Efficient marking process for anti-counterfeiting codes of cartridge tubes

A pod tube and high-efficiency technology, which is applied to manufacturing tools, metal processing equipment, welding equipment, etc., can solve the problems of inconvenient marking and low marking efficiency of pod tubes, and achieve convenient marking and improve marking efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

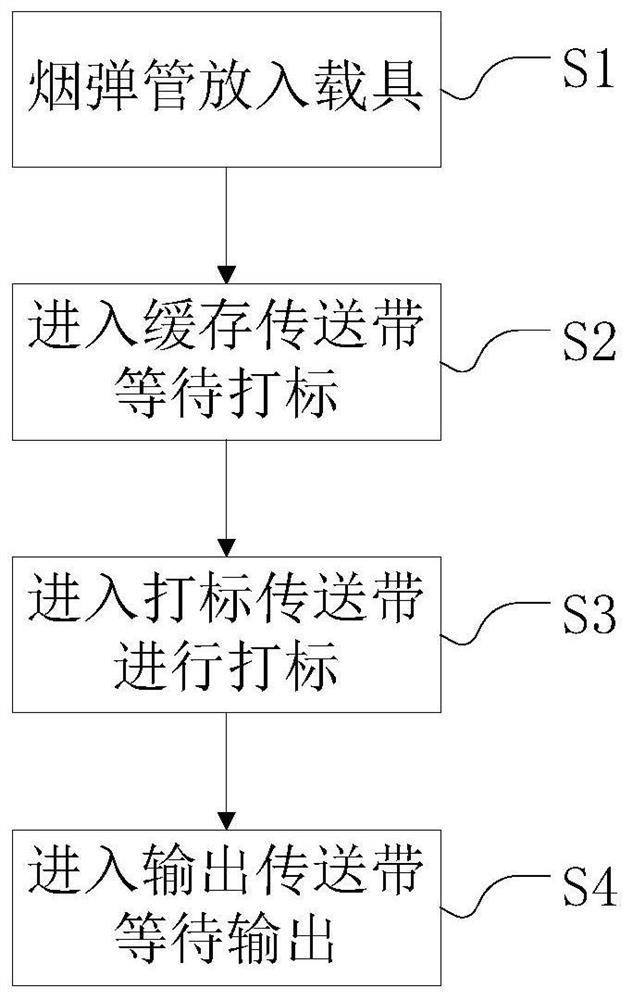

[0020] Such as Figure 1-3 The high-efficiency marking process for anti-counterfeiting codes of pod tubes shown includes the following steps:

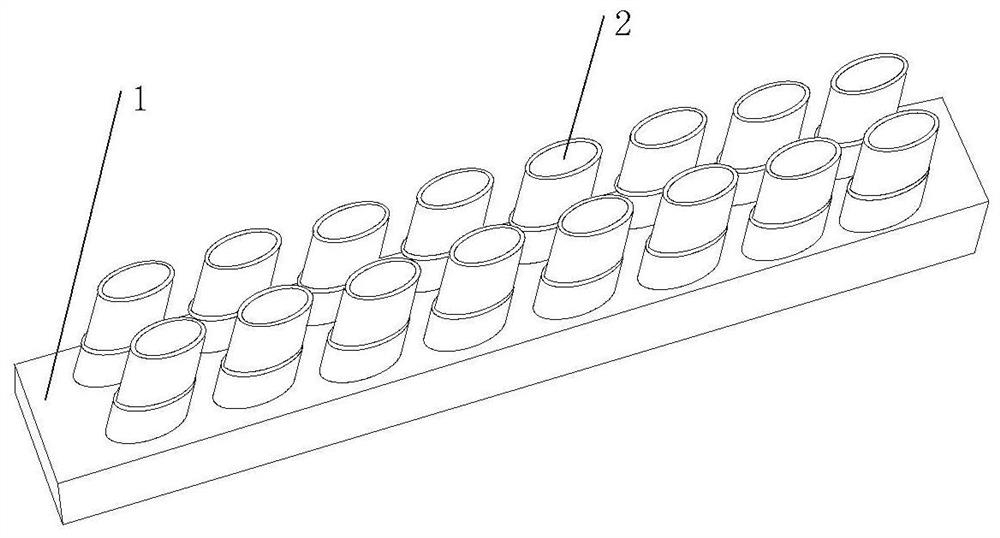

[0021] S1: Place two rows of pod tubes 2 symmetrically on the carrier 1, and put the carrier 1 into the buffer conveyor belt 3;

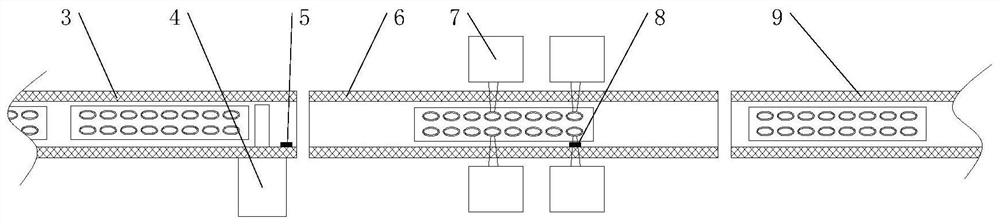

[0022] S2: When the carrier 1 runs to the end of the buffer conveyor belt 3, the blocking cylinder 4 controls whether the carrier 1 enters the marking conveyor belt 6, the marking conveyor belt 6 and the buffer conveyor belt 3 are connected, and the marking conveyor belt 6 is driven by a stepping motor;

[0023] S3: Several groups of laser marking machines 7 are symmetrically arranged on both sides of the middle section of the marking conveyor belt 6, and the laser marking machines 7 complete the laser marking task of the pod tube 2 on the current marking c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com