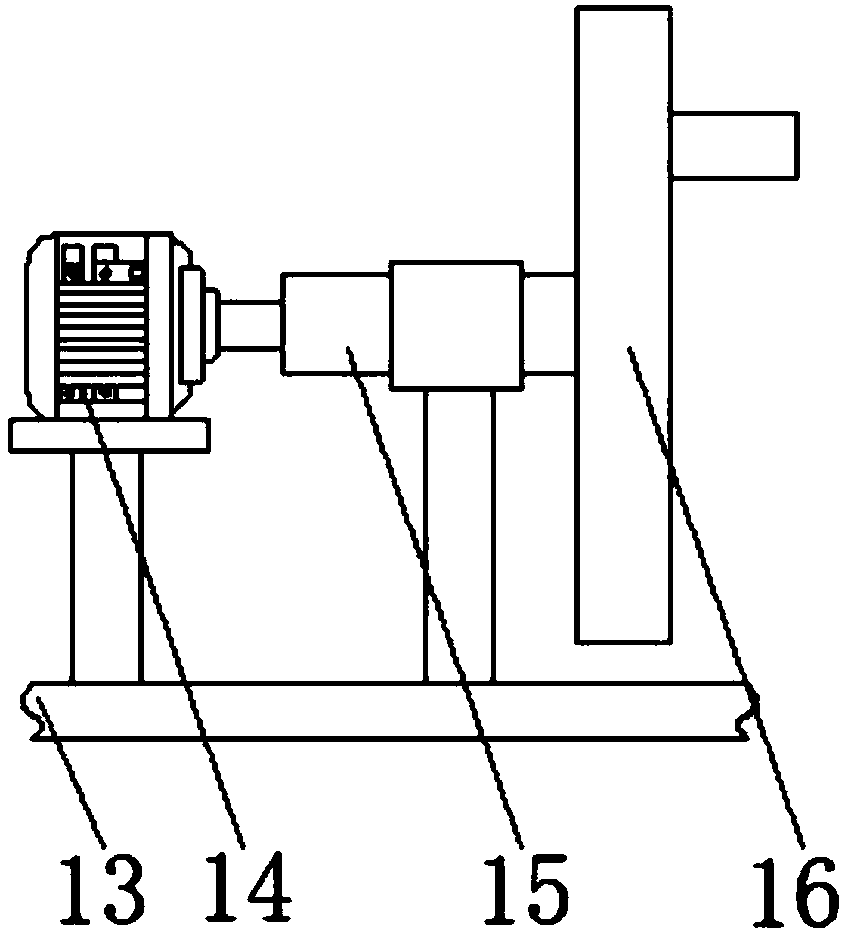

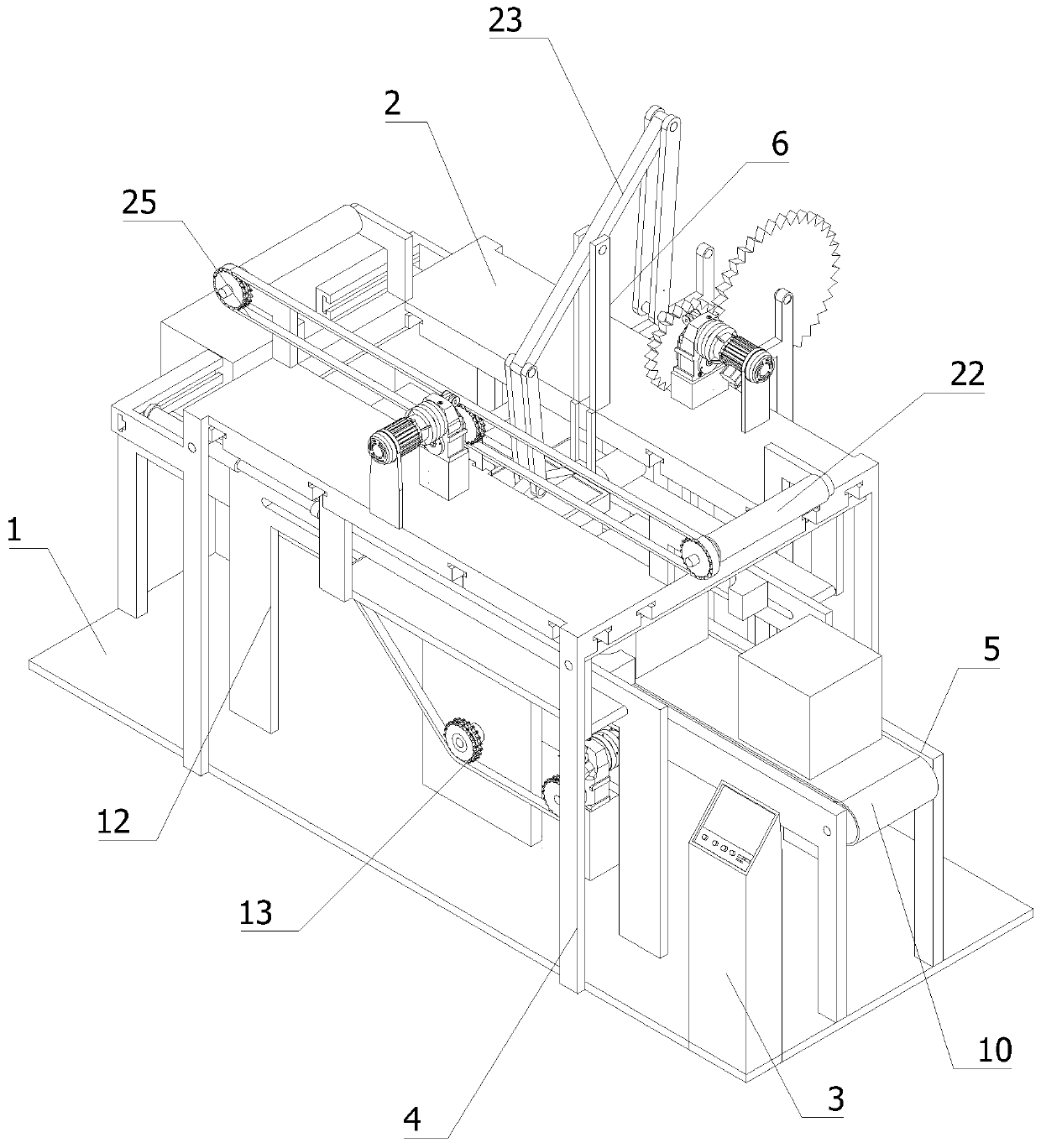

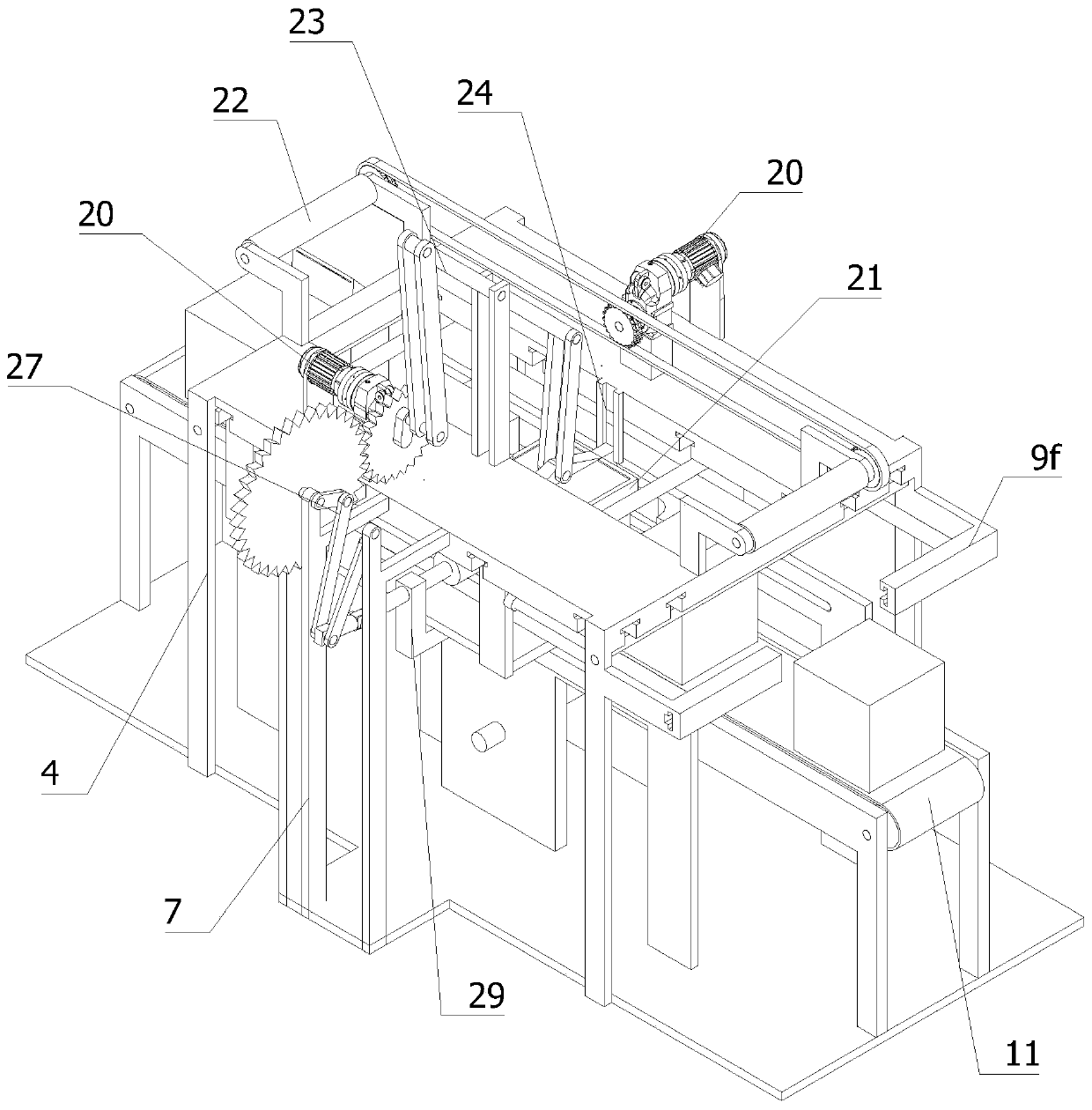

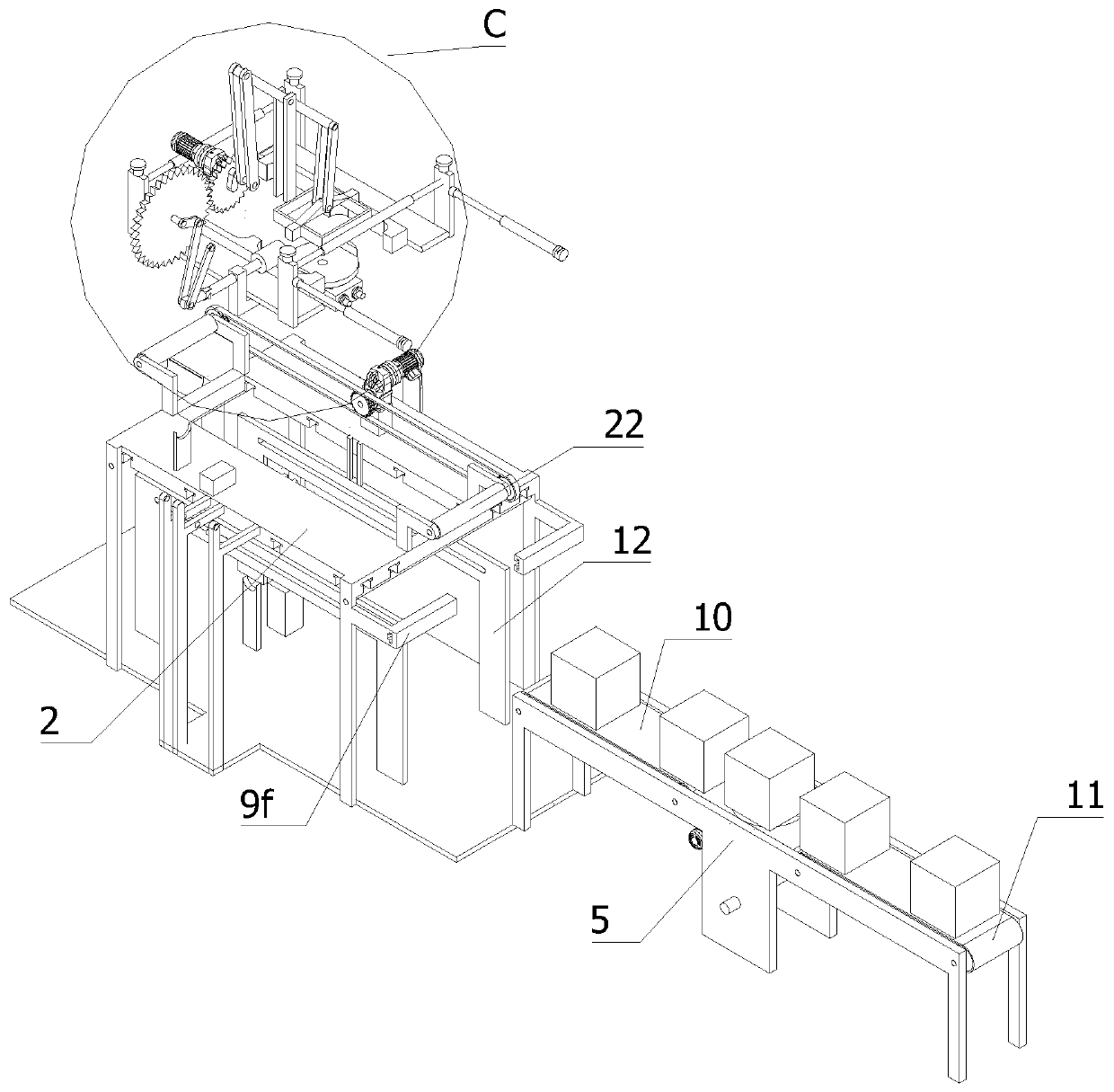

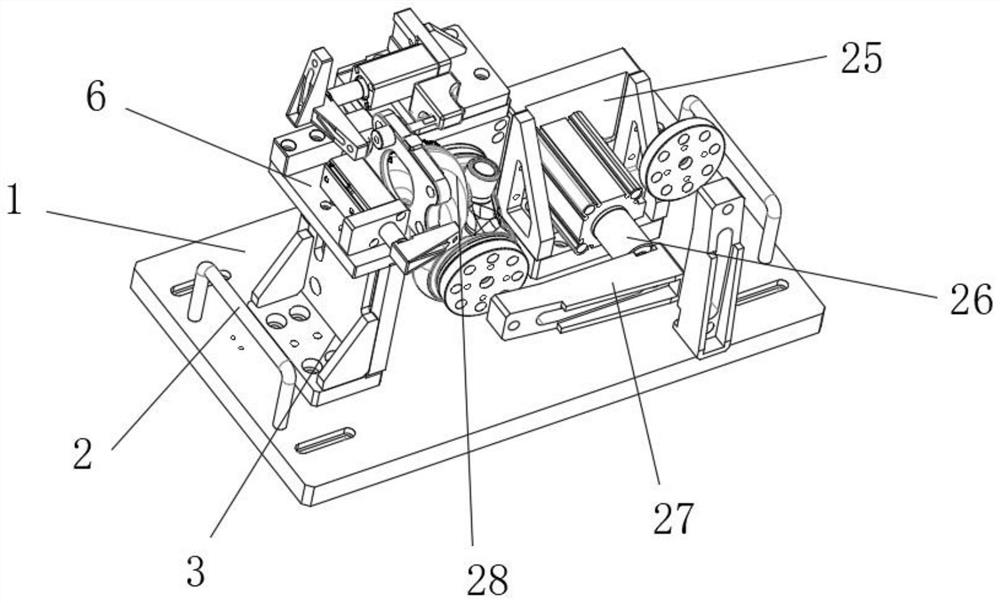

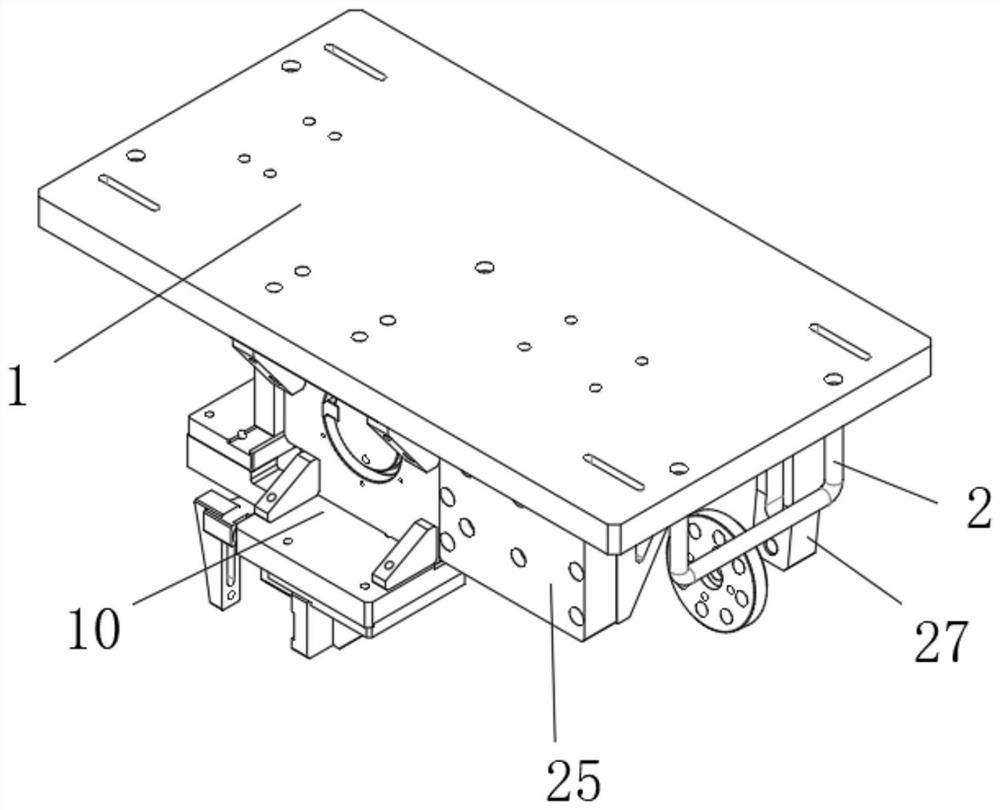

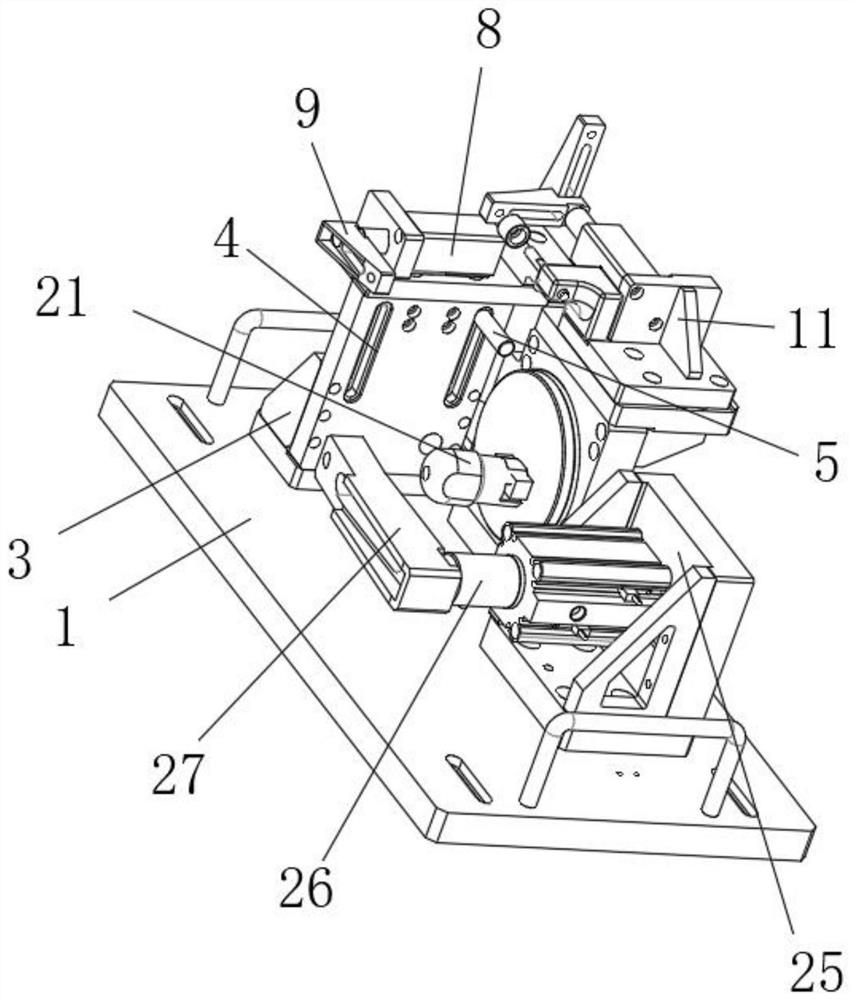

Magnetic sheet stacking device and magnetizer

PendingCN112002549AEasy to implementLow costMagnetic bodiesInductances/transformers/magnets manufactureClassical mechanicsEngineering

The invention discloses a magnetic sheet stacking device and a magnetizer. The device comprises a material conveying mechanism which is provided with two material conveying assemblies which are respectively used for conveying tiled magnetic sheets and plastic sheets; a feeding mechanism which is provided with a first sliding block, wherein the first sliding block is provided with two feeding grooves which are used for receiving a magnetic sheet and a plastic sheet respectively; a material taking mechanism which is provided with a rotary disc and a plurality of material taking assemblies, wherein the rotary disc is vertically arranged, the material taking assemblies are installed on the rotary disc, every two adjacent material taking assemblies take one magnetic sheet and one plastic sheetcorrespondingly, and the magnetic sheets and the plastic sheets come from the first sliding blocks; a stacking mechanism which is provided with a first material channel extending horizontally and a material pushing plate located at the starting end of the first material channel, wherein the material pushing plate pushes the magnetic sheets and the plastic sheets to be away from the material takingassembly, the material pushing plate is provided with an avoiding channel, and the avoiding channel allows the material taking assembly to pass through. According to the magnetic sheet stacking device and the magnetizer, the magnetic sheets and the plastic sheets can be automatically stacked, magnetizing efficiency is improved, labor is saved, and meanwhile stacking and marking errors are prevented.

Owner:肇庆高峰机械科技有限公司

Stainless steel strip laser marking machine based on visual identification and positioning

ActiveCN109702350AConvenient markingEasy to pullLaser beam welding apparatusEngineeringVisual perception

The invention belongs to the technical field of marking, and particularly relates to a stainless steel strip laser marking machine based on visual identification and positioning. The stainless steel strip laser marking machine based on visual identification and positioning comprises a machine cabinet, wherein universal wheels are installed on the machine cabinet. A material release disc and a material collection disc are arranged on the upper side of the machine cabinet and fixedly installed on the machine cabinet through installation frames. A plurality of light sources are uniformly distributed on the arc-shaped wall, close to a fixing block, of an arc-shaped cover. An installation plate is horizontally arranged on the upper side of the fixing block and installed on the machine cabinet through a lifting mechanism. A hollow cylinder is arranged on the lower sides of a marking module and a CCD visual identification module and installed on the marking module and the CCD visual identification module at the same time, and the position of the hollow cylinder corresponds to the position of a marking hole. A tight press mechanism and an adjusting mechanism are arranged in an open groovewhich is formed in the fixing block. The stainless steel strip laser marking machine based on visual identification and positioning has the advantages that the structure is reasonable, a stainless steel strip can be pressed to be flat and stable through the tight press mechanism, marking is conducted advantageously, and the influence of the ambient light on visual identification and positioning can be reduced.

Owner:苏州因斯特光电技术有限公司

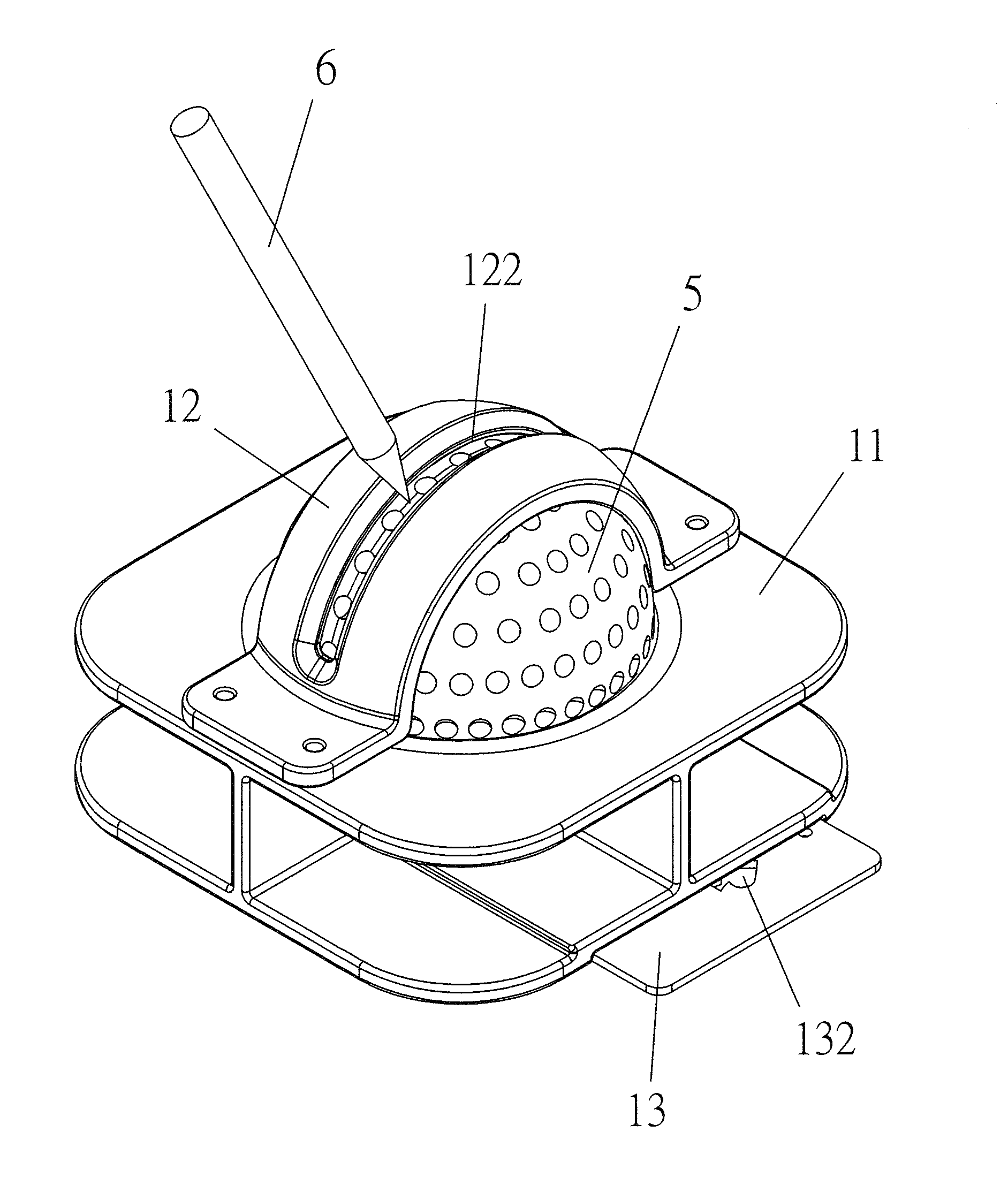

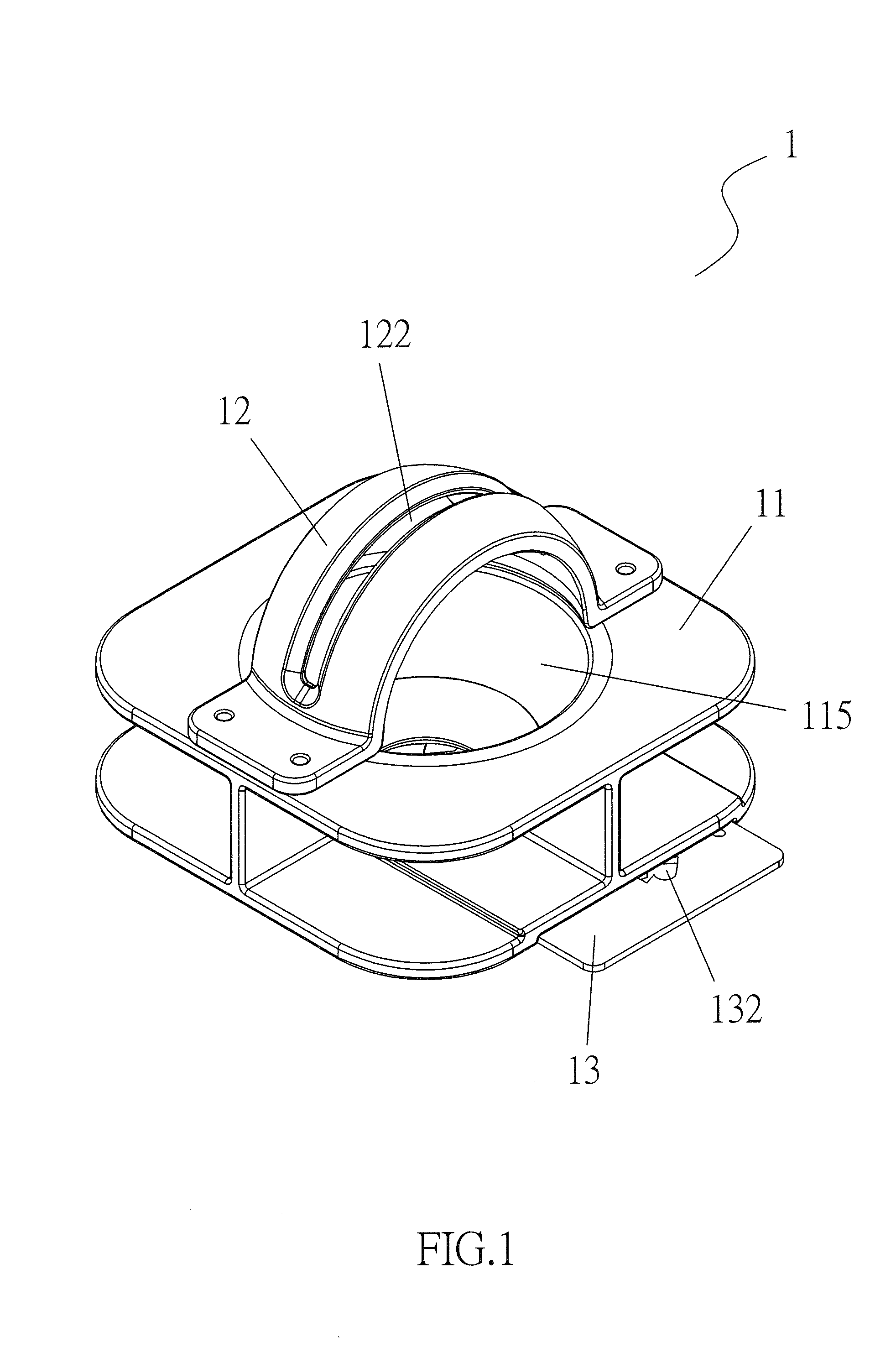

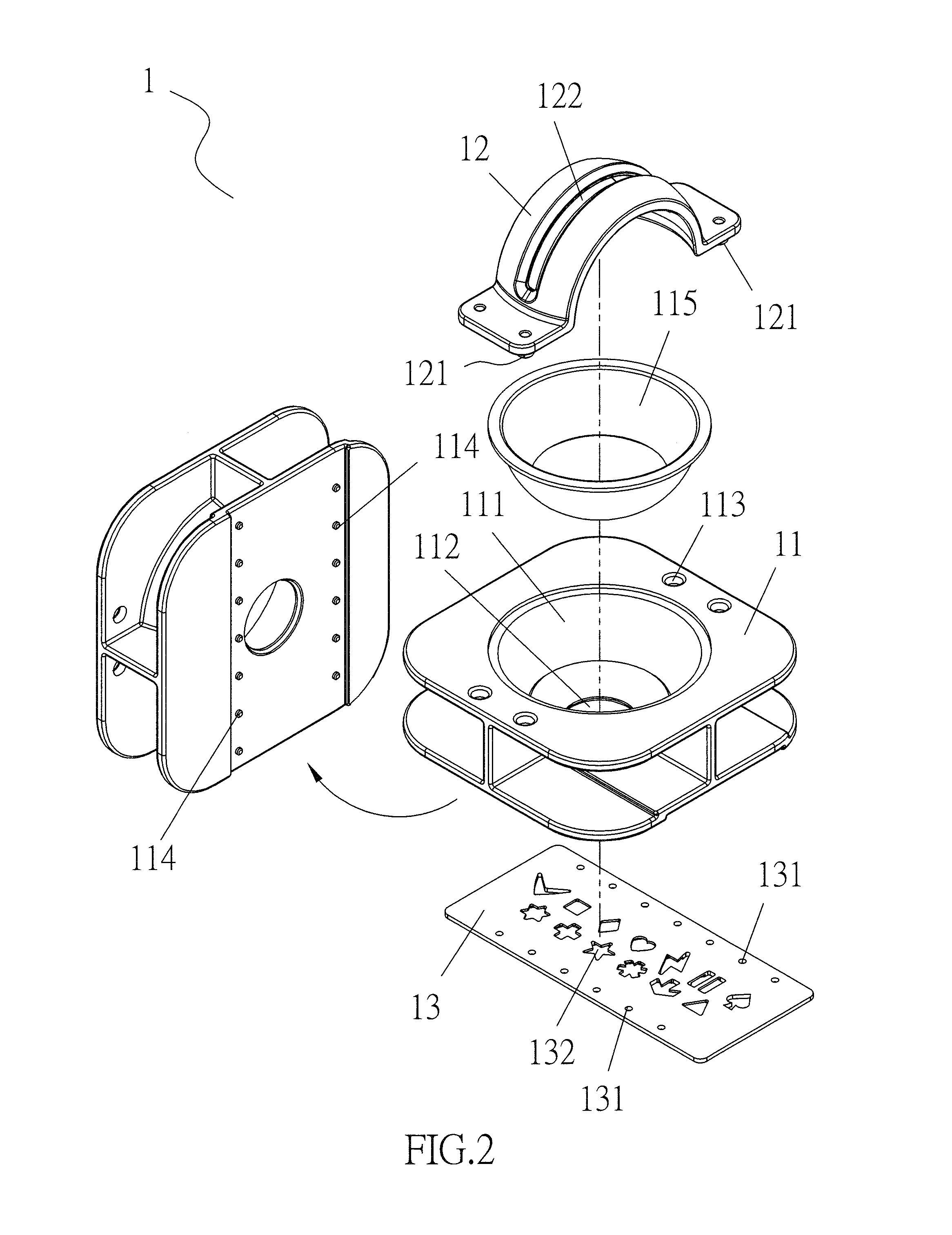

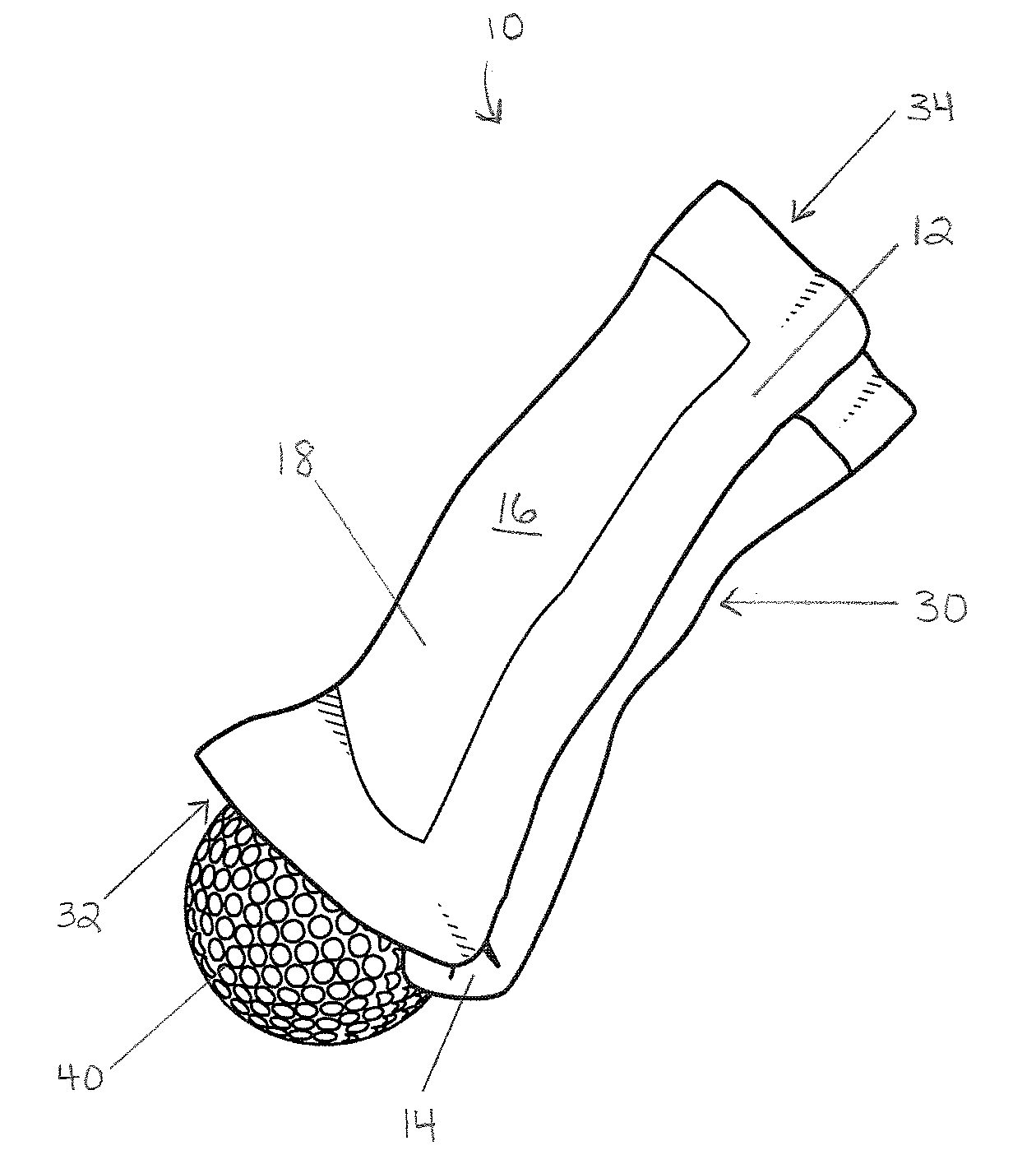

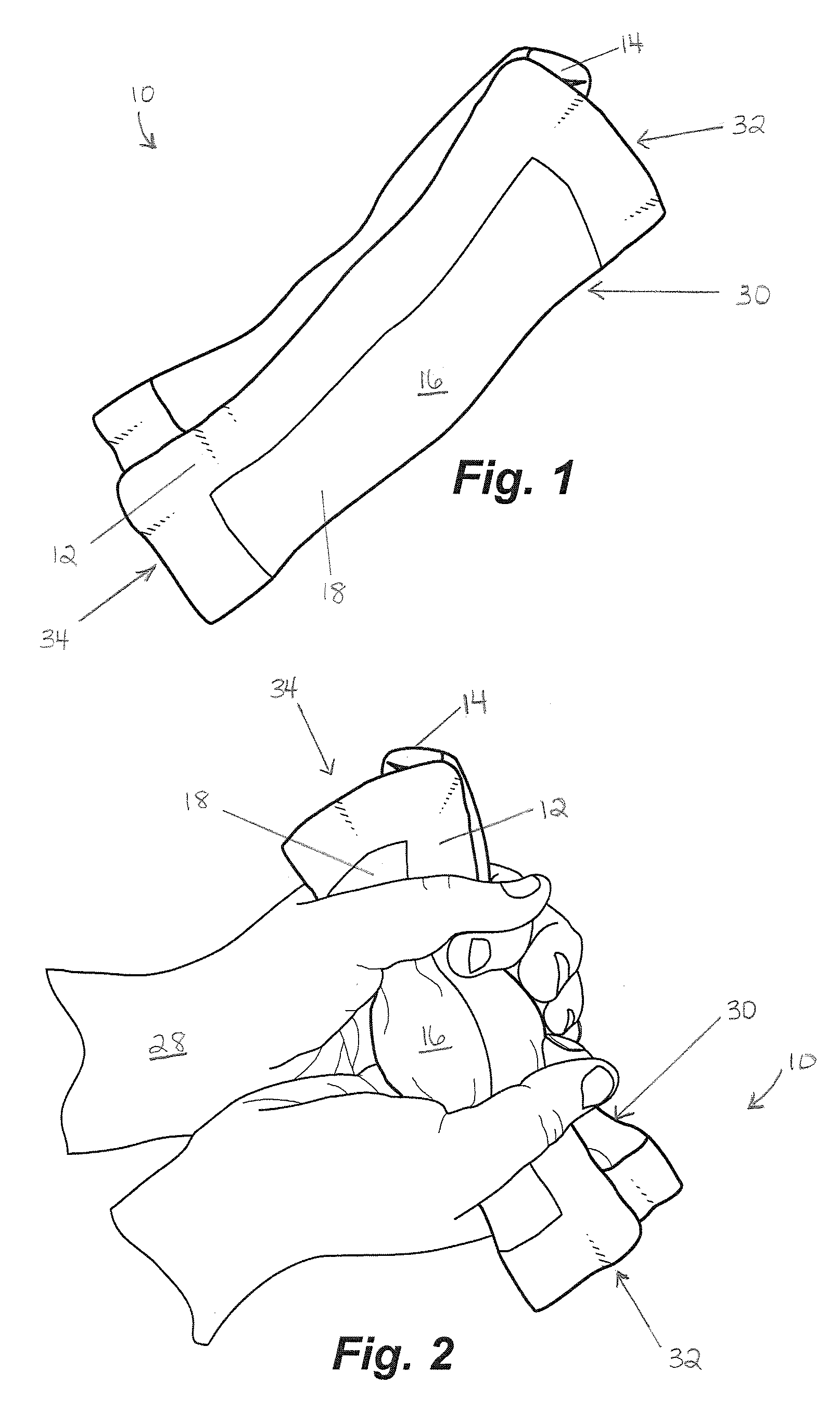

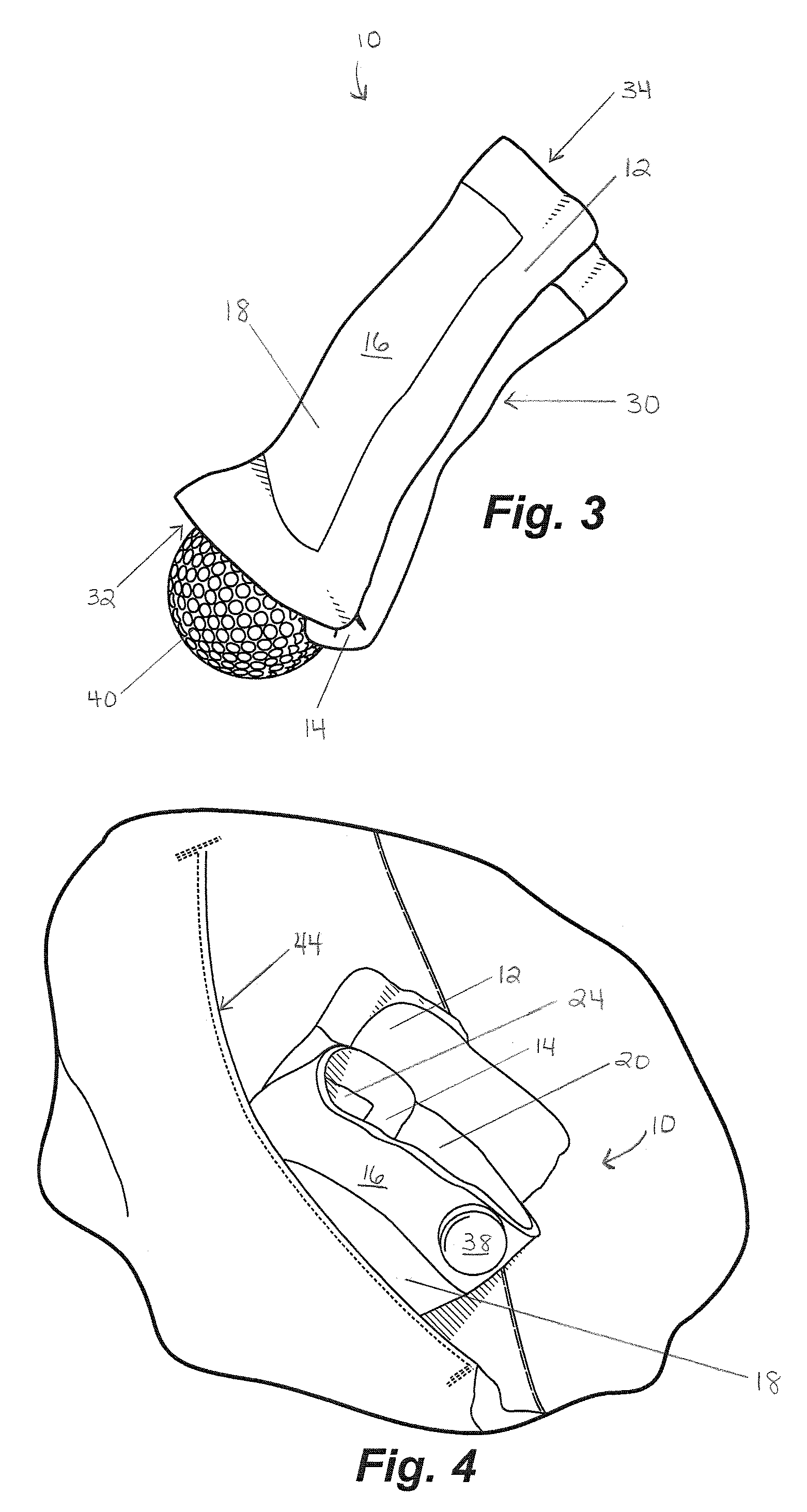

Marking Device for Golf Balls

InactiveUS20150075395A1Precise positioningConvenient markingBall sportsRotary pressesEngineeringGolf Ball

A marking device for golf balls comprises a seat, an arch-shaped retainer, and a bottom plate. The seat defines a central recess and defines a bottom opening that communicates with the central recess. The seat is provided with an anti-slip pad within the central recess. Also, the seat is provided with upper positioning means and lower positioning means. The arch-shaped retainer is provided with retainer positioning means corresponding to the upper positioning means of the seat. The bottom plate is provided with plate positioning means corresponding to the lower positioning means of the seat. Therefore, the arch-shaped retainer and the bottom plate can be properly positioned on the seat. Furthermore, the arch-shaped retainer defines a central slit and the bottom plate defines a plurality of hollowed-out symbols. As such, the marking device can mark a line or symbol on a golf ball conveniently.

Owner:LIAO YUN HSIAN

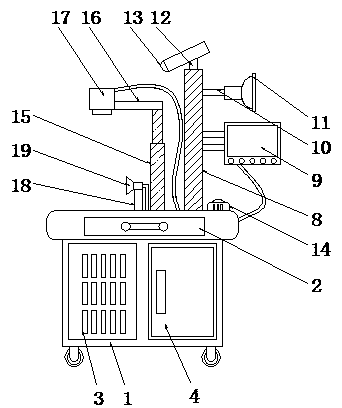

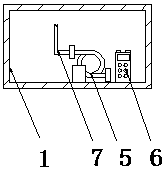

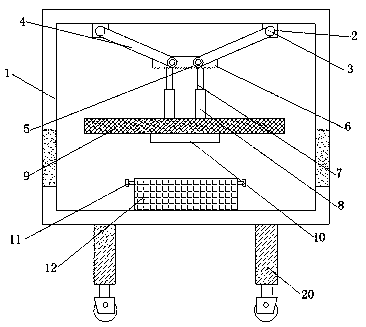

Fully-automatic laser marking machine with prompting function

InactiveCN108057958AConvenient queryRemind attention to safetyLaser beam welding apparatusProximity sensorEngineering

The invention discloses a fully-automatic laser marking machine with a prompting function. The fully-automatic laser making machine comprises a bottom table, wherein the front side of the bottom tableis provided with a drawer in an embedded manner; the position, close to the lower portion of the drawer, at the front side of the bottom table is equipped with a side door; the position, close to oneside of the side door, of the front side of the bottom table is equipped with heat dissipation holes; an air blower is mounted inside the bottom table; one end of the air blower is connected with a hose; a KY12S type controller is mounted at one side of the air blower; and a supporting rod is mounted above the bottom table. The fully-automatic laser marking machine is scientific and reasonable instructure, and is safe and convenient to use; a camera is arranged for recording a marking process, so that faults are conveniently inquired; a human body proximity sensor and a loudspeaker are arranged, so that voice can be made to remind people; the air blower is arranged, so that impurities and dust on the surface of a packaging box are removed, and therefore, unclear marking is prevented; andthe telescopic pole is arranged to freely regulate a distance from a marking head to a packaging box, so that packaging boxes of different types are marked.

Owner:盐城星辰包装材料有限公司

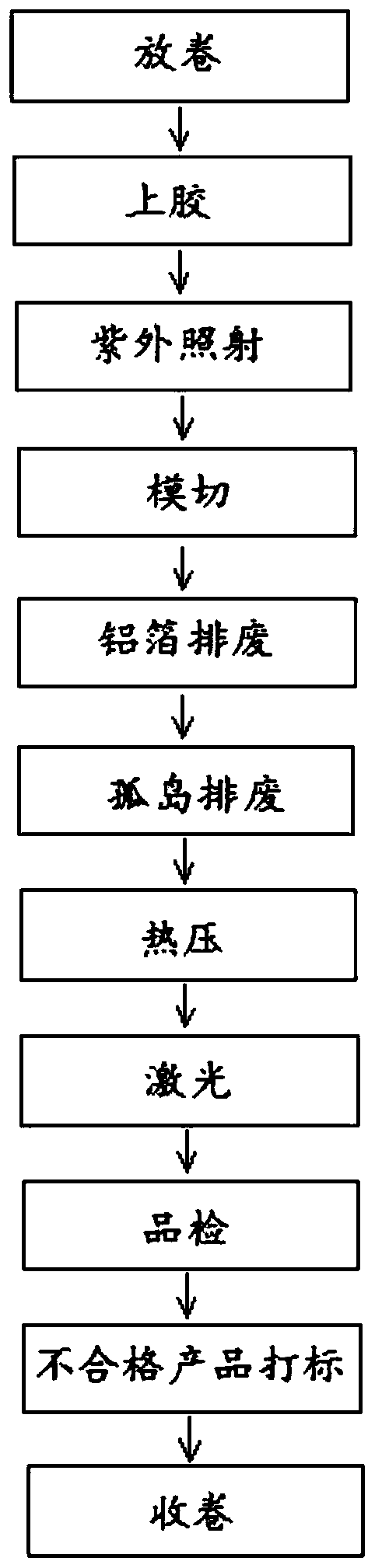

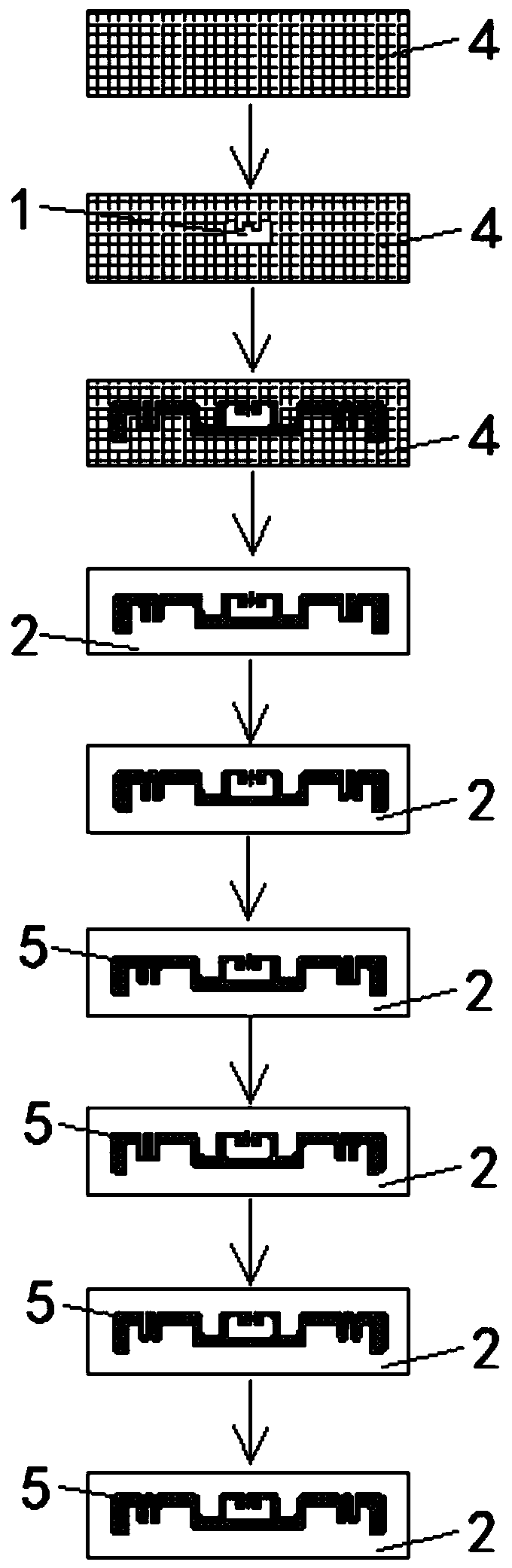

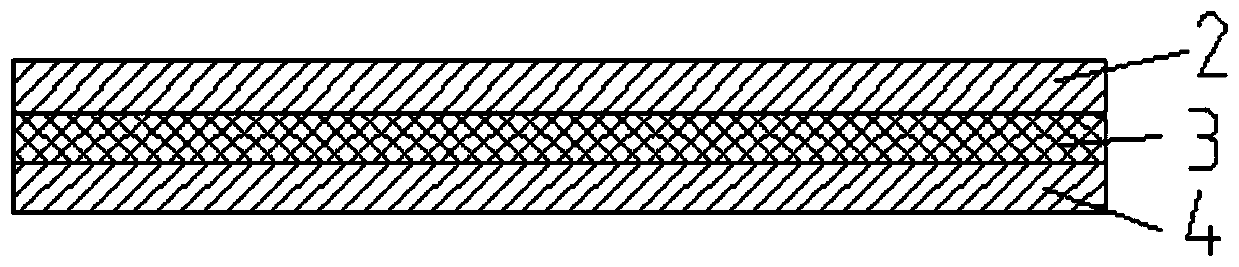

Manufacturing method of environment-friendly RFID tag antenna

InactiveCN110350292AReduce pollutionReduce processing difficultyAntenna supports/mountingsRadiating elements structural formsTag antennaEngineering

The invention relates to a manufacturing method of an environment-friendly RFID tag antenna; the manufacturing method comprises the following steps of S1, coating an island at a raw material set position with glue of 10-20 [mu]m to form a glue layer; S2, enabling the raw materials which are glued to be subjected to die cutting treatment, and meanwhile, carrying out waste discharge treatment to obtain a primary product; S3, carrying out hot-pressing treatment on the primary product; S4, carrying out laser cutting treatment on the hot-pressed primary product to obtain a finished product; and S5,carrying out inspection on the finished product to obtain a qualified product. The method has the beneficial effects that a traditional chemical corrosion processing technology is replaced by adopting a physical processing technology, so that the processing difficulty is reduced, the processing efficiency is improved, the environmental pollution is greatly reduced, and meanwhile, the production cost is lowered.

Owner:武汉中鼎智科物联网科技有限公司

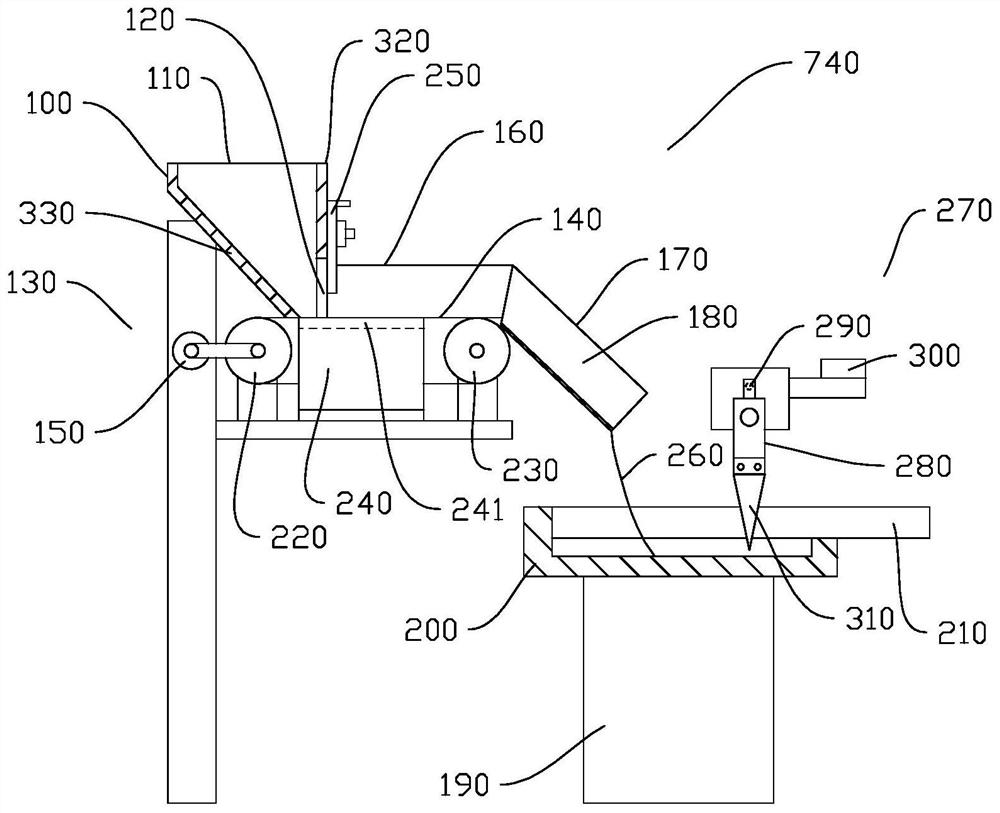

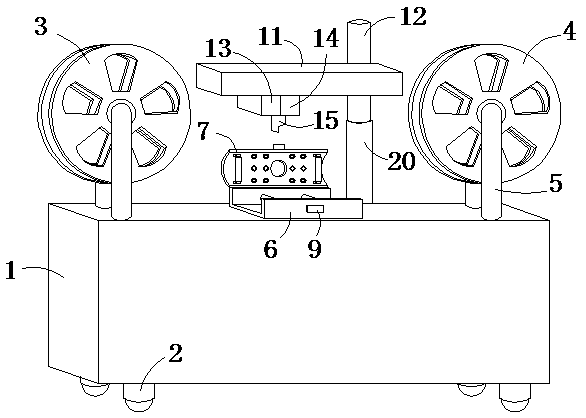

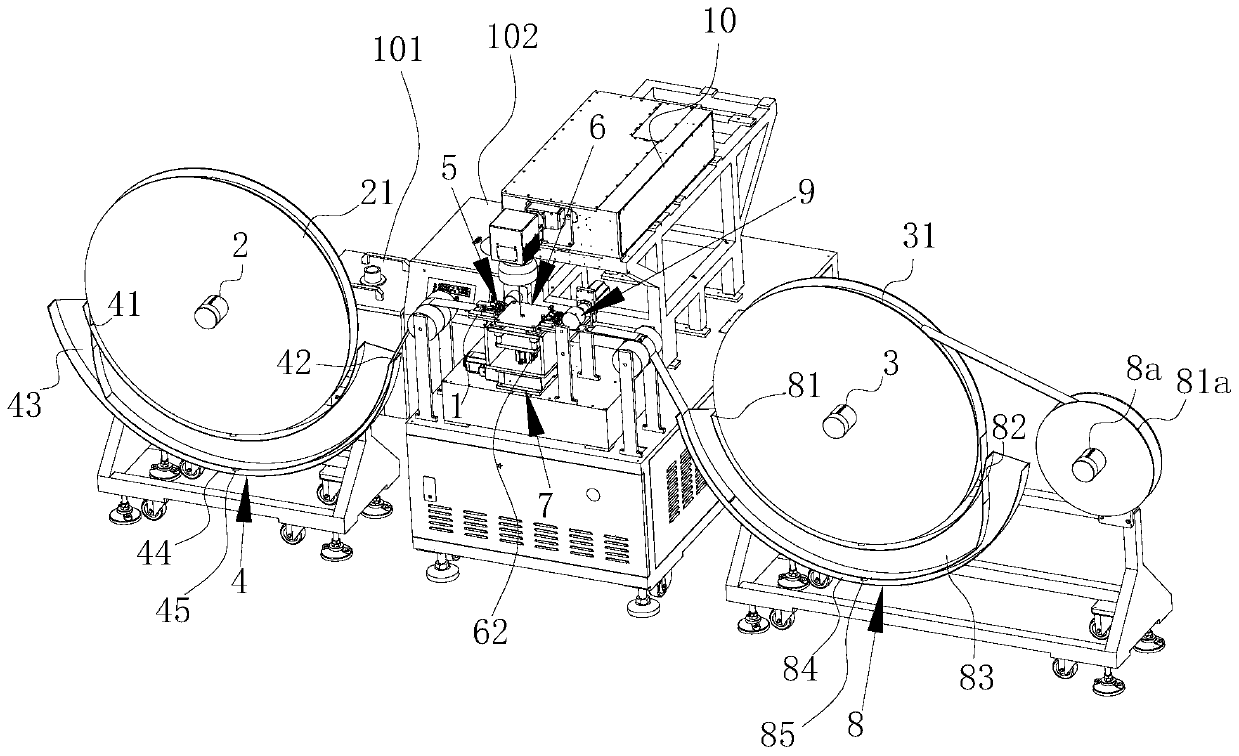

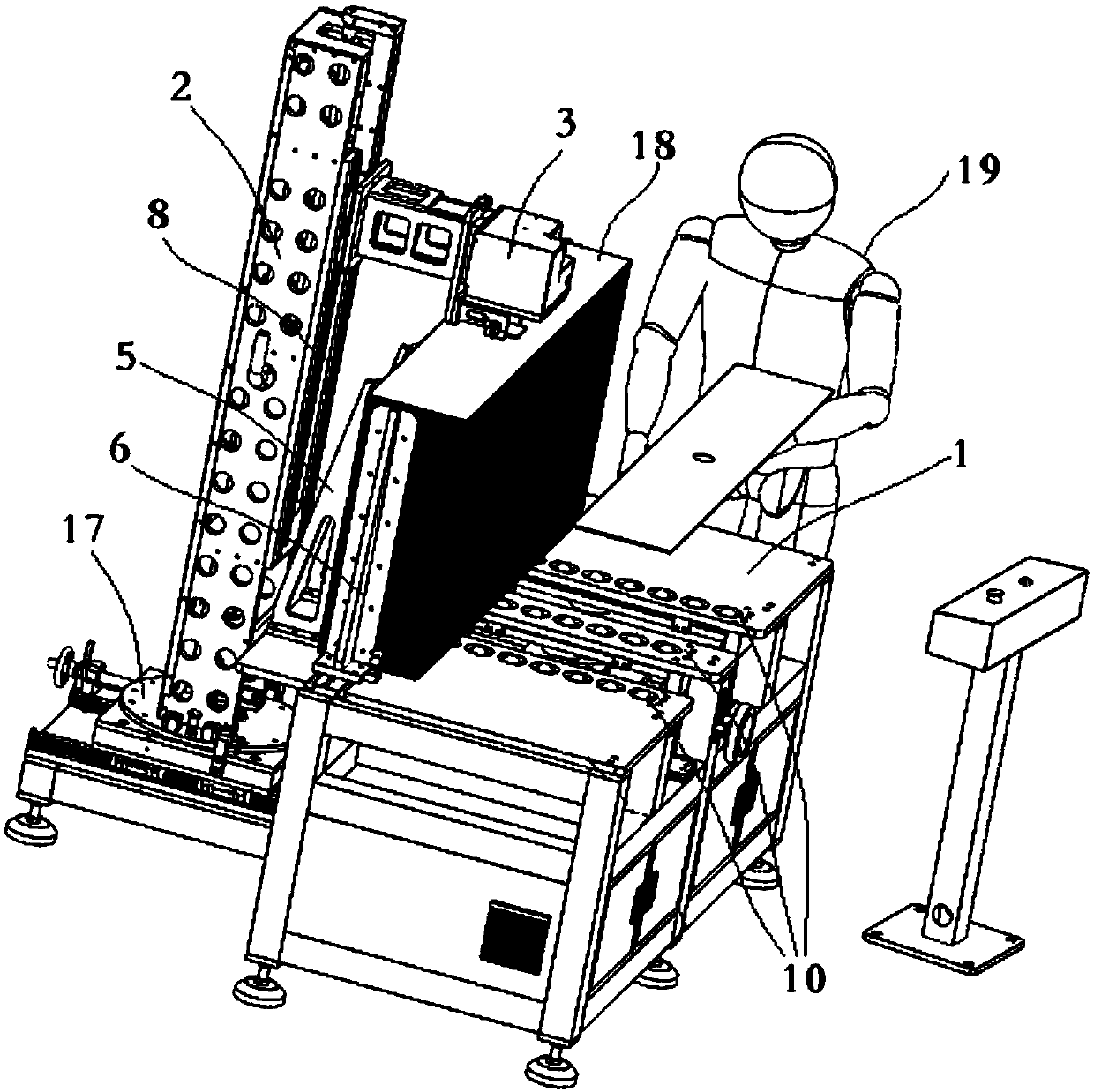

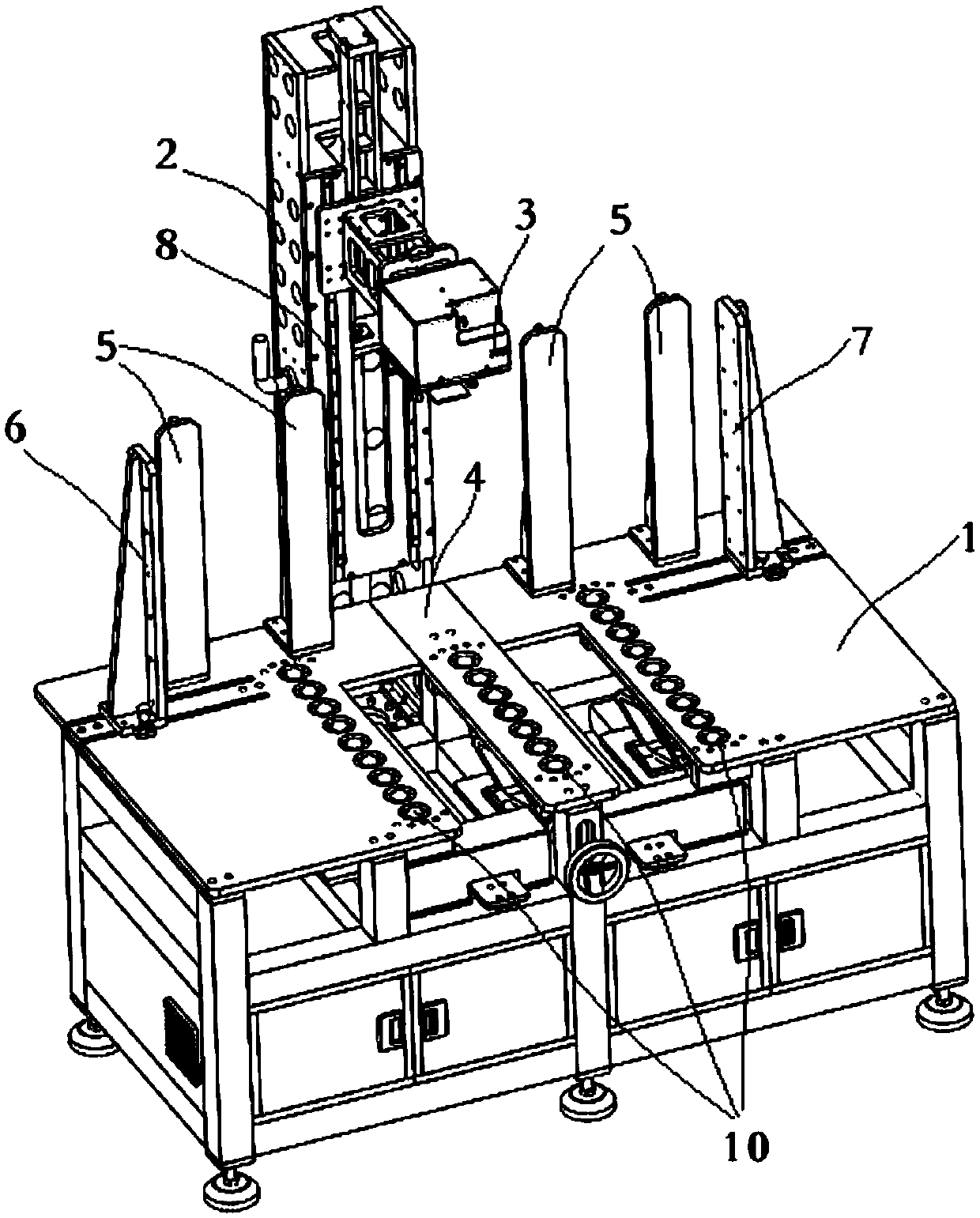

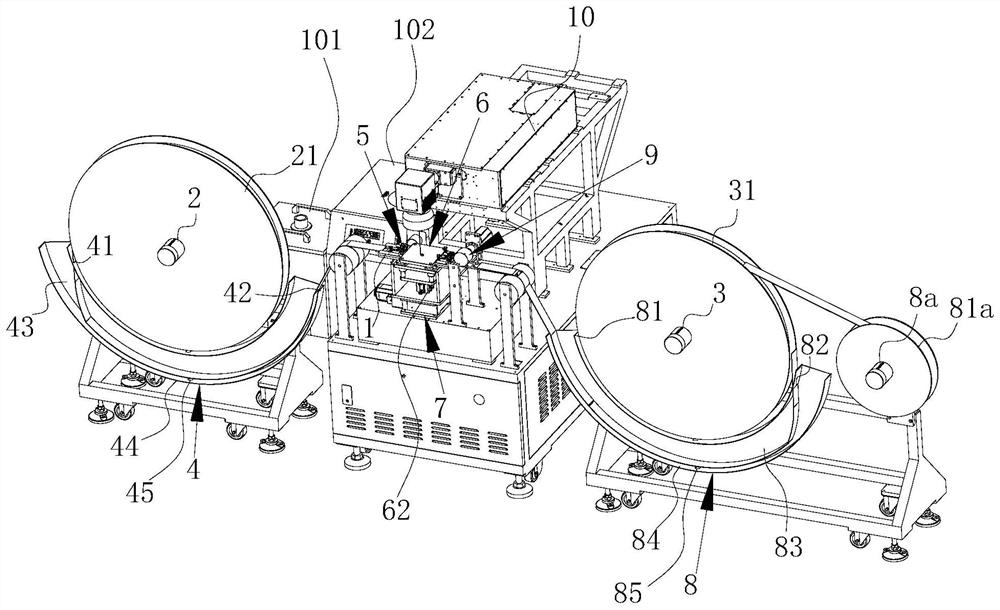

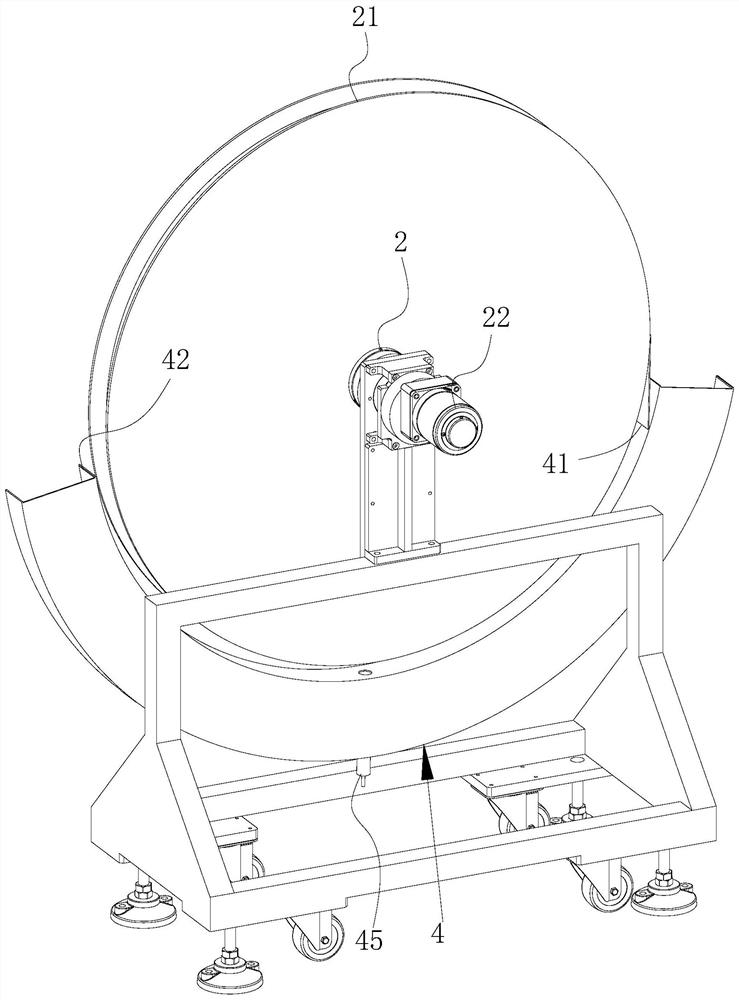

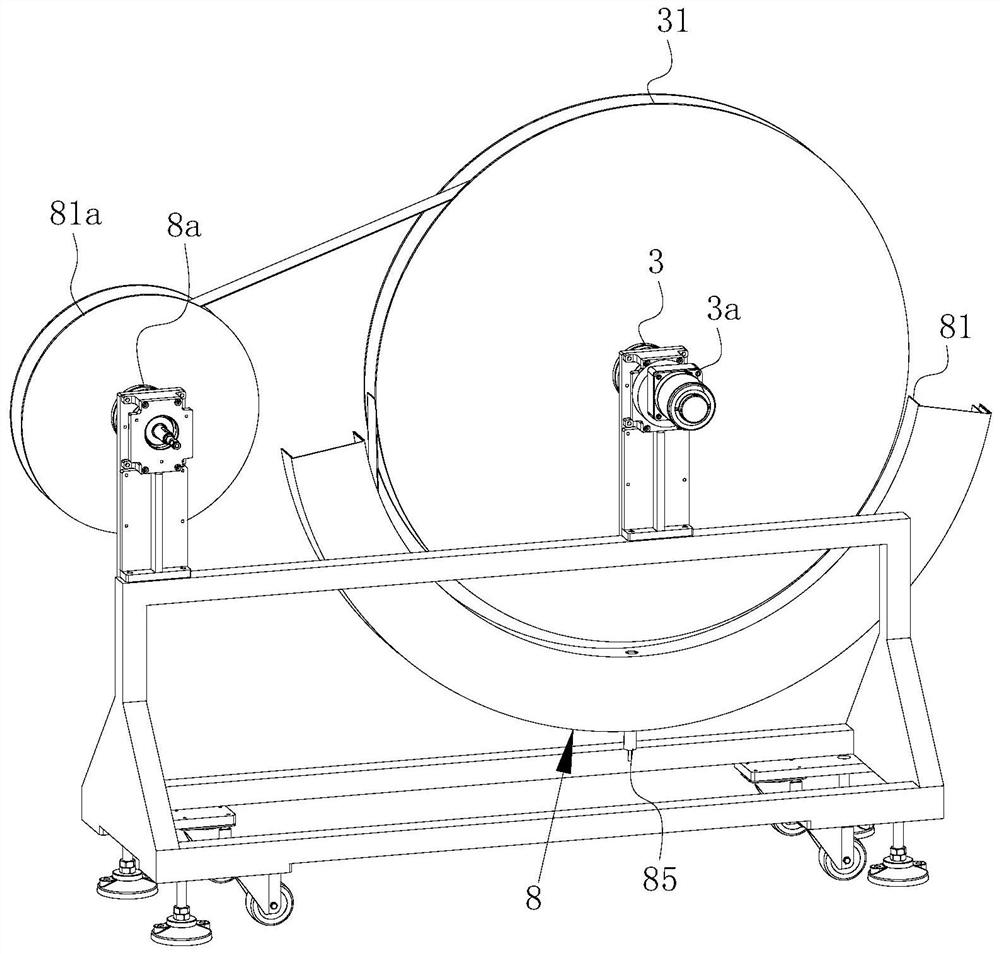

Automatic roll material machining device, laser marking system and roll material machining method

ActiveCN110091060AEasy to transportEasy to collectLaser beam welding apparatusEngineeringDrive motor

The invention provides an automatic roll material machining device. The automatic roll material machining device comprises a carrying platform, a feeding roll, a material collecting roll and a material collecting driving motor; the feeding roll is arranged on one side of the carrying platform and used for winding unmarked material strips; the material collecting roll is arranged on the side, opposite to the feeding roll, of the carrying platform and used for winding marked material strips; the material collecting driving motor is connected to the material collecting roll and used for driving the material collecting roll to rotate; and the automatic roll material machining device further comprises a first anti-deformation mechanism, the first anti-deformation mechanism is arranged on the outer side of the feeding roll and provided with a feeding port and a discharging port, the feeding port faces the roll surface of the feeding roll, a buffering cavity communicating with the feeding port and the discharging port is formed in the first anti-deformation mechanism, the buffering cavity is provided with a buffering surface parallel to the circumferential direction of the feeding roll, and the buffering surface is used for making contact with the back faces of the material strips and located between the feeding port and the discharging port. The invention further provides a laser marking system and a roll material machining method. The purpose that the roll materials are not prone to being deformed in the laser marking process is achieved.

Owner:HANS LASER TECH IND GRP CO LTD

Portable cleaning device for golf equipment and method therefor

InactiveUS20070169297A1Convenient markingSafe cleaningBoard cleaning devicesCarpet cleanersEngineeringGolf Ball

A portable cleaning device for golf equipment that may be folded and carried in a golfer's pocket without interfering with the golfer's swing or leaking any cleaning liquid. The cleaning device is capable of cleaning not only golf balls but other golf equipment, such as golf clubs, as well. The cleaning device also has a golf ball marker removably coupled thereto so that the golfer may conveniently mark the place of the golf ball before picking it up to clean it. The cleaning device is also capable of being safely washed in a washing machine.

Owner:WADE WILLIE J

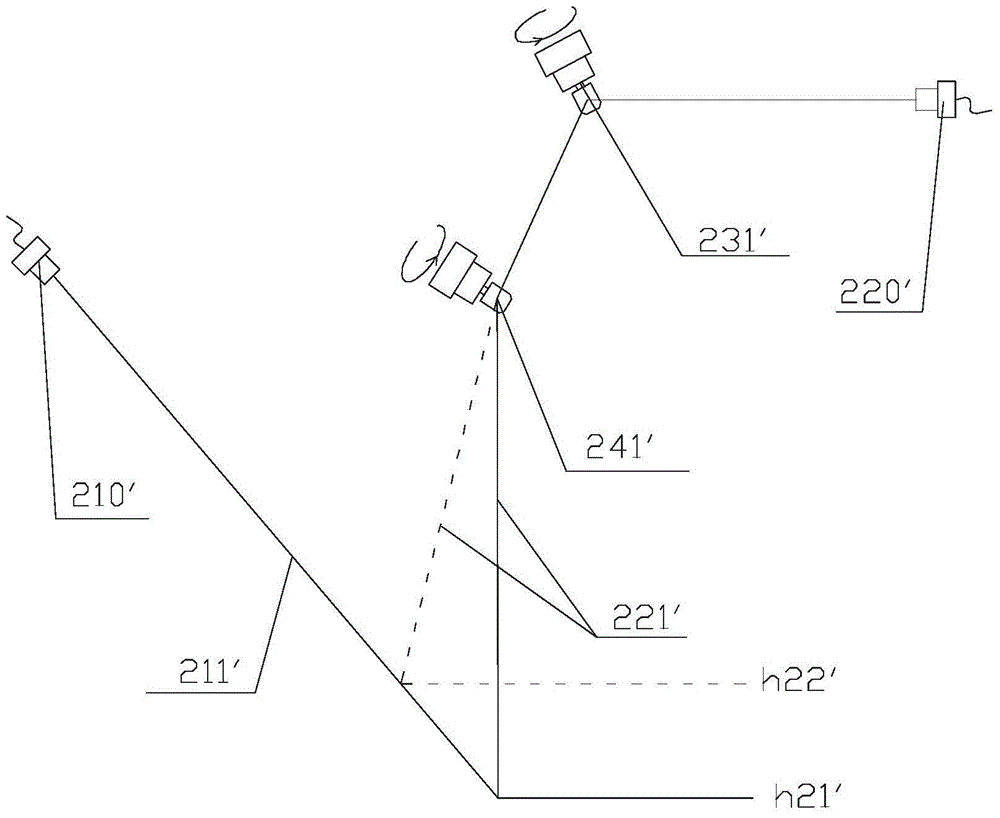

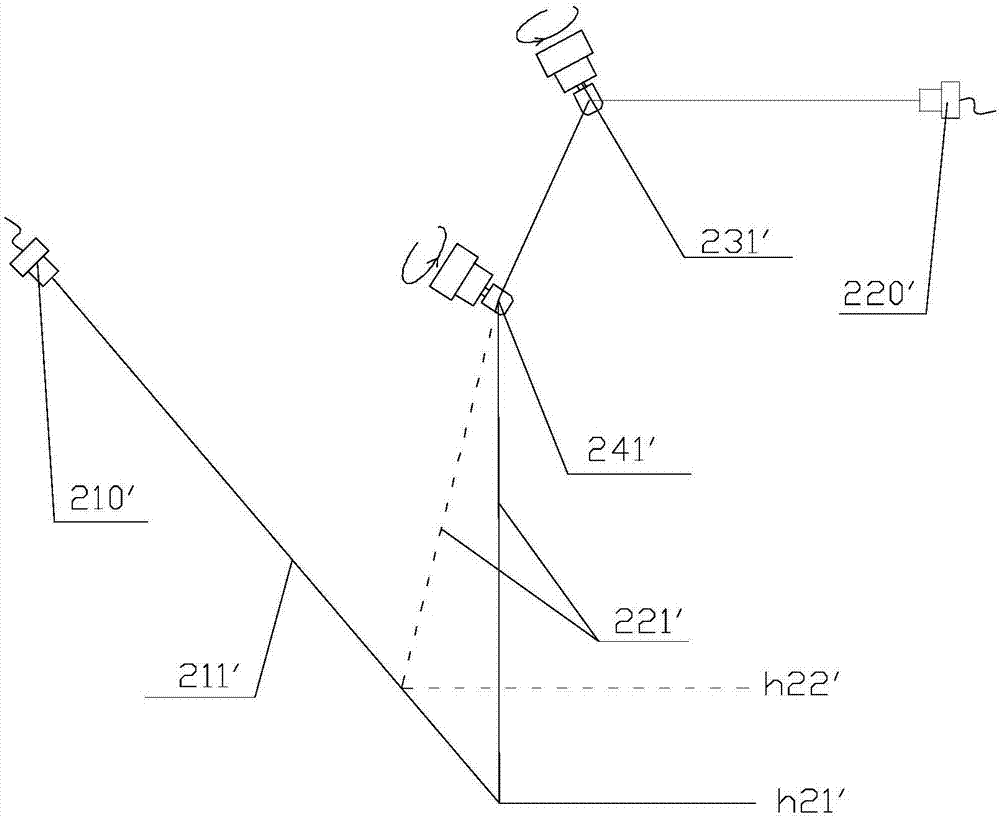

A marking method based on controllable distance indication and 3D laser marking machine

ActiveCN104551409BConvenient markingImprove conveniencePrintingLaser beam welding apparatusLight beamLaser

A controllable distance indication method and a controllable distance indication device for a 3D laser marking machine. The controllable distance indication device comprises a first visible light indicator (110, 110a, 110b, 210, 210', 310), a second visible light indicator (120, 220, 220', 320) and a control unit (8). The first visible light indicator can emit a first visible light beam (111, 111a, 111b, 211, 211', 311) to a marking area. A reflection device is arranged in the light path of the second visible light indicator and used for reflecting a second visible light beam (121, 121a, 121b, 221, 221', 321). After the second visible light beam is reflected, the second visible light beam and the first visible light beam converge in the marking area. The control unit controls the deflection angle of the reflection device so that the convergence point of the first visible light beam and the second visible light beam corresponds to an initial focal point of the 3D laser marking machine. In this way, the initial focal distance of the laser marking machine is displayed by controlling convergence of the visible light beams, and the controllable distance indication device can carry out focusing automatically and complete indication of the initial focal distance accurately and rapidly.

Owner:GUANGZHOU NEW CKLASER CO LTD

Rat tail cutter

InactiveCN108066038AConvenient markingAvoid pollutionAnimal fetteringSurgical veterinaryRat tailEngineering

The invention discloses a rat tail cutter which comprises a box body, a rat tail clip and a cutting blade. Both ends of the box body are provided with openings, and the outer walls of the tops of thetwo ends of the box body are provided with an inlet plate insertion groove and an outlet plate insertion groove respectively. Equidistantly-distributed baffle insertion grooves are formed in the outerwall of the top of the box body, and the baffle insertion grooves are located between the inlet plate insertion groove and the outlet plate insertion groove. The vertical sections of the inlet plateinsertion groove, the outlet plate insertion groove and the baffle insertion grooves each are of a C-shaped structure. An inlet plate is inserted in the inlet plate insertion groove and includes a porous inlet plate and a clamping piece plate. A rat head clamping plate is inserted in the outlet plate insertion groove, and baffles are inserted in the baffle insertion grooves. According to the rat tail cutter, the position of a support can be adjusted according to the length or weight of the rat and the part of the rat to be exposed, an adjustment can be made according to sizes and lengths of different rats, the rat tails and rat heads can be fixed, to facilitate the taking of the rat tail and the marking on the rat ear, the time is saved, and a sample can be protected from pollution.

Owner:SHANGHAI CHEST HOSPITAL

Double-station optical fiber marking device for manufacturing laser devices

ActiveCN112077454APrevent dust fallConvenient markingLaser beam welding apparatusPhysicsErbium lasers

The invention discloses a double-station optical fiber marking device for manufacturing laser devices. The marking device comprises a device body, a marking mechanism and clamps. The marking mechanismcomprises an air cylinder, an installing plate, a stabilizing structure, a driving assembly, a marking device body and a cooling assembly. According to the marking device, by arranging the device body and the marking mechanism, the function of preventing dust from falling on the marking device body when the device is not used can be achieved. By means of the cooling assembly, when the marking device body works, the function of cooling the marking device body is achieved. By arranging the installing plate, a magnet and replaceable clamp bodies, the function of conveniently replacing the replaceable clamp bodies is achieved, and then the device is suitable for marking different models of laser devices. On the whole, the function of using the marking device body alternately is achieved, andthe temperature of the marking device body is prevented from being too high and influencing performance of the marking device body. While marking is carried out, the other sets of clamps are fed and discharged, and the production efficiency is improved.

Owner:湖北安一辰光电科技有限公司

Marking device with lifting function

ActiveCN110948114AMark accuratelyConvenient markingLaser beam welding apparatusStructural engineeringMechanical engineering

Owner:西刻标识设备(上海)有限公司

Marking machine having dust-removing function

InactiveCN108099424AWith dust removal functionHealth hazardDirt cleaningOther printing apparatusEngineeringHuman health

The invention discloses a marking machine having a dust-removing function. The marking machine comprises a base, wherein a lifting device is fixedly connected on one side of the top part of the base,a supporting plate is fixedly connected to the top part of the lifting device, a supporting shaft is rotatably connected to the top part of the supporting shaft, a top plate is fixedly connected to the top part of the supporting shaft, both sides of the top part of the top plate are fixedly connected with vertical plates respectively, a lead screw is rotatably connected between opposite sides of the two vertical plates, and the surface of the lead screw is in threaded connection with a movable block. The marking machine relates to the related technical field of marking machines. The marking machine having the dust-removing function pumps out smoke dust debris by means of a sucking pump, and conveys the smoke dust debris into a material discharge for undergoing adsorption treatment by meansof an adsorption solution, thereby avoiding harms to the human health due to pollution caused by the smoke dust debris, being conductive to improving the processing effect, ensuring the processing quality, being able to place the materials on a workbench conveniently, being capable of marking the materials of different heights, and improving the convenience in the using process.

Owner:XINGUANG NUMERICAL CONTROL TECH

Total detection machine for gear shifting shaft

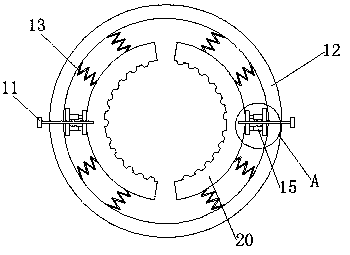

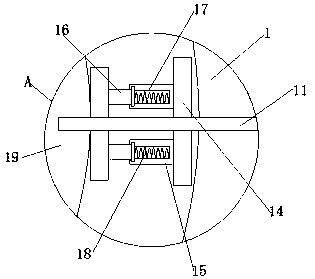

PendingCN114216662AImplement automatic detectionImprove detection efficiencyMachine part testingDetection of fluid at leakage pointCircular discEngineering

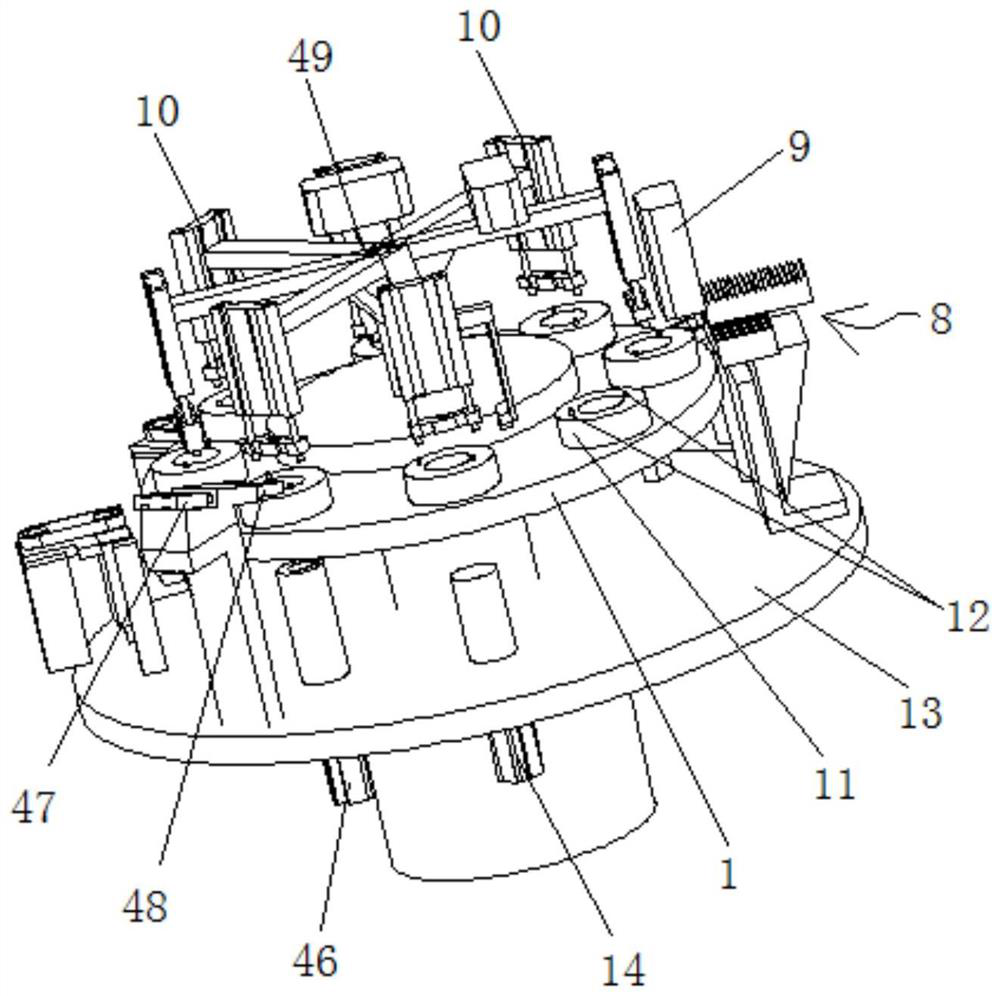

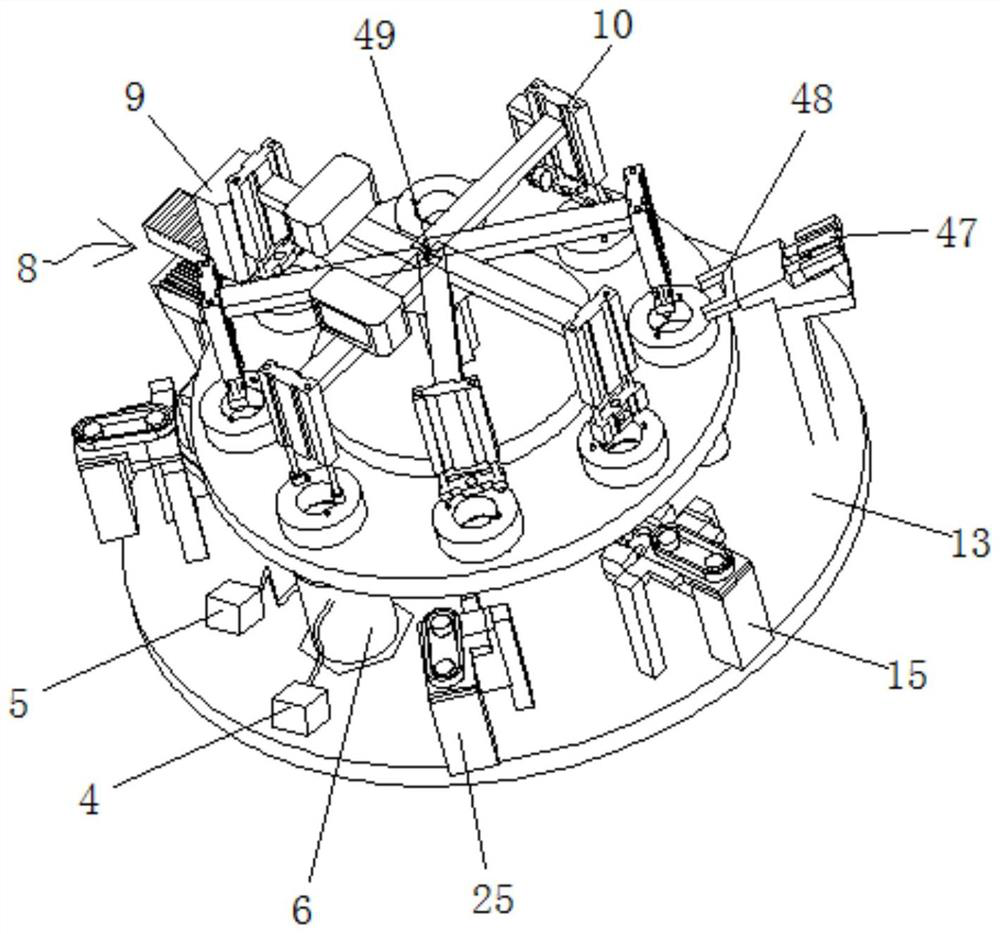

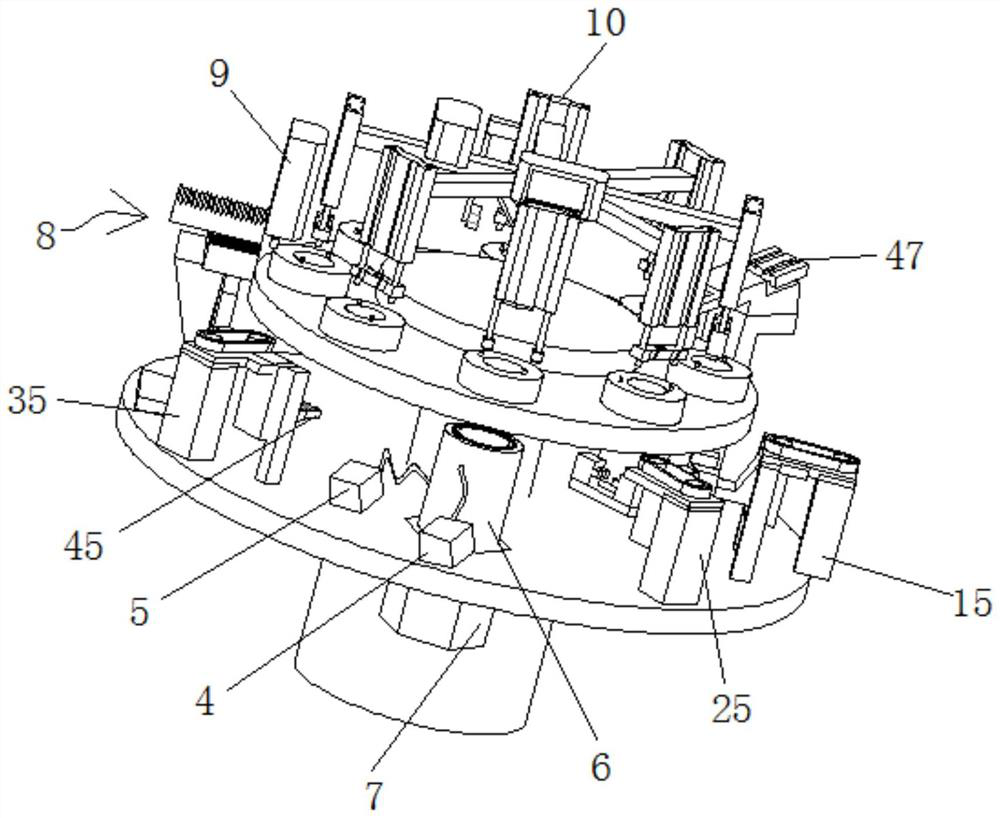

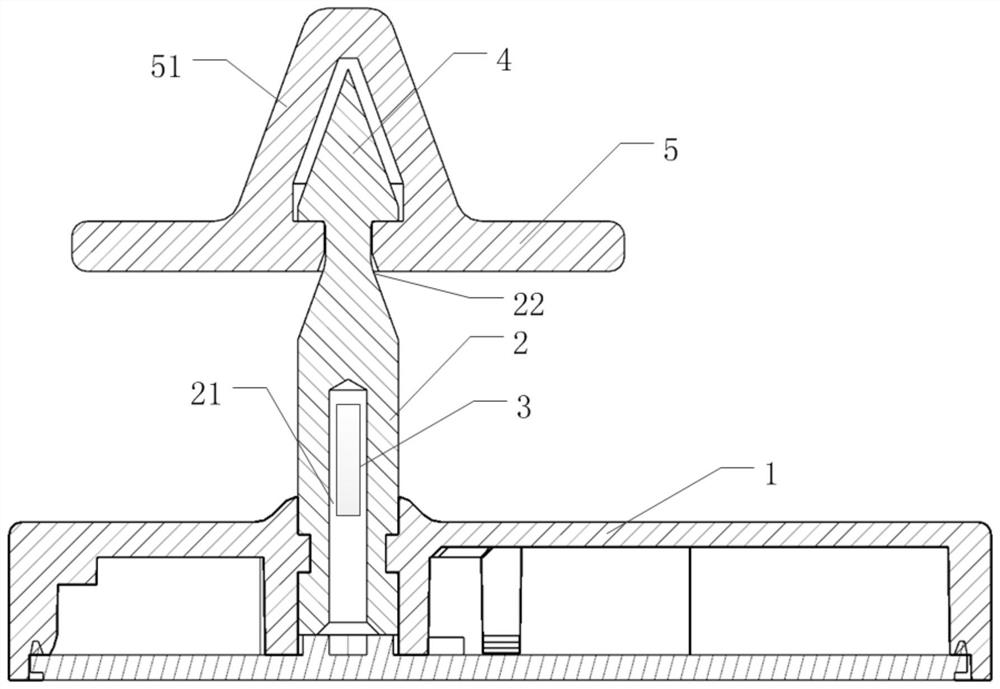

The invention relates to a gear-shifting shaft general detection machine, which comprises a disc, a detection device I, a detection device III and a positioning device, and is characterized in that the disc is horizontally and rotatably arranged, and a plurality of detection holes which are used for placing gear-shifting shafts and are through up and down are uniformly formed in the edge of the disc along the circumferential direction at intervals; the positioning device is fixedly erected above the disc and used for positioning the gear shifting shafts at the multiple detection holes. The first detection device and the third detection device are installed below the disc in the circumferential direction of the disc at intervals, the first detection device is used for detecting whether the gear shifting shaft at the corresponding detection hole is located at the neutral gear or not, and the third detection device is used for detecting the gear shifting force when the gear shifting shaft at the corresponding detection hole rotates. The gear shifting shaft detection device has the advantages of being compact in structure, capable of achieving automatic detection of multiple detection indexes of the gear shifting shaft, high in detection efficiency and high in accuracy.

Owner:武汉泛洲精冲有限公司

Male tag needle, needle temperature measuring male tag and ear tag

PendingCN111758602AGood thermal conductivityImprove temperature measurement accuracyOther apparatusBiomedical engineeringEar tag

The invention discloses a male tag needle, a needle temperature measuring male tag and an ear tag. The ear tag comprises the needle temperature measuring male tag and a female tag; the male tag comprises a male tag base and a middle shaft; and the male tag needle also comprises a middle shaft. A cavity is designed in the middle shaft, and a temperature sensor is installed in the cavity. The end ofthe middle shaft is connected with a needle, and the part of the middle shaft connected with the needle is concave. The middle shaft is made of beryllium bronze. According to the design, under the condition that an elastic structure is not designed, it can be guaranteed that a temperature measuring sensor can make tight contact with the ear of an animal all the time, marking is more convenient and faster through the small-size needle head, caused wounds are smaller, and the problem that ear cartilages are hard and difficult to penetrate can be solved.

Owner:四川御智微科技有限公司

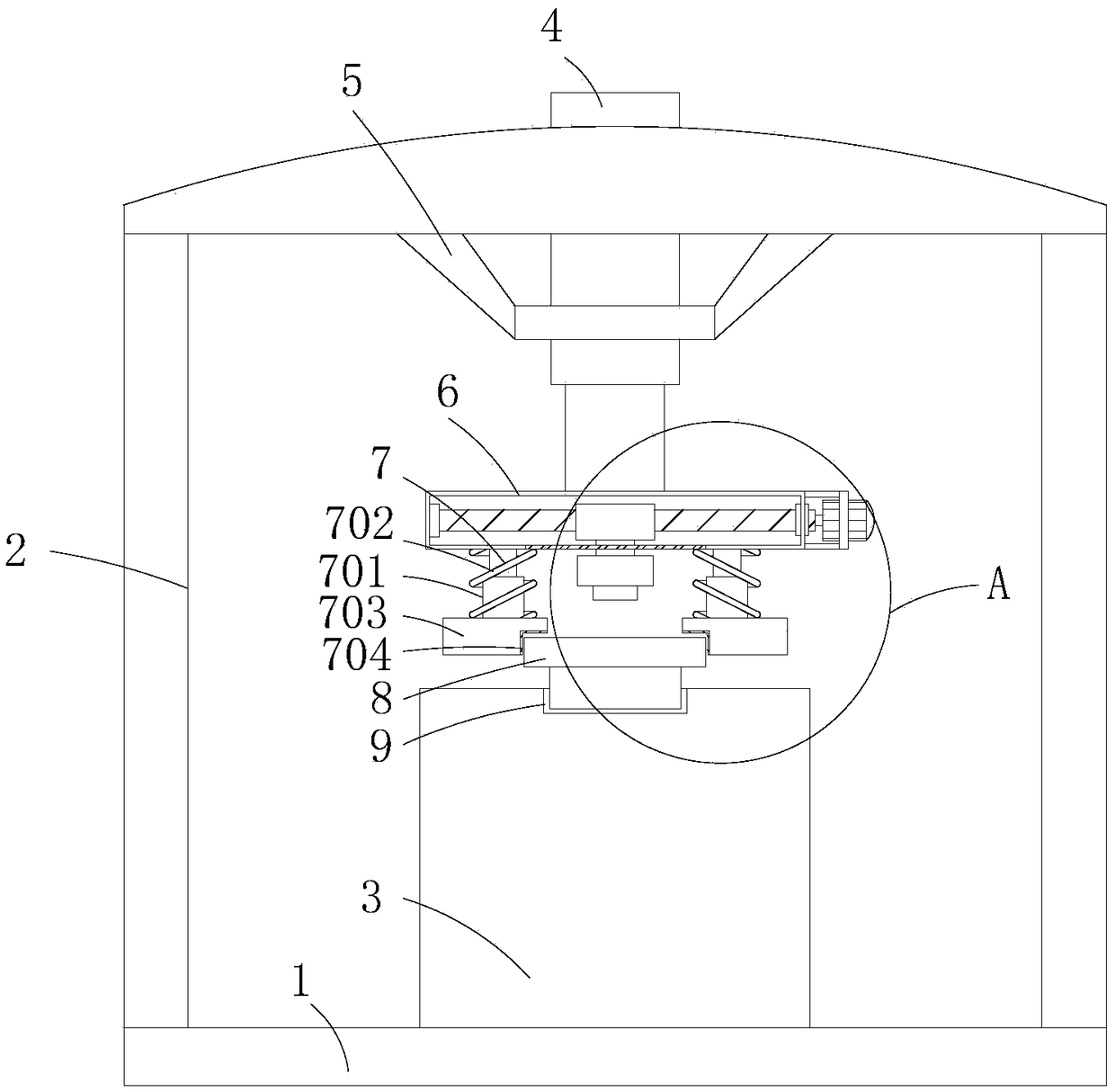

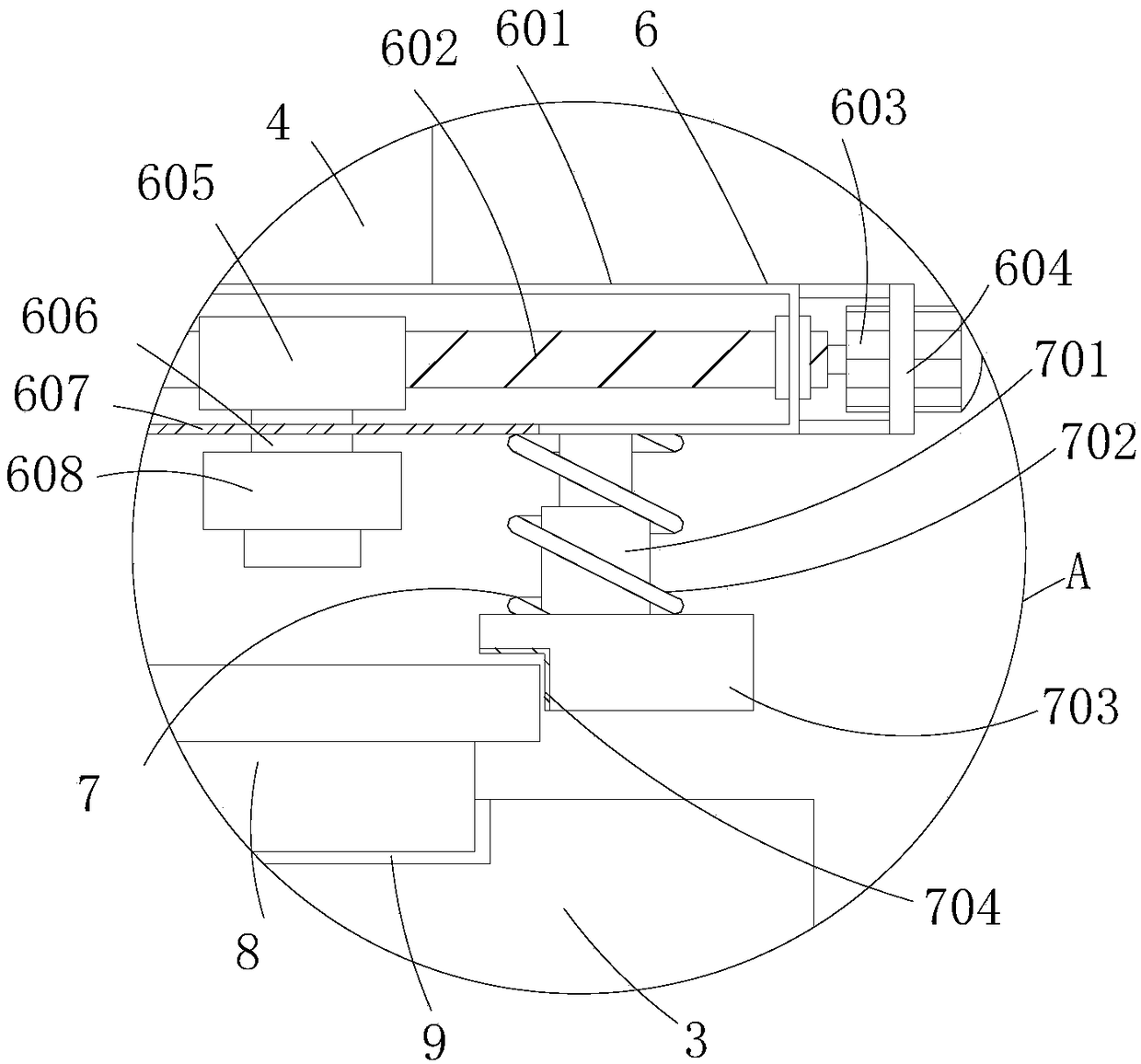

Automobile fuel tank cap marking device

The invention discloses an automobile fuel tank cap marking device which relates to the field of automobile component processing technology. The automobile fuel tank cap marking device comprises a base, a supporting frame, a supporting seat, a hydraulic rod, a marking mechanism, a fixing mechanism and a lid. The side surface of top of the base is fixedly connected with bottom of the supporting frame. The hydraulic rod penetrates through the middle part of top of the supporting frame and is fixedly connected with the supporting frame. The bottom of the hydraulic rod is fixedly connected with top of the marking mechanism. The side surface of bottom of the marking mechanism is fixedly connected with the fixing mechanism. The marking mechanism comprises a fixed rod, a threaded rod, a rotatingmotor, a threaded sleeve, a slide block, a chute and a marking head. The fixing mechanism comprises a telescopic rod, a spring and a fixing block. According to the automobile fuel tank cap marking device, the fixing block is driven to drop through the hydraulic rod for fixing the lid by the fixing block, thereby facilitating fixation of the lid; and furthermore in a fixing process, the marking head is downwards moved for facilitating marking on the lid, thereby simplifying a lid marking process, and improving preparing efficiency.

Owner:邵清清

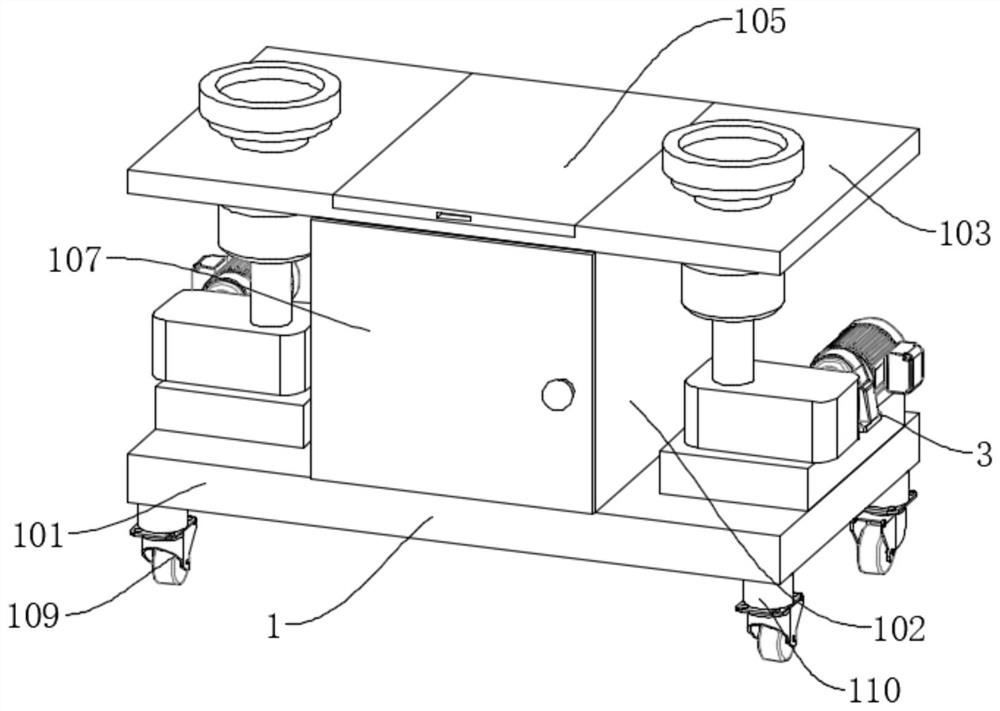

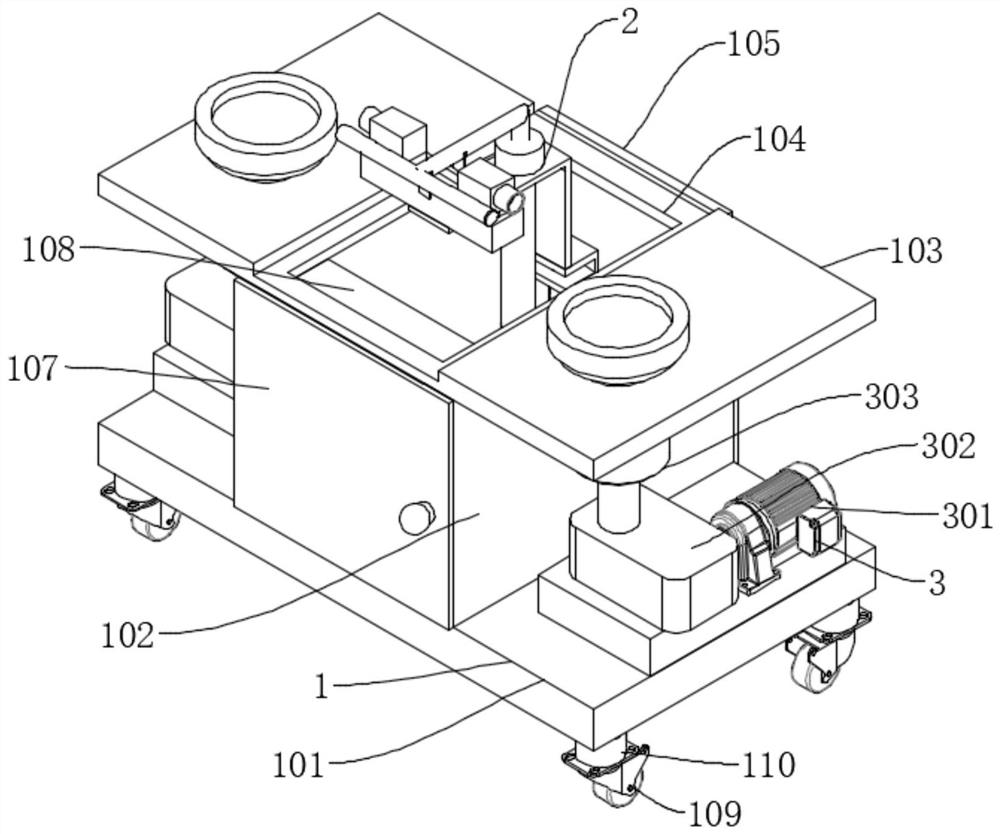

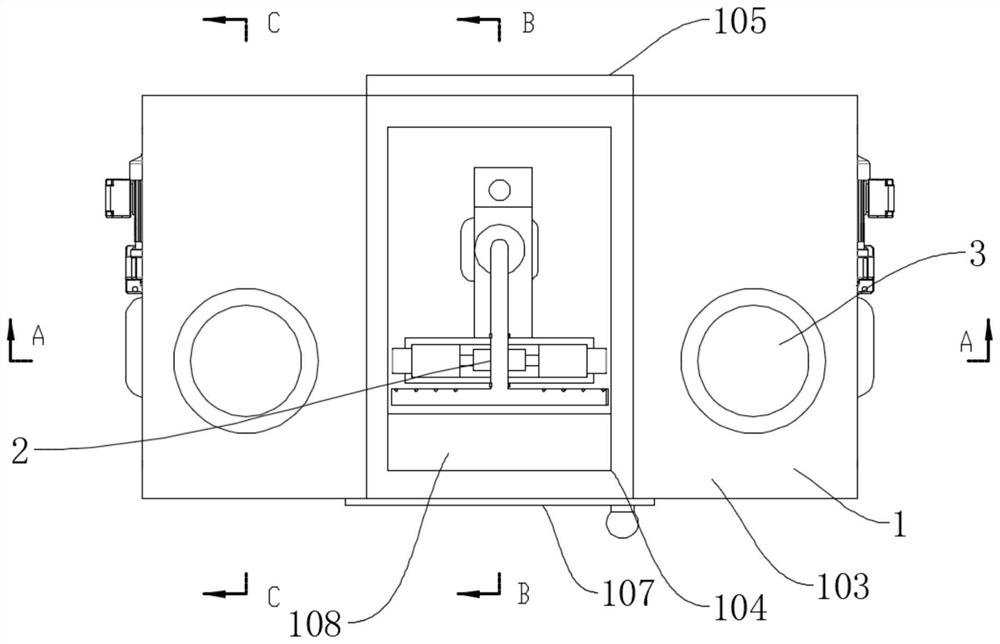

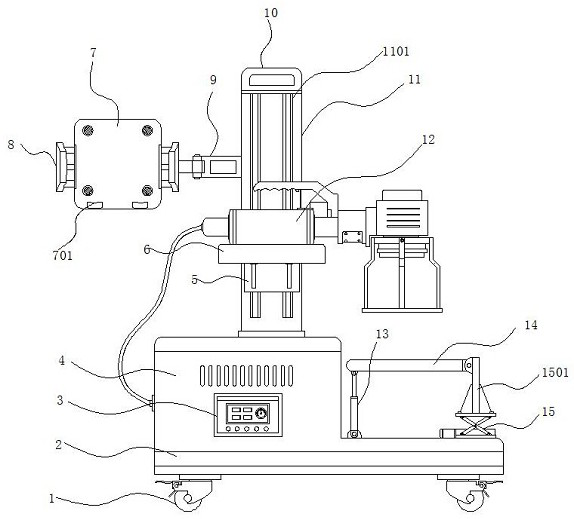

Movable laser marking machine convenient to assemble

InactiveCN112059427AConvenient markingImprove applicabilityLaser beam welding apparatusEngineeringStructural engineering

The invention discloses a movable laser marking machine convenient to assemble which specifically comprises a bottom plate, a cabinet, a lifting device, a marking pore plate and a sliding groove. Universal wheels are installed at four corners of the bottom of the bottom plate correspondingly; the cabinet is installed on one side of the top of the bottom plate; a control panel is arranged in the middle of one end of the cabinet; the lifting device is installed at the top end of the cabinet; a shear type frame is installed on the other side of the top of the bottom plate; a pore plate installation frame is fixed to the top end of the shear type frame; the marking pore plate is hinged to the top of the side, close to the cabinet, of the pore plate installation frame; and a hydraulic telescopic rod is hinged to the side, close to the cabinet, of the bottom end of the marking pore plate. According to the movable laser marking machine convenient to assemble, by arranging the shear type frameand the hydraulic telescopic rod, the height and the angle of the marking pore plate can be adjusted, materials with different specifications and sizes can be marked conveniently by adjusting the height, the angle can be adjusted, marking can be conducted at different angles of the materials conveniently, and the applicability is higher.

Owner:DONGGUAN UNIV OF TECH

Automatic packaging and marking device

InactiveCN110053822AEasy to packConvenient markingWrapper twisting/gatheringPackaging automatic controlProduction lineEngineering

The invention relates to the technical field of industrial processing, in particular to an automatic packaging and marking device. The automatic packaging and marking device comprises a base, a top frame, a conveying mechanism, a packaging mechanism and a marking mechanism, wherein the top frame is arranged above the base through a plurality of supporting legs, the conveying mechanism is arrangedon the base in the length direction of the base by a workbench, the packaging mechanism is arranged above the top frame through a supporting frame, the marking mechanism is arranged on one side of thewidth direction of the top frame through a plurality of supports, a controller is arranged at one corner of the base, a workbench is arranged on the base in the length direction of the base, the packaging mechanism and the marking mechanism are arranged above the center of the workbench, and the controller controls the conveying mechanism, the packaging mechanism and the marking mechanism. According to the automatic packaging and marking device, the marking and packaging of products are synchronously completed through the controller, so that the products can be conveniently subjected to multi-surface packaging and marking, the packaging and marking omission and blindness are avoided, the labor output and a production line are reduced, and the working efficiency is improved.

Owner:LISHUI FEITIANREN MACHINERY DESIGN CO LTD

Marking machine and using method

The invention discloses a marking machine and a using method. The marking machine comprises a base, a baffle plate, a first storage box, a second storage box, a first railway, a detecting device, a control box, an operating panel, a supporting post, an electric pushing rod, a laser marking machine total head, a fixing device, a connecting rod, a swinging device, a second railway, a third railway,a motor, a cam, a cam shaft, a fixing sleeve, a first connecting rod connector, a second connecting rod connector, a connecting rod, a rocking rod, a magnet, a buckle, a hairbrush, a first connectingpost, a second connecting post, a clamping plate, a third connecting post and a fourth connecting post; the upper surface of the base is fixedly connected with the second railway; one end of the second railway is fixedly connected with the fixing device; and the other end of the second railway is fixedly connected with the baffle plate. The marking machine and the using method have the beneficialeffects that marking is precise, the automation degree is high, time is shortened, the marking machine is convenient to use and is high in efficiency, the defective rate is reduced, and the using method is simple and easy to operate.

Owner:MINGGUANG SANYOU ELECTRONICS

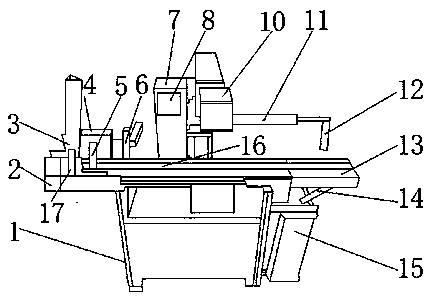

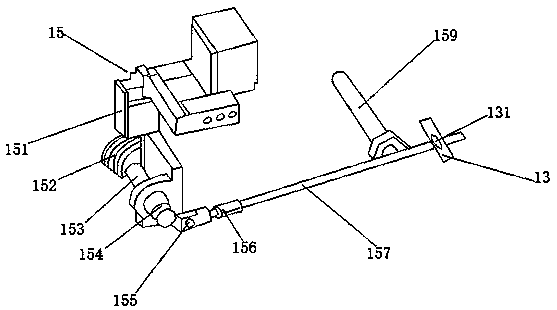

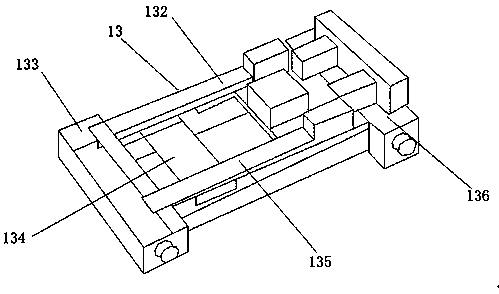

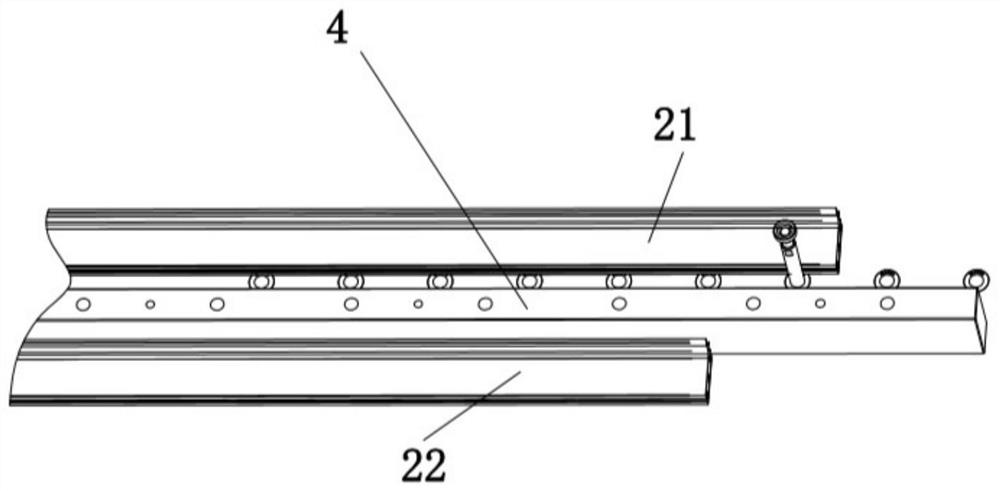

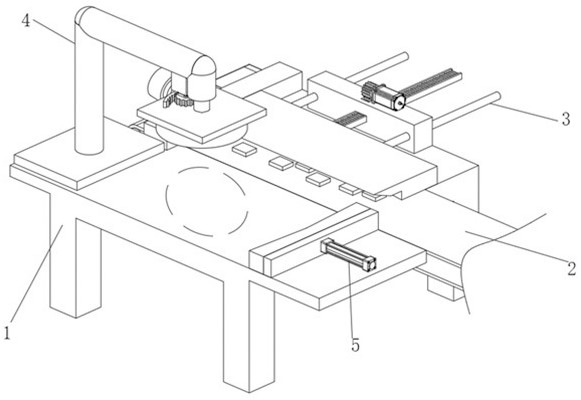

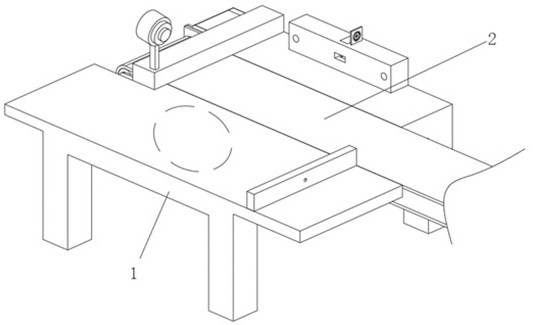

Skylight guide rail finish sawing machine gauge

PendingCN112097610AEasy to managePrecise positioningUsing optical meansMechanical measuring arrangementsEngineeringMachine

The invention relates to a skylight guide rail finish sawing machine gauge which comprises a machine table, a positioning strip and a transverse sliding rail, the middle of the end face of the machinetable divides the end face of the machine table into a length detection face and a marking working face through the transversely-arranged positioning strip, and the two ends of the length detection face are provided with a positioning end detection assembly and a translation end detection assembly respectively. A transverse sliding rail is installed on the rear supplement edge of the length detection face of the machine table, an air cylinder positioning module connected with the translation end detection assembly is installed on the transverse sliding rail, and a marking machine corresponding to the marking working face is installed at the position, close to the installation positioning end detection assembly, of the machine table. The method has the advantages of simple operation, highdetection efficiency, convenient data recording, convenient management, good universality and the like.

Owner:NINGBO MINTH AUTOMOTIVE PARTS RES&DEV CO LTD

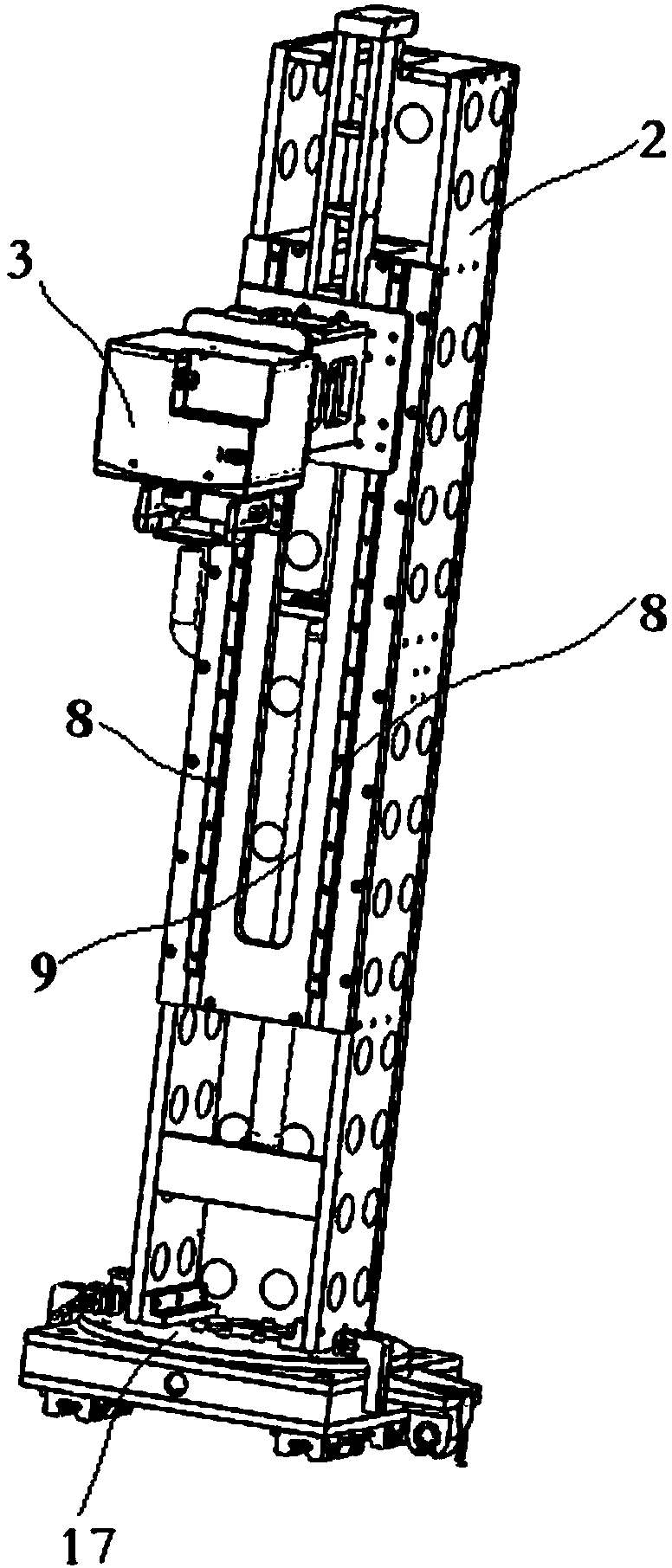

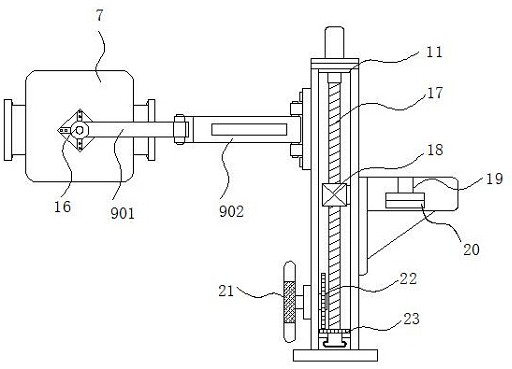

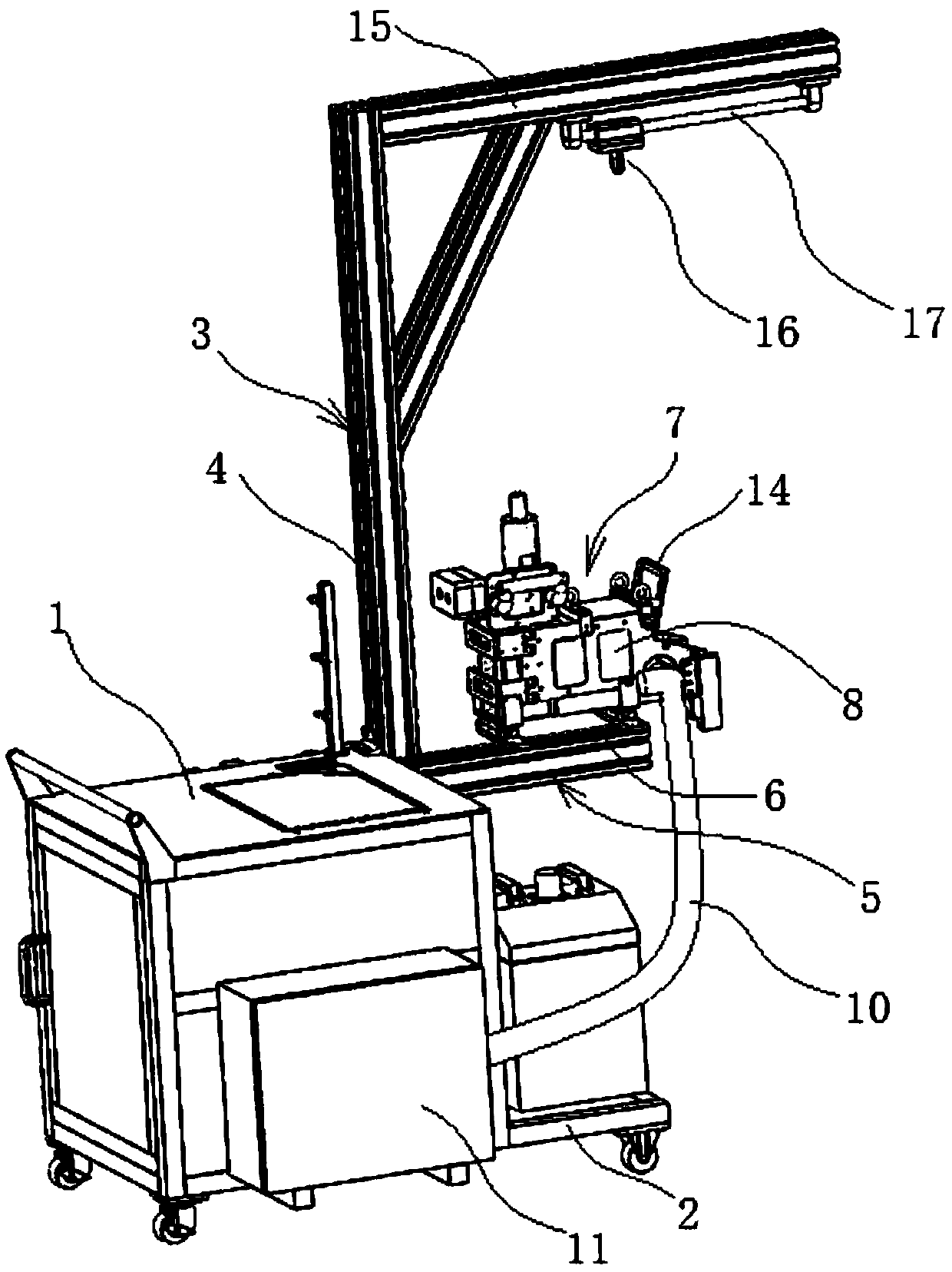

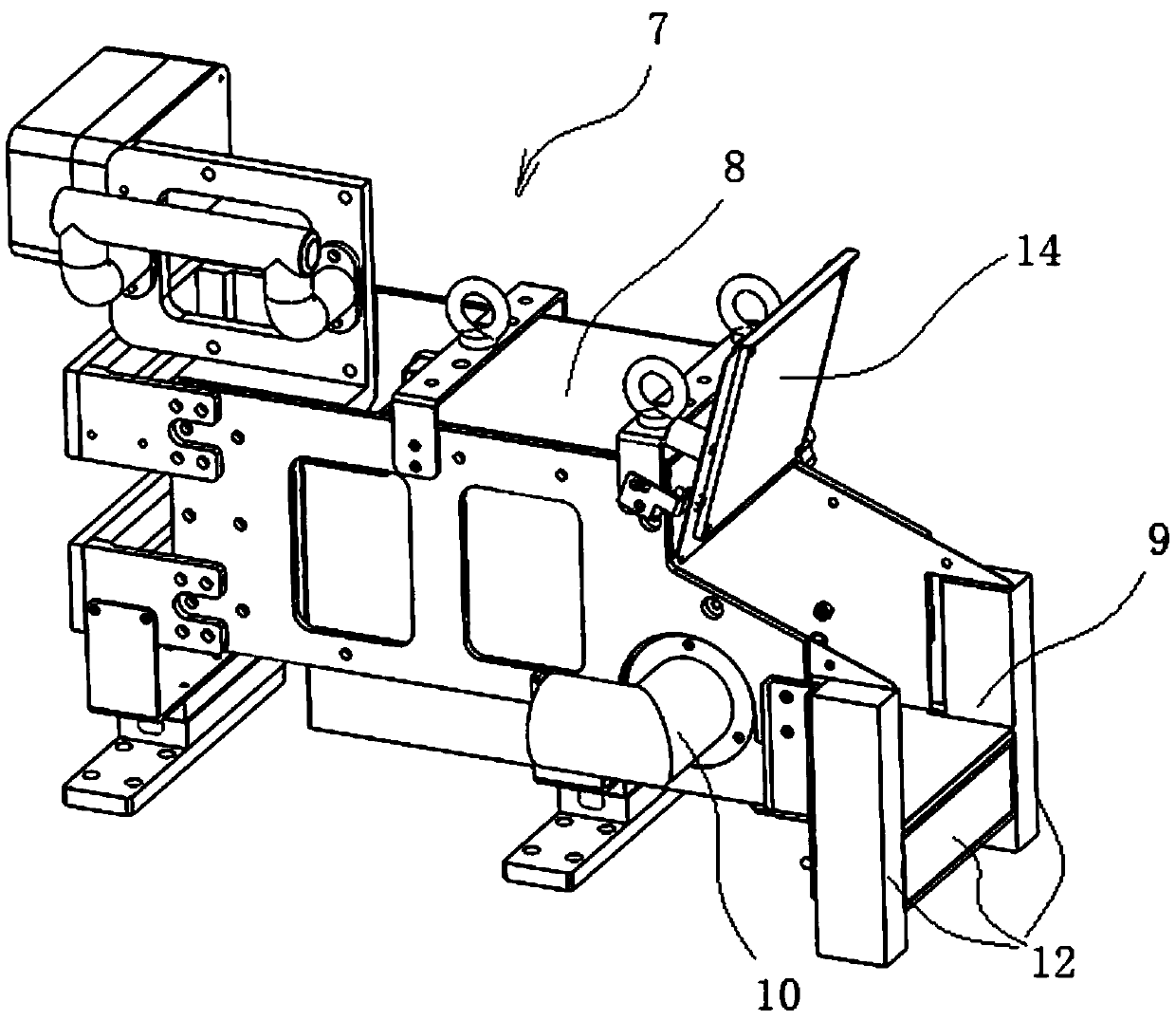

Automatic marking machine for truck and passenger car wheels

The invention provides an automatic marking machine for truck and passenger car wheels and specifically relates to the technical field of wheel rim marking. The automatic marking machine for the truckand passenger car wheels comprises a support column, a machine head, a height adjustment mechanism, a controller and an upper computer. The height adjustment mechanism is fixed to the top end of thesupport column. The machine head is connected with the height adjustment mechanism. Both the machine head and the upper computer are connected with the controller. Both the controller and the upper computer are fixed to the support column. The height adjustment mechanism is in sliding connection with a sliding block assembly. The sliding block assembly is fixedly connected with a connecting part.A machine head backboard is fixed to the machine head. The machine head backboard is hinged to the connecting part through a hinge. A tension spring is arranged on the machine head. The two ends of the tension spring are fixed to a side wall of the machine head and the connecting part correspondingly. One side of the support column is further provided with a conveying rail. The conveying rail is located below the machine head. The automatic marking machine for the truck and passenger car wheels has the advantages that manpower is saved; the automatic marking machine can be used for marking ofwheel rims of the trucks and passenger cars in the conveying rail; vibration in the process of marking is reduced; and a needle head does not touch a position which does not need to be marked by mistake.

Owner:镇江威尔耐车轮制造有限公司

A coil material automatic processing device, a laser marking system and a coil material processing method

ActiveCN110091060BEasy to transportEasy to collectLaser beam welding apparatusElectric machineryEngineering

The invention provides an automatic processing device for coiled materials, which includes a loading platform, a feeding roller, a feeding roller and a feeding driving motor; ; The take-up roller is arranged on the side of the carrier platform opposite to the feed roller, and is used to reel the marked material tape; the take-up drive motor is connected to the take-up roller to drive the take-up roller to rotate; it also includes the first An anti-deformation mechanism, the first anti-deformation mechanism is on the outside of the feed roller, the first anti-deformation mechanism is provided with a feeding port and a discharging port, the feeding port faces the roller surface of the feeding roller, and the first anti-deformation mechanism is inside There is a buffer cavity connected to the feed port and the discharge port. The buffer cavity is provided with a buffer surface parallel to the circumferential direction of the feed roller. The buffer surface is used to contact the back of the material belt. Between the material openings, the present invention also provides a laser marking system and a coil material processing method, which have the purpose of making the coil material not easily deformed during the laser marking process.

Owner:HANS LASER TECH IND GRP CO LTD

Automatic positioning and marking clamp

Owner:无锡市蠡湖铸业有限公司

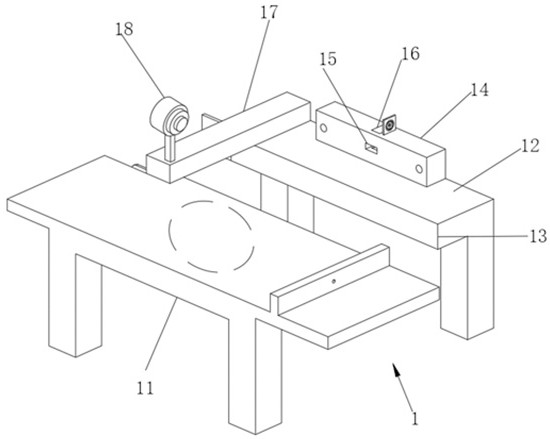

An assembly line batch laser marking device

ActiveCN114378447BTake the hassle out of controllingMarking speed is fastLaser beam welding apparatusComputer hardwareEngineering

The invention relates to the technical field of laser marking, in particular to an assembly line batch laser marking device. It includes a marking table, a feeding device for transporting products is installed on the marking table, a pushing device for pushing the product is installed on the marking table, and a laser marking device is installed on the side of the marking table away from the pushing device. The marking device of the target, the marking table includes a marking frame and a positioning frame, the marking frame and the positioning frame are set horizontally, and a transmission slot is set between the marking frame and the positioning frame, and the marking frame and the positioning frame pass through The side rails are fixedly connected. The present invention captures the product data on the conveyor belt through the set camera, and when the number of products on the conveyor belt reaches the specified quantity, the transmission of the product to the conveyor belt is controlled by the conveying unit, and the product is pushed to the punching box by the pushing device. On the label frame, the trouble of manually controlling the number of products is eliminated, and the marking speed of products is accelerated.

Owner:BEIJING JCZ TECH

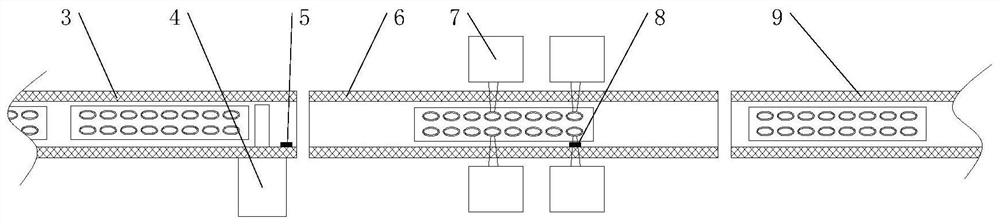

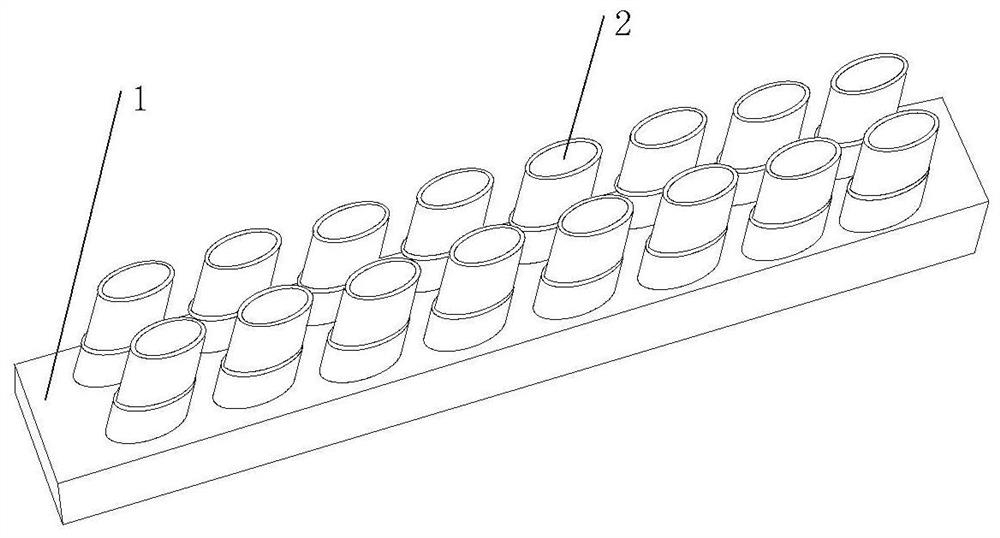

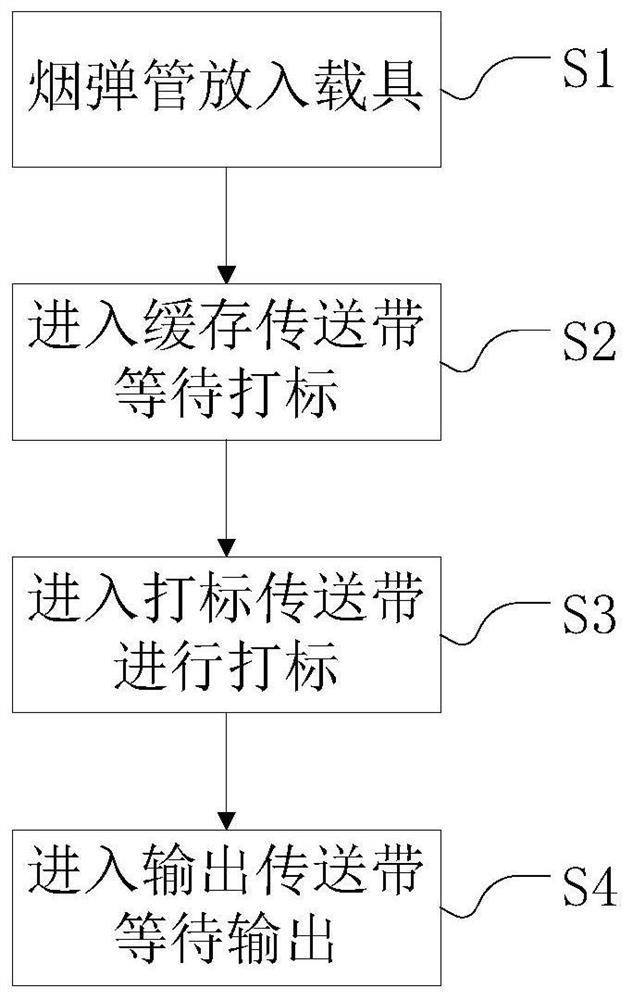

Efficient marking process for anti-counterfeiting codes of cartridge tubes

PendingCN113084333AReduced drying processReduce film two stepsLaser beam welding apparatusLaser engravingElectric machinery

The invention discloses an efficient marking process for anti-counterfeiting codes of cartridge tubes. The process comprises the following steps that S1, two rows of cartridge tubes are symmetrically placed on a carrier, and the carrier is placed on a cache conveyor belt; S2, when the carrier runs to the tail end of the cache conveyor belt, a blocking air cylinder controls whether the carrier enters a marking conveyor belt or not, the marking conveyor belt is connected to the cache conveyor belt in a bearing mode, and the marking conveyor belt is driven by a step motor; S3, a plurality of sets of laser marking machines are symmetrically arranged at the two sides of the middle section of the marking conveyor belt, and the laser marking machines complete the laser marking task of the cartridge tubes on the current marking conveyor belt; and S4, after the cartridge tubes on the carrier are marked, the carrier is conveyed to an output conveyor belt through the marking conveyor belt, and marking is completed. According to the efficient marking process for the anti-counterfeiting codes of the cartridge tubes, the two sets of cartridge tubes are marked at the same time in a laser engraving mode, the marking speed is high, and the marking efficiency is remarkably improved.

Owner:张琴

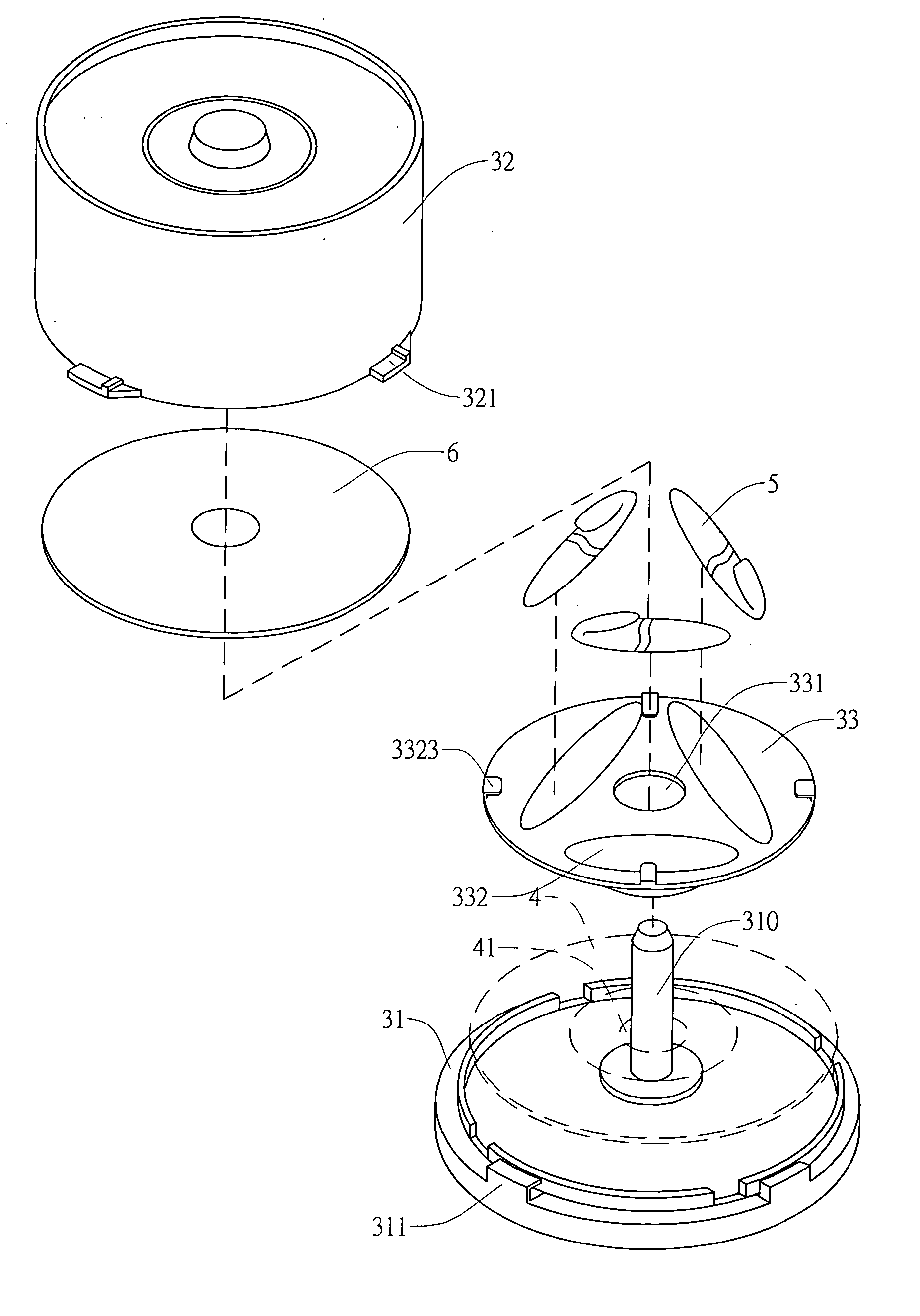

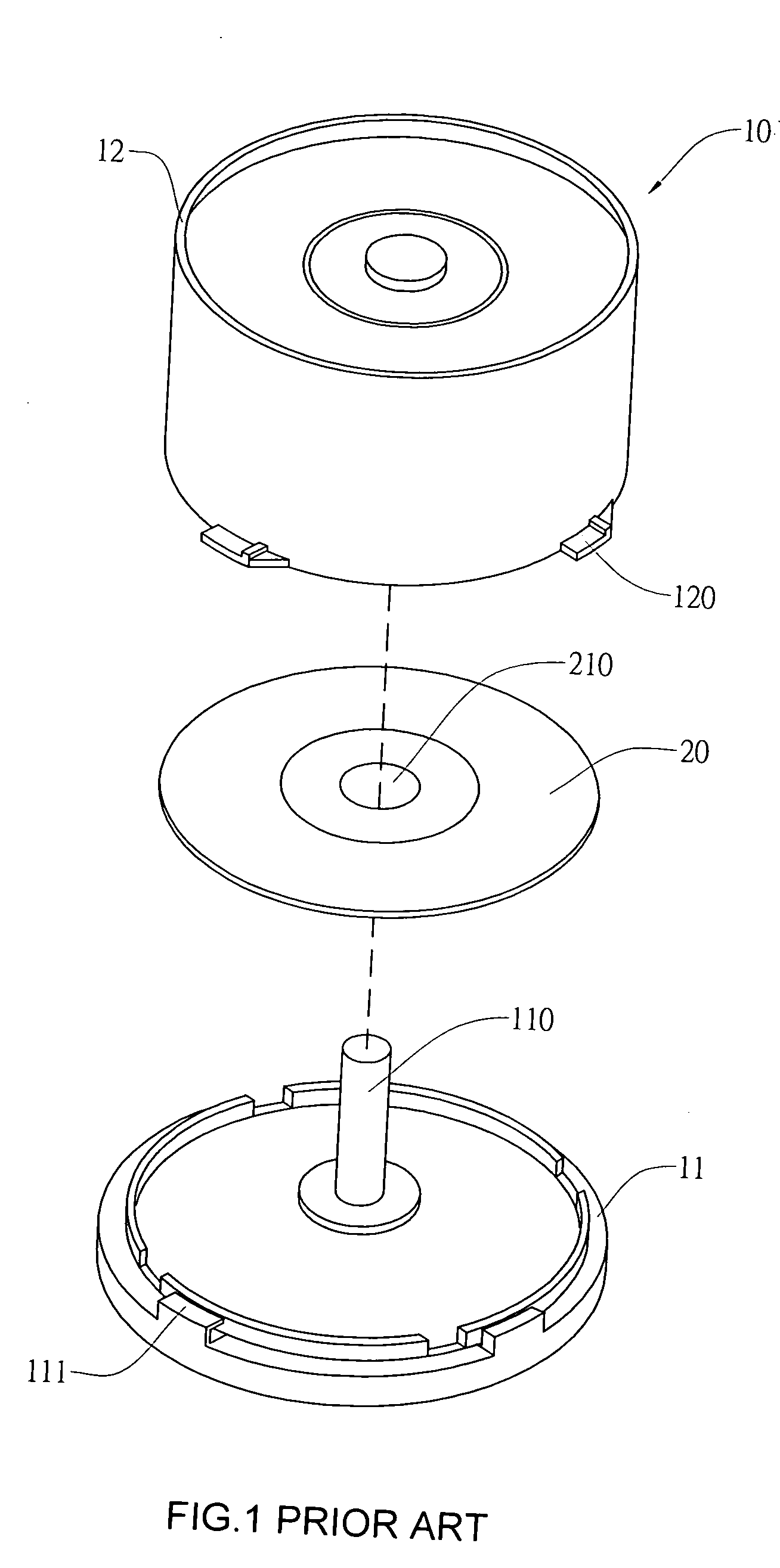

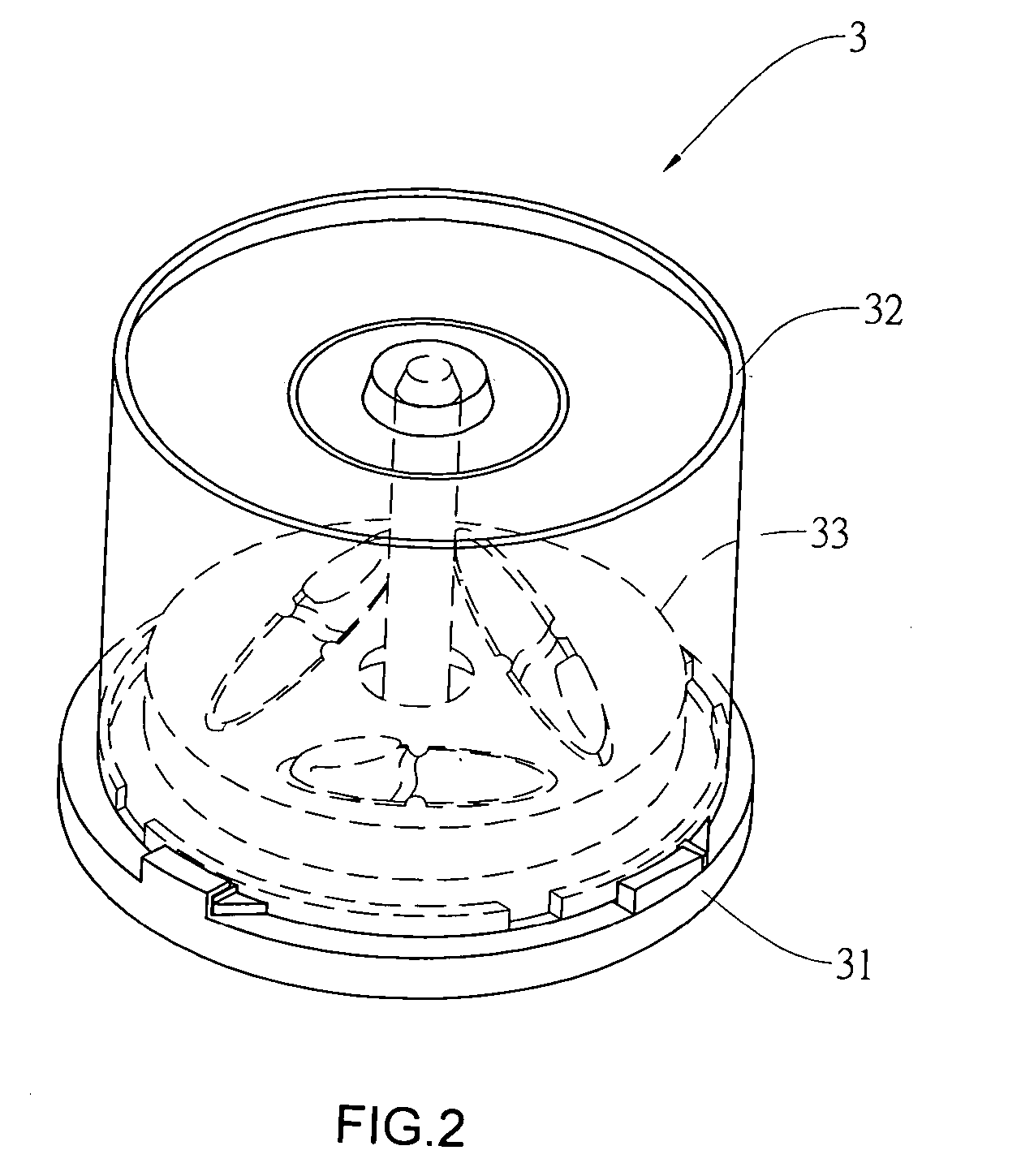

Optical disk container with writing tool holding device

InactiveUS20050274632A1Marking the optical disks convenientlyConvenient markingApparatus modification to store record carriersRecord information storageMechanical engineeringOptical disc

Owner:CASE PAX INT

Convenient-to-adjust laser marking device

The invention discloses a convenient-to-adjust laser marking device. The convenient-to-adjust laser marking device comprises a shell body, wherein a mounting block is fixed on an inner wall of the upper end of the shell body through a screw; a side wall at one end of the mounting block is connected with a mounting shaft through a key; a rotating rod is connected with a side wall at one end of themounting shaft in a rotating manner; the other end of the rotating rod is connected with a connection shaft through a pin; the connection shaft is located in a connection plate; a bottom-end side wallof the connection plate is fixedly provided with a fixed rod through a screw and the other end of the fixed rod is in sliding connection with a retractable rod; a mounting plate is welded on a bottom-end side wall of the retractable rod; a laser generator is arranged on the mounting plate; a placement plate is welded on an inner wall of the shell body; a pull rod is arranged on a side wall at oneend of the placement plate; a baffle plate sleeves the outer part of the pull rod in a sliding manner; a placement block is fixed on a bottom-end side wall of the baffle plate through a screw. According to the convenient-to-adjust laser marking device, the rotating rod is controlled to rotate on the mounting shaft and the retractable rod is controlled to slide in the fixed rod, so that the position of a laser generator in the shell body is adjusted and the height of the laser generator is adjusted, and furthermore, the laser generator is convenient for marking.

Owner:SUZHOU SAIJIA LASER TECH

Marking equipment

InactiveCN110948113AConvenient markingQuality improvementLaser beam welding apparatusSmoke EmissionMechanical engineering

The invention relates to marking equipment. According to the marking equipment, a laser marking device is connected to the second sliding rail of a first cross beam in a sliding mode, the laser marking device can move in a horizontal direction; the first cross beam is connected to the first sliding rail of a stand column in a sliding mode, so that the first cross beam can drive the laser marking device to move up and down along the stand column; and therefore, the laser marking device can conveniently mark a workpiece. The laser marking device is provided with a protective cover; a marking opening used for emitting laser is formed in the protective cover; the protective cover is connected with a smoke suction pipeline; and the smoke suction pipeline is connected with a smoke treatment device; and thus, smoke generated when the laser ablates a mark on the workpiece can pass through the smoke suction pipeline from the protective cover and enter the smoke treatment device so as to be treated, and working environment will not be affected.

Owner:西刻标识设备(上海)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com