Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Avoid affecting smoothness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

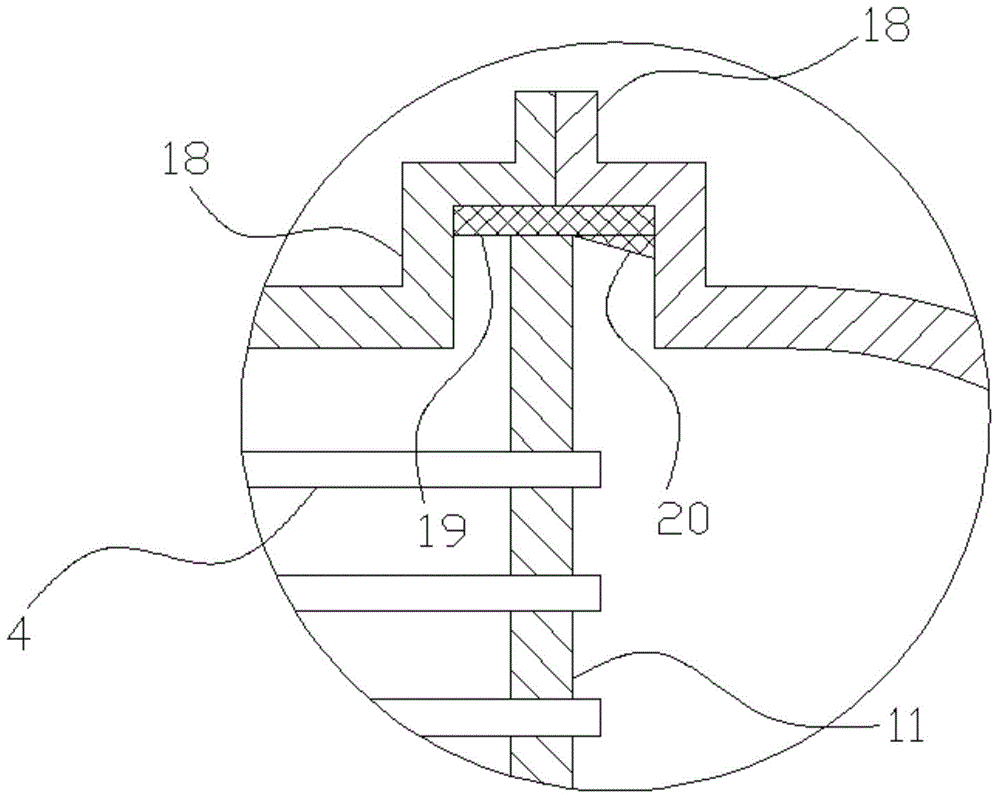

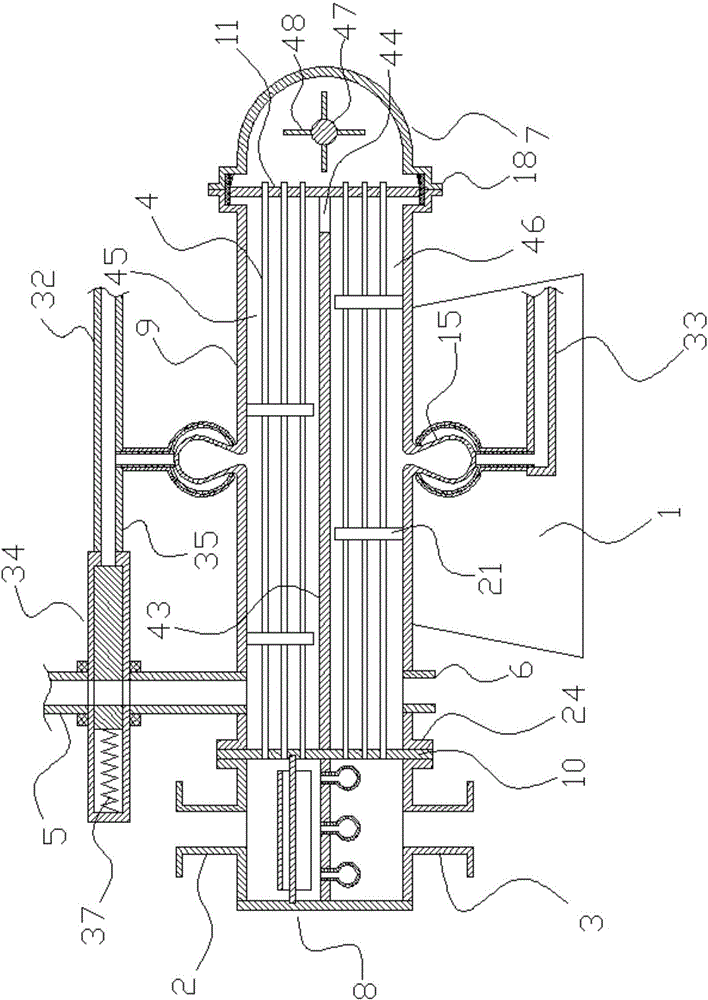

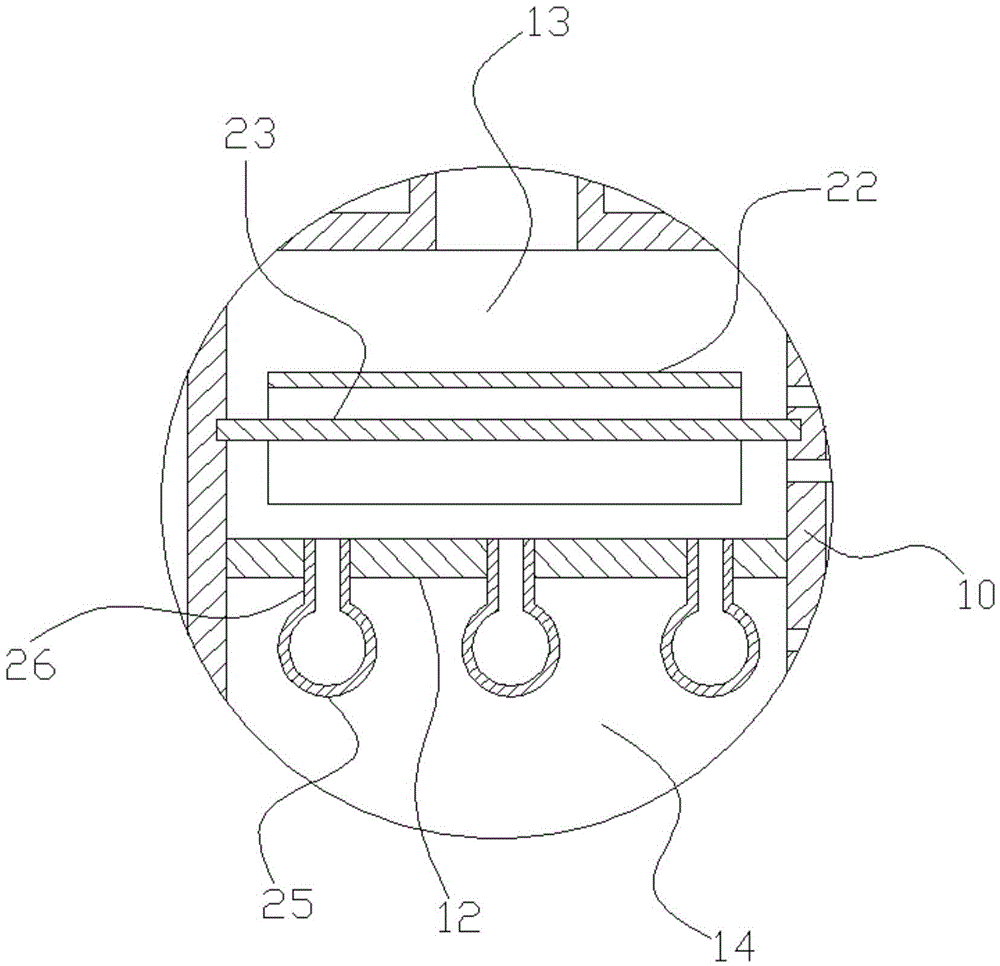

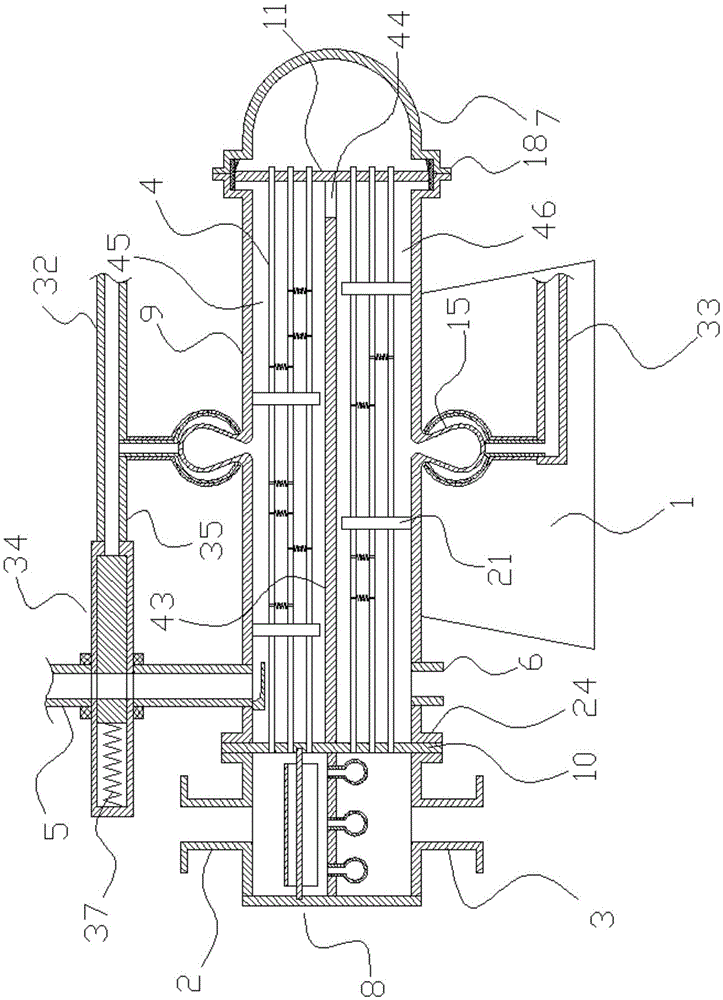

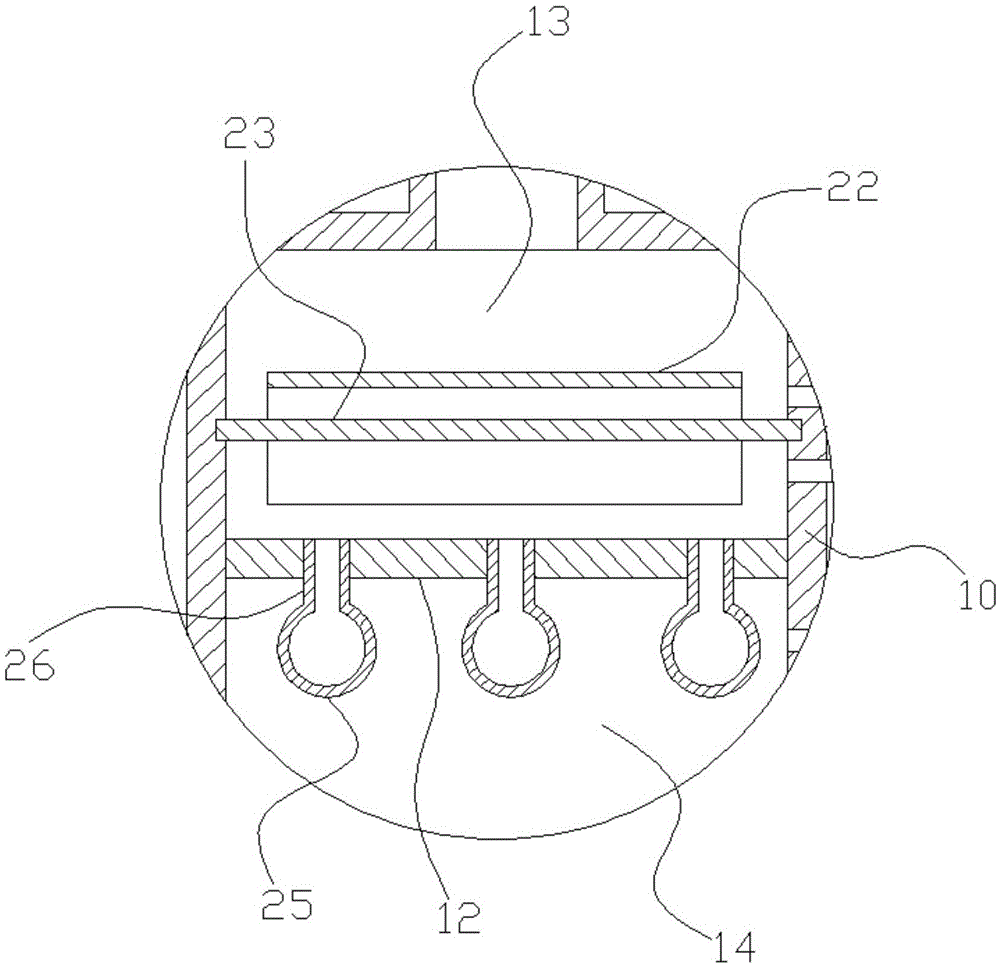

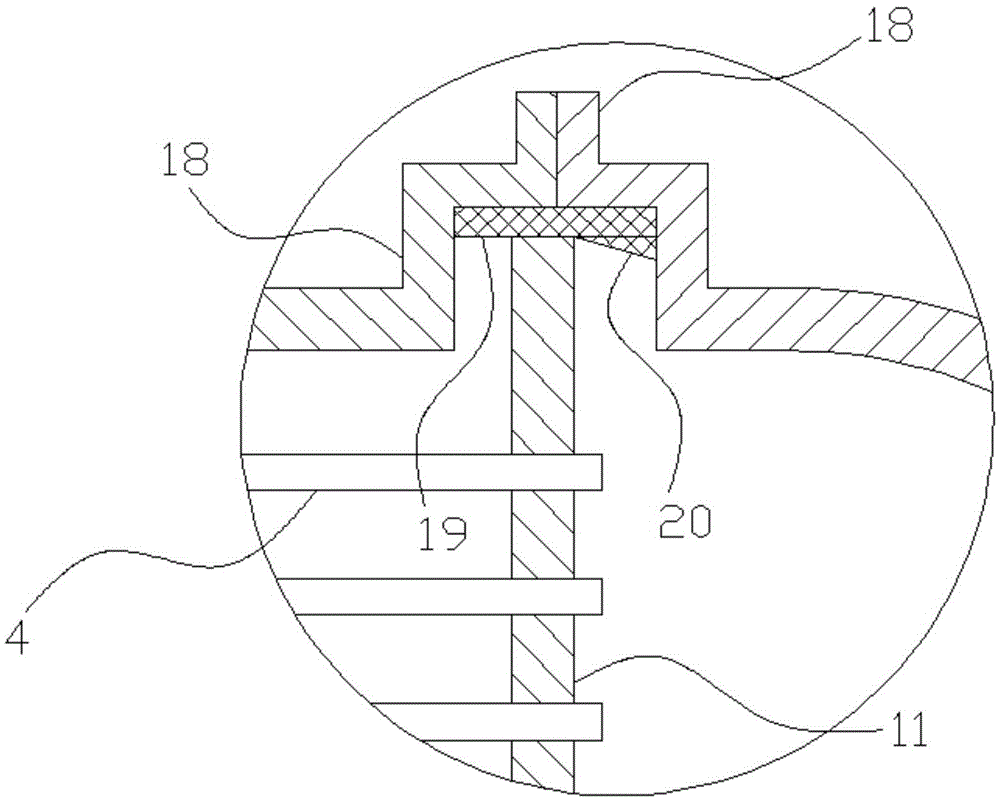

Shell-and-tube heat exchanger

InactiveCN104634141AAvoid damageSmooth circulationCorrosion preventionHeat exchanger casingsPlate heat exchangerShell and tube heat exchanger

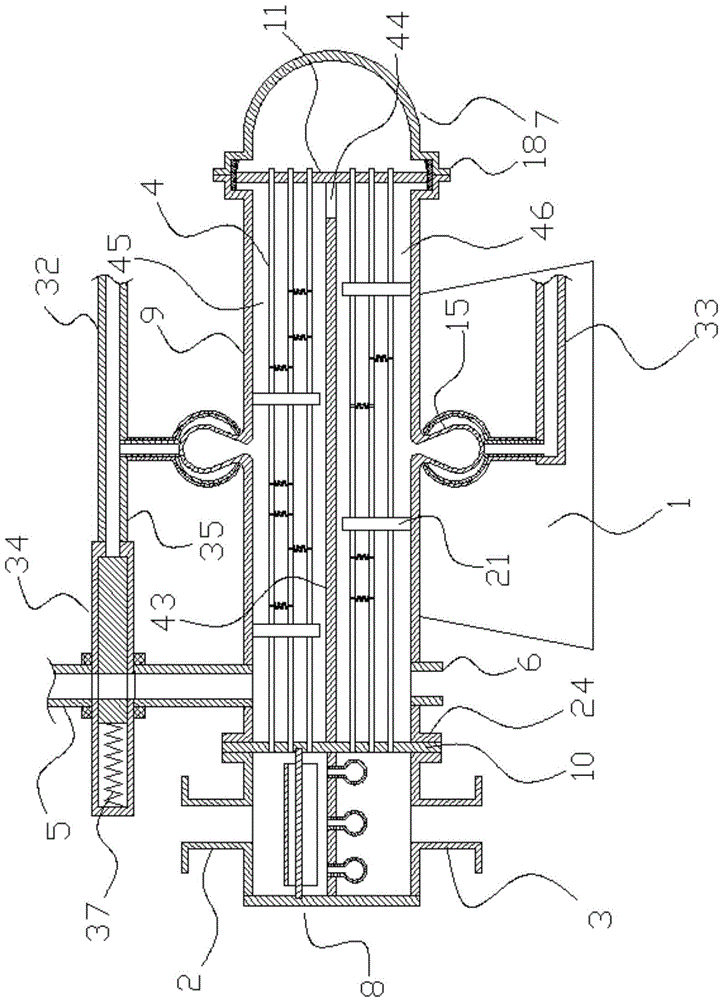

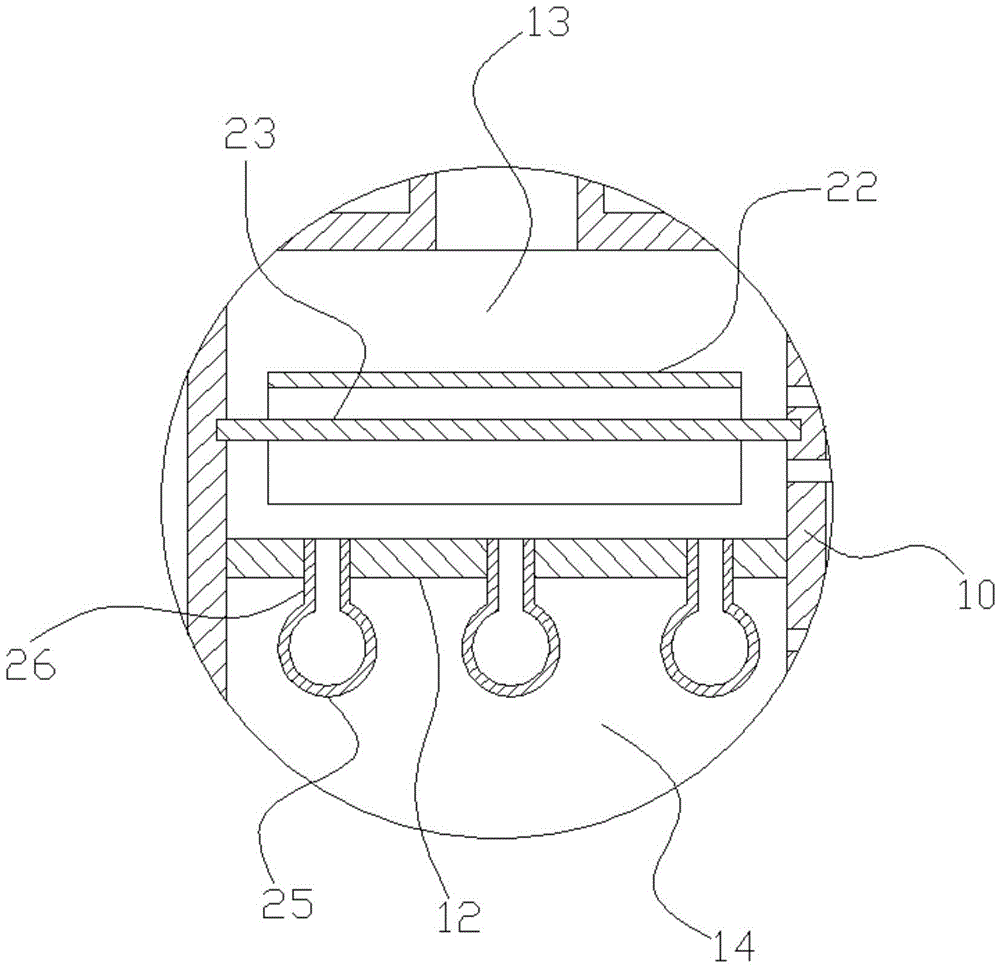

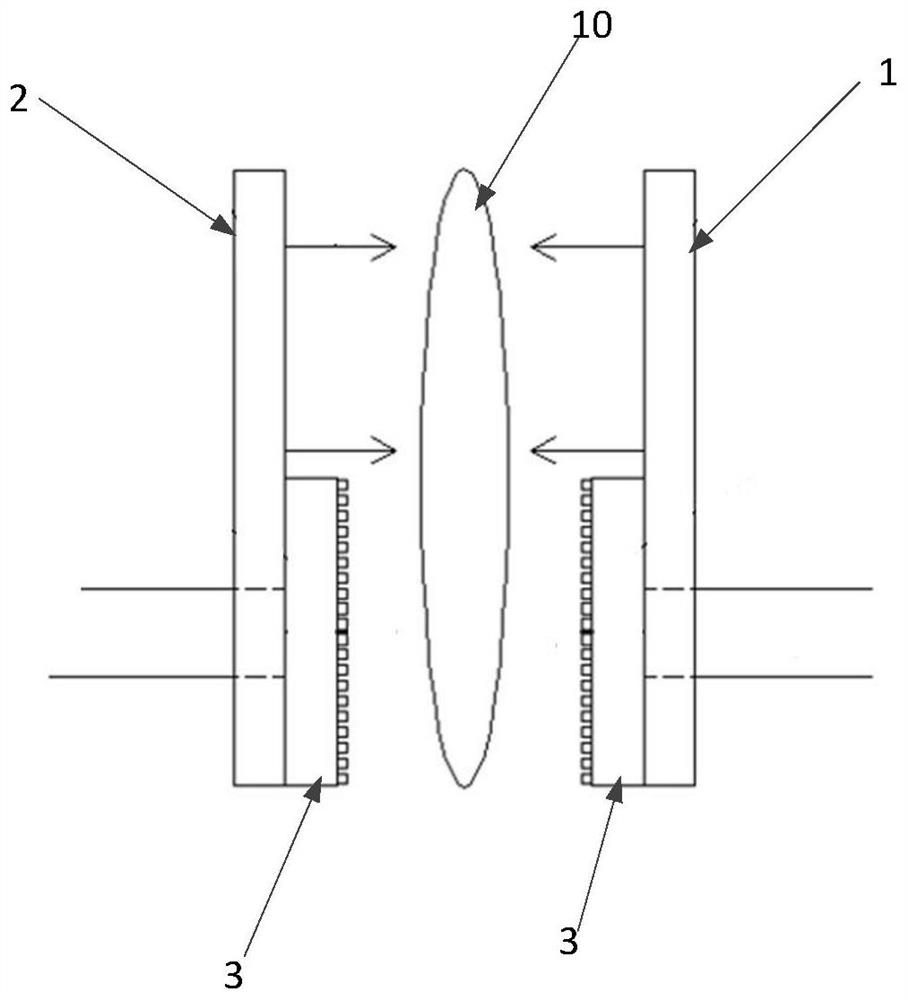

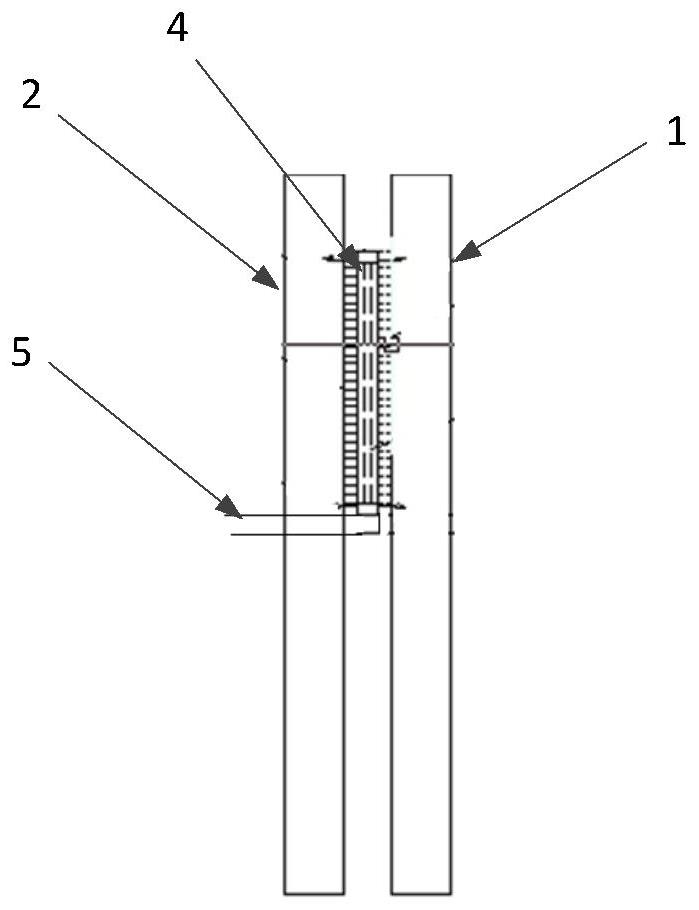

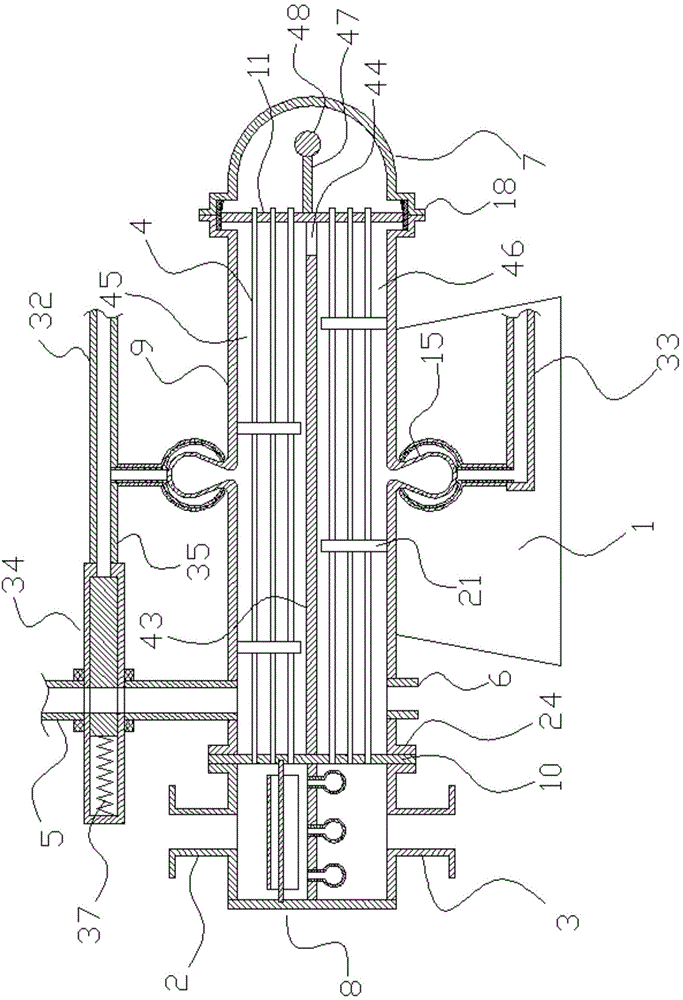

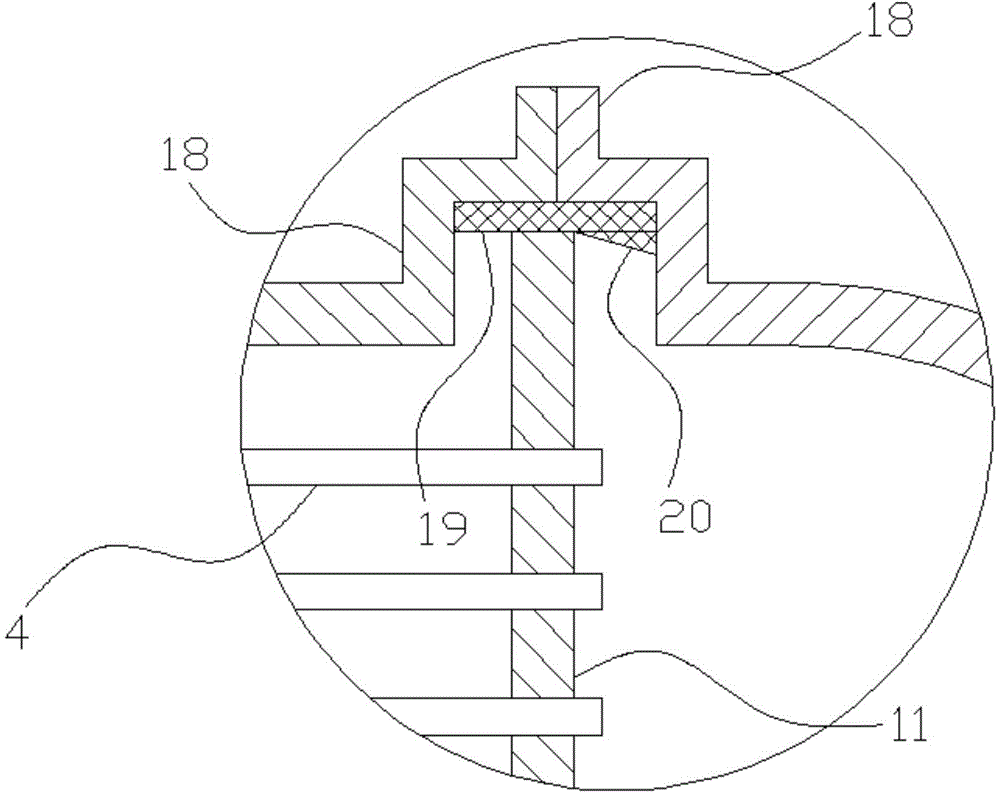

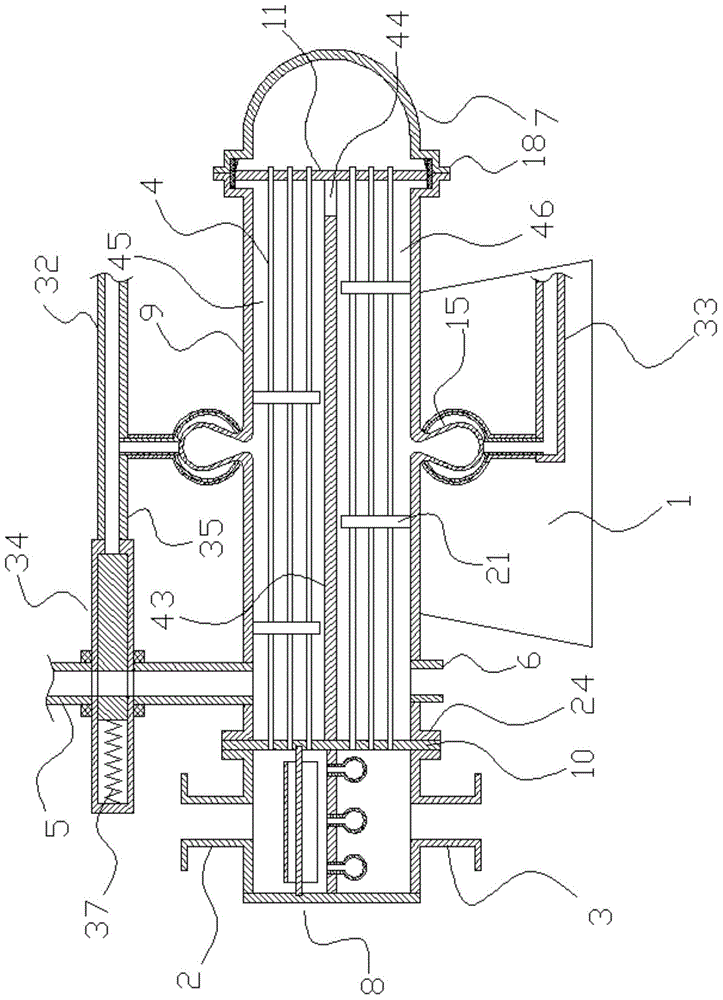

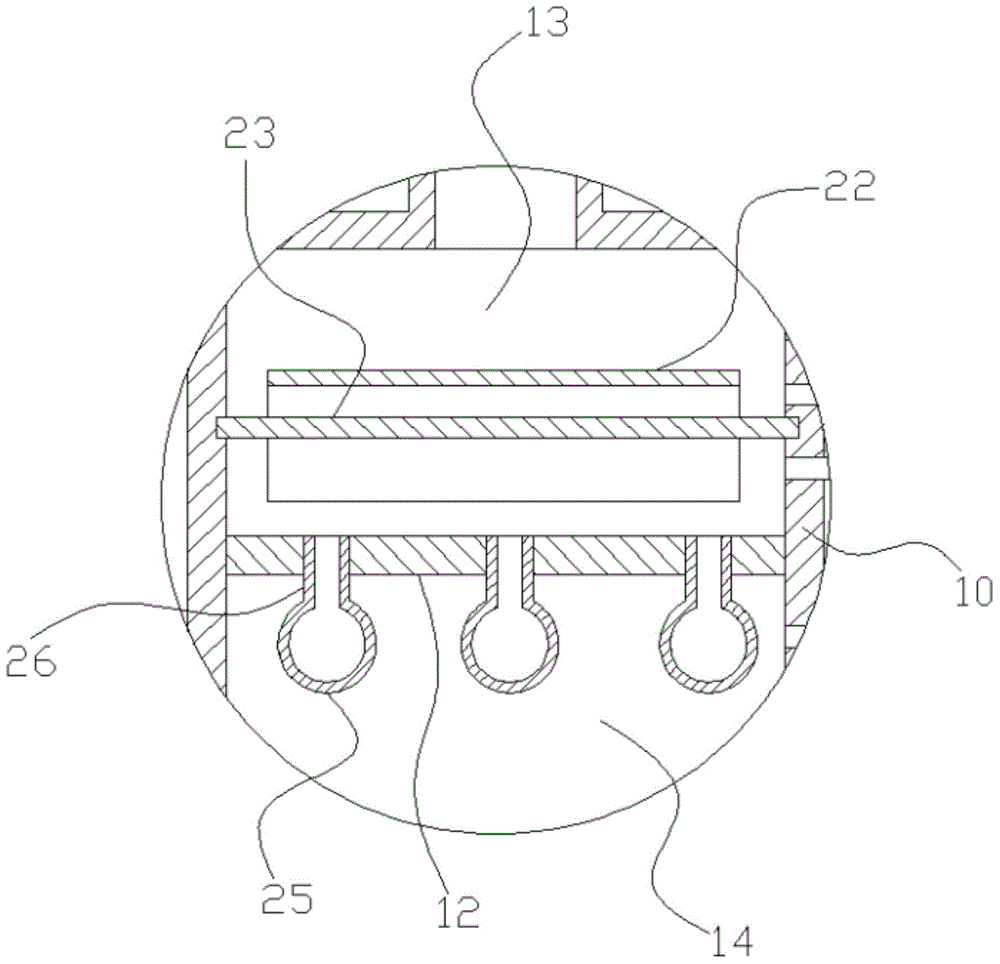

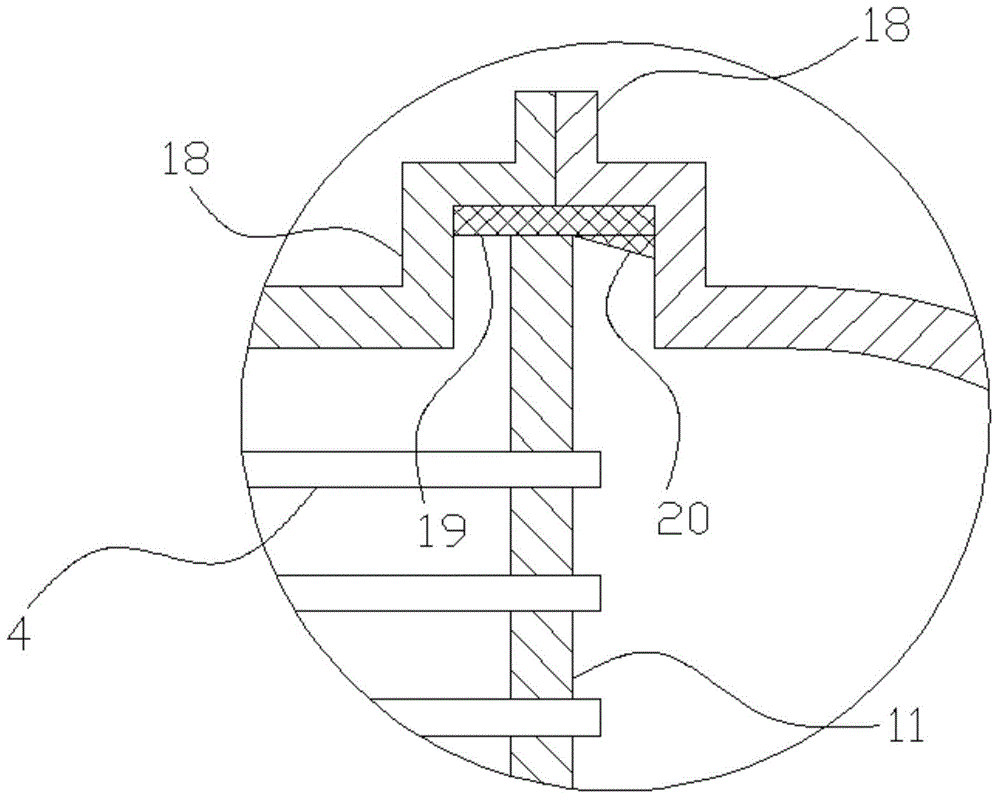

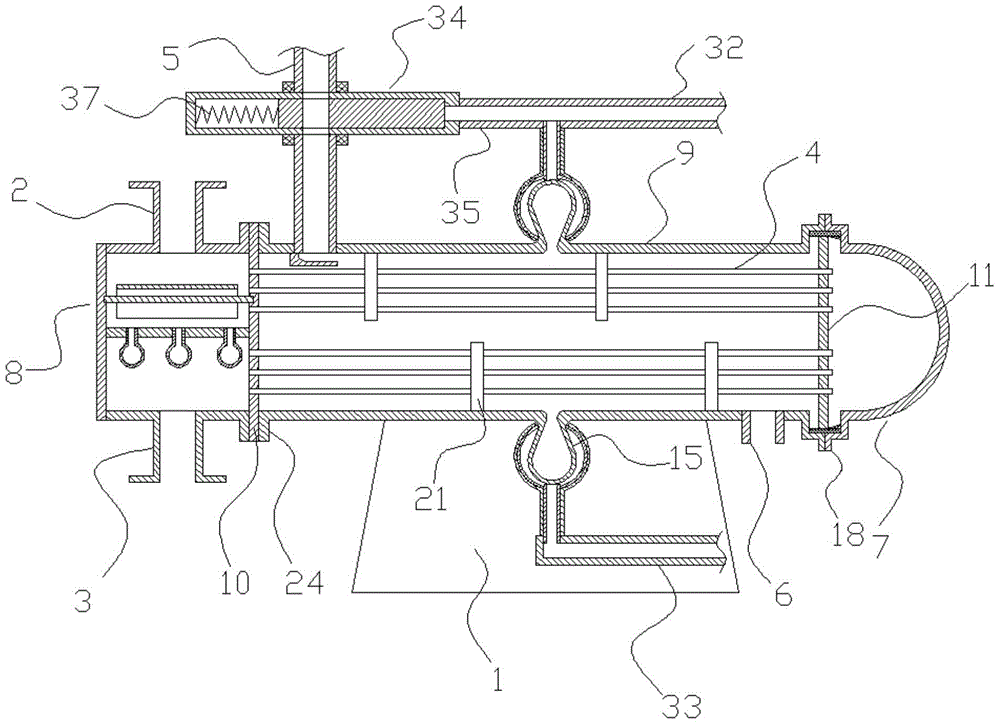

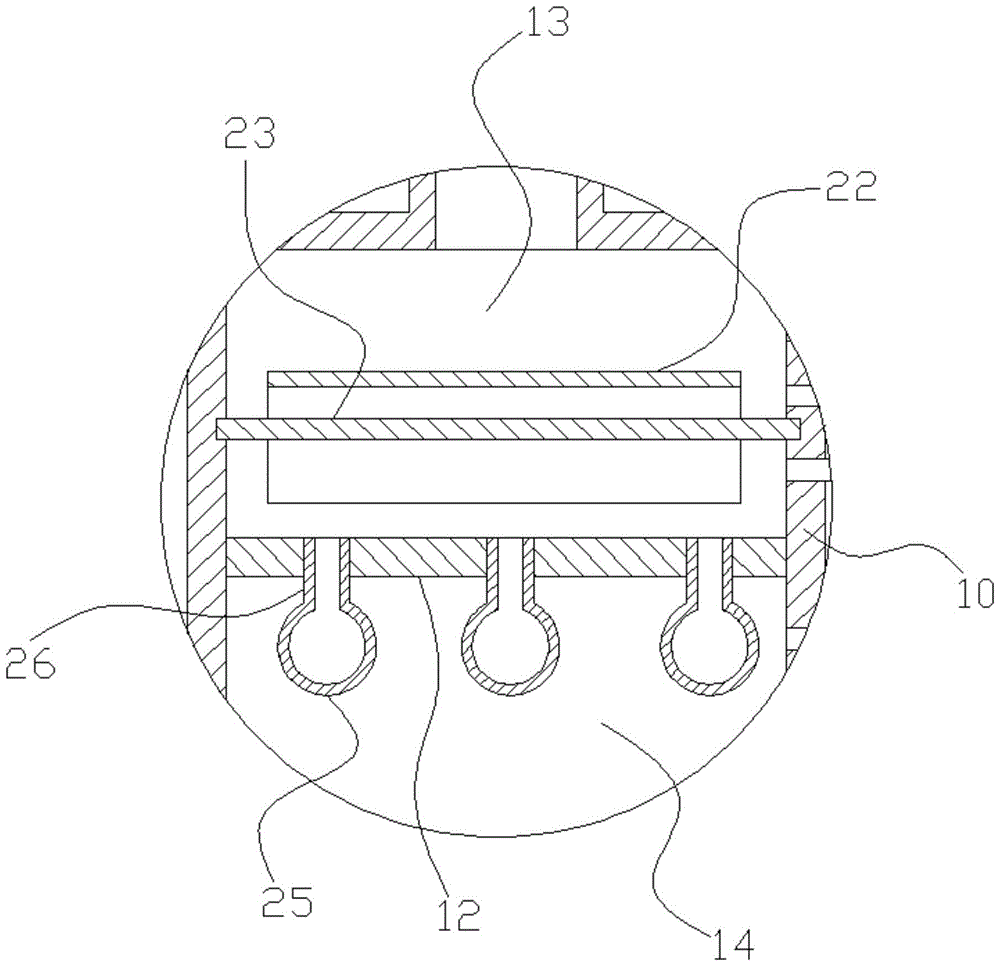

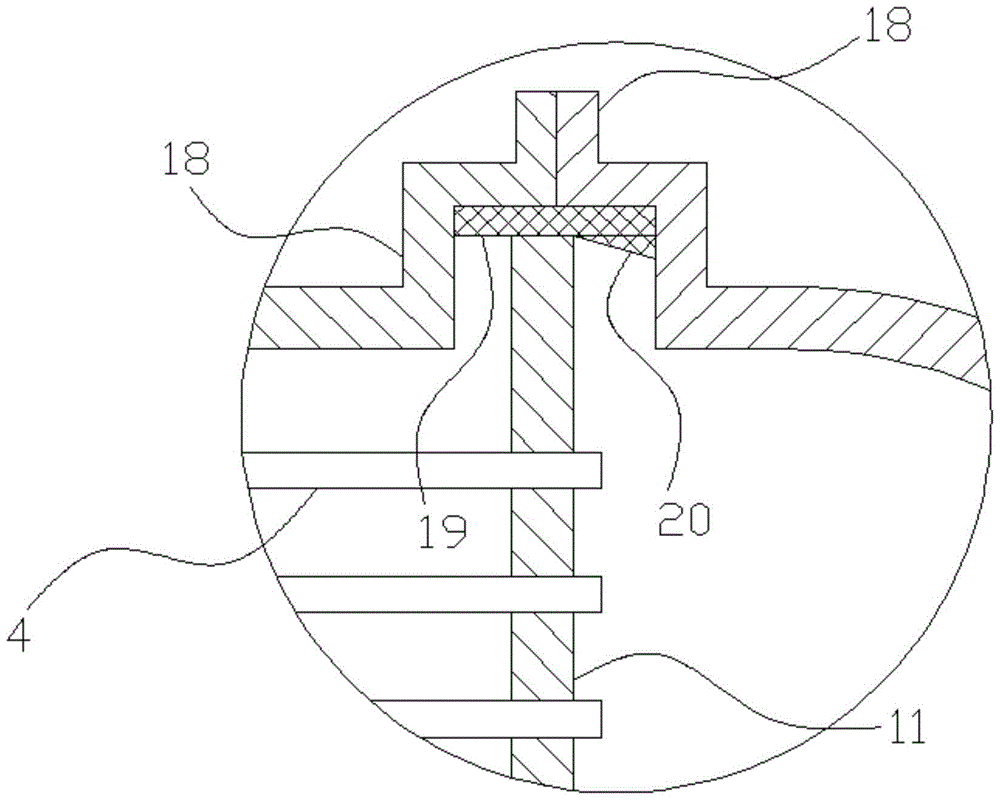

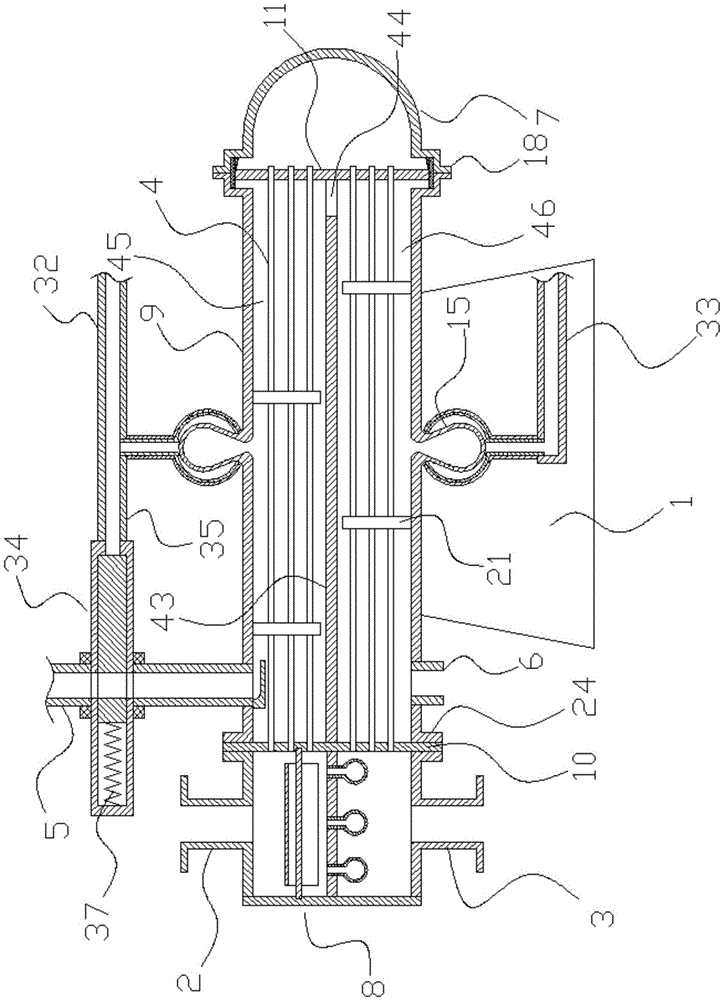

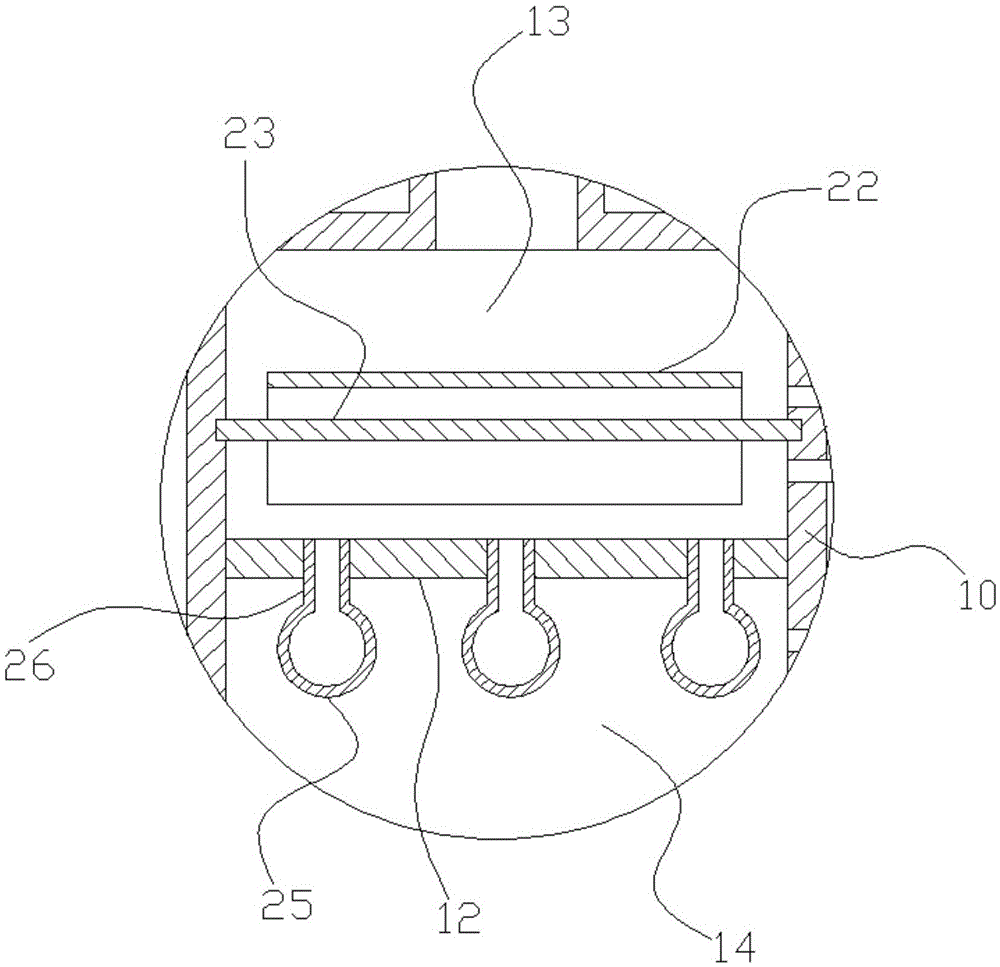

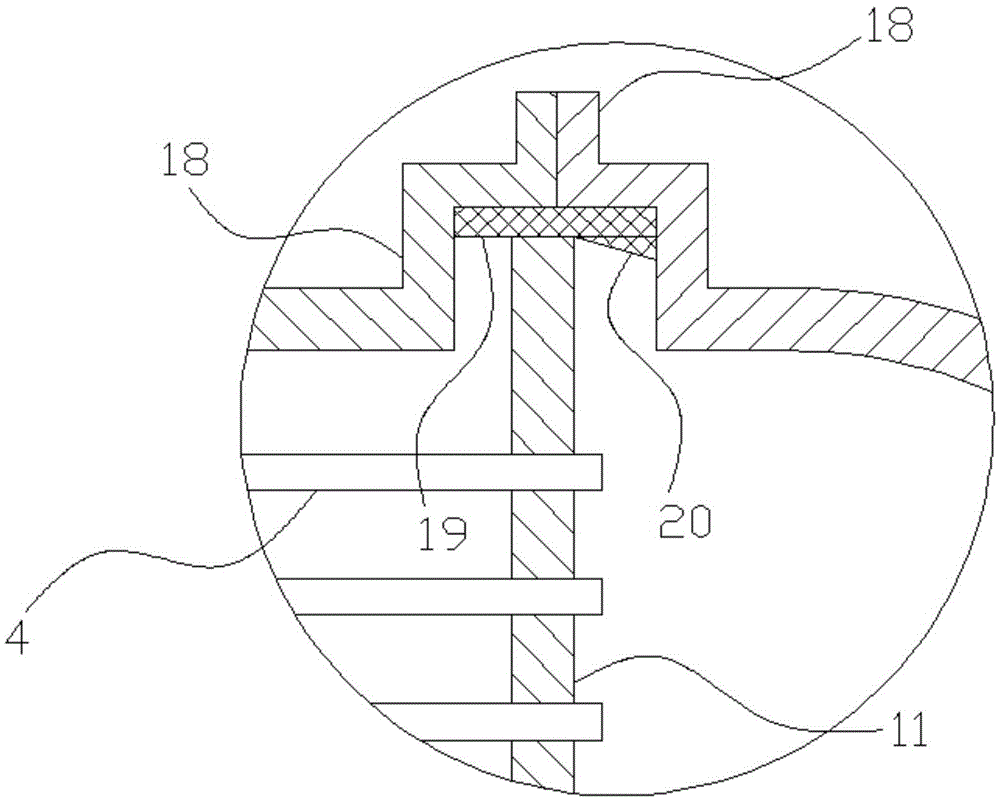

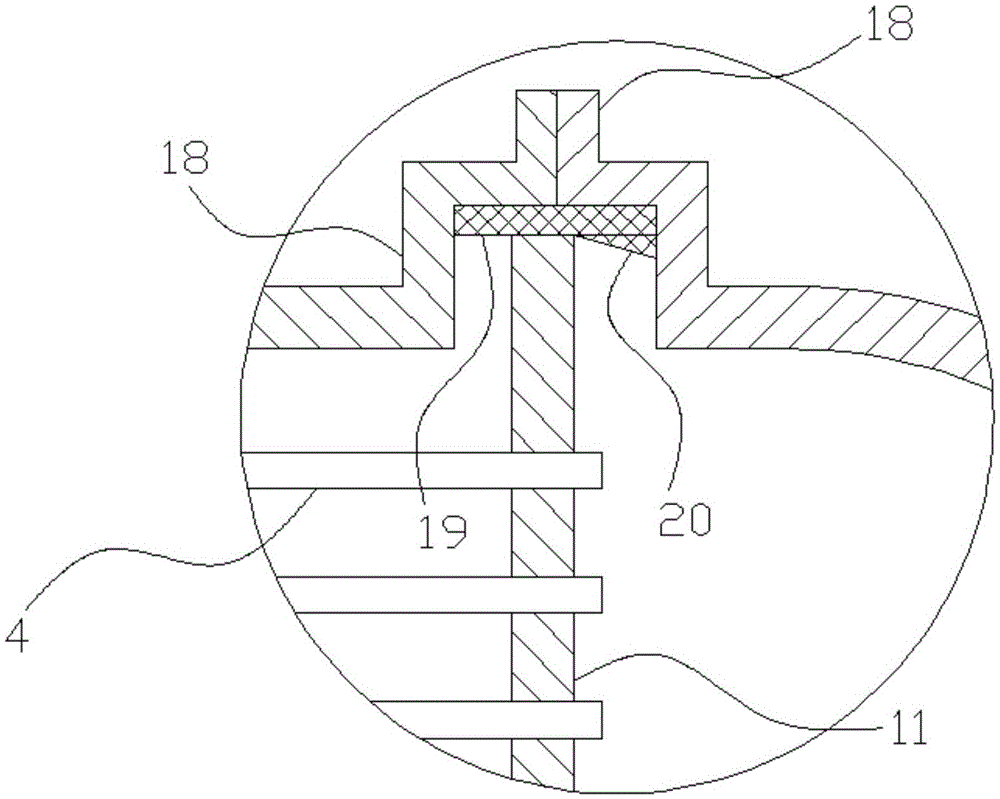

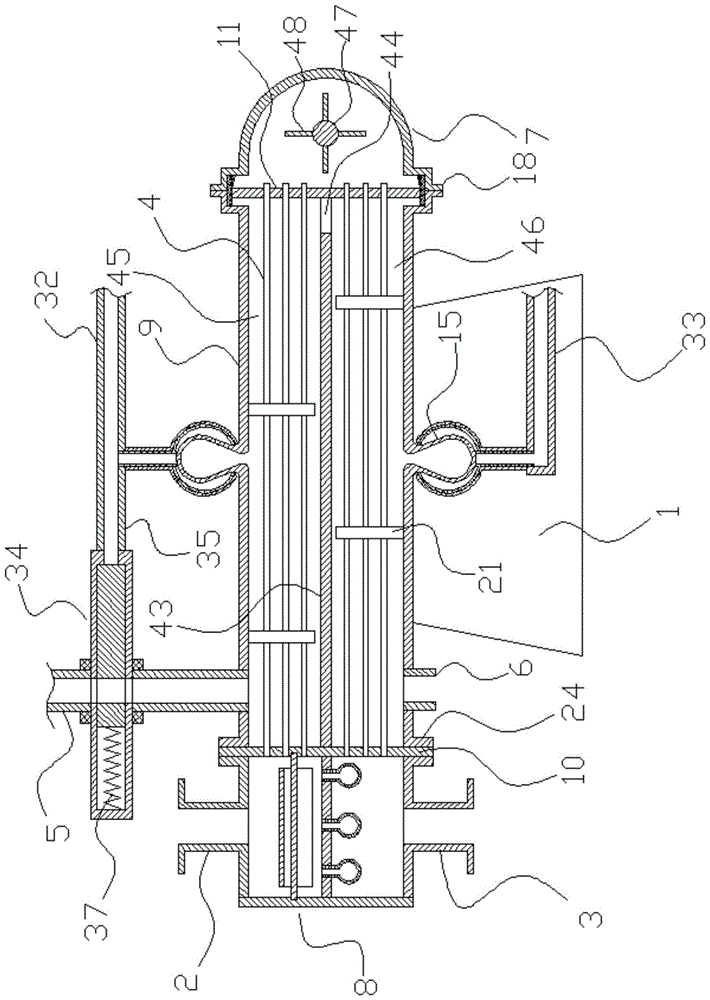

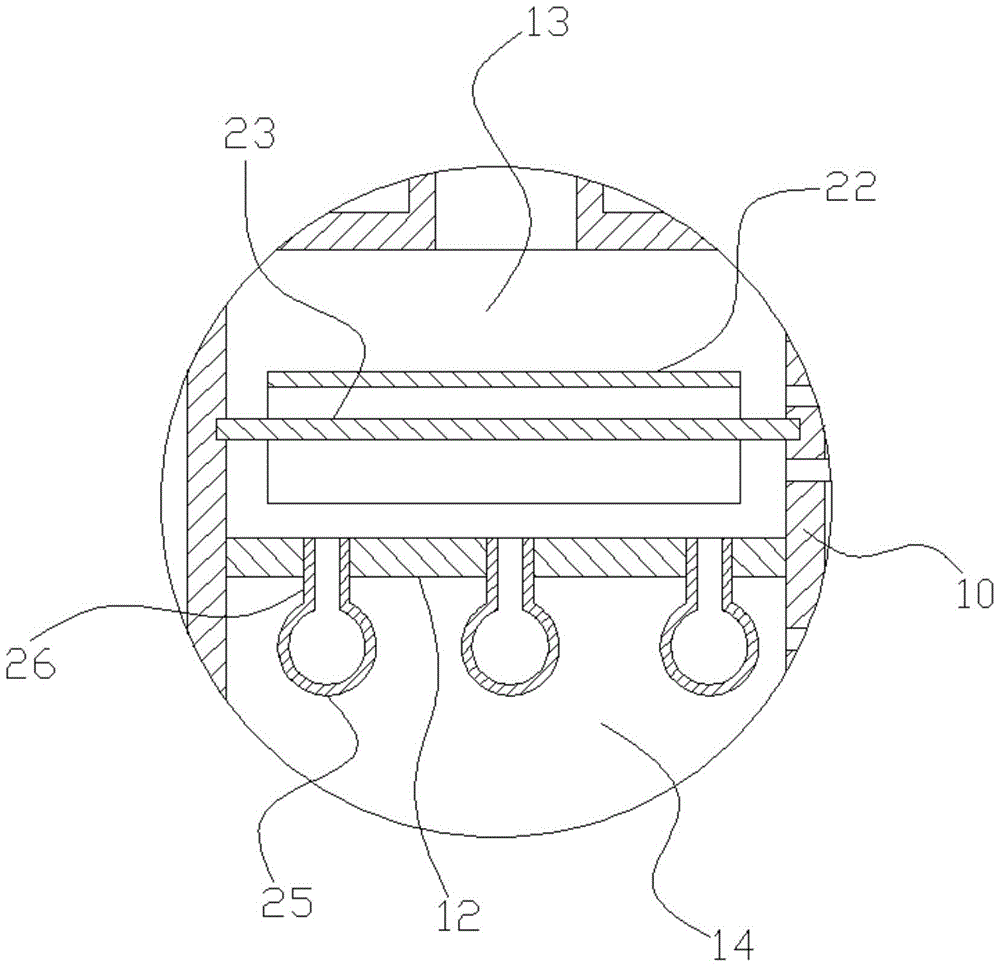

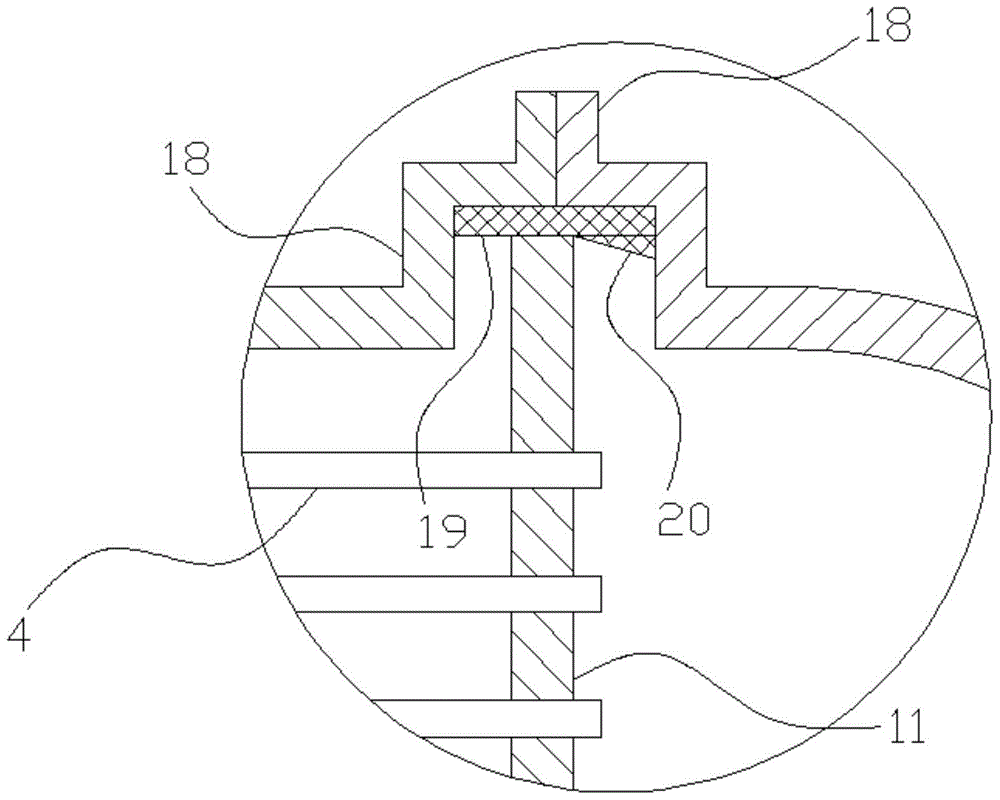

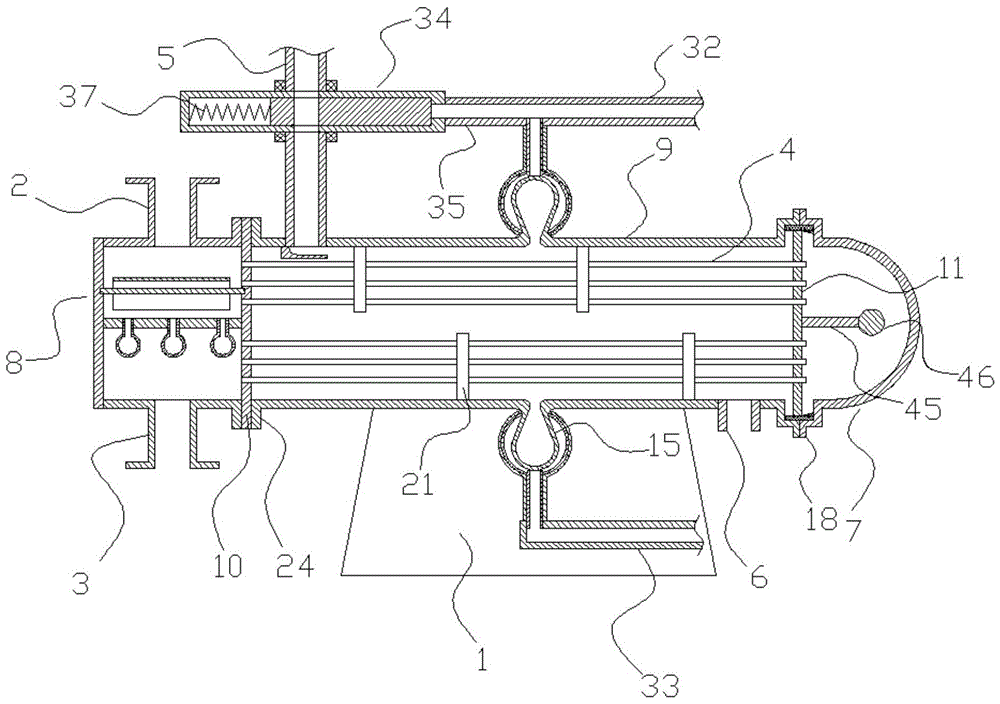

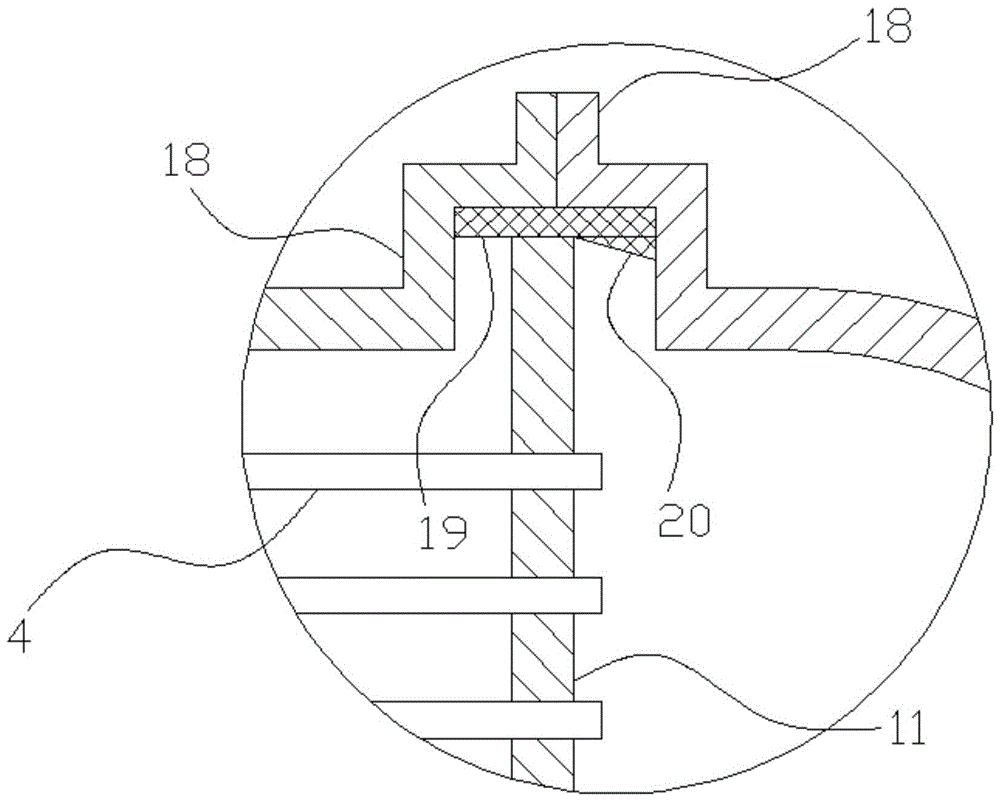

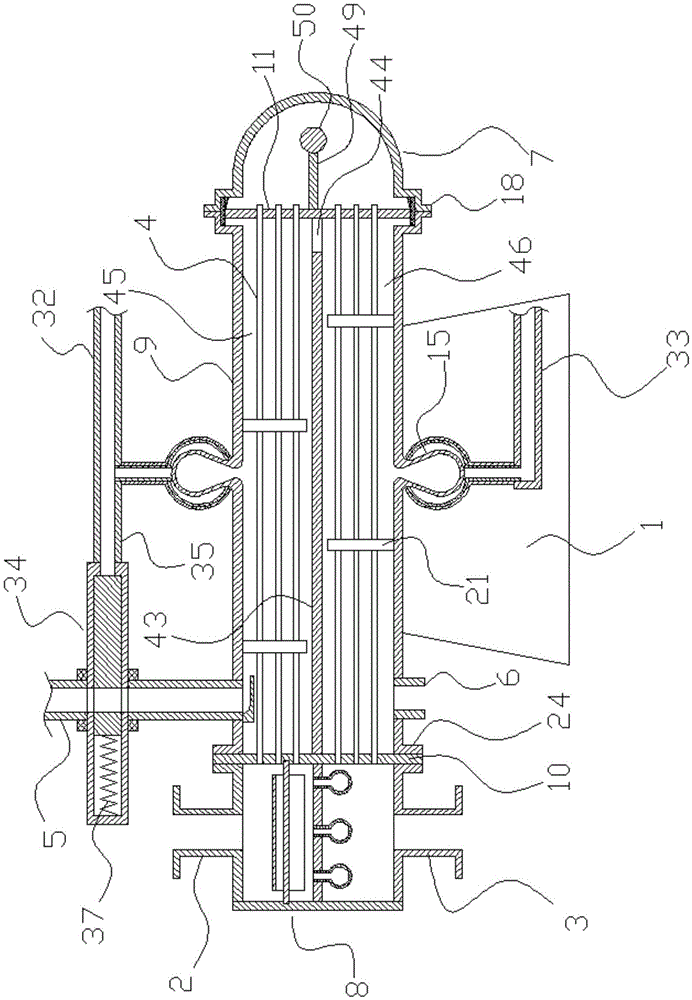

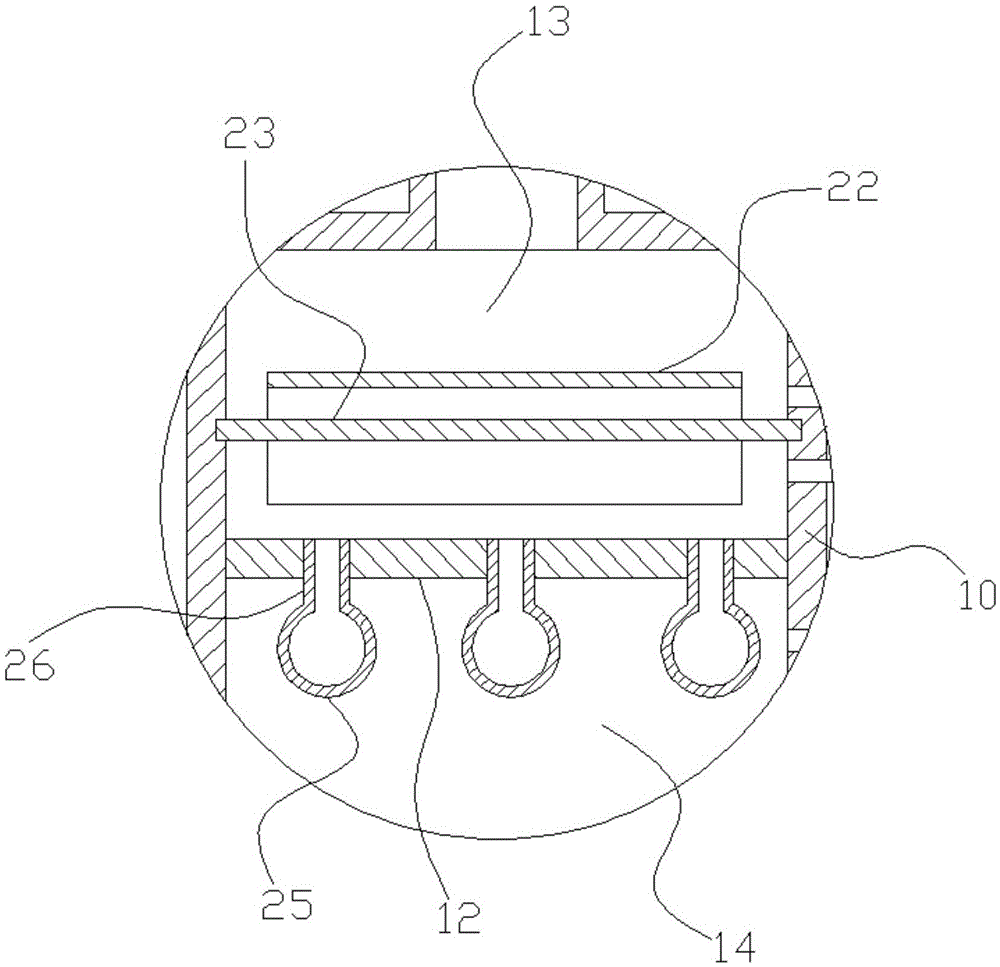

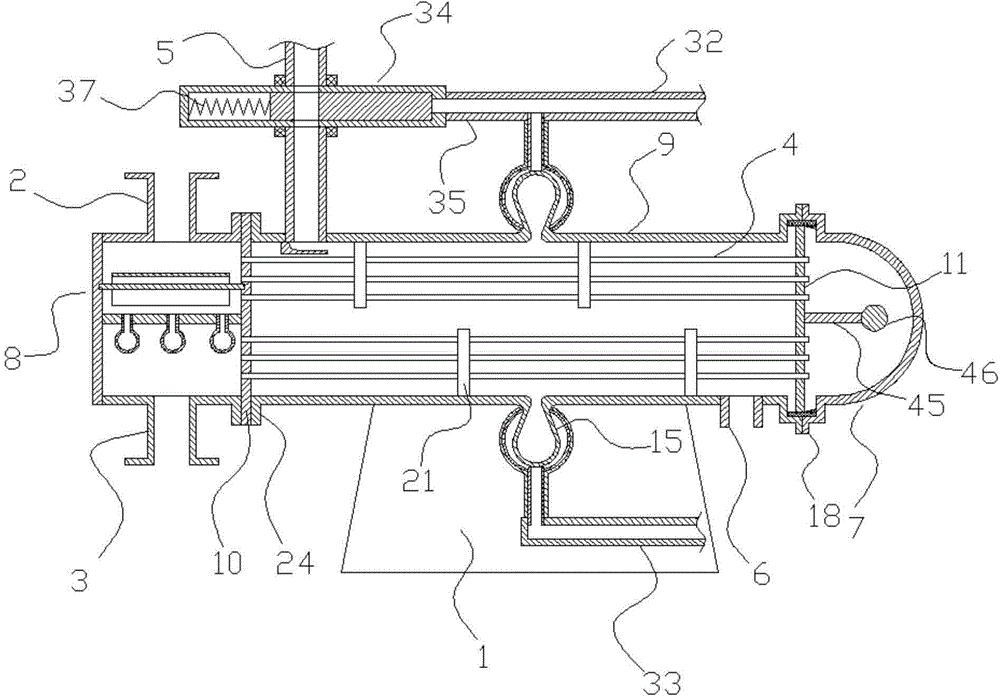

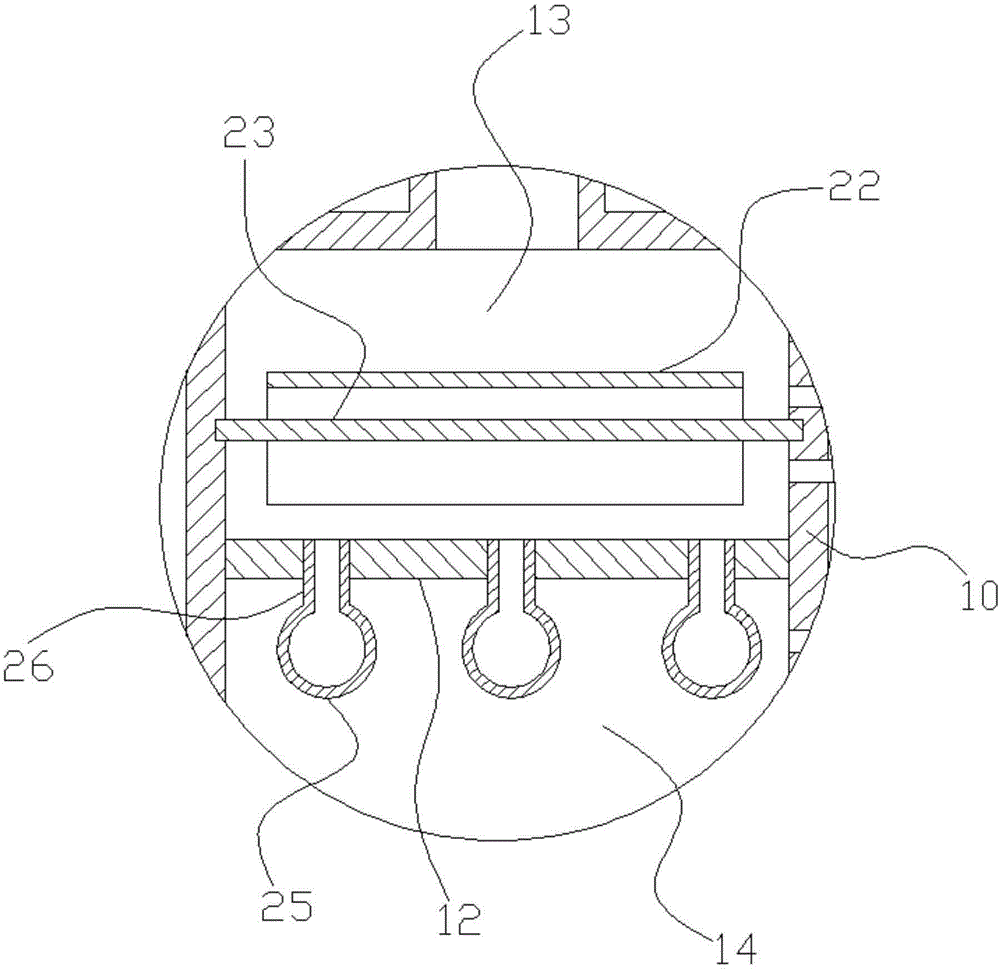

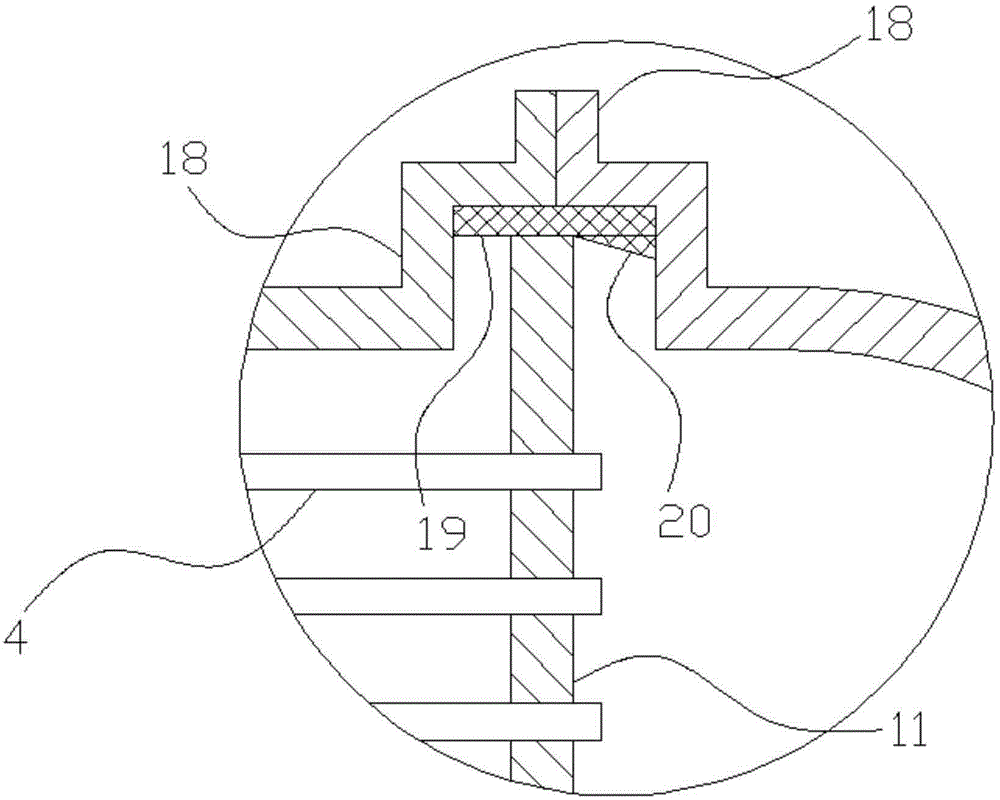

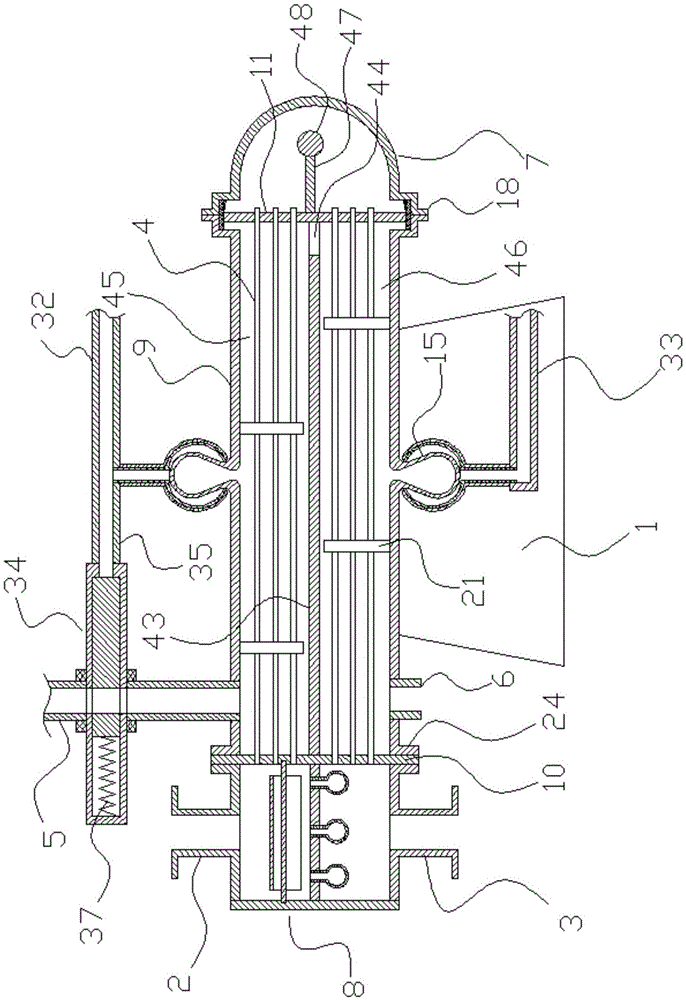

The invention discloses a shell-and-tube heat exchanger. By the shell-and-tube heat exchanger, heat exchange between two types of liquid can be implemented effectively; the shell-and-tube heat exchanger has temperature difference compensation ability; and the circumstance that the heat exchanger is damaged due to over large temperature difference stress between a shell and heat exchanging tubes can be avoided. The shell-and-tube heat exchanger comprises a tube pass portion, a shell pass portion and a plurality of supports, wherein the tube pass portion comprises a tube pass inlet tube, a tube pass outlet tube and a plurality of heat exchanging tubes; the shell pass portion comprises a heat exchanger outer shell, a shell pass inlet tube and a shell pass outlet tube; the heat exchanger outer shell consists of an end socket, a shell head and a channel; a fixing tube plate is arranged between the shell head and the channel; an end socket tube plate is arranged between the end socket and the channel; the inside of the shell head is divided into a tube pass flow inlet cavity and a tube pass flow outlet cavity by a tube pass flow separating plate; and the channel is provided with an expansion joint. The shell-and-tube heat exchanger has the advantages that the position of the expansion joint easily deforms, a structural temperature difference compensating effect is achieved by the slidable end socket tube plate, and structural damage caused by over large temperature difference stress is avoided.

Owner:CHINA JILIANG UNIV

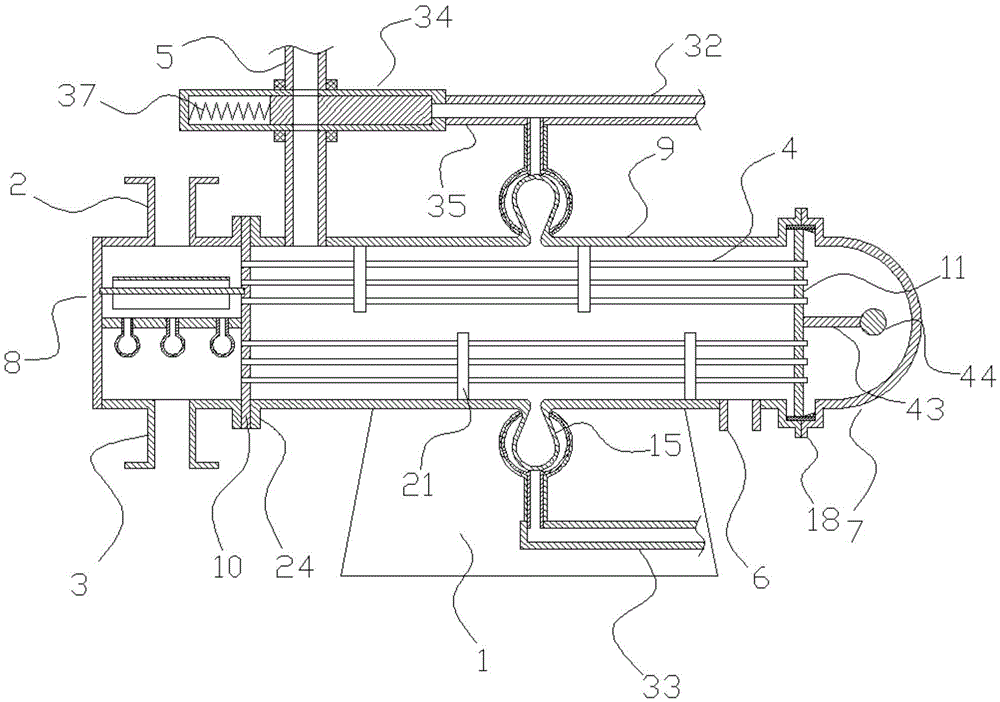

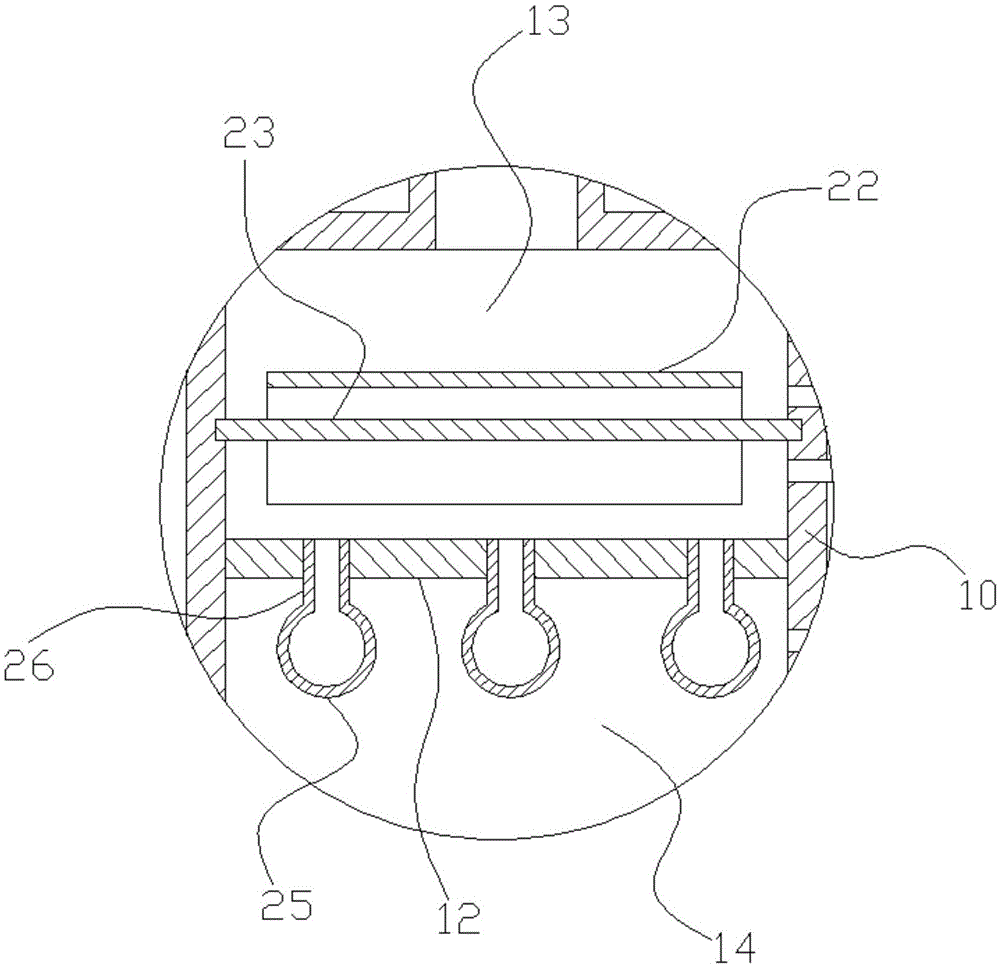

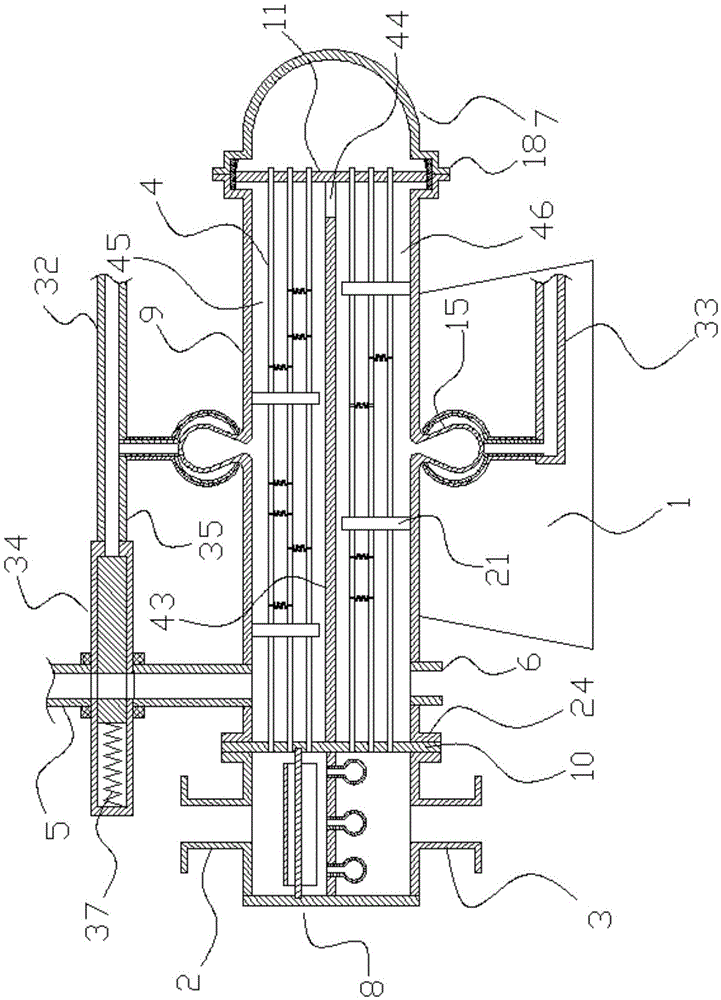

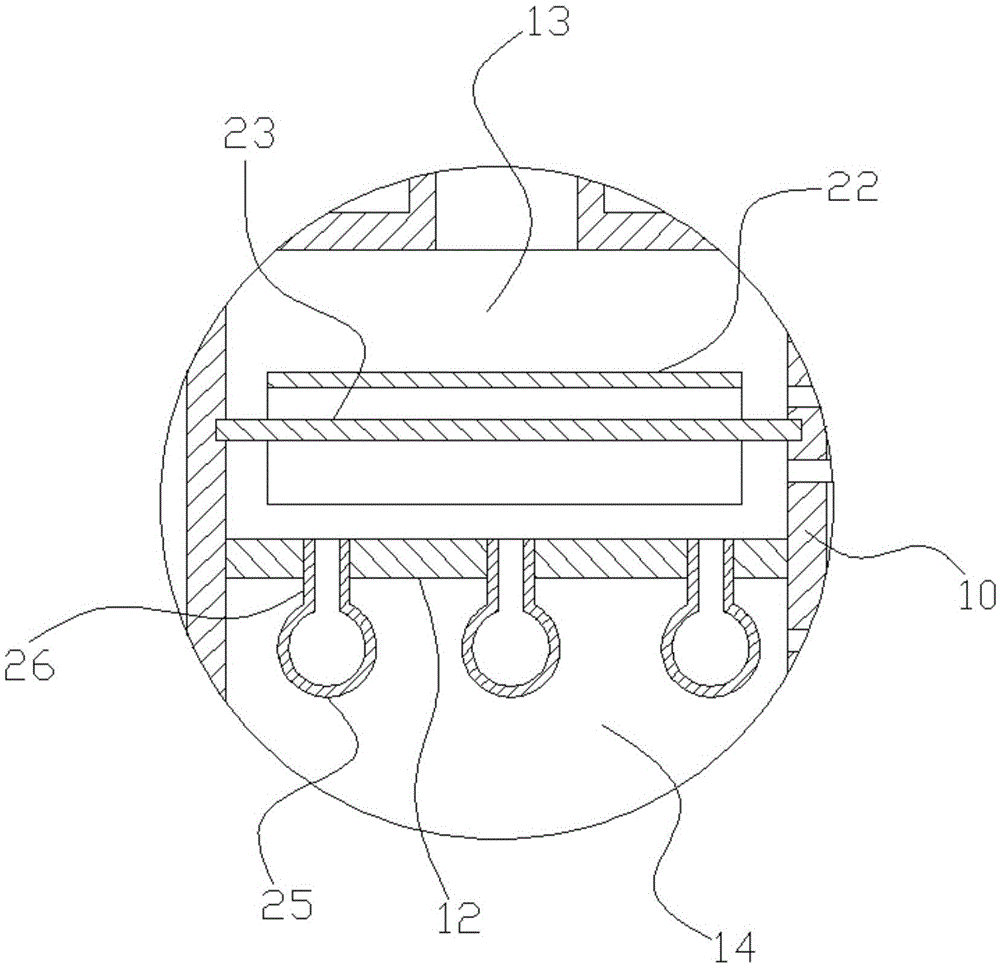

Double-sided polishing device and double-sided polishing method

ActiveCN114274041AAvoid affecting smoothnessFinal product manufactureSemiconductor/solid-state device manufacturingPhysicsSilicon chip

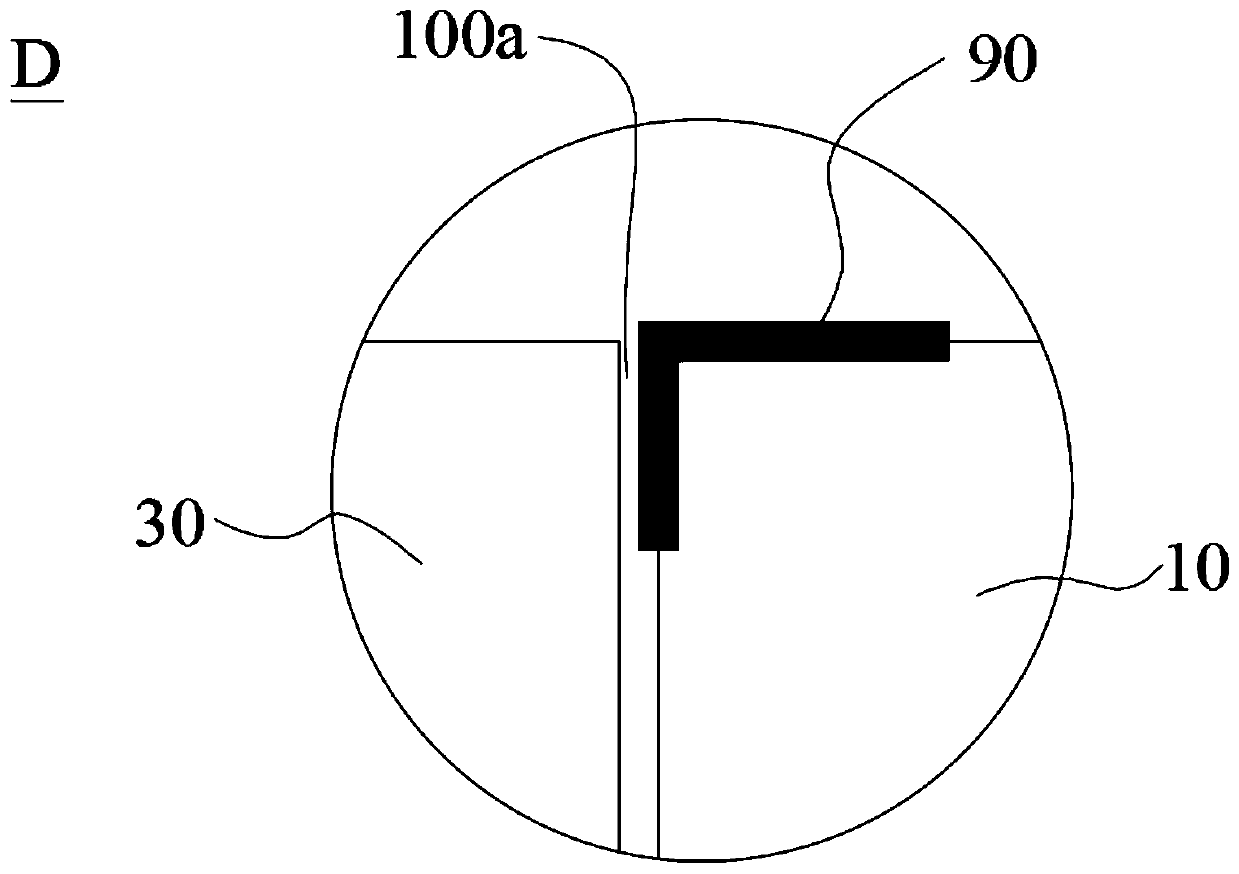

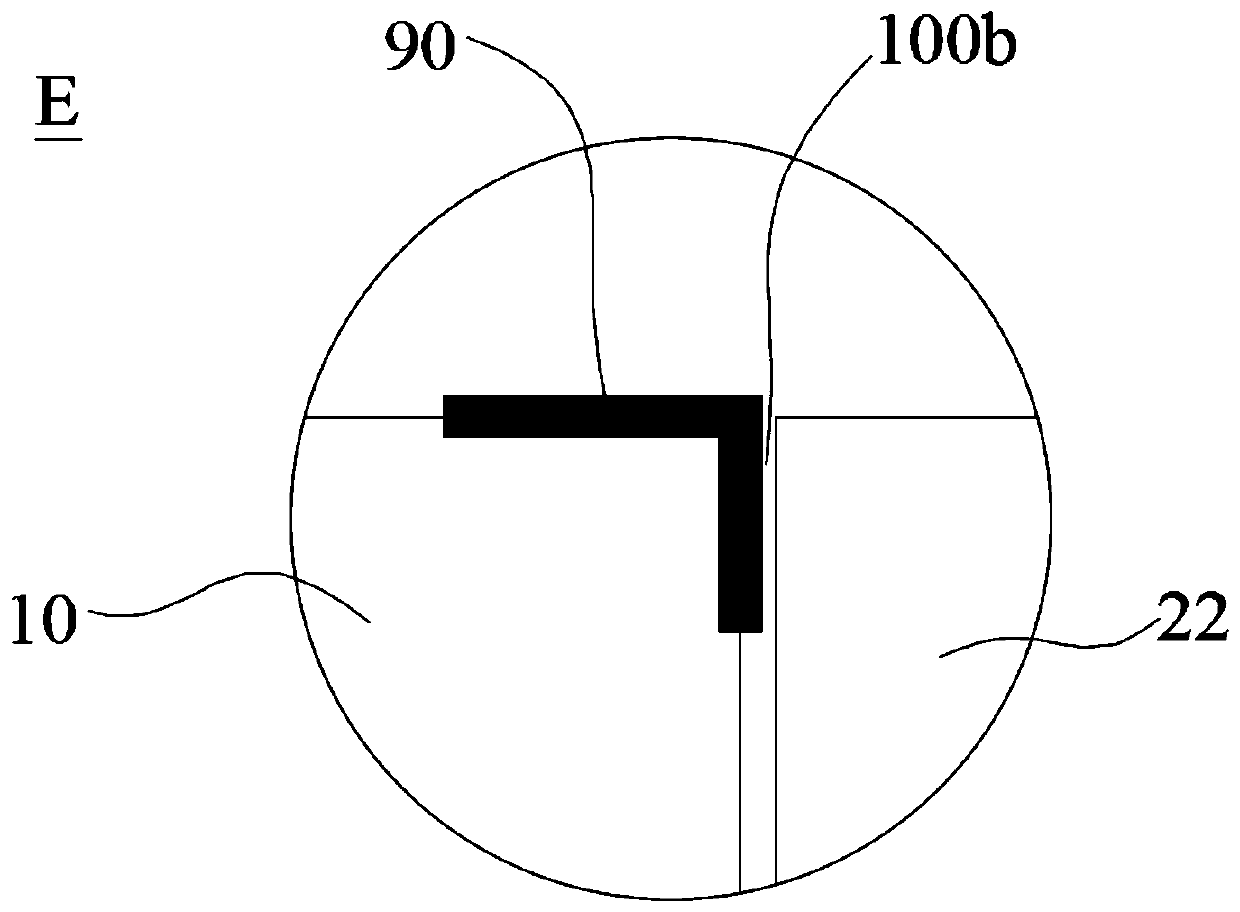

The invention relates to a double-sided grinding device, which is used for grinding two opposite surfaces of a silicon wafer, and comprises an annular bearing structure, a grinding device and a grinding device, and is characterized in that the annular bearing structure is used for supporting the silicon wafer from the peripheral side in the radial direction; the two static pressure supporting pieces are oppositely arranged, are respectively positioned on two sides of the silicon wafer, and are used for supporting the silicon wafer in a non-contact manner through fluid static pressure; the two grinding wheels are oppositely arranged and used for grinding the two opposite faces of the silicon wafer, the two static pressure supporting pieces comprise the first static pressure supporting piece and the second static pressure supporting piece, and the first static pressure supporting piece is used for adsorbing the ground silicon wafer; and the cleaning structure is used for cleaning the first static pressure supporting piece. The invention further relates to a double-sided grinding method. Through the arrangement of the cleaning structure, the static pressure supporting piece used for adsorbing the silicon wafer is cleaned, and the smoothness of the wafer is prevented from being influenced.

Owner:XIAN ESWIN MATERIAL TECH CO LTD +1

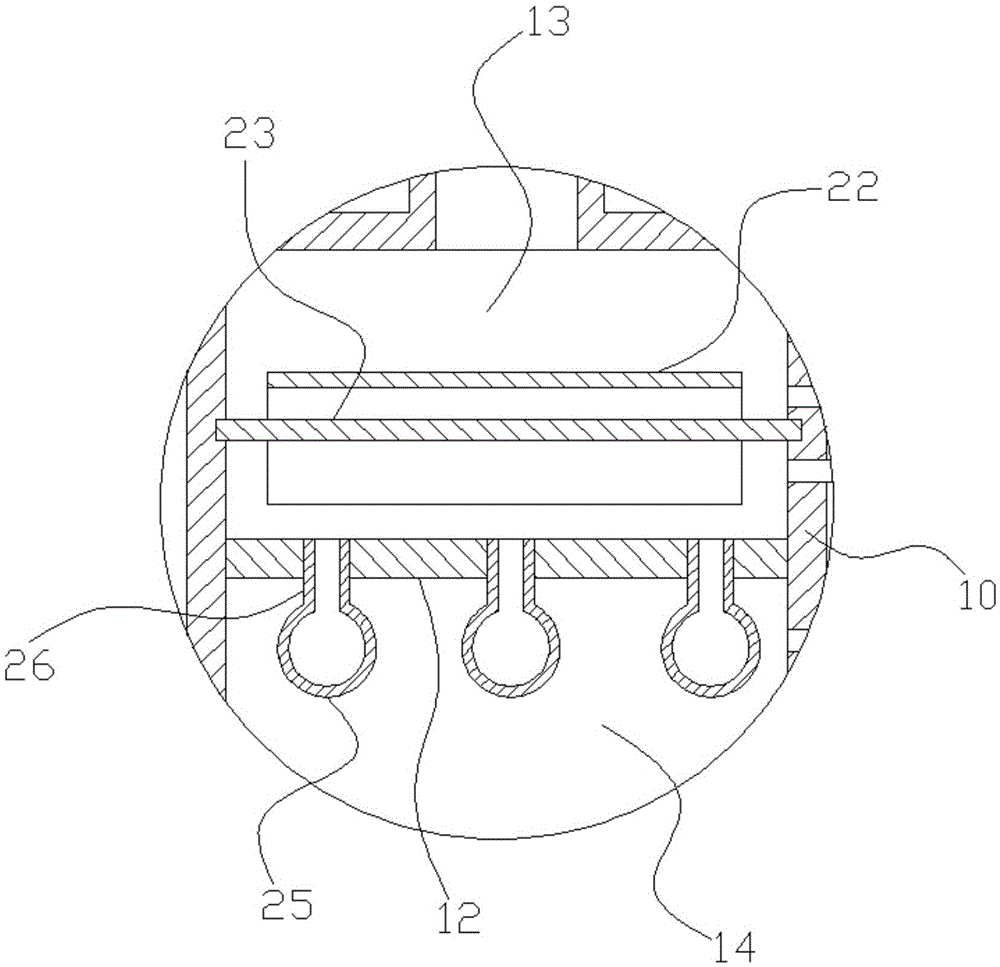

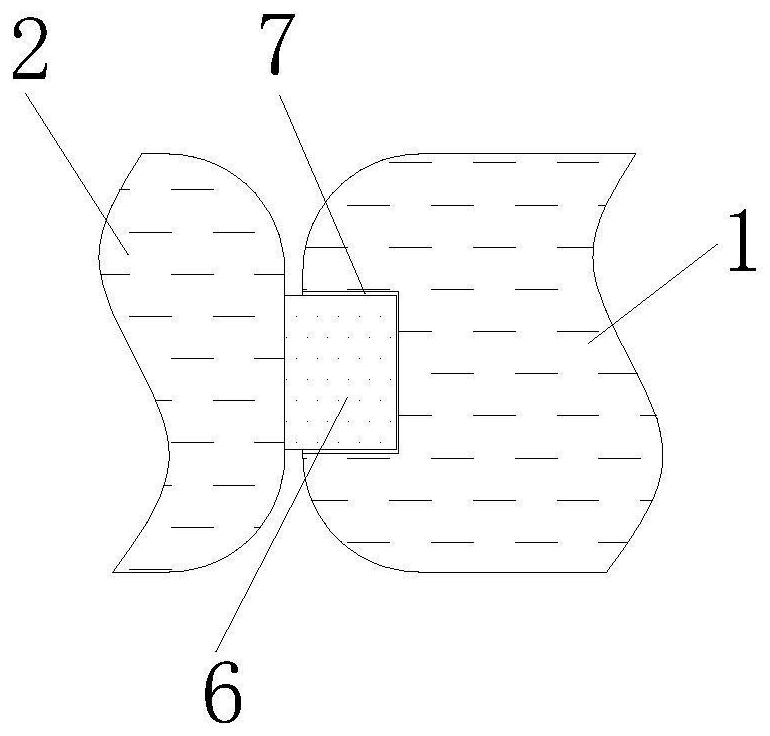

Overturning device for paint spraying of automobile parts

InactiveCN113600379AEasy to hold and transferAvoid affecting smoothnessSpraying apparatusPretreated surfacesMotor vehicle partStructural engineering

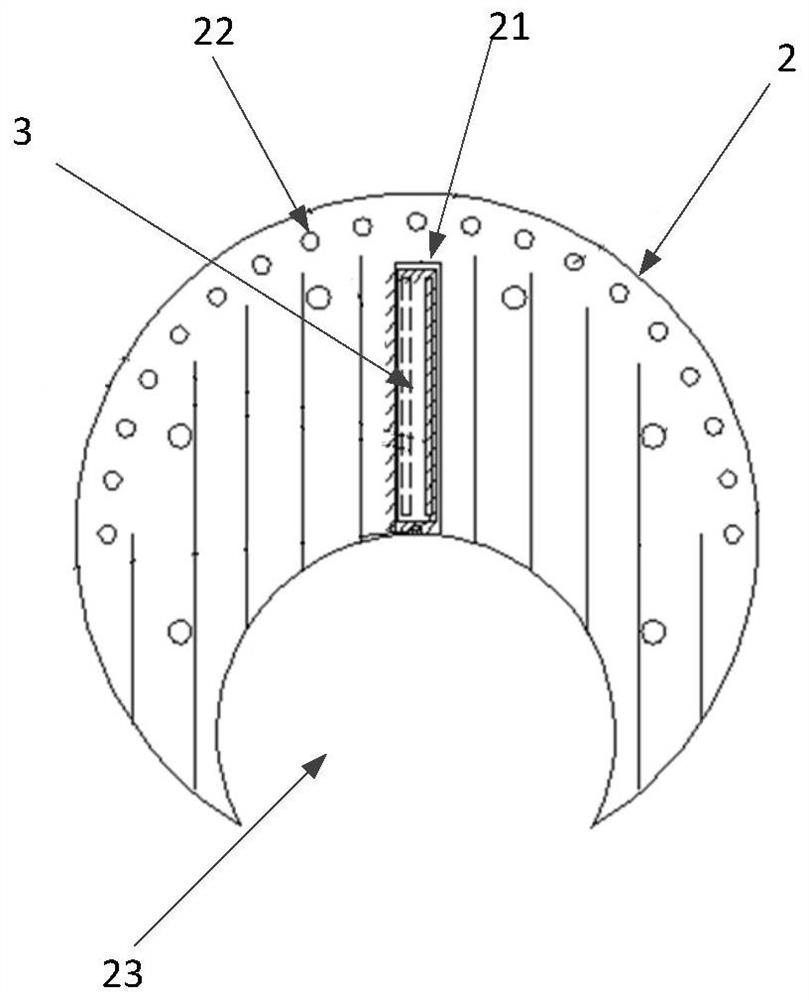

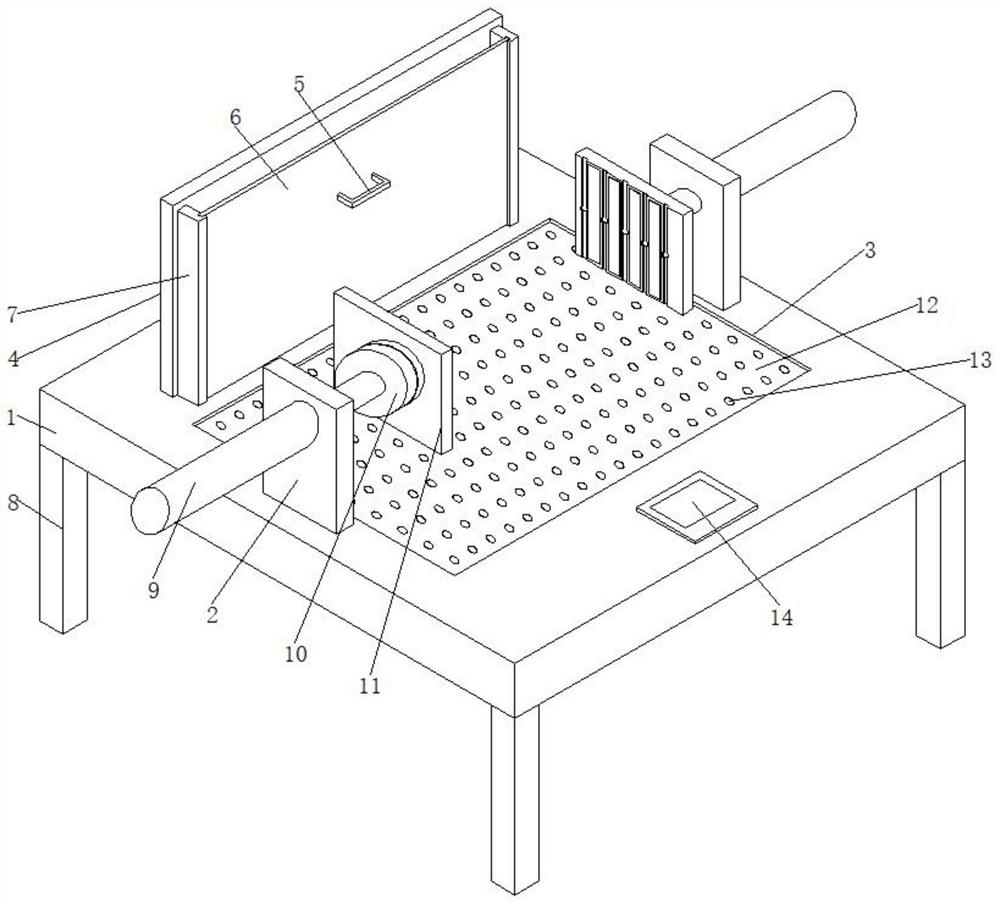

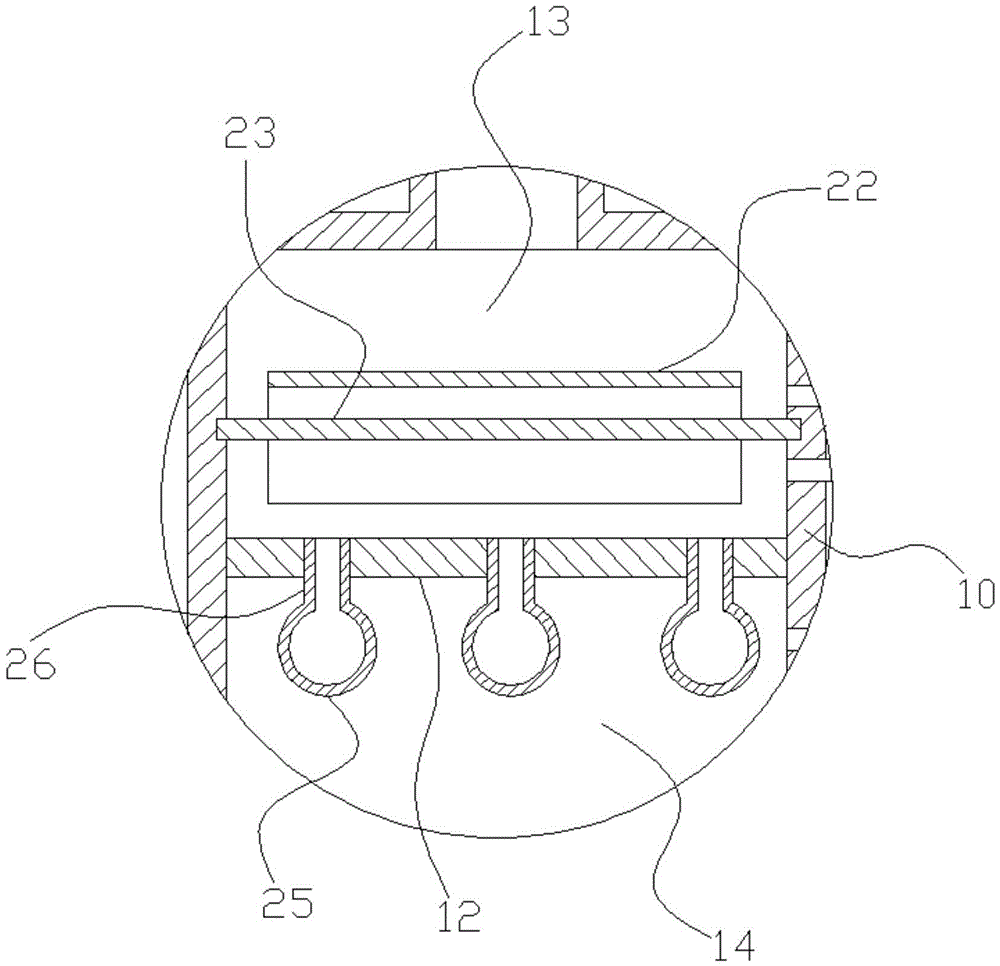

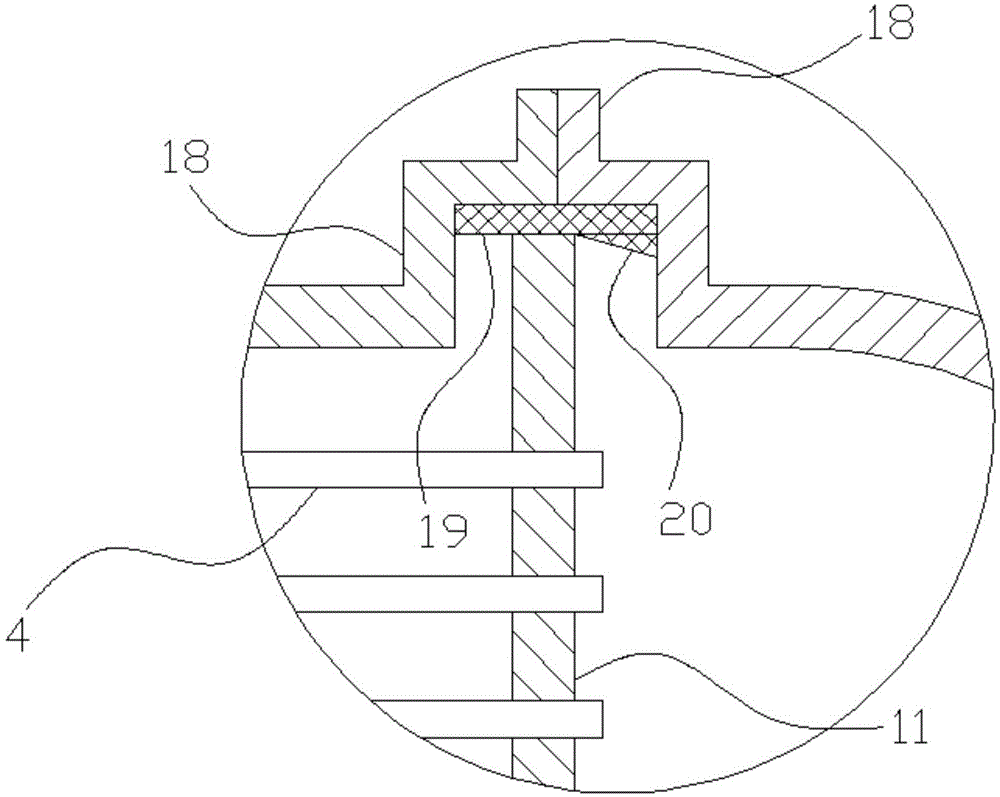

The invention relates to the technical field of automobile part paint spraying, and discloses an overturning device for paint spraying of automobile parts. The overturning device comprises an operation table, fixed plates, an opening and a vertical plate. The number of the fixing plates is two, the two fixing plates are vertically arranged on the operation table and fixed to the front end and the rear end of the operation table, the fixing plates at the front end and the rear end are parallel to each other, electric push rods are installed above the surfaces of the fixing plates, the extension ends of the electric push rods penetrate to the inner sides of the fixing plates, rotary tables are installed at the tail ends of the extension ends of the electric push rods, and clamping plates are mounted on the surfaces of the rotary tables. According to the overturning device for paint spraying of the automobile parts, the opening is located in the operation table below an overturning structure, electric heating wires are arranged in the opening, a partition plate and L-shaped baffles which are used for preventing paint from being attached are arranged at the positions, above the electric heating wires, of the opening, drying work can be carried out through heat carried by airflow in the paint spraying process, and after spraying is completed, clamping and transferring of the parts are facilitated, the smoothness is prevented from being affected, and further paint baking work can be carried out when needed.

Owner:扬州市宝丰机械有限公司

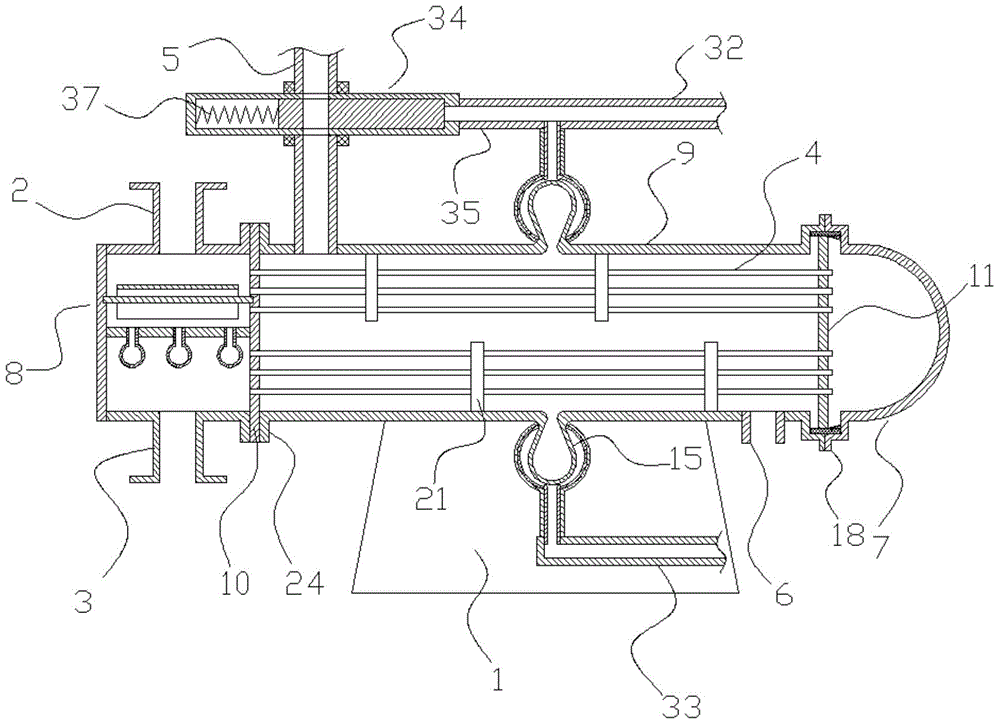

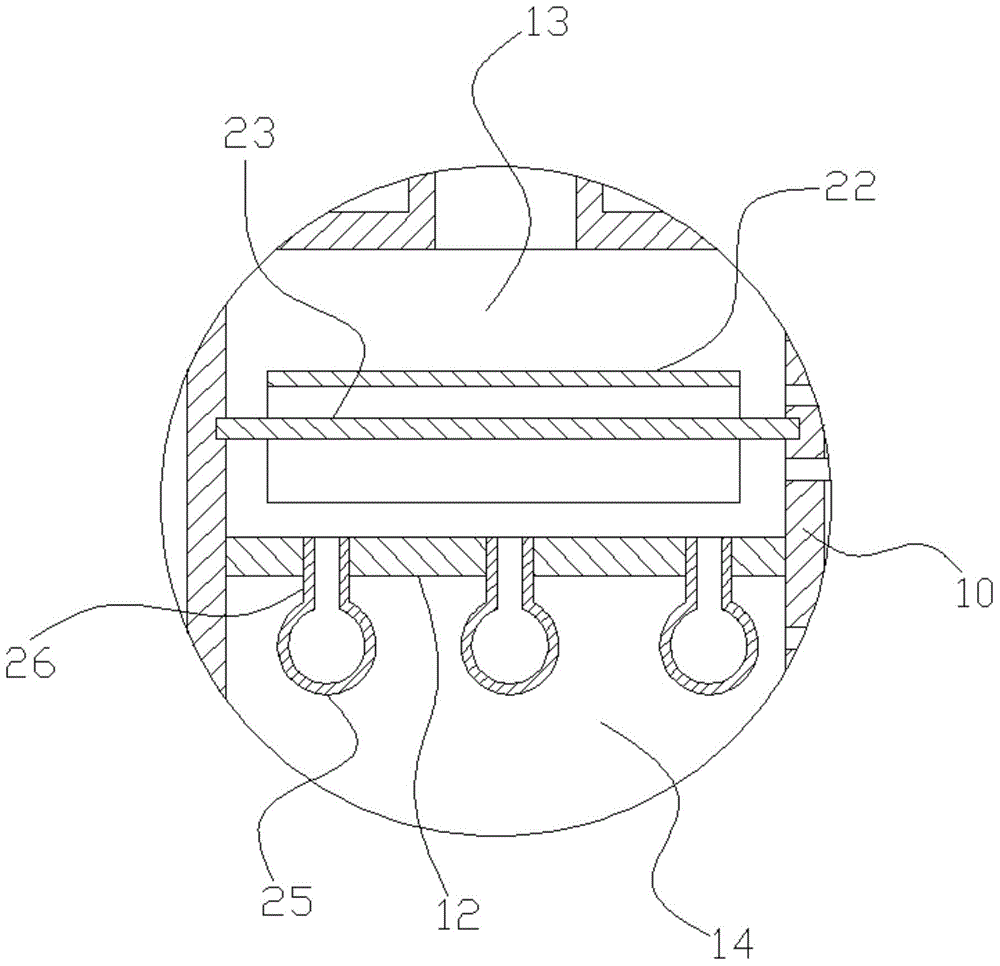

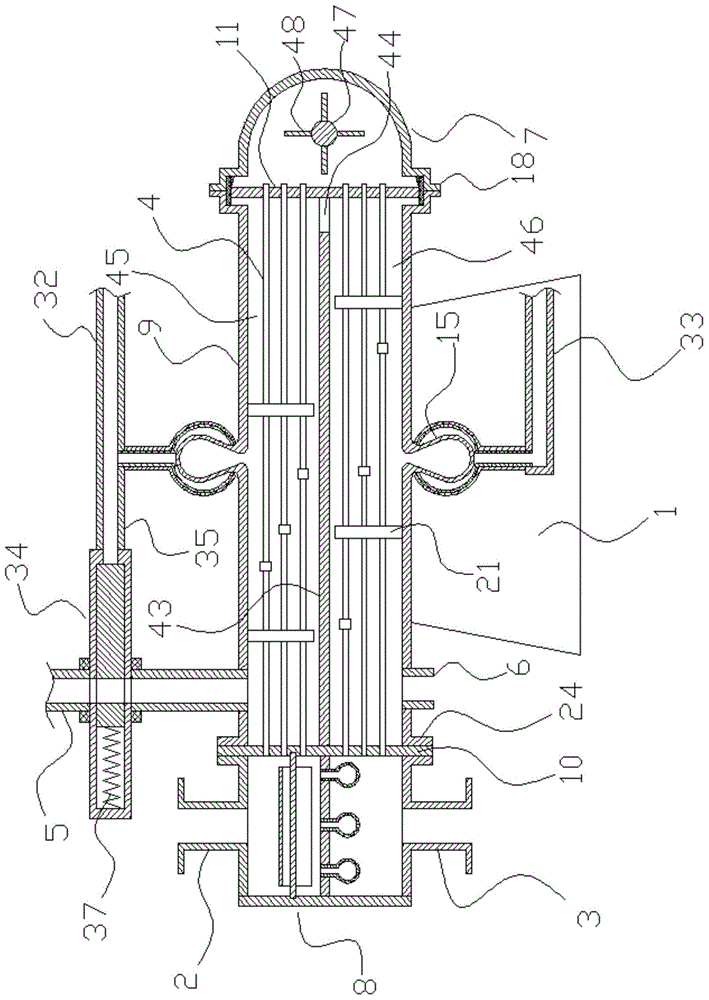

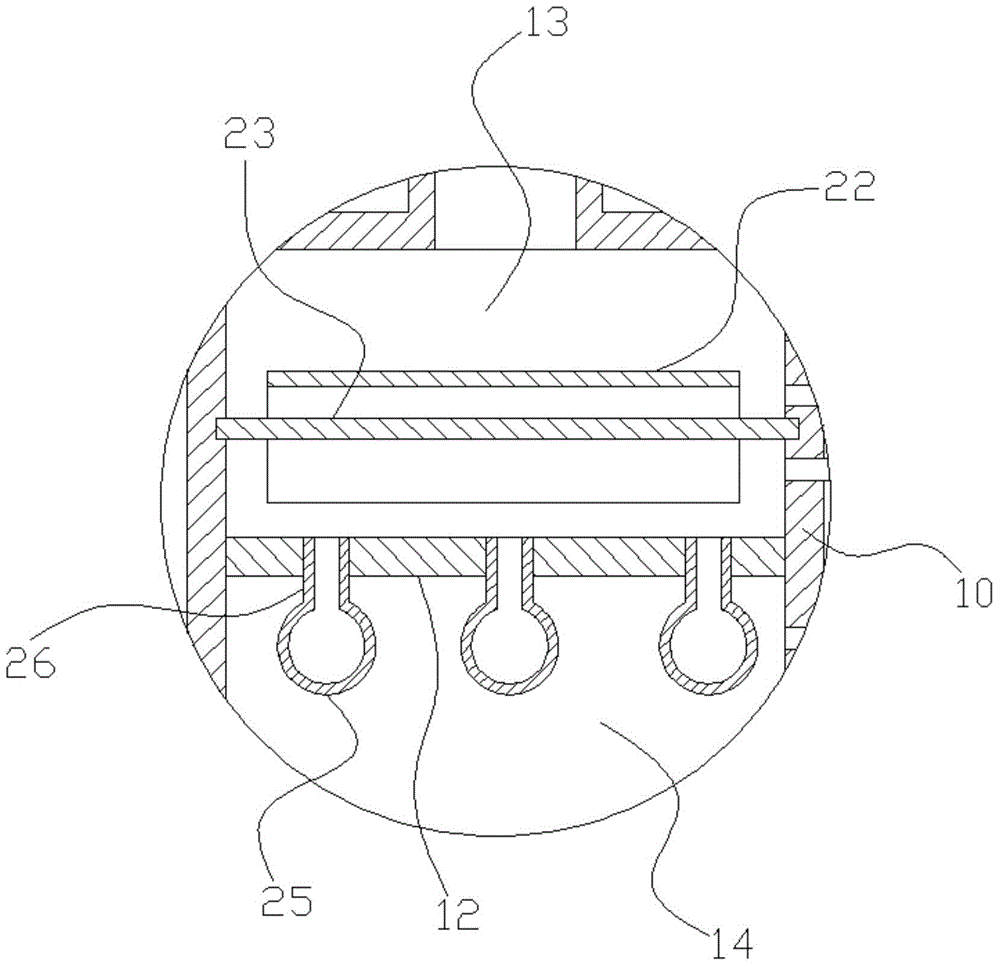

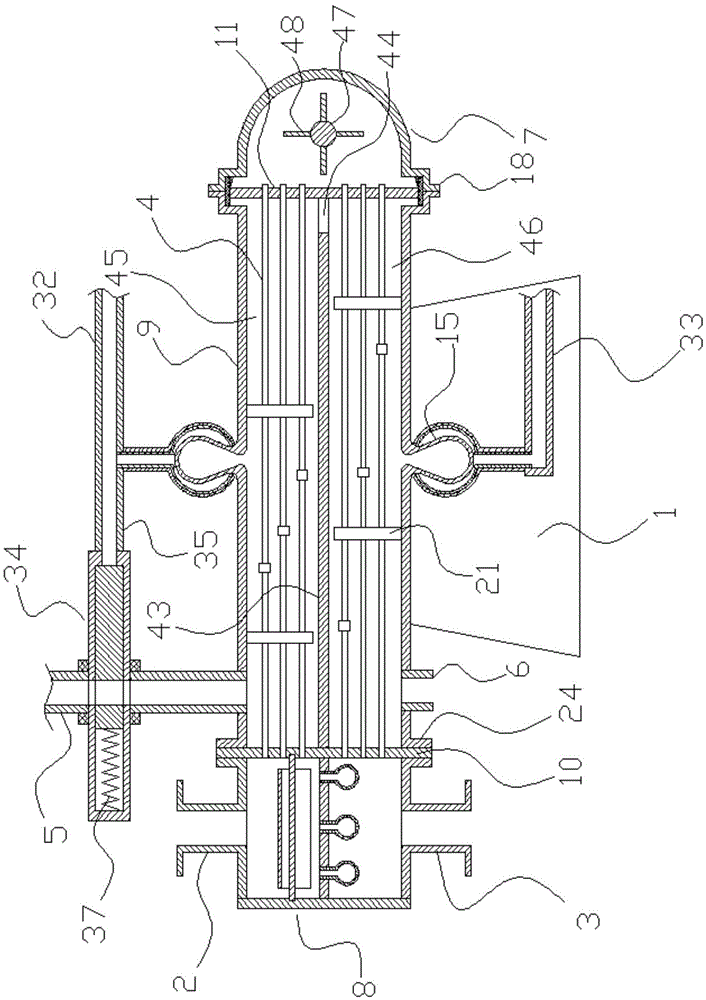

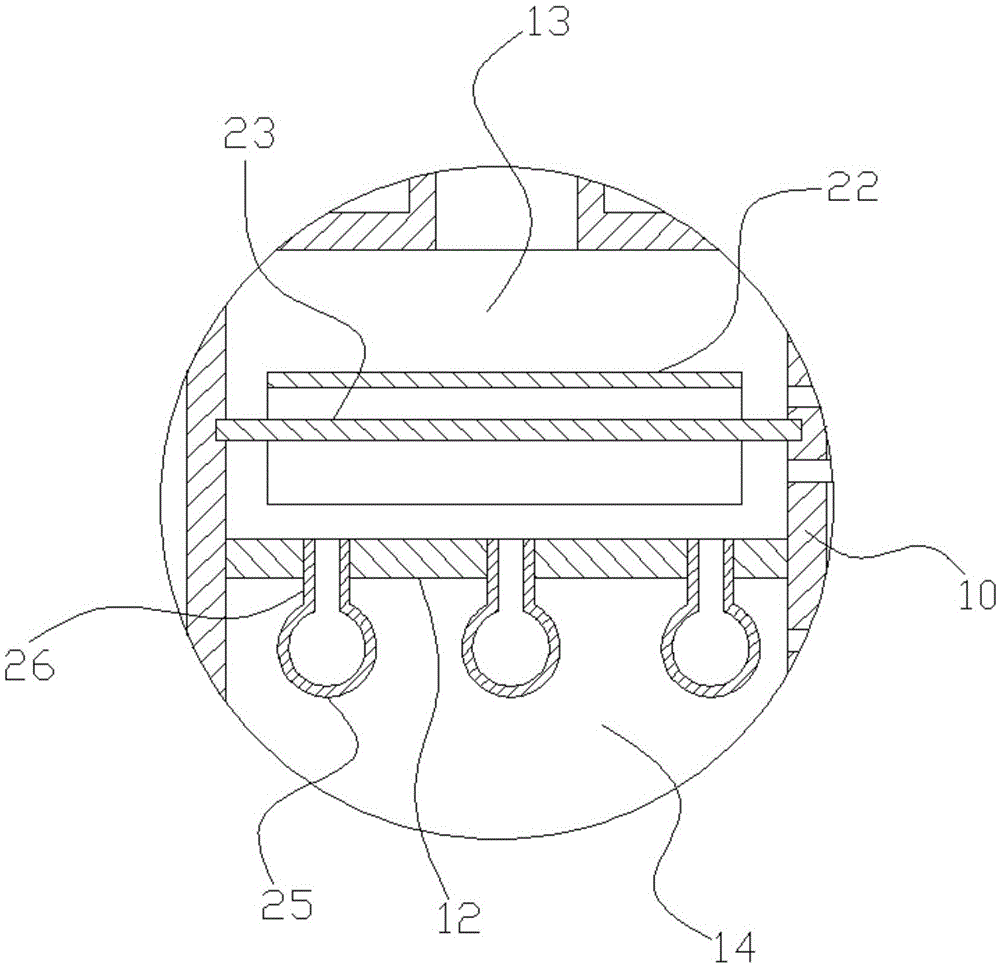

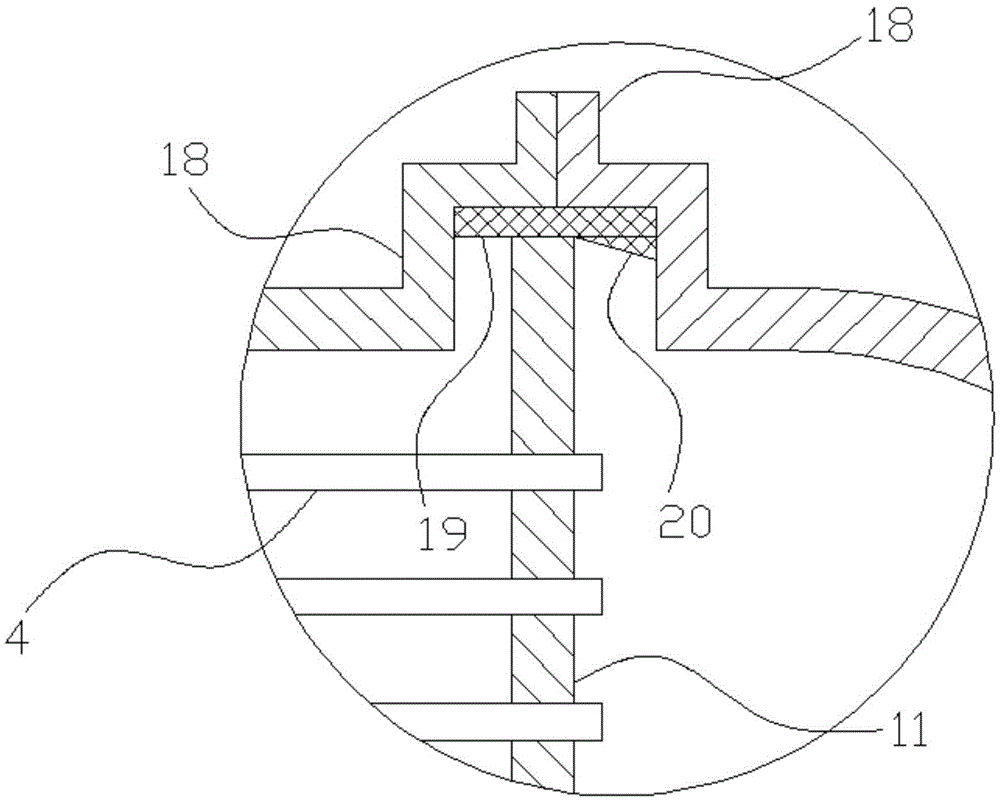

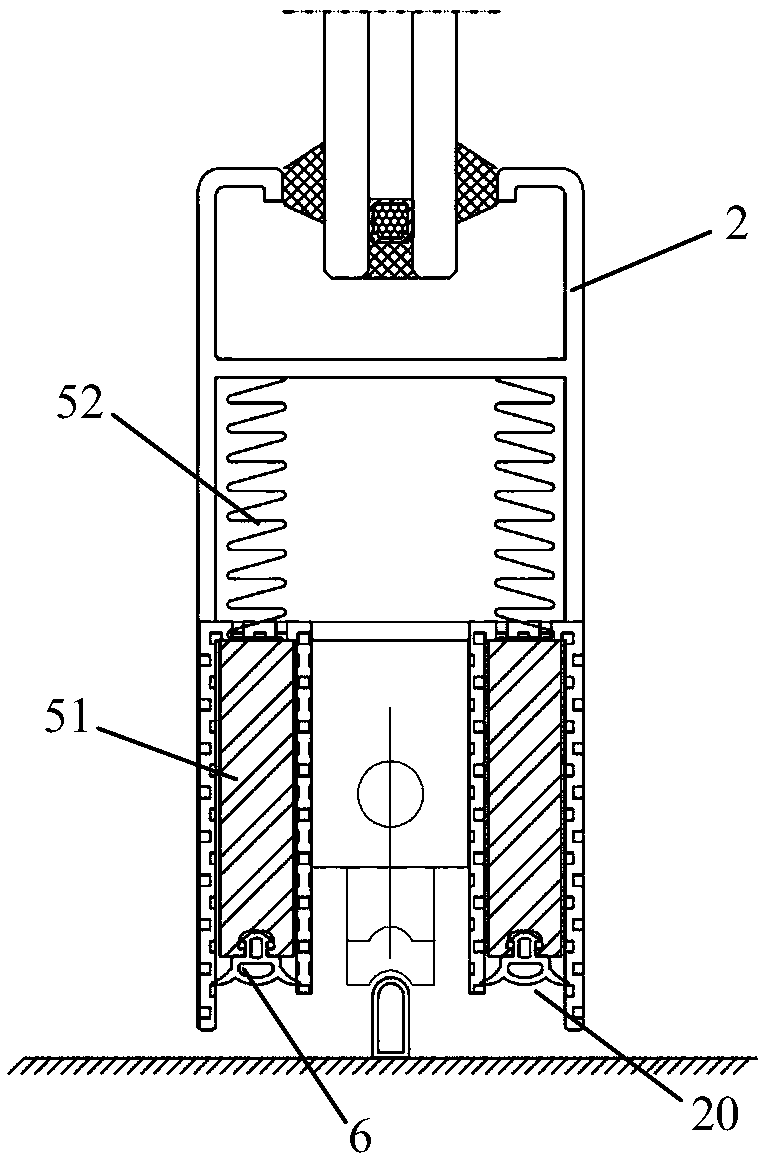

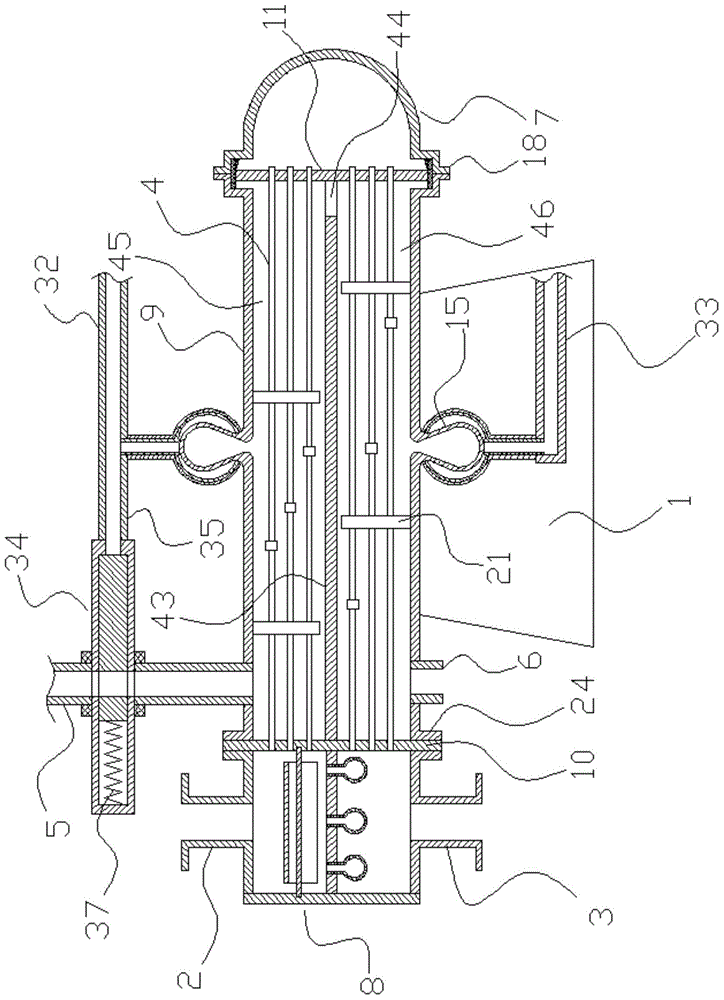

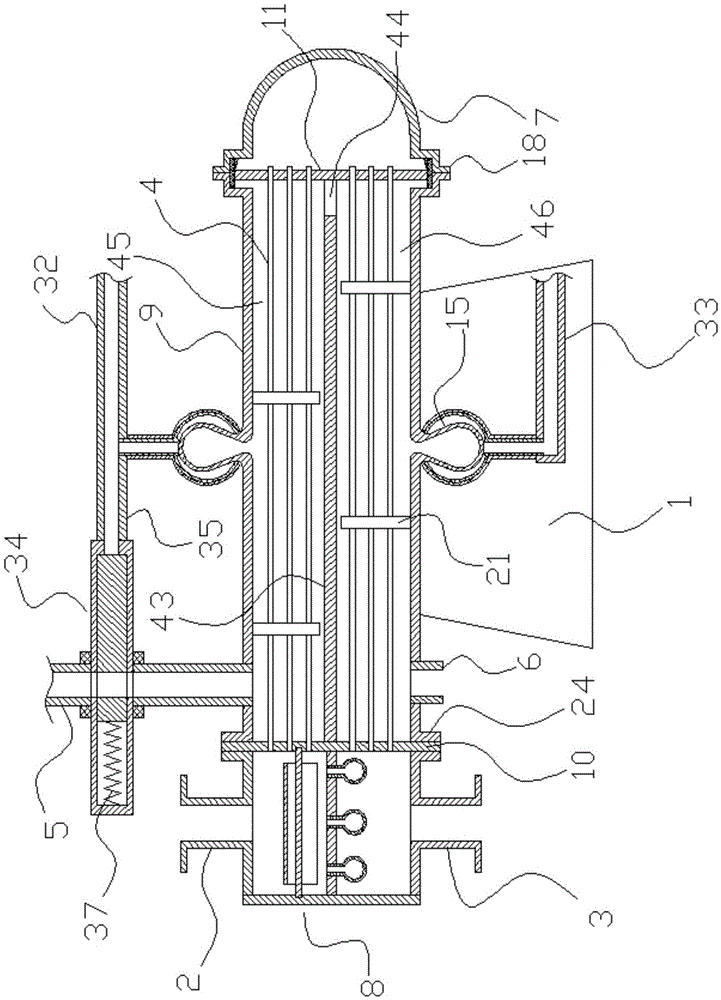

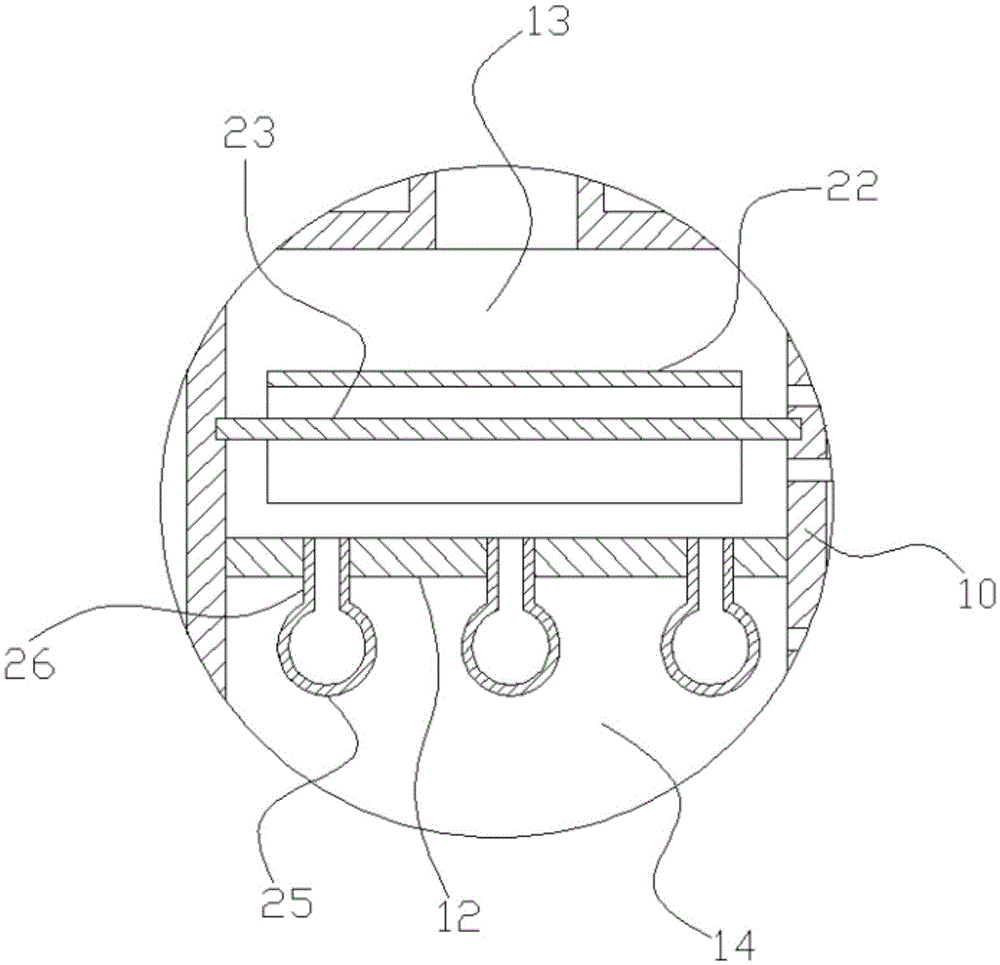

Tube array type heat exchange device

InactiveCN104654836AAvoid structural damageAvoid Adhesive BuildupHeat exchanger casingsStationary tubular conduit assembliesEngineeringExpansion joint

The invention discloses a tube array type heat exchange device, and aims at providing a heat exchange device with the advantages that the heat exchange between two kinds of liquid can be effectively realized, the temperature difference compensation capability is realized, and the damage due to too great temperature difference stress between a casing and a heat exchange tube can be prevented. The tube array type heat exchange device comprises a tube pass part, a casing pass part and a plurality of support frames, wherein the tube pass part comprises a tube pass inlet tube, a tube pass outlet tube and a plurality of heat exchange tubes, the casing pass part comprises a heat exchanger outer casing, a casing pass inlet tube and a casing pass outlet tube, the heat exchanger outer casing consists of a sealing head, a casing head and a tube box, a fixing tube plate is arranged between the casing head and the tube box, a sealing head tube plate is arranged between the sealing head and the tube box, the inside of the casing head is separated into a tube pass flow inlet cavity and a tube pass flow outlet cavity through one tube pass flow separation plate, and an expansion joint is arranged on the tube box. The tube array type heat exchange device has the beneficial effects that the characteristic that the expansion joint part is relatively easy to deform can be used for being matched with the slidable sealing head tube plate to achieve the structural temperature difference compensation effect, and the structure damage due to too great temperature difference stress can be avoided.

Owner:CHINA JILIANG UNIV

Tube-shell type heat exchange device

InactiveCN104654832AAvoid damageSmooth circulationHeat exchanger casingsStationary tubular conduit assembliesCompensation effectEngineering

The invention discloses a tube-shell type heat exchange device and aims to provide a heat exchange device which can effectively achieve heat exchange between two types of liquid, has temperature difference compensation capacity and can be prevented from being damaged due to over-large temperature difference stress between a shell and a heat exchange tube. The tube-shell type heat exchange device comprises a tube pass part, a shell pass part and a plurality of brackets, wherein the tube pass part comprises a tube pass inlet tube, a tube pass outlet tube and a plurality of heat exchange tubes; the shell pass part comprises an outer heat exchanger shell, a shell pass inlet tube and a shell pass outlet tube; the outer heat exchanger shell consists of a sealing head, a shell head and a tube box; a fixed tube plate is arranged between the shell head and the tube box; a sealing head tube plate is arranged between the sealing head and the tube box; a tube pass flow partition plate partitions the interior of the shell head into a tube pass inflow cavity and a tube pass outflow cavity; an expansion joint is arranged on the tube box. The tube-shell type heat exchange device has the beneficial effects that according to the characteristic hat the expansion joint is relatively easy to deform, by the cooperation of the slidable sealing head tube plate, the structural temperature difference compensation effect can be achieved, and the structural damage caused by over-large temperature difference stress is avoided.

Owner:CHINA JILIANG UNIV

Chemical engineering heat exchanger

InactiveCN104596323AAvoid damageSmooth circulationHeat exchanger casingsStationary tubular conduit assembliesCompensation effectCompound (substance)

The invention discloses a chemical engineering heat exchanger and aims to provide a heat exchanger which can effectively realize heat exchange between two liquors, has capability of temperature difference compensation and can be prevented from being damaged due to excessively large temperature difference stress between a shell and heat exchange tubes. The chemical engineering heat exchanger comprises a tube pass part, a shell pass part and a plurality of brackets, wherein the tube pass part comprises a tube pass inlet tube, a tube pass outlet tube and the plurality of heat exchange tubes; the shell pass part comprises a heat exchanger shell body, a shell pass inlet tube and a shell pass outlet tube; the heat exchanger shell body comprises a seal head, a shell head and a tube box; a fixed tube plate is arranged between the shell head and the tube box; a seal head tube plate is arranged between the seal head and the tube box; a tube pass flow baffle is used for dividing the interior of the shell head into a tube pass inflow cavity and a tube pass outflow cavity; an expansion joint is arranged on the tube box. The chemical engineering heat exchanger has the benefits that a structural temperature difference compensation effect can be achieved in combination with the slidable seal head tube plate based on a characteristic of easiness for deformation at the expansion joint, and structural damage caused by excessively large temperature difference stress is avoided.

Owner:CHINA JILIANG UNIV

Tube array type heat exchanger

InactiveCN104654835AAvoid damageSmooth circulationHeat exchanger casingsStationary tubular conduit assembliesCompensation effectEngineering

The invention discloses a tube array type heat exchanger, and aims at providing a heat exchanger with the advantages that the heat exchange between two kinds of liquid can be effectively realized, the temperature difference compensation capability is realized, and the damage due to too great temperature difference stress between a casing and a heat exchange tube can be prevented. The tube array type heat exchanger comprises a tube pass part, a casing pass part and a plurality of support frames, wherein the tube pass part comprises a tube pass inlet tube, a tube pass outlet tube and a plurality of heat exchange tubes, the casing pass part comprises a heat exchanger outer casing, a casing pass inlet tube and a casing pass outlet tube, the heat exchanger outer casing consists of a sealing head, a casing head and a tube box, a fixing tube plate is arranged between the casing head and the tube box, a sealing head tube plate is arranged between the sealing head and the tube box, one tube pass separation plate separates the inside of the casing head into a tube pass flow inlet cavity and a tube pass flow outlet cavity, and an expansion joint is arranged on the tube box. The tube array type heat exchanger has the beneficial effects that the characteristic that the expansion joint part is relatively easy to deform can be utilized to be matched with the slidable sealing head tube plate to achieve the structural temperature difference compensation effect, and the structure damage due to too great temperature difference stress is avoided.

Owner:卢晓丽

Double-pass double-liquid heat exchange device

InactiveCN104697368AAvoid damageSmooth circulationCorrosion preventionHeat exhanger sealing arrangementEngineeringTemperature difference

The invention discloses a double-pass double-liquid heat exchange device and aims to provide a heat exchange device which can effectively realize heat exchange between two liquid, has the temperature difference compensation capacity and can prevent a shell and heat exchange tubes from being damaged caused by overlarge temperature difference stress between the shell and the heat exchange tubes. The double-pass double-liquid heat exchange device comprises a tube pass part, a shell pass part and a plurality of support frames, wherein the tube pass part comprises a tube pass inlet tube, a tube pass outlet tube and a plurality of heat exchange tubes; the shell pass part comprises a heat exchanger shell, a shell pass inlet tube and a shell pass outlet tube; the heat exchanger shell consists of a sealing head, a shell head and a tube box; a fixed tube plate is arranged between the shell head and the tube box; a sealing head tube plate is arranged between the sealing head and the tube box; the inner part of the shell head is divided into a tube pass flow inlet cavity and a tube pass flow outlet cavity through a tube pass flow isolation plate; an expansion joint is arranged on the tube box. The double-pass double-liquid heat exchange device has the benefits that through the characteristic that the deformation of the expansion joint is relatively easy and in cooperation with the slideable sealing head tube plate, a structural temperature difference compensation function can be realized, and the structure damage caused by overlarge temperature difference stress is avoided.

Owner:CHINA JILIANG UNIV

Tube-shell type double-liquid heat exchange device

InactiveCN104654834AAvoid damageSmooth circulationHeat exchanger casingsStationary tubular conduit assembliesCompensation effectEngineering

The invention discloses a tube-shell type double-liquid heat exchange device and aims to provide a heat exchange device which can effectively achieve heat exchange between two types of liquid, has temperature difference compensation capacity and can be prevented from being damaged due to over-large temperature difference stress between a shell and a heat exchange tube. The tube-shell type double-liquid heat exchange device comprises a tube pass part, a shell pass part and a plurality of brackets, wherein the tube pass part comprises a tube pass inlet tube, a tube pass outlet tube and a plurality of heat exchange tubes; the shell pass part comprises an outer heat exchanger shell, a shell pass inlet tube and a shell pass outlet tube; the outer heat exchanger shell consists of a sealing head, a shell head and a tube box; a fixed tube plate is arranged between the shell head and the tube box; a sealing head tube plate is arranged between the sealing head and the tube box; a tube pass flow partition plate partitions the interior of the shell head into a tube pass inflow cavity and a tube pass outflow cavity; an expansion joint is arranged on the tube box. The tube-shell type double-liquid heat exchange device has the beneficial effects that according to the characteristic hat the expansion joint is relatively easy to deform, by the cooperation of the slidable sealing head tube plate, the structural temperature difference compensation effect can be achieved, and the structural damage caused by over-large temperature difference stress is avoided.

Owner:CHINA JILIANG UNIV

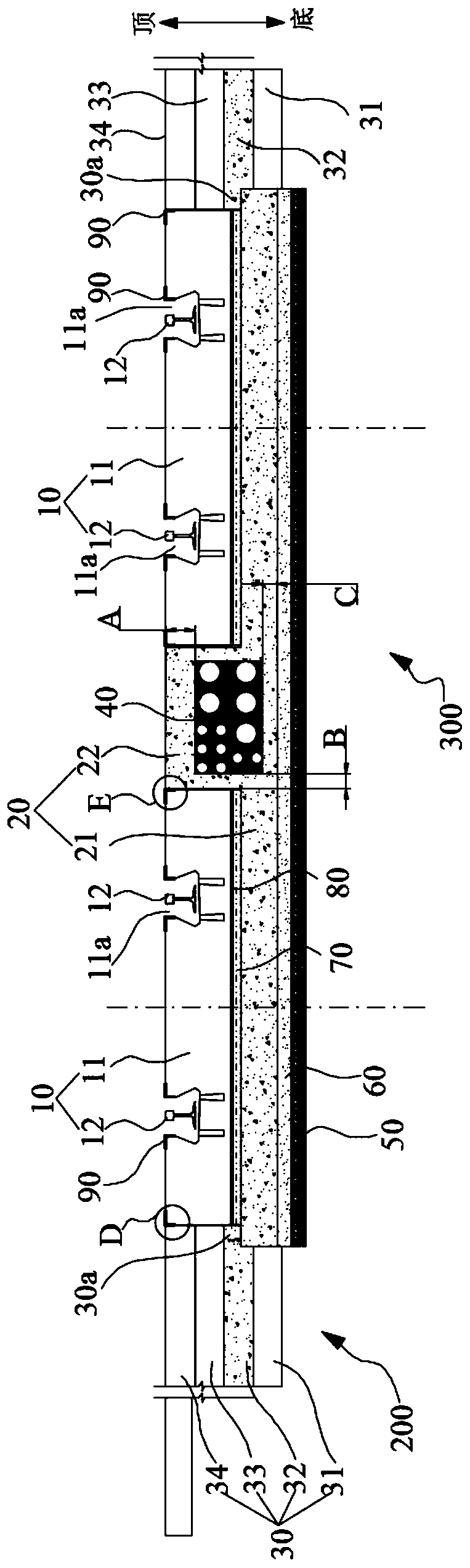

Level crossing structure of rail transit

PendingCN111549583AImprove mechanical performanceEven by forceBallastwayTrackwayArchitectural engineering

The embodiment of the invention provides a level crossing structure of rail transit. The level crossing structure comprises a track structure body and a foundation plate, the foundation plate comprises a first part and a second part, the first part is supported below the track structure body, the second part fills an inter-line area between every two adjacent track structure bodies, and the firstpart and the second part are integrally formed. Due to the fact that the first part and the second part are integrally formed, the second part can bear automobile loads and transmit the automobile loads to the first part, and then the first part evenly transmits the loads to a roadbed foundation bed of a track structure. In this way, it is guaranteed that the roadbed foundation bed under the double-line or multi-line track structure is evenly stressed, and uneven settlement caused by uneven stress of the roadbed foundation bed under the double-line or multi-line track structure is prevented.

Owner:CHINA RAILWAY SIYUAN GRP SOUTHWEST SURVEY & DESIGN CO LTD +1

High-brightness black double-paint-layer spraying process for automobile exterior trimming parts

The invention provides a high-brightness black double-paint-layer spraying process for an automobile exterior trimming part. The high-brightness black double-paint-layer spraying process is characterized by comprising the following steps that a, pretreatment is conducted, specifically, oil stains and dust on the surface of the exterior trimming part are removed; b) flame treatment: carrying out flame treatment on the to-be-painted surface of the pre-treated exterior trimming part; c) double-paint-layer spraying: firstly, a primer is used as a first-layer paint to be sprayed on the flame-treated surface of the exterior trimming part, a second-layer paint is formed by stirring and mixing 30% by mass of colored paint, 67% by mass of varnish and 3% by mass of a-OH-containing high-molecular compound, then, a-NCO-containing curing agent is added into the second-layer paint, and the second-layer paint is sprayed on the flame-treated surface of the exterior trimming part; wherein the mass ratio of the high-molecular compound containing-OH to the curing agent containing-NCO is 100: 26, and finally, the second layer of paint is sprayed to the outer surface, where the first layer of paint is sprayed, of the exterior trimming part. The produced exterior trimming part is smooth in paint surface, free of impurities and high in percent of pass.

Owner:WUHAN LIAOYUAN MOLDING

High-strength and high-hardness ceramic gum abutment

ActiveCN111807865AGood biocompatibilityIncrease connection forceImpression capsAdditive manufacturing apparatusFiberMetal free

The invention belongs to the technical field of ceramic teeth, and relates to a high-strength and high-hardness ceramic gum abutment. The ceramic gum abutment is prepared from, by weight, 90 to 110 parts of zirconium oxide powder, 60-90 parts of titanium dioxide, 20 to 50 parts of aluminum oxide fibers, 0.2 to 1.0 part of ferric oxide, 0.1 to 2.0 parts of a dispersant, 20 to 50 parts of light-cured resin, 0.1 to 0.5 part of a photoinitiator, 0.1 to 3.0 parts of an adhesive, 0.5 to 5.0 parts of a coloring agent, 0.5 to 1.0 part of a pore-forming agent and 500 parts of a solvent; and the particle size of the zirconium oxide powder ranges from 100 nm to 500 nm, the particle size of the titanium dioxide ranges from 400 nm to 1000 nm, the diameter of the aluminum oxide fibers ranges from 50 nmto 200 nm, and the length of the aluminum oxide fibers ranges from 10 [mu]m to 200 [mu]m. According to the high-strength and high-hardness ceramic gum abutment, the surface of the ceramic gum abutmentis pure white and free of metallic luster, the surface is free of cracks in the machining process, the service life of the gum abutment is long, and safety is good.

Owner:嘉兴饶稷科技有限公司

Double-pass double-liquid heat exchange device

InactiveCN104697368BAvoid damageSmooth circulationCorrosion preventionHeat exhanger sealing arrangementTemperature differenceEngineering

The invention discloses a double-pass double-liquid heat exchange device and aims to provide a heat exchange device which can effectively realize heat exchange between two liquid, has the temperature difference compensation capacity and can prevent a shell and heat exchange tubes from being damaged caused by overlarge temperature difference stress between the shell and the heat exchange tubes. The double-pass double-liquid heat exchange device comprises a tube pass part, a shell pass part and a plurality of support frames, wherein the tube pass part comprises a tube pass inlet tube, a tube pass outlet tube and a plurality of heat exchange tubes; the shell pass part comprises a heat exchanger shell, a shell pass inlet tube and a shell pass outlet tube; the heat exchanger shell consists of a sealing head, a shell head and a tube box; a fixed tube plate is arranged between the shell head and the tube box; a sealing head tube plate is arranged between the sealing head and the tube box; the inner part of the shell head is divided into a tube pass flow inlet cavity and a tube pass flow outlet cavity through a tube pass flow isolation plate; an expansion joint is arranged on the tube box. The double-pass double-liquid heat exchange device has the benefits that through the characteristic that the deformation of the expansion joint is relatively easy and in cooperation with the slideable sealing head tube plate, a structural temperature difference compensation function can be realized, and the structure damage caused by overlarge temperature difference stress is avoided.

Owner:CHINA JILIANG UNIV

A shell and tube heat exchanger

InactiveCN104634138BAvoid damageSmooth circulationHeat exchanger casingsStationary tubular conduit assembliesShell and tube heat exchangerPlate heat exchanger

The invention discloses a shell-and-tube heat exchanger. By the shell-and-tube heat exchanger, heat exchange between two types of liquid can be implemented effectively; the shell-and-tube heat exchanger has temperature difference compensation ability; and the circumstance that the heat exchanger is damaged due to over large temperature difference stress between a shell and heat exchanging tubes can be avoided. The shell-and-tube heat exchanger comprises a tube pass portion, a shell pass portion and a plurality of supports, wherein the tube pass portion comprises a tube pass inlet tube, a tube pass outlet tube and a plurality of heat exchanging tubes; the shell pass portion comprises a heat exchanger outer shell, a shell pass inlet tube and a shell pass outlet tube; the heat exchanger outer shell consists of an end socket, a shell head and a channel; a fixing tube plate is arranged between the shell head and the channel; an end socket tube plate is arranged between the end socket and the channel; the inside of the shell head is divided into a tube pass flow inlet cavity and a tube pass flow outlet cavity by a tube pass flow separating plate; and the channel is provided with an expansion joint. The shell-and-tube heat exchanger has the advantages that the position of the expansion joint easily deforms, a structural temperature difference compensating effect is achieved by the slidable end socket tube plate, and structural damage caused by over large temperature difference stress is avoided.

Owner:中山市斯坦尼化工机械有限公司

High strength and high hardness ceramic gum abutment

ActiveCN111807865BGood biocompatibilityIncrease connection forceImpression capsAdditive manufacturing apparatusFiberAdhesive

Owner:嘉兴饶稷科技有限公司

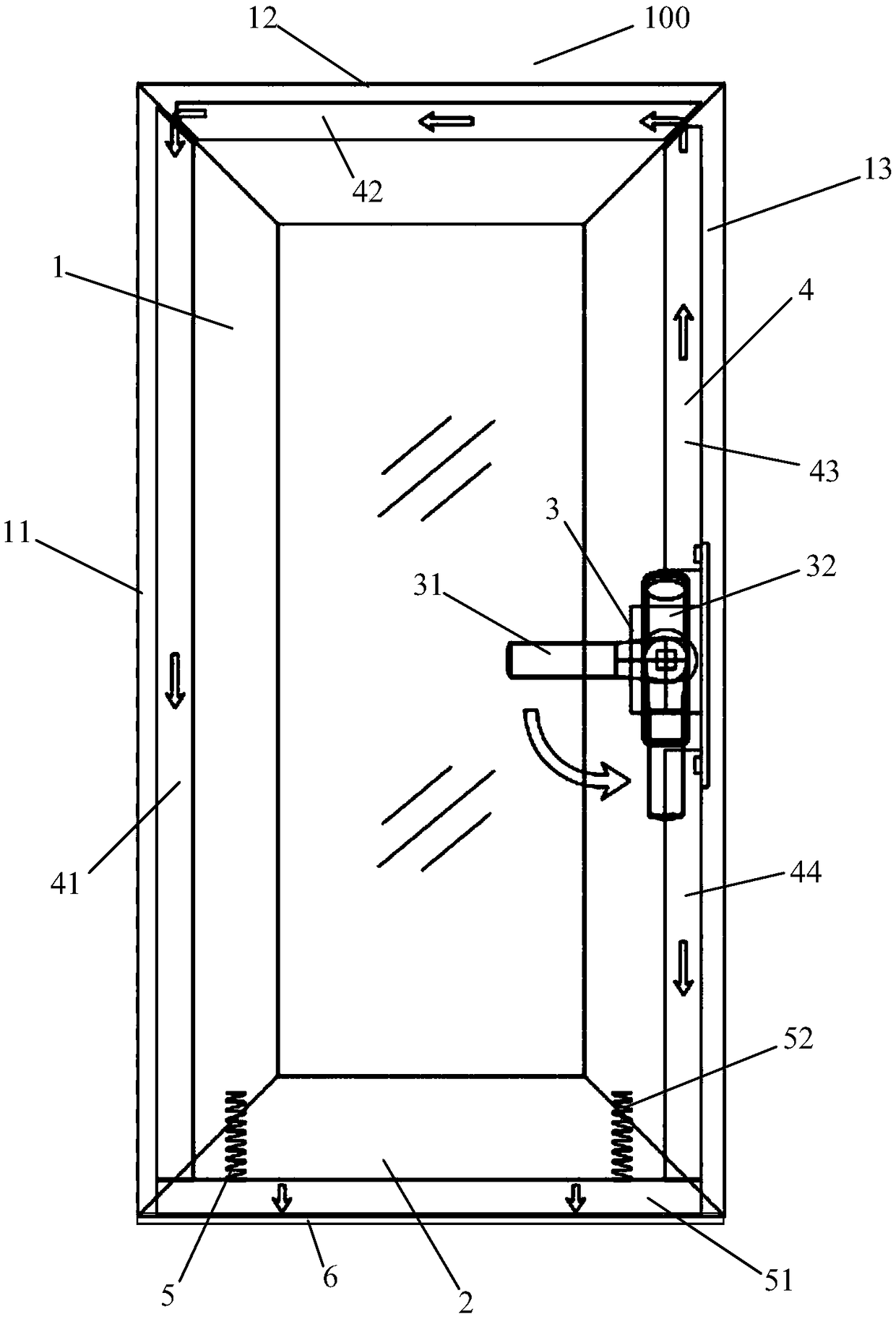

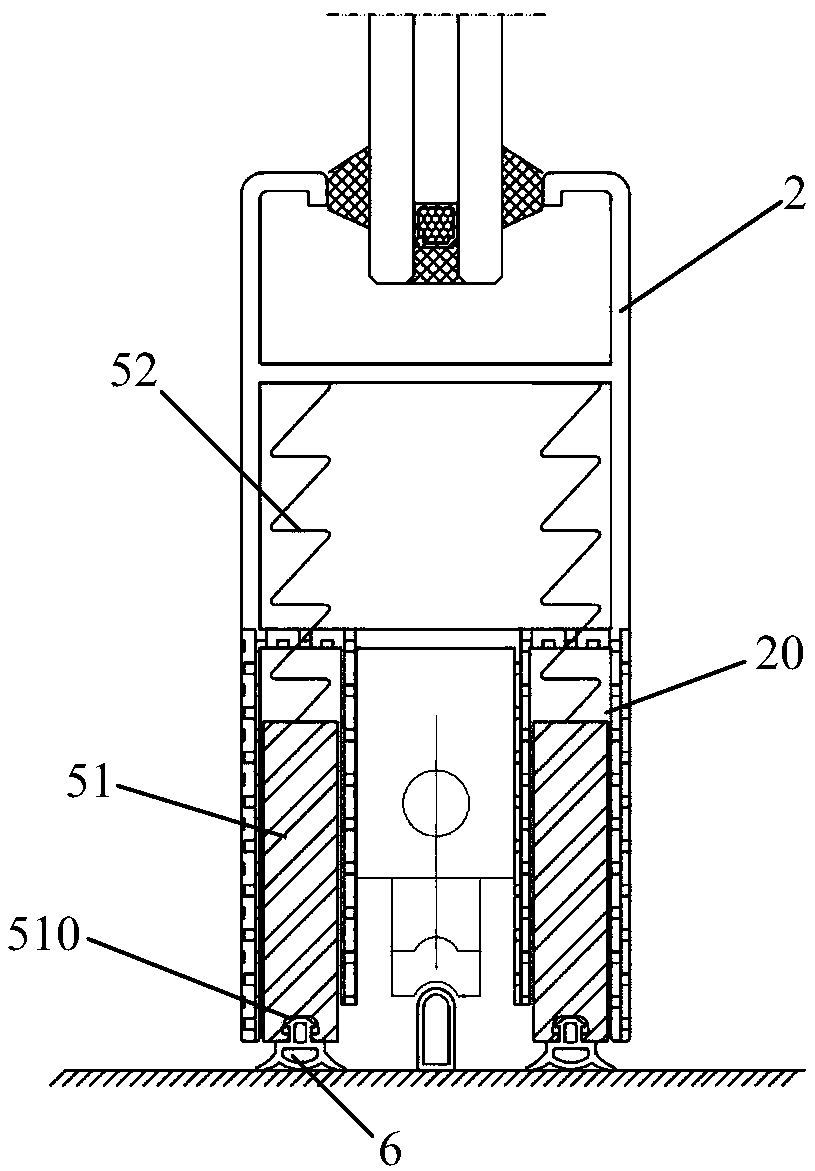

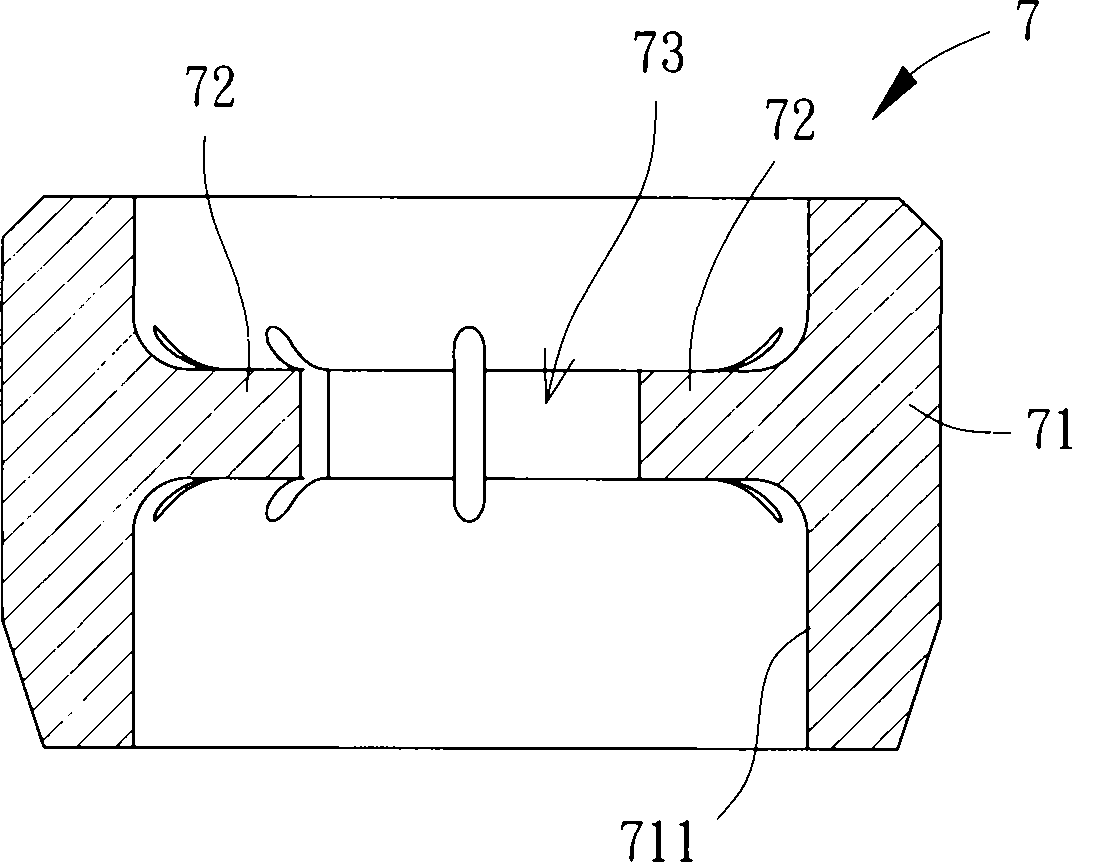

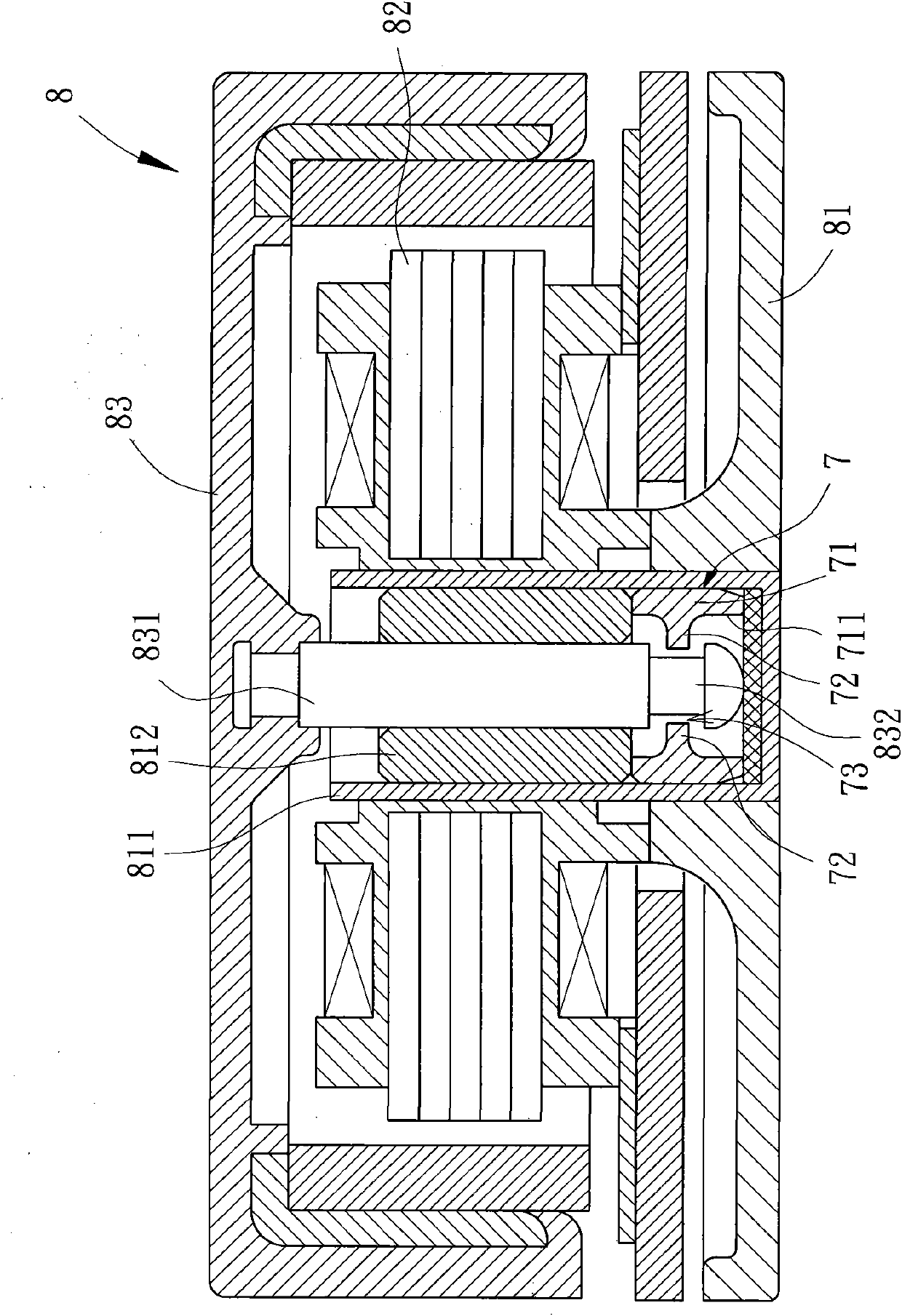

Sealing mechanism of push-pull device

ActiveCN106948733BAvoid affecting smoothnessPush and pull fullySealing arrangementsPush pullEngineering

Owner:GUANGDONG JMA CUSTOMIZE WINDOWS & DOORS SYST CO LTD

Double-liquid heat exchange device

InactiveCN104654831AAvoid damageSmooth circulationHeat exchanger casingsStationary tubular conduit assembliesCompensation effectTemperature difference

The invention discloses a double-liquid heat exchange device and aims at providing a heat exchange device which can effectively realize heat exchange between two kinds of liquid, has a temperature difference compensation capacity and can prevent a shell and heat exchange tubes from being damaged due to excessive large temperature difference stress. The double-liquid heat exchange device comprises a tube pass portion, a shell pass portion and a plurality of supports, wherein the tube pass portion comprises a tube pass inlet tube, a tube pass outlet tube and a plurality of heat exchange tubes, the shell pass portion comprises a heat exchanger shell body, a shell pass inlet tube and a shell pass outlet tube, the heat exchanger shell body consists of a seal head, a shell head and a tube box, a fixing tube plate is arranged between the shell head and the tube box, a seal head tube plate is arranged between the seal head and the tube box, a tube pass flow isolating plate divides the internal portion of the shell head into a tube pass flow inlet chamber and a tube pass flow outlet chamber, and an expansion joint is arranged on the tube box. The double-liquid heat exchange device has the beneficial effects that a structural temperature difference compensation effect can be achieved through the characteristic of relatively easy deformation of the position of the expansion joint in combination with the slidable seal head tube plate, and structural damage is prevented from being caused due to excessively large temperature difference stress.

Owner:CHINA JILIANG UNIV

Shell and tube heat exchanger

InactiveCN104613794BAvoid damageSmooth circulationHeat exchanger casingsStationary tubular conduit assembliesPlate heat exchangerShell and tube heat exchanger

The invention discloses a shell-and-tube heat exchanger and aims to a heat exchanger, which allows effective heat exchange between two liquids, which allows thermal difference compensation and which prevents damage caused by high thermal difference between a housing and heat exchange tubes. The shell-and-tube heat exchanger comprises a tube side portion, a shell side portion and a plurality of supports; the tube side portion comprises a tube side inlet tube, a tube side outlet tube and a plurality of heat exchange tubes; the shell side portion comprises a shell, a shell side inlet tube and a shell side outlet tube; the shell is composed of a sealing head, a shell head and a tube box; a fixing tube plate is disposed between the shell head and the tube box; a sealing head tube plate is disposed between the sealing head and the tube box; a tube side partition plate divides the inside of the shell head into a tube side inflow cavity and a tube side outflow cavity; the tube box is provided with an expansion joint. The shell-and-tube heat exchanger has the advantages that the expansion joint which easily deforms and the sealing head tube plate are used together to function in structural thermal difference compensating, and structural damage caused by high thermal difference stress is avoided.

Owner:佛山市顺德区华名新能源科技有限公司

a heat exchanger

InactiveCN104764347BAvoid damageSmooth circulationPipeline expansion-compensationCorrosion preventionPlate heat exchangerTemperature difference

The invention discloses a heat exchanger. The heat exchanger can effectively realize the heat exchange between two fluids, and has the temperature difference compensating ability, and can prevent the damage caused by too big temperature difference stress between a shell body and a heat exchange pipe. The heat exchanger comprises a tube pass part, a shell pass part, and several brackets; the tube pass part comprises a tube pass inlet tube, a tube pass outlet tube, and a plurality of heat exchange tubes; the shell pass part includes an outer shell body of the heat exchanger, a shell pass inlet tube, and a shell pass outlet tube; the outer shell body of the heat exchanger is composed of an enclosure head, a shell head and a tube box; a fixing tube plate is arranged between the shell head and the tube box, and an enclosure head tube plate is arranged between the enclosure head and the tube box; a tube pass flow isolating plate partitions the inner part of the shell body into a tube pass inflow cavity and a tube pass outflow cavity; an expansion joint is arranged on the tube box. The heat exchanger has the following beneficial effects: through the characteristics of relatively easy deformation of the expansion joint, and cooperation of the slideable enclosure tube plate, the heat exchanger can play a role of structural temperature compensation, and avoid the structural damage caused by too big temperature difference stress.

Owner:CHINA JILIANG UNIV

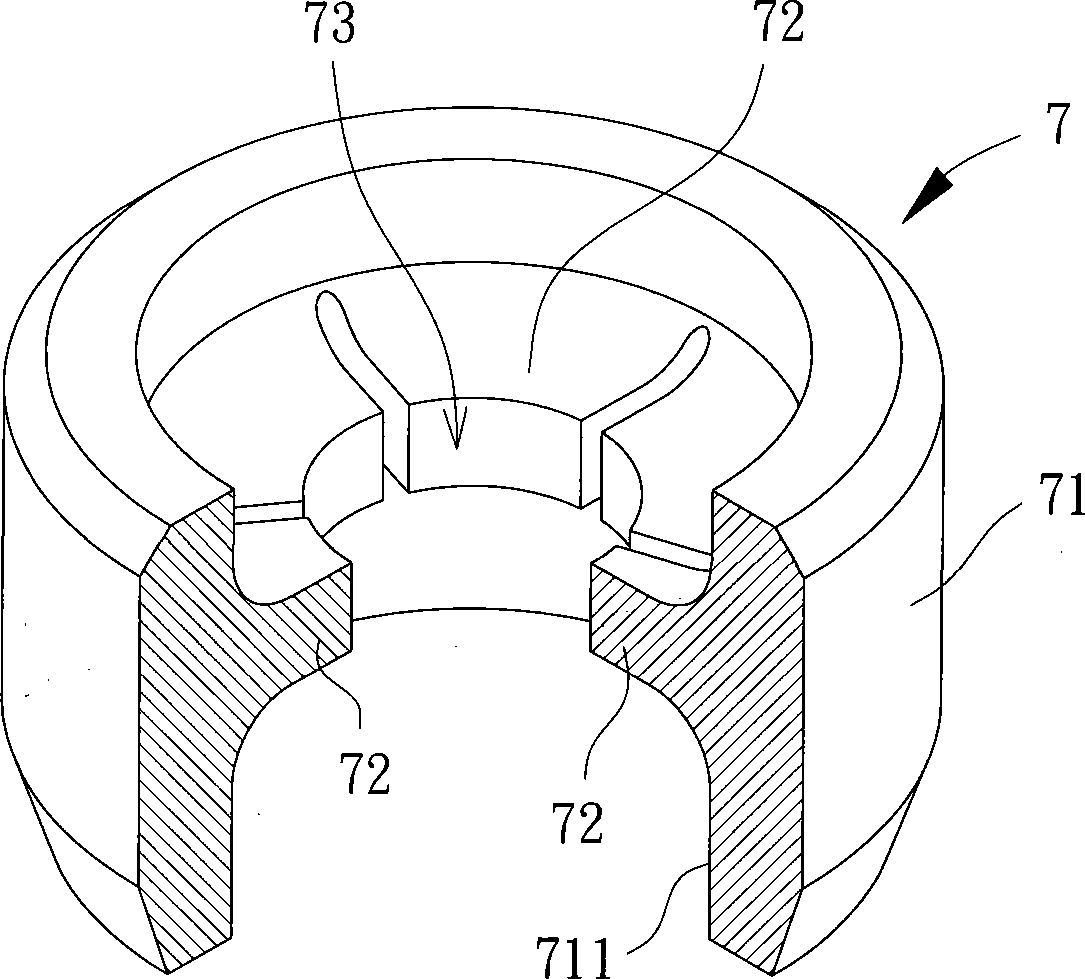

Retaining ring of mandrel of motor

ActiveCN102377265BAvoid deformation concentrationAvoid crackingMagnetic circuit rotating partsEngineeringRetaining ring

Owner:SUNONWEALTH ELECTRIC MACHINE IND

A shell and tube heat exchanger

InactiveCN104634141BAvoid damageSmooth circulationCorrosion preventionHeat exchanger casingsShell and tube heat exchangerPlate heat exchanger

The invention discloses a shell-and-tube heat exchanger. By the shell-and-tube heat exchanger, heat exchange between two types of liquid can be implemented effectively; the shell-and-tube heat exchanger has temperature difference compensation ability; and the circumstance that the heat exchanger is damaged due to over large temperature difference stress between a shell and heat exchanging tubes can be avoided. The shell-and-tube heat exchanger comprises a tube pass portion, a shell pass portion and a plurality of supports, wherein the tube pass portion comprises a tube pass inlet tube, a tube pass outlet tube and a plurality of heat exchanging tubes; the shell pass portion comprises a heat exchanger outer shell, a shell pass inlet tube and a shell pass outlet tube; the heat exchanger outer shell consists of an end socket, a shell head and a channel; a fixing tube plate is arranged between the shell head and the channel; an end socket tube plate is arranged between the end socket and the channel; the inside of the shell head is divided into a tube pass flow inlet cavity and a tube pass flow outlet cavity by a tube pass flow separating plate; and the channel is provided with an expansion joint. The shell-and-tube heat exchanger has the advantages that the position of the expansion joint easily deforms, a structural temperature difference compensating effect is achieved by the slidable end socket tube plate, and structural damage caused by over large temperature difference stress is avoided.

Owner:CHINA JILIANG UNIV

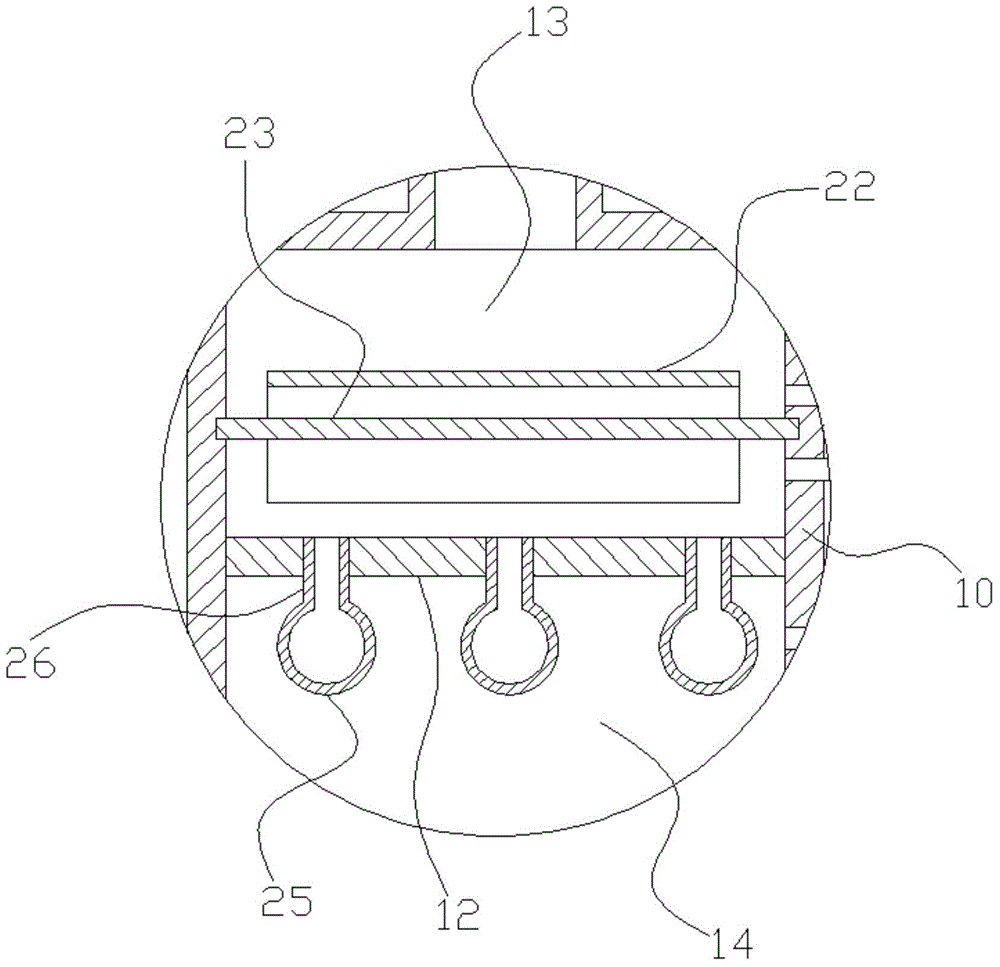

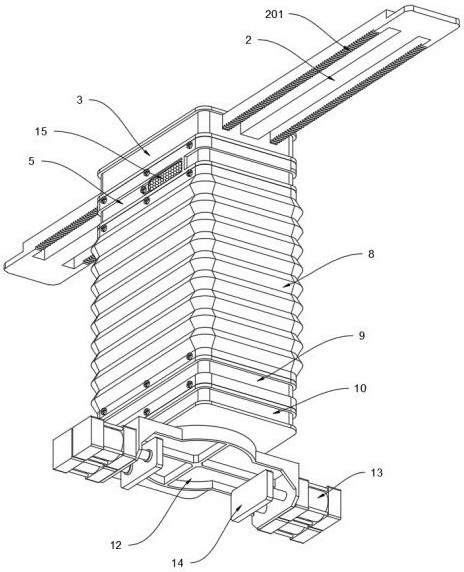

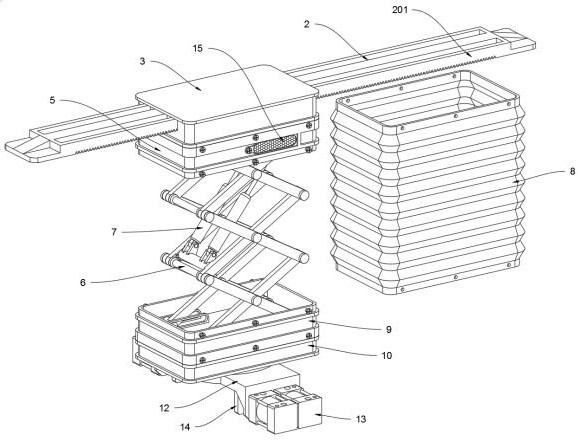

Gantry type stacking and lifting device based on energy-saving brick production

PendingCN114476967AChange the stacking angleAvoid affecting smoothnessFouling preventionDispersed particle filtrationBrickStructural engineering

The invention provides a gantry type stacking and lifting device based on energy-saving brick production, relates to the technical field of energy-saving brick production and processing, and solves the problems that when a traditional gantry type stacking and lifting structure is used in an energy-saving brick production place, dust-proof sealing protection consciousness is lacked, and in the long-term use process, the energy-saving brick production cost is low. The problems that dust particles generated during energy-saving brick production are extremely prone to being deposited and attached to all connecting parts, and the smoothness of stacking and lifting operation is affected are solved. The two ends of the supporting track are fixedly connected with the two supports correspondingly, and the outer side of the supporting track is connected with a movable top base. The top connecting seat is connected to the bottom of the movable top seat, and the top connecting seat is connected with the bottom connecting seat through a telescopic frame; while the telescopic frame is adjusted in a telescopic mode, the dustproof telescopic shell is adjusted in a telescopic mode synchronously, the telescopic frame is sealed and protected through the dustproof telescopic shell, and it is avoided that external dust and impurities are attached to all connecting parts of the telescopic frame, and smoothness of telescopic adjustment of the telescopic frame is affected.

Owner:江苏振丰环保集团有限公司

A chemical heat exchanger

InactiveCN104596323BAvoid damageSmooth circulationHeat exchanger casingsStationary tubular conduit assembliesCompensation effectCompound (substance)

The invention discloses a chemical engineering heat exchanger and aims to provide a heat exchanger which can effectively realize heat exchange between two liquors, has capability of temperature difference compensation and can be prevented from being damaged due to excessively large temperature difference stress between a shell and heat exchange tubes. The chemical engineering heat exchanger comprises a tube pass part, a shell pass part and a plurality of brackets, wherein the tube pass part comprises a tube pass inlet tube, a tube pass outlet tube and the plurality of heat exchange tubes; the shell pass part comprises a heat exchanger shell body, a shell pass inlet tube and a shell pass outlet tube; the heat exchanger shell body comprises a seal head, a shell head and a tube box; a fixed tube plate is arranged between the shell head and the tube box; a seal head tube plate is arranged between the seal head and the tube box; a tube pass flow baffle is used for dividing the interior of the shell head into a tube pass inflow cavity and a tube pass outflow cavity; an expansion joint is arranged on the tube box. The chemical engineering heat exchanger has the benefits that a structural temperature difference compensation effect can be achieved in combination with the slidable seal head tube plate based on a characteristic of easiness for deformation at the expansion joint, and structural damage caused by excessively large temperature difference stress is avoided.

Owner:CHINA JILIANG UNIV

Shell-and-tube double-liquid heat exchange device

InactiveCN104654834BAvoid damageSmooth circulationHeat exchanger casingsStationary tubular conduit assembliesCompensation effectEngineering

The invention discloses a tube-shell type double-liquid heat exchange device and aims to provide a heat exchange device which can effectively achieve heat exchange between two types of liquid, has temperature difference compensation capacity and can be prevented from being damaged due to over-large temperature difference stress between a shell and a heat exchange tube. The tube-shell type double-liquid heat exchange device comprises a tube pass part, a shell pass part and a plurality of brackets, wherein the tube pass part comprises a tube pass inlet tube, a tube pass outlet tube and a plurality of heat exchange tubes; the shell pass part comprises an outer heat exchanger shell, a shell pass inlet tube and a shell pass outlet tube; the outer heat exchanger shell consists of a sealing head, a shell head and a tube box; a fixed tube plate is arranged between the shell head and the tube box; a sealing head tube plate is arranged between the sealing head and the tube box; a tube pass flow partition plate partitions the interior of the shell head into a tube pass inflow cavity and a tube pass outflow cavity; an expansion joint is arranged on the tube box. The tube-shell type double-liquid heat exchange device has the beneficial effects that according to the characteristic hat the expansion joint is relatively easy to deform, by the cooperation of the slidable sealing head tube plate, the structural temperature difference compensation effect can be achieved, and the structural damage caused by over-large temperature difference stress is avoided.

Owner:CHINA JILIANG UNIV

A shell-and-tube heat exchanger

ActiveCN104613793BAvoid damageSmooth circulationHeat exchanger casingsStationary tubular conduit assembliesTemperature stressPlate heat exchanger

The invention discloses a tube-and-shell heat exchanger and aims to provide a heat exchanger, allowing effective heat exchange between two liquids, having thermal difference compensating capacity and preventing damage caused by thermal difference stress between a shell and heat exchange tubes. The tube-and-shell heat exchanger comprises a tube side portion, a shell side portion and a plurality of supports; the tube side portion comprises a tube side incoming tube, a tube side outgoing tube and a plurality of heat exchange tubes; the shell side portion comprises a housing, a shell side incoming tube and a shell side outgoing tube; the housing is composed of a seal head, a shell head and a tube box; a fixing tube plate is disposed between the shell head and the tube box; a seal head tube plate is disposed between the seal head and the tube box; a tube side partition plate divides the inside of the shell head into a tube side inflow cavity and a tube side outflow cavity; the tube box is provided with an expansion joint. The tube-and-shell heat exchanger has the advantages that the expansion joint featuring ease of deformation and the seal head tube plate slidable fit to function in structural thermal difference compensation, and structural damage caused by excessively high thermal temperature stress is avoided.

Owner:枣庄科顺数码有限公司

A chemical heat exchange device

InactiveCN104697367BAvoid damageSmooth circulationCorrosion preventionHeat exchanger casingsChemical industryTemperature stress

The invention discloses a heat exchanging device for chemical industry, and aims to provide a heat exchanging device which can effectively realize the heat exchange of two kinds of liquid, has the capability of compensating for temperature difference, and can prevent the damage of a shell due to the excessive differential temperature stress between the shell and a heat exchanging tube. The heat exchanging device comprises a tube pass part, a shell pass part and a plurality of supports, wherein the tube pass part comprises a tube-pass inlet tube, a tube-pass outlet tube and a plurality of heat exchanging tubes; the shell pass part comprises an outer shell of the heat exchanging device, a shell-pass inlet tube and a shell-pass outlet tube; the outer shell of the heat exchanging device consists of an end cap, a shell head and a tube box, a fixing tube plate is arranged between the shell head and the tube box, an end-cap tube plate is arranged between the end cap and the tube box, a tube-pass flow partition plate divides the inside of the shell head into a tube-pass flow inlet cavity and a tube-pass flow outlet cavity, and an expansion joint is arranged on the tube box. The heat exchanging device disclosed by the invention has the benefits that through the characteristic that the expansion joint is relatively easy to deform, the end-cap tube plate which can slide is matched, so that the heat exchanging device has a structural effect of compensating for temperature difference, and the structural damage due to the excessive differential temperature stress can be avoided.

Owner:CHINA JILIANG UNIV

Tube-and-shell heat exchanger

ActiveCN104613793AAvoid damageSmooth circulationHeat exchanger casingsStationary tubular conduit assembliesTemperature stressPlate heat exchanger

The invention discloses a tube-and-shell heat exchanger and aims to provide a heat exchanger, allowing effective heat exchange between two liquids, having thermal difference compensating capacity and preventing damage caused by thermal difference stress between a shell and heat exchange tubes. The tube-and-shell heat exchanger comprises a tube side portion, a shell side portion and a plurality of supports; the tube side portion comprises a tube side incoming tube, a tube side outgoing tube and a plurality of heat exchange tubes; the shell side portion comprises a housing, a shell side incoming tube and a shell side outgoing tube; the housing is composed of a seal head, a shell head and a tube box; a fixing tube plate is disposed between the shell head and the tube box; a seal head tube plate is disposed between the seal head and the tube box; a tube side partition plate divides the inside of the shell head into a tube side inflow cavity and a tube side outflow cavity; the tube box is provided with an expansion joint. The tube-and-shell heat exchanger has the advantages that the expansion joint featuring ease of deformation and the seal head tube plate slidable fit to function in structural thermal difference compensation, and structural damage caused by excessively high thermal temperature stress is avoided.

Owner:枣庄科顺数码有限公司

Shell and Tube Heat Exchanger

InactiveCN104654832BAvoid damageSmooth circulationHeat exchanger casingsStationary tubular conduit assembliesPlate heat exchangerShell and tube heat exchanger

The invention discloses a tube-shell type heat exchange device and aims to provide a heat exchange device which can effectively achieve heat exchange between two types of liquid, has temperature difference compensation capacity and can be prevented from being damaged due to over-large temperature difference stress between a shell and a heat exchange tube. The tube-shell type heat exchange device comprises a tube pass part, a shell pass part and a plurality of brackets, wherein the tube pass part comprises a tube pass inlet tube, a tube pass outlet tube and a plurality of heat exchange tubes; the shell pass part comprises an outer heat exchanger shell, a shell pass inlet tube and a shell pass outlet tube; the outer heat exchanger shell consists of a sealing head, a shell head and a tube box; a fixed tube plate is arranged between the shell head and the tube box; a sealing head tube plate is arranged between the sealing head and the tube box; a tube pass flow partition plate partitions the interior of the shell head into a tube pass inflow cavity and a tube pass outflow cavity; an expansion joint is arranged on the tube box. The tube-shell type heat exchange device has the beneficial effects that according to the characteristic hat the expansion joint is relatively easy to deform, by the cooperation of the slidable sealing head tube plate, the structural temperature difference compensation effect can be achieved, and the structural damage caused by over-large temperature difference stress is avoided.

Owner:CHINA JILIANG UNIV

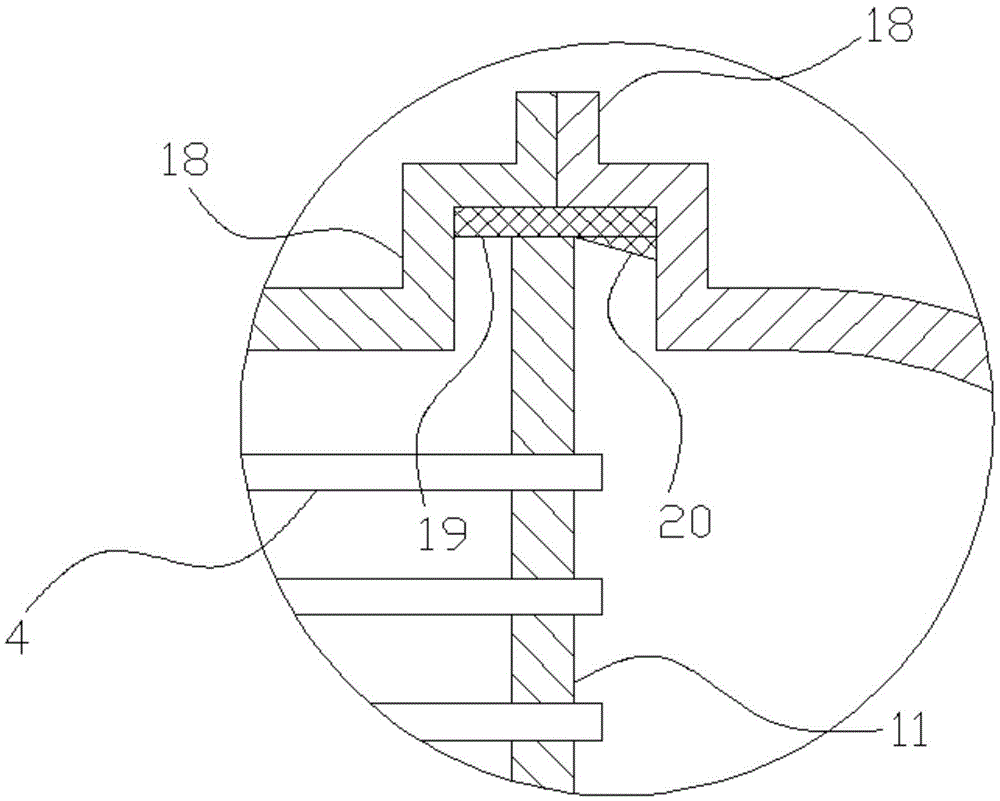

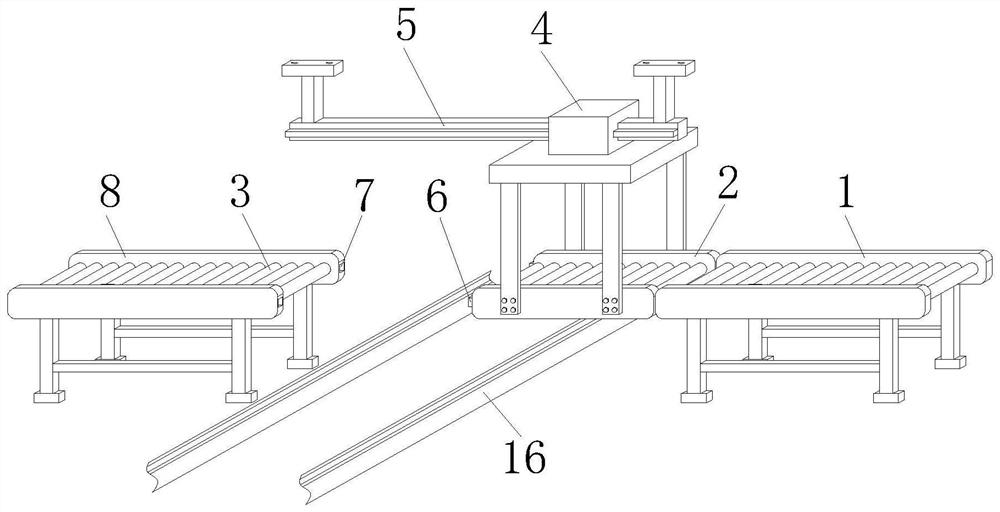

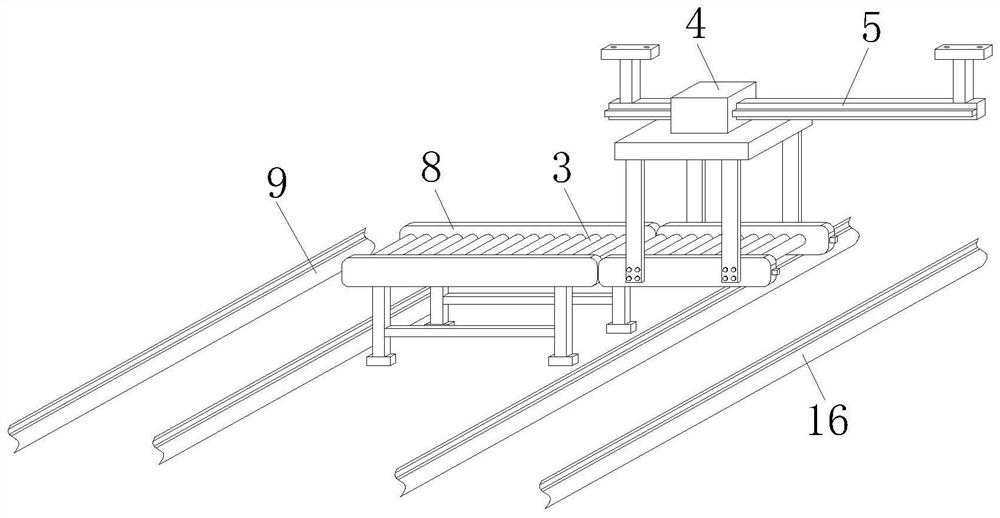

Full-automatic remains transfer system and fixed roller conveying belt thereof

PendingCN113697407AEasy to operateSave manpower and material resourcesLighting and heating apparatusCleaningAutomotive engineeringTransmission system

The invention discloses a full-automatic remains transfer system and a fixed roller conveying belt thereof. The automatic remains transfer system comprises frostless refrigerated cabinets, an intelligent rail car, the fixed roller conveying belt, a movable roller conveying belt, a replacement area and a central control communication transmission system. Through the cooperation of the frostless refrigerated cabinets, the intelligent rail car, the fixed roller conveying belt, the movable roller conveying belt, the replacement area and the central control communication transmission system, remains can be automatically stored in the corresponding frostless refrigerated cabinets, the operation process is automatic, more manpower and material resources are saved, and the remains are protected through an access control system so as to be prevented from being lost; and by arranging the replacement area, a faulty rail car on an original A rail or B rail can be moved to an auxiliary rail to be replaced with a standby rail car through a replacement car, so that the influence of accidental faults on system operation is reduced, the stability of the system in use is improved, and the safety of remains in operation is further guaranteed.

Owner:黑龙江省哈南科技开发有限责任公司

double pass heat exchanger

InactiveCN104654833BAvoid damageSmooth circulationHeat exchanger casingsStationary tubular conduit assembliesPlate heat exchangerCompensation effect

The invention discloses a double-pass heat exchanger and aims at providing a heat exchanger which can effectively realize heat exchange between two kinds of liquid, has a temperature difference compensation capacity and can prevent a shell and heat exchange tubes from being damaged due to excessive large temperature difference stress. The double-pass heat exchanger comprises a tube pass portion, a shell pass portion and a plurality of supports, wherein the tube pass portion comprises a tube pass inlet tube, a tube pass outlet tube and a plurality of heat exchange tubes, the shell pass portion comprises a heat exchanger shell body, a shell pass inlet tube and a shell pass outlet tube, the heat exchanger shell body consists of a seal head, a shell head and a tube box, a fixing tube plate is arranged between the shell head and the tube box, a seal head tube plate is arranged between the seal head and the tube box, a tube pass flow isolating plate divides the internal portion of the shell head into a tube pass flow inlet chamber and a tube pass flow outlet chamber, and an expansion joint is arranged on the tube box. The double-pass heat exchanger has the beneficial effects that a structural temperature difference compensation effect can be achieved through the characteristic of relatively easy deformation of the position of the expansion joint in combination with the slidable seal head tube plate, and structural damage is prevented from being caused due to excessively large temperature difference stress.

Owner:CHINA JILIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com