Stainless steel strip laser marking machine based on visual identification and positioning

A laser marking machine and visual recognition technology, applied in the field of marking, can solve the problems of inaccurate base point positioning, affecting visual inspection, and insufficient marking accuracy of steel strips, so as to avoid the impact and reduce the effect of irradiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

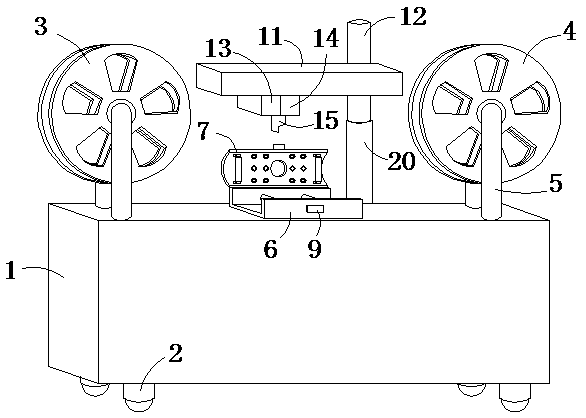

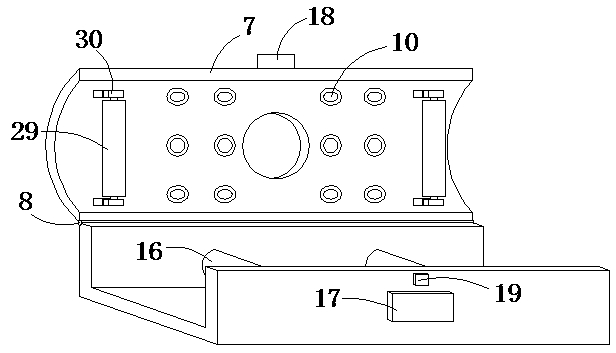

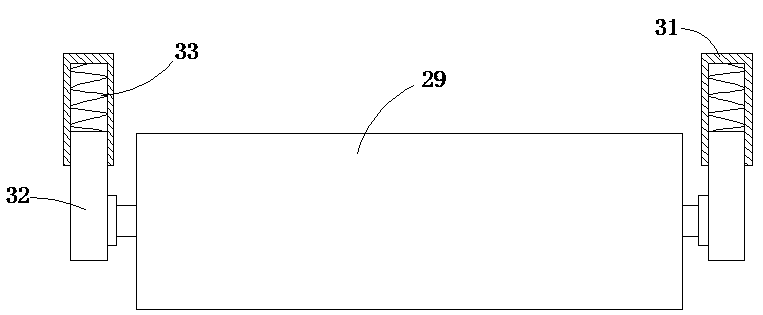

[0026] like Figure 1-5 As shown, a stainless steel strip laser marking machine based on visual recognition and positioning includes a cabinet 1 equipped with universal wheels 2, the overall device is convenient to move, and the upper side of the cabinet 1 is provided with a discharge tray 3 and a collection tray 4 , discharging and receiving respectively, the discharging tray 3 and the receiving tray 4 rotate simultaneously, the discharging tray 3 and the receiving tray 4 are fixedly installed on the cabinet 1 through the mounting frame 5, the discharging tray 3 and the receiving tray There is a fixed block 6 between the disks 4, and the fixed block 6 is fixedly connected with the upper end surface of the cabinet 1. The upper end surface of the fixed block 6 is provided with a slot, and the upper side of the fixed block 6 is horizontally provided with an arc-shaped cover 7, and one end of the arc-shaped cover 7 passes through the The rotating shaft 8 is rotatably connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com