An assembly line batch laser marking device

A laser marking and assembly line technology, applied in the field of laser marking, can solve the problems of affecting the rapid production of products, slowing down the speed of product marking, and low accuracy, so as to speed up laser marking, ensure normal marking, and speed up marking speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

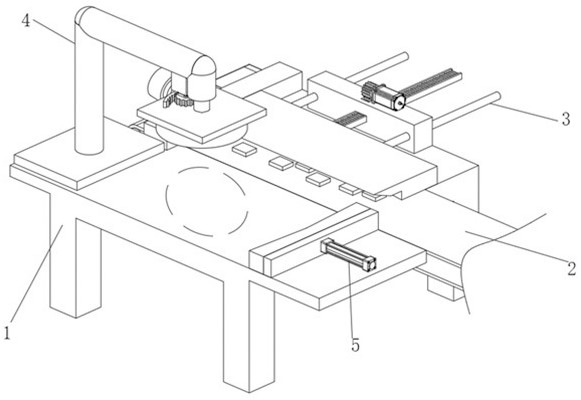

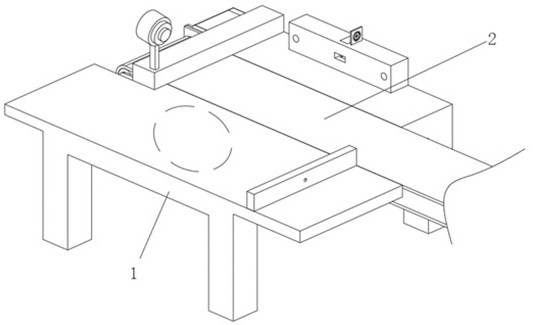

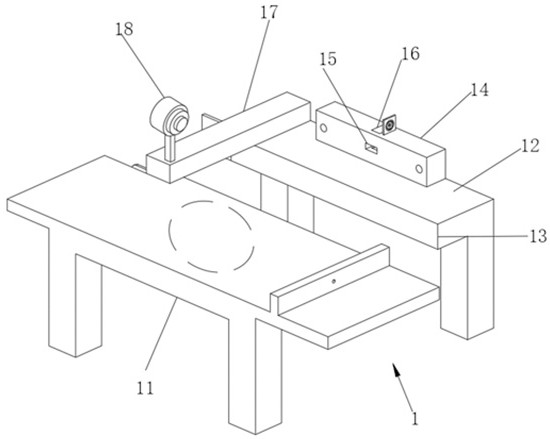

[0039] see Figure 1-Figure 9 As shown, the purpose of this embodiment is to provide an assembly line batch laser marking device, including a marking table 1, a feeding device 2 for transporting products is installed on the marking table 1, and a The pushing device 3 for pushing the product, and the marking device 4 for laser marking is provided on the side of the marking table 1 away from the pushing device 3;

[0040] The marking table 1 includes a marking frame 11 and a positioning frame 12. The marking frame 11 and the positioning frame 12 are arranged horizontally, and a transmission slot 13 is arranged between the marking frame 11 and the positioning frame 12. The conveyor belt 21 in the slot 13 is provided with a driving device at one end of the conveyor belt 21. The driving device includes a conveying motor 23 installed on the side wall of the positioning frame 12, and a conveying wheel 22 is installed on the rotating shaft of the conveying motor 23. Inside the convey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com